Belimo SRA-100 User manual

Technical manual BA 0113

Filling level

SRA – 100 8M

Filling level limit switch

for conductive filling level supervision

in electrical conductive liquids

Useable

for filling level resp. limit value detection in liquid container

as dry run protection for pumps

for two-position-control in plants

ATEX II (1) G [Ex ia Ga] IIB/IIC resp. ATEX II (1) D [Ex ia Da] IIIB/IIIC

Certification for the connection of conductive level transducer in explosion

hazardous areas

Measuring range adjustable up to 8M resp. 0,125µS/cm

Different configurable switching delays

Wide range power supply from 20 to 253V AC and DC

L a u t e r b a c h s t r . 5 7 – 8 4 3 0 7 E g g e n f e l d e n – G e r m a ny

T e l : + 4 9 8 7 2 1 / 9 6 6 8 - 0 – F a x : + 4 9 8 7 2 1 / 9 6 6 8 - 30

i n f o @ a c s - c o n t r o l s y s t e m . d e – w w w . a c s - c o n t r o l s y s t e m . d e

SRA – 100 8M

page 2 of 8

Index

Order code ..................................................................................................................... 2

Application .................................................................................................................... 3

Function .................................................................................................................... 3 / 4

Safety notes ................................................................................................................... 5

Safety notes ............................................................................................................. 5

Installation ...................................................................................................................... 5

Maintenance ................................................................................................................... 5

Repair ............................................................................................................................. 5

Electrical connection .................................................................................................... 6

Operation and display elements .................................................................................... 7

Technical data ............................................................................................................... 8

Order code

SRA – 100 – U0 8M Basic variant

ExSRA – 100 – U0 8M Variant with certification acc. to ATEX

SRA – 100 8M

page 3 of 8

Application

The filling level limit switch SRA – 100 8M is used, to evaluate one or two filling levels resp. limit levels in

electrically conductive liquids with a conductivity of minimum 0,125µS/cm resp. a resistance of maximum 8M.

For the connection of level resp. measurement transducer in explosion hazardous areas, the device is equipped

with two intrinsically safe supply and signal circuits.

Function

Measuring principle

The signal circuit of the filling level limit switch is connected to the reference electrode or the metallic wall of the

container resp. pipe and to the measuring electrode.

The alternating voltage, that is generated by the integrated electronic is than applied either between the

electrode rods or between the electrode rods and the metallic wall of the container resp. pipe that is connected

to the metallic process connection, realizing the reference electrode.

Due to the use of a alternating voltage the corrosion at the electrode rod and the electrolytic decomposition of

the filling liquid is avoided.

As soon as the electrically conductive liquid makes a connection between the electrodes resp. between the

electrode and the metallic wall of the container resp. pipe, an alternating current flows, that causes a decrease

of the alternating voltage.

Signal evaluation

An evaluation circuit supervises this alternating voltage. A voltage drop is detected and the evaluation circuit

switches the relay resp. relays, depending on the set safety function.

The switching state of the relays is indicated at the front side of the device by two yellow LED’s.

Switching delay

In some applications it is necessary to compensate heavy signal fluctuations that may be produced by mixing

machines or at fill-in resp. emptying of containers, to avoid spurious switching actions.

Two switches at the front side of the device allows the configuration of a switching delay of 0,5 / 3 / 5 / 8 s.

This delay time effects both channels separately, at activation and deactivation of the filling level relays.

Sensitivity range

The device can be adjusted in the resistance range 1 to 8 M. Within this range a fine adjustment can be

carried out by a trimmer at the front side of the device.

Configuration of the second output relay S2

The second output relay can be configured in two operation modes:

2nd filling level relay to electrode at CH1 (relay switches like filling level relay S1 – parallel mode)

Filling level relay to electrode at CH2 (two channel mode: CH1 to S1 / CH2 to S2)

SRA – 100 8M

page 4 of 8

Safety function

The safety function defines the operation principle of the output relays

Maximum safety: The relay switches off, if the switching level is transgressed

(liquid connection between measuring and reference electrode),

or the power supply fails.

Minimum safety: The relay switches off, if the switching level is underrun

(no liquid connection between measuring and reference electrode),

or the power supply fails.

For the function two-position-control the safety function must be set identically for both channels, CH1 and CH2.

This can be carried out by two switches, one per channel, at the front side of the filling level limit switch.

Two-position-control s (pump control)

The activation of the two-position-control is made by a switch at the front side of the device.

Two-position-control with minimum safety Two-position-control with maximum safety

at parallel mode relay S1 and S2 at parallel mode relay S1 and S2

For the function two-position-control the safety function must be set identically for both channels, CH1 and CH2.

This can be carried out by two switches, one per channel, at the front side of the filling level limit switch.

SRA – 100 8M

page 5 of 8

Safety notes

Each person that is engaged with inauguration and operation of this device, must have read and

understood this technical manual and especially the safety notes.

Installation, electrical connection, inauguration and operation of the device must be made by a qualified

employee according to the informations in this technical manual and the relevant standards and rules.

The device may only be used within the permitted operation limits that are listed in this technical manual.

Every use besides these limits as agreed can lead to serious dangers.

The device meets the legal requirements of all relevant EC directives.

Safety notes for electrical operating supplies

for explosive hazardous areas

If a device is installed and operated in explosive hazardous areas, the general Ex construction standards

(EN/IEC 60079-14, VDE0165), this safety notes and the enclosed EC conformity certificate must be observed.

The installation of explosive hazardous systems must be carried out principally by specialist staff.

The device meets the classification: II (1) G [Ex ia Ga] IIB/IIC resp. II (1) D [Ex ia Da] IIIB/IIIC

The device is conceived for detection of limit levels at liquids in explosive hazardous areas, that needs devices

of category 1 resp. category 1/2.

The measured medium may also be combustible liquids.

The filling level limit switch is a affiliated operating supply and may only be used outside explosion hazardous

areas.

Installation

The filling level limit switch is conceived for vertical installation on a standard fastening rail acc. to

EN/IEC 60715 TH 35-7,5 resp. TH35-15.

EN/IEC 60715 TH 35-7,5

EN/IEC 60715 TH35-15

The device must be installed protected against dust and humidity, e.g. in control stations or in a suitable

protection housing with a minimum protection classification IP55 acc. to EN/IEC 60529.

The devices must be installed wheather and stroke protected, ideally at places without direct solar radiation.

This is especially important in warm climatic regions.

Maintenance

The device is free of maintenance.

Repair

A repair may only be carried out by the manufacturer. When sending back the device, add a note with the

description of the error and the application.

0158

SRA – 100 8M

page 6 of 8

Electrical connection

The electrical connection of the device must be carried out according to the respective country specific

standards. Incorrect installation or adjustment could cause applicationally conditioned risks.

Power supply input, measuring input and relay output channels are safe galvanically isolated from each other.

This is also valid for both relay output channels among each other.

Connection of the signaling transmitter resp. measuring transducer – measuring inputs

For the two or three-wire connection cable between the filling level limit switch and the signaling transmitter

resp. measuring transducer a standard installation cable or multi-wire cable for measuring intends with a

maximum of 25 per wire can be used.

The use of a shielded signal cable is not required in principle, but is recommended, if strong electromagnetic

influences could happens, e.g. due to machines or radio equipment. In that case the shielding of the cable

should be connected to earth only at the side of signaling transmitter resp. measuring transducer.

The signal cable should be installed separated from power leading wires.

If more than two limit levels with the same reference potential should be evaluated, several filling level limit

switches could be connected in parallel. For this purpose only the reference connection of all devices must be

connected with each other (see scheme below - right).

Connection of the signaling and control equipments – relay outputs

Inductive loads at the relay contacts, e.g. auxiliary contactors or magnetic vents may only be used with a free-

wheeling diode or a RC protection circuit to avoid high voltage peaks.

For inauguration it is suggested, to deactivate all connected control devices, to avoid unwanted control

reactions.

Connection of the power supply voltage

Due to the integrated wide range power supply, for connection to supply voltages from 20...253V AC / DC, the

filling level limit switch is suitable for using in all common energy supply networks.

At variants with ATEX certificate, the supply voltage range is 20...253V AC resp. 20...125V DC.

The connection is reverse polarity protected.

A switch, that is marked as separator as well as a over current protection switch (nominal current 10 A) must

be installed near the device into the supply lead.

single channel operation two channel operation four channel operation

resp. by parallel connection of two

two-position-control s filling level limit switch SRA – 100

SRA – 100 8M

page 7 of 8

Operation and display elements

Function indicator

ON green LED ready status, power supply voltage on

FAIL not supported

S1 yellow LED output relay S1 switched on

S2 yellow LED output relay S2 switched on

Adjustment trimmer

For fine adjustment of the response sensitivity within the sensitivity range.

A turn to the right leads to a switching reaction at a higher liquid resistance.

For adjustment proceed like follows:

Liquid must create an electrically conductive connection between measuring and reference electrode of the

connected measuring transducer

Turn adjustment trimmer to the left (counterclockwise), till the output relays switches off

Turn adjustment trimmer to the right (clockwise), till the output relay switches on

Turn adjustment trimmer by an additional half turn to the right (clockwise)

Configuration switches

Switch 1, 2, 3 no function

switch

switching state

1

OFF

2

OFF

3

OFF

Switch 4 function output relay S1

switch

switching state ON

switching state OFF

4

two-position-control s

limit level function

Switch 5 safety function channel 1 (CH1)

switch

switching state ON

switching state OFF

5

minimum safety

maximum safety

Switch 6 safety function channel 2 (CH2)

switch

switching state ON

switching state OFF

6

minimum safety

maximum safety

Switch 7 no function

switch

switching state

7

OFF

Switch 8, 9 time delay for both channels CH1 / CH2

switching state S8

switching state S9

time delay

ON

ON

0,5 seconds

OFF

ON

3 seconds

ON

OFF

5 seconds

OFF

OFF

8 seconds

Switch 10, 11, 12 configuration output relay S2

S 10

S 11

S 12

function output relay S2

OFF

OFF

ON

2nd filling level relay at CH1 (maximum electrode) – parallel mode

ON

OFF

OFF

filling level relay at CH2 (minimum electrode) – two channel mode

OFF

OFF

OFF

output relay S2 deactive

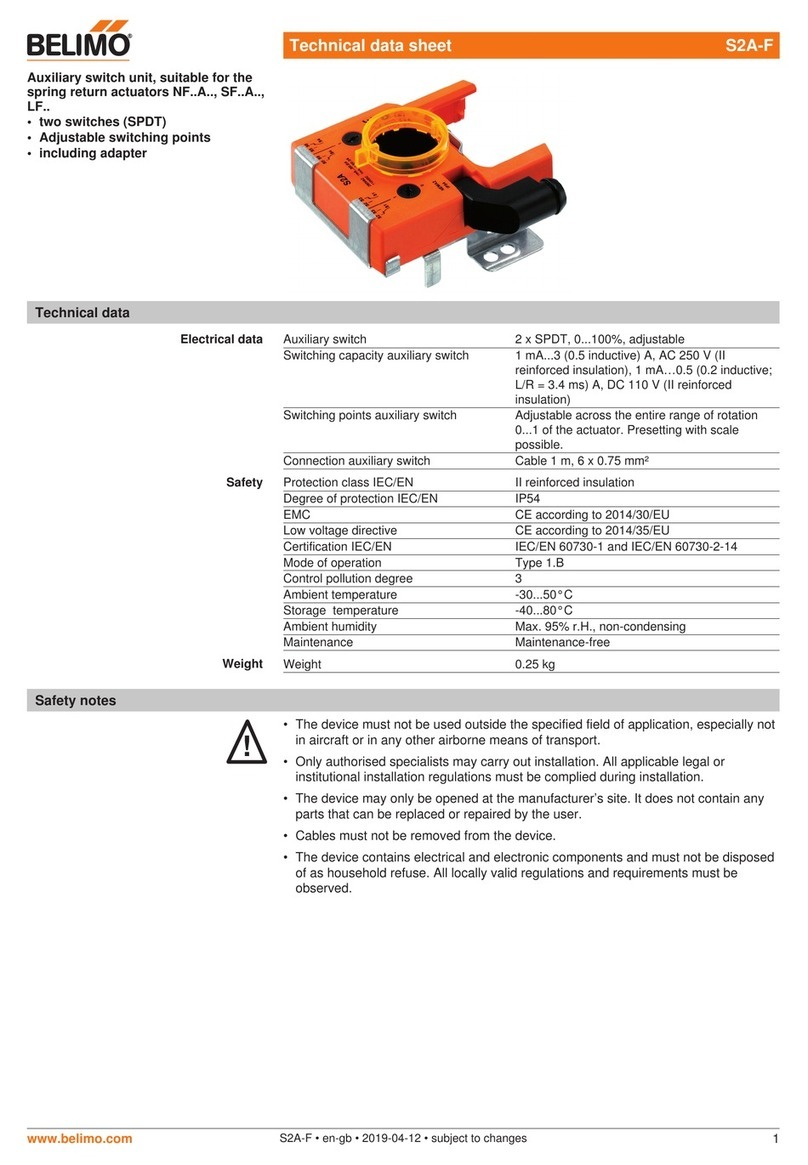

Configuration switches

12 DIL switches,

for setting the desired

functionality

Function indicator

3 LED’s for indication

of operating states

Adjustment trimmer

for fine adjust of the

response sensitivity

within the configured

sensitivity range

S2

S1

Fail

ON

SRA – 100 8M

page 8 of 8

Technical data

Auxiliary power supply

Permitted supply voltage: Basic variant 20 V to 253 V AC / DC 48...62 Hz,

ATEX variant 20 V to 253 V AC 48...62 Hz resp. 20...125V DC

reverse polarity protected

Power consumption: 3,5 VA / 1,3 W

Overvoltage category: II acc. to EN/IEC 61010-1

Protection classification: II double or reinforced insulation

Isolation voltage: 4kV~ Auxiliary power to relay outputs to signal inputs

Galvanic isolation: All supply, input and output channels among each other as well as both relay outputs

from each other are safe galvanically isolated.

Relay outputs

Function: 2x potential-free changeover contact

Switching power of the contacts: U~ maximum 253 V AC

I~ maximum 10 A AC

P~ maximum 2500 VA at ohmic load / 500 VA at cos ≥ 0,7

for use of connection of level resp. measuring transducer in

explosion hazardous areas max. 250V AC / 5 A / 100 VA

at U-

maximum I-

maximum P-

30 V

10 A

5 A at ATEX variant

300 W

100 W at ATEX variant

110 V

0,3 A

33 W

220 V

0,12 A

26,4 W

Switching cycles: 100.000 switching cycles at maximum contact load

Signal inputs

Level transducer: One resp. two filling level electrodes with common reference electrode

Supply voltage: 10 V (90 Hz 15 Hz)

Supply current: 1 mA

Measuring range: 8M resp. 0,125µS/cm

Materials

Connection housing: PA – polyamide

Terminal housing: PA – polyamide

Sticker: PE – polyester

Connection terminals

Number: 3 terminal blocks with each 4 terminals, everlasting screws

Connection cross-section: maximum 1 x 2,5 mm or 2 x 1,5 mm

Housing style

Housing: Series installation housing, 22,5mm wide

Weight: 145 g

Environmental conditions

Environmental temperature: Single installation – 40°C...+85°C resp. -20°C..+60°C at ExSRA-100-U0

Series installation – 40°C...+70°C resp. -20°C..+50°C at ExSRA-100-U0

Protective housing – 40°C...+50°C resp. -20°C..+40°C at ExSRA-100-U0

Climatic classification: 3K3 resp. 3M2 EN/IEC 60721-3-3

Protection classification: IP20 EN/IEC 60529

EM – compatibility: emission EN/IEC 61326-1 operation device class B

immunity EN/IEC 61326-1 industrial range

This manual suits for next models

2

Table of contents

Other Belimo Switch manuals

Popular Switch manuals by other brands

Lynx

Lynx S VD 5812 Reference manual

Westermo

Westermo Lynx DSS L205-S1-EX user guide

Keithley

Keithley 3700A Series user manual

Targus

Targus USB 2.0 DVD/CD-ROM Slim External Drive user guide

Brocade Communications Systems

Brocade Communications Systems 7800 Hardware installation guide

steute

steute Ex STM 298 Series Mounting and wiring instructions