Belimo CRK24-B1 Instruction manual

www.belimo.eu S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes 1 / 20

Table of contents

Overview of the system 2

Brief description, Accessories 3

Technical data sheet

Technical data 5

Safety notes 5

Product features 6

Configuration 6

Electrical installation 6

Operation 7

Functions

Introduction 9

Function overview 9

Setpoint determination 10

Pre-comfort 11

Energy hold off (EHO) 11

Chilled ceiling with dew point monitoring 12

External setpoint shift 12

External temperature sensor (ai1) 13

Analogue outputs 13

Dimensions, installation, commissioning, service

Dimensions [mm] 15

Mechanical installation 15

Electrical installation 15

Design for supply / wire sizing 16

Commissioning / Power On response 16

Test and simulation mode 16

Internal Function test 17

Simulation control sequence 17

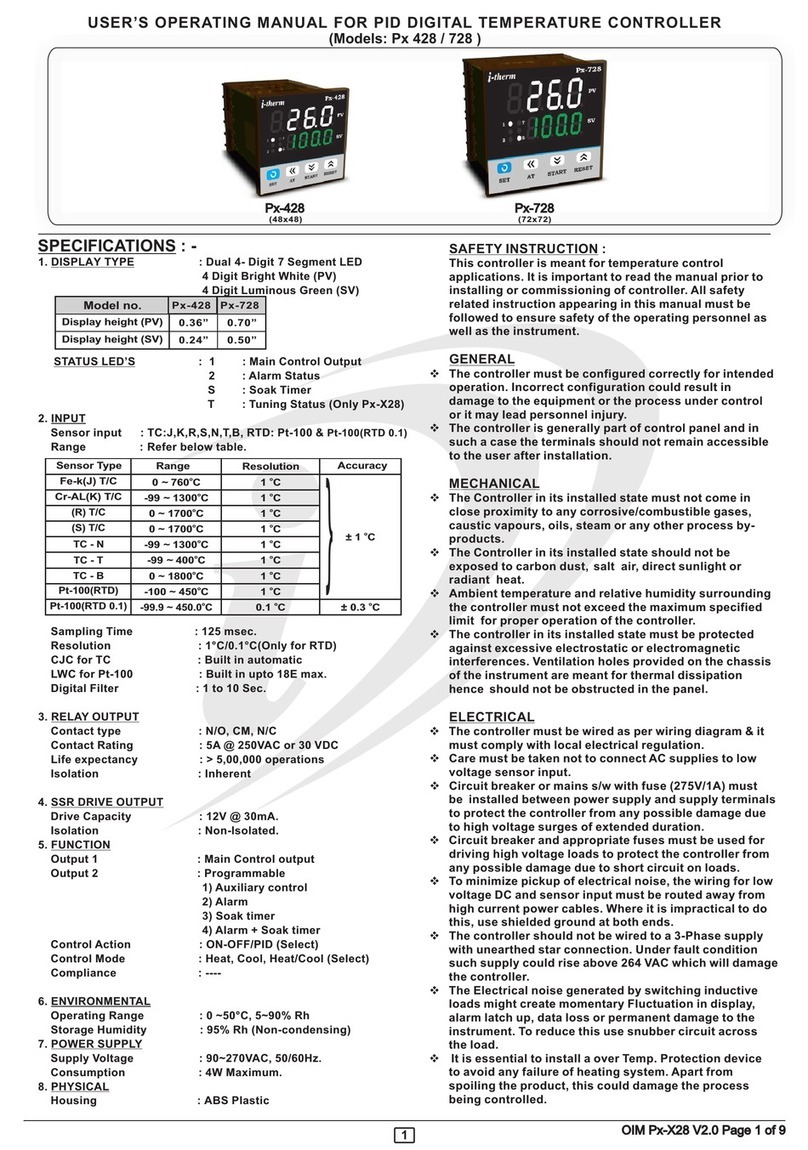

Product information CRK24-B1

Temperature controller for

heated/chilled ceiling systems

CRK24-B1 Overview of the system

2 / 20 S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes www.belimo.eu

Heated/chilled ceiling applications

Single room controller

Accessories

CRK24-B1

6-way ball valve and rotary actuators

EXT-K3B2-..-.. + LR24A-MP / LR24A-SR

Diagnostic and setting device

ZTH EU

Setting for MP / MFT(2) actuators

PC-Tool

Connection cable ZTH-VAV to CRK24, Diagnostic socket 1/2

ZK1-VAV

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

www.belimo.eu S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes 3 / 20

CRK24-B1 Brief description, Accessories

Brief description

The room temperature controller CRK24-B1 is precisely designed for the regulation of heated /

chilled ceilings. The output sequence of the controller is calibrated to the new 6-way ball valve

R3015-..-..-B2 / R3020-..-..-B2 with LR24A-MP / LR24A-SR actuator. This controller should

therefore only be utilised in the actuator in combination with the 6-way ball valve.

The multitude of override features makes possible an economically and energetically optimised

system solution for individualised control of the room climate.

Device

Standard model CRK24-B1 with user interface (setpoint

adjustment, mode switch and status display). For operation,

see page 7.

Accessories

Mechanical accessories Type Description

CRZA-A Spare cover without user interface

CRZW Spare baseplate

.

.

.

.

.

.

.

4 / 20 S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes www.belimo.eu

CRK24-B1

www.belimo.eu S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes 5 / 20

Technical data sheet CRK24-B1

Technical data

Electrical data Nominal Voltage AC 24 V 50/60 Hz

Dimensioning 3 VA, without actuators

Power supply range AC 19.2 … 28.8 V

Connections Terminal block 1 … 3: 2.5 mm2

Terminal block 4 … 8: 1.5 mm2

Functional data Control characteristics P

– P-band heating / cooling Selectable: 2.0 K / 1.0 K or 4.0 K / 2.0 K

External temperature sensor (ai1) Type NTC, 5 k�, Power supply range 10 … 45°C

e.g. Belimo Type TFK

Setpoint Adjustment range 15 … 36°C (Default 21°C)

– Energy hold off (EHO)

– Pre-comfort

Heating 15°C / Cooling 40°C

Heating –3 K / Cooling +3 K

Dead band 1 K

Frost protection limit 10°C

Operation

– Mode switch and status display (LED) AUTO (green) – ECO (orange) – MAX (red)

– Rotary knob for setpoint adjustment ±3 K

Communication connection for field devices 2 x PP (for PC-Tool, ZTH EU, etc.)

Inputs 2 x analogue, 2 x digital

– External temperature sensor (ai1) Type NTC, 5 k�, Power supply range 10 … 45°C

– External setpoint shift (ai2) 0 … 10 V correspond to: 0 … 10 K

– Digital inputs (di1, di2,) Contact rating 10 mA

Output 1x analogue

– 6-way ball valve (ao1) (0) 2 … 10 V, max. 5 mA

Norms and Standards Protection class III Safety extra-low voltage

Degree of protection IP30 (EN 60529)

Mode of operation Type 1 (EN60730-1)

Software class A (EN 60730-1)

EMC CE according to 2004/108/EU

Ambient conditions

– Operation 0 … +50°C / 20 … 90% r.h. (non-condensating)

– Transport and storage 25 … +70°C / 20 … 90% r.h. (non-condensating)

Dimensions / Weight Dimensions (H x W x D) 99 x 84 x 32 mm

Weight 105 g

Housing colour Baseplate NCS2005-R80B light grey (corresponds approximately

to RAL 7035)

Cover RAL9003 signal white

Temperature controller for single-room

applications with one analogue output:

• The 6-way ball valve for the regulation of

a heated/chilled ceiling can be connected

with the analogue output ao1.

Safety notes

!

• The controller is not allowed to be used outside the specified field of application, especially

in aircraft or in any other airborne means of transport.

• It may only be installed by suitably trained personnel. Any legal regulations or regulations

issued by government agency authorities must be observed during assembly.

• The device does not contain any parts that can be replaced or repaired by the user.

• The device contains electrical and electronic components and is not allowed to be disposed

of as household refuse. All locally valid regulations and requirements must be observed.

.

.

.

.

.

.

.

6 / 20 S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes www.belimo.eu

CRK24-B1 Technical data sheet

Product features

Energy hold off

(EHO)

In energy saving mode, the room temperature is regulated to the building protection level, i.e.

the heating setpoint is significantly reduced or the cooling setpoint is significantly increased, for

instance in a room with an open window.

Pre-comfort The room temperature is reduced to stand-by level, i.e. the heating setpoint is slightly reduced

and/or the cooling setpoint is slightly increased, for instance in a room that is temporarily

unoccupied.

Frost If the current room temperature falls below 10°C, then the frost function will be activated.

Dew point limitation If the optional connectable dew point limiter responds, then the valve is moved into neutral

position.

External temperature sensor An external temperature sensor can be connected at analogue input ai1.

External setpoint shift An external DC 0 ... 10 V signal at the analogue input ai2 can be used to shift the basic setpoint

by 0 ... 10 K, e.g. for summer/winter compensation.

The functions are described in detail on pages 9 to 13.

Electrical installation

Wiring diagram

U5

CRK24-B1

EHO

13

y

5

U

2

~

AC 24 V

0 … 10 V

12 7 86

ao1

1

U5

2

4

di2

3

5

ai1/di

1a

i2

~

Notes

• Connect via safety isolation transformer.

• Parallel connection of other actuators possible.

Note the performance data.

!

Configuration

Configuration ao1 modulating ao1 On/Off

1 2 3 4 5 6

ON

OFF

l

[V]

ao

1

10

7.3

4.7

2

0 10 33 66 90 100 [%]

l

[V]

ao

1

10

6

2

0 10 33 66 90 100 [%]

Shifting

Pre-comfort

Dew point limiter

Actuator for 6-way valve

External NTC

temperature sensor

DIP

Default settings

1 P-Band normal P-Band wide

2 Output ao1 modulating Output ao1 On/Off

ao1

(heating)

ao1

(cooling)

ao1

(heating)

ao1

(cooling)

Inputs Outputs

3ai1 External temperature sensor 6 ao1 System output for 6-way valve

di1 Pre-comfort Other connections

4 di2 Energy hold off / dew point 7 PP1 Diagnostic socket 1

5 ai2 External setpoint shift

www.belimo.eu S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes 7 / 20

Operation CRK24-B1

1

2

3

4

5

6

7

8

21

Mode switch and status display

Selection can be made between three operating modes:

• AUTO – optimum comfort mode

The room will be kept at comfort zone status insofar as the external

control signals permit this. All control functions are enabled.

• ECO – optimum energy mode

The room will be kept at pre-comfort status insofar as the external

control signals permit this. Reduced heating (–3 K) and elevated

cooling setpoints (+3 K) are in effect in this status. Starting from this

status, the room can be returned to comfort status within a short time.

Sequence control is enabled. The operating mode ECO is intended

for rooms not continuously occupied and/or for reduced requirements.

• MAX – Boost function

The room will be heated or cooled at maximum power, insofar as the

external control signals permit this.

The Boost function is switched off:

– Timer off

– Setpoint is reached

– Selection of a different mode (AUTO or ECO)

Measuring point terminals

Measuring points for all connection terminals (also during operation).

Internal function test

A comprehensive internal function test can be started with the mode

switch which makes it possible to check the controller, including

nominal voltage (AC 24V). The three LEDs (status display) are used

thereby to display the voltage level and the statuses.

Simulation control sequence

The rotary knob for the setpoint adjustment can be used to simulate

the connected actuators, and thus the heating and cooling control

sequences, independent of the room temperature.

ZTH EU / PC-Tool connection

The diagnostic socket 1 is used for PP communications with the

connected Belimo MFT actuator. Physical access to the valve actuator

can be dispensed with as a result.

Operating level 1 – Operation Operating mode / Setpoint

DIP switch for configuration

DIP switches 1 and 2

Basic setpoint setting WH (heating setpoint)

Potentiometer 15 … 36°C (Default 21°C)

Label for settings

Recording the settings used

(DIP switch and basic setpoint)

Operating level 2 – Configuration Application / Parameters

Operating level 3 – Service Test / Simulation

Rotary knob for setpoint adjustment

Potentiometer ±3 K

Mode switch

• MAX

• ECO

• AUTO

Status display

• MAX (red)

• ECO (orange)

• AUTO (green)

O

rder-Nr

.

Order-Nr.

CR24-B2xxxxx

W

H

U5/

2

U5/

1

12

ON

OFF

21

36

15

Measuring point

terminals

ZTH EU / PC-Tool connection

Internal function test

Basic setpoint settingDIP switch for configuration

Label for settings

1

2

3

4

5

6

7

8

Rotary knob for

simulation of control sequence

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

8 / 20 S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes www.belimo.eu

CRK24-B1

www.belimo.eu S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes 9 / 20

Functions CRK24-B1

Introduction

The control functions of the CRK24-B1 define the behaviour of the controller output or influence

the current setpoint, respectively.

Operation can be automated and comfort and energy savings potential enhanced through the

utilisation of corresponding sensor mechanisms at the input side.

The corresponding functions are described in detail in the following.

Function overview CRK24-B1

Supply AC 24 V / 50/60 Hz

Application – Room temperature controller in the comfort zone

– Internal temperature sensor (Type NTC, Power supply range 10 … 45°C)

– Setpoint (adjustment range 15 ... 36°C)

Operation – Mode selection switch: AUTO – ECO – MAX

– Mode display LED: AUTO – ECO – MAX

– Setpoint adjustment rotary knob ±3 K

Inputs – Pre-comfort

– Dew point limitation

– Energy hold off (EHO)

– External temperature sensor (Type NTC 5 kΩ, Power supply range 10 … 45°C)

– External setpoint shift 0 … 10 V

Output – 2 … 10 V System output: Belimo 6-way ball valve

Functions – Control characteristics: P

– P-Band, switchable

– Output can be switched (modulating / On/Off)

– Room temperature monitoring (frost)

– Internal Function test with nominal voltage check

– Commissioning mode with simulation of output and sequence

– Diagnostics via integrated PC-Tool connection

Installation Surface mounting with flush-mounted or surface-mounted connection

Application documentation

Continually expanded, comprehensive documentation with specific applications is available for the

CRK24-B1 controller.

10 / 20 S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes www.belimo.eu

CRK24-B1 Functions

Operating status Heating setpoint Cooling setpoint

Comfort Basic setpoint WH

±3 K setpoint adjustment

+ Setpoint shift 0 … 10 V

Comfort-Heating setpoint WA

+1 K dead band

Pre-comfort Comfort-Heating setpoint WA

– 3 K Pre-comfort-Offset heating

Comfort-Heating setpoint WA

+1 K dead band

+3 K Pre-comfort-Offset cooling

Energy hold off fix 15°C (building protection) fix 40°C (building protection)

Frost fix 10°C without function

Setpoint calculation

Examples Comfort Pre-comfort

Y

tR

+1 K dead band

23°C Comfort setpoint WA

Y

tR

+1 K dead band

23°C Comfort setpoint WA

+3 K Pre-comfort-Offset

Cooling

–3 K Pre-comfort-Offset

Heating

[%]

100

0

EHO

Valve opening

tRoom [°C]

Dead band

WH Basic setpoint

WA current setpoint

Pre-comfort

Frost

Dew point

Ws Setpoint shift 0 … 10 V

Setpoint adjustment ±3 K

www.belimo.eu S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes 11 / 20

CRK24-B1 Functions

Pre-comfort Digital input di1

If a local detector (e.g. a motion detector) has an effect on the digital

input di1 and closes the corresponding contact, then the room will be

regulated to stand-by level, i.e. the heating setpoint is reduced by 3 K or

the cooling setpoint is raised by 3K, respectively.

Typical applications

– One motion detector, light switch or other detector at di1 reduces the

energy consumption in unoccupied rooms.

– Superordinate imperative command, e.g. GLT.

Notes

– The frost limit is monitored with the internal sensor during Pre-comfort

when an external temperature sensor is used.

– As a result of the automatic sensor recognition feature, the switch-over

to Pre-comfort takes approximately 40 seconds.

12

3

~

ai/di1

AC 24 V

NTC

CRK24-B1

[%]

100

0

Energy Hold Off (EHO) Digital input di2

If a local detector (e.g. a window switch) has an effect on the digital input

di2 and closes the corresponding contact, then the room will be regulated

in energy-savings mode to the building protection level, i.e. the heating

setpoint is significantly reduced (15°C) and/or the cooling setpoint is

significantly raised (40°C), so that sensitive furnishings (plants, pictures,

etc.) will not be able to suffer any damage.

Typical applications

– One window switch at di2 stops energy consumption as soon as the

window is opened until the lower or upper building protection limit has

been reached.

– Superordinate imperative command, e.g. GLT.

Notes

– The 6-way valve is moved into neutral position during the Energy Hold

Off (ao1 = 6 V).

– The mode switch (operating level 1) is deactivated during the Energy

Hold Off (the input di2 has higher priority).

tRoom [°C]

WA

Pre-comfortY

Pre-comfort

12

4

~

di2

AC 24 V

CRK24-B1

[%]

100

0

tRoom [°C]

WA

EHOY

Energy Hold Off

Legend

Y Output signal

WACurrent setpoint

Legend

Y Output signal

WACurrent setpoint

12 / 20 S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes www.belimo.eu

CRK24-B1 Functions

Chilled ceiling with dew point limiter Digital input di2

If the optional connectable dew point limiter responds, then the output

ao1 is overridden to 6 V by means of the input di2 (external dew point

limiter). The 6-way ball valve moves into neutral position.

Typical applications

Chilled ceiling systems in which one dew point limit is required.

12 7

~

~

ao1 U51

4

di2

AC 24 V

CRK24-B1

12 5

U5

6

3

YBelimo actuator for 6-way valve

Cooling / Heating

Dew point reached

Dew point

l

[V]

ao

1

10

7.3

4.7

2

0 10 33 66 90 100 [%]

ao1

(heating)

ao1

(cooling)

Dew point

External setpoint shift Analogue input ai2

1 2

5

0 … 10 V

ai2

AC 24 V

CRK24-B1

~

An external DC 0...10 V signal at the analogue input ai2 can be used to

raise the basic setpoint by 0 ... 10 K (corresponding to

0 … 10 V).

Typical application

Summer/Winter Compensation

W [°C]

S [V]

5.00

26

21

16

10

Notes

A negative shift is possible by setting the basic setpoint to the desired

final setpoint, e.g. from 21°C (default value) to 16°C. This results in the

following correspondences:

– 0 … 5 V: 16 … 21°C and

– 5 … 10 V: 21 … 26°C (see illustration at the left).

Legend

W Setpoint

S Shift signal

Setpoint shift

www.belimo.eu S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes 13 / 20

CRK24-B1 Functions

External temperature sensor (ai1)

An external NTC temperature sensor can be connected at analogue input ai1. Sensor type: NTC

5k (5 kΩ), e.g. Belimo TFK.

Typical applications

• More flexible placement of the sensor for recording the room temperature

• Temperature measurement in the ventilation channel for recording the average room

temperature.

12

3

AC 24 V

CRK24-B1

ai/di1

T

~

Notes

• The controller recognises it automatically if an

external sensor is connected. No additional

adjustments are required.

• The simultaneous utilisation of Pre-comfort

at di1 is possible, although in this case a

switchover to the internal sensor is made (see

also «Pre-comfort»). As a result, the current room

temperature is monitored for building protection.

External NTC

temperature sensor

Pre-comfort

Analogue outputs

LR24A-MP Actuator for 6-way ball valve

• System output «ao1» (Terminal 6). diagnostic socket «U5/1» (Terminal 7).

U5

CRK24-B

1

13

y5

U

2

~

AC 24 V

12 7 86

ao1 1U5

24

di2

3

5

ai1/di1 ai2

~

Note

When using an LR24A-MP, it is expedient to direct

the communications signal U5 of the actuator to the

controller. Interventions can be implemented on the

actuator by means of controller diagnostic socket 1

without the need for direct physical access. LR24A-MP

Actuator for 6-way valve

14 / 20 S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes www.belimo.eu

CRK24-B1

www.belimo.eu S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes 15 / 20

Dimensions, installation, commissioning, service CRK24-B1

1 2 3 4 5 6 7 8

1.5mm2

2.5mm2AC 24 V -

-

1

2

3

4

5

6

7

8

1 2 3 4 5 6 7 8

Cam

Left stop

1

2

3

1 2 3 4 5 6 7 8

1. Remove the housing cover.

2. Pull out slightly the wall of the housing to

release the pcb.

3. Remove the PCB.

Rotary knob for setpoint adjustment

If the rotary knob has been removed proceed

as follows:

a. Insert the rotary knob approximately half

way and turn it clockwise as far as the stop.

b. Remove the knob and align it so that the

cam is flush with the left stop (see left).

c. Insert the knob fully.

Dimensions [mm]

56

60

56

99

84

90

32

Mechanical installation

Electrical installation

Flush-mounted connection

Surface-mounted connection

Terminal connection 1 … 8

16 / 20 S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes www.belimo.eu

CRK24-B1 Dimensions, installation, commissioning, service

Power supply design / wire sizing

In addition to the actual wire sizing, attention must also be paid to the surrounding area and the

cable routing. Signal cables must not be laid in the vicinity of load cables, objects liable to cause

EMC interference. etc. Paired or layer stranded cables improve immunity to interference.

24 V supply

Wire sizing and cabling

The wire sizing and installation of the AC 24 V supply, the fuse protection, and the cables are

dependent on the total operated load and local regulations.

Account must be taken of the following performance data, including starting currents:

– Wire sizing values for room temperature controllers: 3 VA per CRK24-B1

– Wire sizing values for the valve actuators can be obtained from current data sheets and

product information (www.belimo.eu)

– Other devices to be operated with the AC 24 V supply

– Reserve capacity for subsequent expansion (if planned)

Analogue input connection ai1 The analogue input ai1 is used to connect an external NTC 5 kΩ temperature sensor. The

sensor value is 5969 Ω at 21°C. A change of 50 Ω corresponds to approximately 0.2 K in this

range.

The sensor cable constitutes a series resistance that must be added to the actual sensor value.

Assuming a cable length of 15 m (2 x 15 = 30 m), the resistance of one 0.75 mm2 Cu cable is

approximately 0.7 Ω, in other words negligible.

To prevent interference, however, the sensor cable should be a maximum of 20 m long.

Commissioning / Power on behaviour

Commissioning 1. Assemble the baseplate of the housing and connect the cables (see page 15)

2. Configure the DIP switches on the printed circuit board according to the required application.

3. Assemble the printed circuit board on the baseplate of the housing and then mount the

housing cover (see page 15)

4. Switch on the nominal voltage AC 24 V

5. Optional: start the test and simulation mode (see below)

When the voltage is applied, the system starts operating normally in AUTO mode unless the

test simulation mode is selected. The active operating status is determined primarily by the

configuration of the DIP switches and the status of the inputs.

Power on behaviour After power on of the voltage supply the output gets initialised as follows:

– ao1 = 0 V

Subsequently the controller switches automatically to the control mode.

Test and simulation mode

All controllers are supplied with two auxiliary programs for commissioning and servicing:

– Internal function test

– Control sequence simulation

Activating test and simulation mode The test and simulation mode of CRK24-B1 controllers can be activated easily with the mode

switch on the operator panel.

To activate test mode

1. Set the mode switch to MAX

– The red LED (MAX status indication) lights up

2. Keep the mode switch pressed for ten seconds

– The internal function test is activated (see below)

To activate simulation mode

3. Press the mode switch again briefly for approx. one second

– The green LED (COMF status indication) flashes

– Control sequence simulation is activated (see below)

Deactivating test and simulation mode The test and simulation mode can be deactivated either by pressing the mode switch again for

ten seconds or by interrupting the power supply. It is also deactivated automatically 15 minutes

after the last user action (auto-reset).

www.belimo.eu S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes 17 / 20

+3

–2

–1

+2

+1

W = X

–3

0

[V]

10

6

2

0

0

–3 +3

CRK24-B1 Dimensions, installation, commissioning, service

Internal function test

The internal function test tests the nominal voltage that is connected to the controller (AC 24 V),

in other words the complete electrical wiring system from the control cabinet to the controller..

The three LEDs (status indication) indicate the voltage level

(see below) and states during the test.

Note

Case B and C do not need further attention. In

case A (<20 V) attention must be paid to the

following points:

– Quality of the wiring and connections

– Cable length and diameter and the transformer

sizing

Nominal voltage (AC 24 V)

LED (status indication) Scenario A Scenario B Scenario C

MAX red flash flash permanently on

ECO orange flash flash permanently on

AUTO green permanently

off flash permanently on

<20 V 20 … 22 V >22 V

Control sequence simulation

CRK24-B1 In the simulation mode, the connected actuator can be operated regardless of the room

temperature. This permits the function of the system to be checked.

Notes

– The external control signals (di1 and di2) are

suppressed during the simulation.

– The potentiometer may be adjusted only slowly,

due to the system-dependent attenuation of the

setpoint potentiometer in simulation mode.

– Simulation mode is automatically deactivated 15

minutes after the last user action (auto-reset).

Potentiometer (setpoint adjustment)

Output

Shift

Heating

Cooling

XpHXpK

out

1

18 / 20 S4-CRK24-B1 • en • v1.2 • 06.2016 • subject to changes www.belimo.eu

CRK24-B1

All-inclusive.

Belimo worldwide: www.belimo.com

5 year

guarantee

World-wide

on your doorstep

Complete product range

froma single source

Tested quality

Short delivery time

Comprehensive support

Switzerland

BELIMO Automation AG

Sales Switzerland

Brunnenbachstrasse 1

CH-8340 Hinwil

Tel. +41 (0)43 843 62 12

Fax +41 (0)43 843 62 66

www.belimo.ch

Benelux

BELIMO Servomotoren BV

BENELUX

Postbus 300, NL-8160 AH Epe

Radeweg 25, NL-8171 MD

Vaassen

Tel. +31 (0)578 57 68 36

Fax +31 (0)578 57 69 15

www.belimo.nl

Germany

BELIMO Stellantriebe

Vertriebs GmbH

Welfenstrasse 27

D-70599 Stuttgart

Tel. +49 (0)711 1 67 83-0

Fax +49 (0)711 1 67 83-73

www.belimo.de

At no charge

Orders:

Tel. 0711 1 67 83-83

Technical Consultation:

Tel. 0711 1 67 83-84

Fax 0711 1 67 83-73

Personal consultation with Regional

Sales Director in:

Berlin, Hanover, Düsseldorf

Leipzig, Frankfurt, Munich

Hamburg, Stuttgart

Austria

BELIMO Automation

Handelsgesellschaft m.b.H.

Geiselbergstrasse 26-32

A-1110 Vienna, Austria

Tel. +43 (0)1 749 03 61-0

Fax +43 (0)1 749 03 61-99

www.belimo.at

Austria West

Tel. +43 (0)644 14 26 365

Fax +43 (0)732 70 10 51

dietmar[email protected]

Hungary

Tel. +36 (06)20/920 46 16

Fax +36 (06)23/37 77 30

gabor.koe[email protected]

Slovakia

Tel. +43 (0)1 749 03 61-0

Fax +43 (0)1 749 03 61-99

Slovenia/Croatia/Bosnia

Tel. +386-(0)41-75 89 63

Fax +386-(0)4-2342-761

Serbia/Montenegro/

Macedonia/Bosnia

Tel./Fax +381-(0)11 311-9127

branimir.petro[email protected]

Table of contents

Popular Temperature Controllers manuals by other brands

Fuji Electric

Fuji Electric PXR3 Series Operation manual

TECH

TECH ST-85 user manual

Alula

Alula RE205 quick start guide

S+S Regeltechnik

S+S Regeltechnik HYGRASGARD ESFF Operating Instructions, Mounting & Installation

MULTISPAN

MULTISPAN UTC-2200G quick start guide

Eurotherm

Eurotherm 2108i Installing and operating instructions