Bell and Howell 785 User manual

-Gf

En

-l t-

et Lrl

bva

BEtt & HOWEtt MODEIS 785, 785C,

785L, 7g5't-4, 795)(, 795-4TS

I

It1

€la

Nr-

"f;

90o

I\ I\

UI\

-lX

tr ia

SR

=.\

\t

J_l

-rF

ur ut

33

or\

T\J

of3

-r l:

J

ut

6

MODrt 785-4TS

\F

Ep

F

\t

rO

t{

9F

r'F

i=

rO

EH

Xr

i g/l

\v

oai

rr"

{\

(,loo

(,l

n

GENERAL INFORMATION

This manual covers the following Bell & Howell tape recorders: Models ?85, ?85C, ?85L,

?85ST-4, ?85X, and ?85-4TS.

The differences between these models are as follows: Model ?85-4TS will record four

tracks monaural orplay back twoor four track pre-recorded stereo tapel Model?8bis designed

for ll? volt, 60 cygfe AC operationl Model ?85-C is designed for ll? volts, b0 to 60 cycle AC

operationl Model 785-L is equipped wi.th a 3-wire power cable and grounding type plugj Uodel

?85-X is designed for ll0 or 220 volts, b0 or 60 cycle AC.

All models wilt a'bcept reels up to ? inches in diameter. Each mode of operation is con-

trolled by a pushbutton.

The tape speeds are 3 3/ 4 -ips.and 7 L/ 2 tps. Using a 1200 ft. reel of tape on four tracks,

the playing or recording time at 3 3/4 ips is four hours; at 7 L/ 2 ips is two hburs.

Connect the recorder to the power source specified for the model being used.

Supplied By:

Bell & Howell Co.

7125 North Kimball Avenue

Chicago 45, lllinois

HOWARD W. SAIUIS &

The lieting of any available replacement part herein does

not constitute in any case a recommendation, warranty or

guarantyby Howard W. Sams & Co., Inc., as to the quality

and guitability of such replacement part. The numbers of

these parts have been compiled from information furnished

to Howard W. Sams & Co. , Inc. , by the manufacturers of

cQ4?8

G CD., I t (C. tndianapolls €i, lndiana

the particular type of replacement part listed. Repro-

duction or use, without express permission, of editorial or

pictorial content, in any manner, is prohibited. No patent

liability is assumed.with respect to the use ol the informa-

tion contained herein. @ ISOZ Howard W. Sams & Co. , Inc. ,

q

l-r

-l

cJr

clt

t\9

-l

€

E

ITI

-

Indianapolis 6, Indiana.

DATE I - 62

Printed in U.S. of America

sET 562 FOTDER 1

Off -Volume

Turning this control clockwise turns the re-

corder on. Further rotation increases the volume.

Tone

Rotating the control clockwise emphasizes the

high f requencies (treble). Rotating the control counter-

elockwise emphasizes the low frequencies (bass).

Monitor

Tolisten when a recording is being made, move

the switch to the monitor position.

Channel Selector

The channel selector selects the channel to be

used for recording or playing back a prerecorded

tape.

Play

Plaees the recorder in the play mode of opera-

tion when depressed.

Rewind and Forward

Depressing ttte rewind button will rewind the

OPERATI NG

Threading the Tape

l. Depress the stop button.

2. Place a full reel of tape on left-hand spindle.

3. Place an empty reel on the right-hand spindle.

4. Unwind about two feet oftape from the full reel.

Hold a section taut and insert it in the tape slot.

Insert the free end into one of the slots in the

empty reel and turn the empty reel by hand to

secure the tape to it And to tal<e up the slack.

Recording

l. Set the channel selector tothe type of recording

to be made.

Thread the tape.

Set the speed change shaft to the desired speed.

Plug t}te microphone into the microphone input

jackto makea live recording oritmaybe placed

in front of the loudspeaker of a radio, phono-

graph, or television set.

To make recordings from a radio, phonograph,

or televlsion set without getting extraneous noise

inthe recording, connect oneend of apatch cord

to the speaker terminals ofa radio, phonograph,

or television receiver. Plug the other end of

the patch cord into the Radio-Phono input jack.

Turn the Olf -Volume control on.

FUNCTION OF CONTROLS

tape at a rapid speed. Depressing the forward button

will advance the tape at a rapid speed.

StoP

Depressing this button will stop the transport

mechanism when in any mode of operation. This but-

ton must be depressed when going from one mode to

another.

Record

To record, depress the record button and while

holding itdown depress theplay button. This prevents

accidental erasure.

Pause

Sliding t}te button to the left will temporarily

stop the mechanism without taking the recorder out

of its mode of operation. Release the button to pro-

ceed.

Speed Change

Pull the speed change shaft up for 3 3/4 ips

operation and down tor 7 L/2 ips operation. Before

operating t}te speed change shaft, make certain the

stop button is depressed.

I NSTRUCTI ONS

7. Depress the Record and Play buttons.

8. $ide the pause button to the left and hold while

adjusting the recording level.

9. Placethe Monitor switchin theNormal position.

Playing a Recording

l. Set the channel selector for the type tape being

played.

Thread the tape.

Set the speed change shaft to the speed at which

the recording was made.

Depress the Play button.

Adjust the volume and tone controls tJtne ae-

slred listening level.

Erasing

A tape is automatically erased when a new re-

cording is made. To erase a tape without putting new

material on it, run thetape through in the record mode

with the volume control turned to its lowest position

and remove all input connections.

* Pause Lever

The Pause lever allows the operator to tempor-

arily stop the recorder while recording without de-

pressingthe $op button. The Pause lever canbe used

to obtain the proper volume level before making a

recording.

2.

3.

4.

5.2.

3.

4,

5.

6.

Page 2

*t l''.. t,:.i'

FIG.I TOP VIEW OF MECHANISM WITH TOP PLATE REMOVED

E

llt

F

\F

Er

F

\E

rO

t{

gF

t'F

.s3

rO

EH

Xr

rli

\v

oqi

rs

-f\

tao

(lt

f|

Playing Dual -Track Tapes

t. Place the channel selector in the l-4 position.

2. Thread the tape onto the reeorder.

3. After thefirst trackis played, take thefull reel,

turn it over and place it on the left spindle.

Place the empty reel on the right spindle.

4. Rethreadthe tape, and the second track isready

to be played.

5. To play dual-track stereo, set the channel se-

lector to the stereo position.

Playing 4 -Track Tapes

l. Place the channel selector in the l-4 position.

2. After the tape has been played or recorded

through on one channel, turn the full reel over

and plaee it on the left spindle and the empty

reel on the right spindle.

3. Place the channel selector in the 3-2 position.

4. After track 2 has been played or recorded, turn

the full reel over and place on the left spindte

and the empty reel on the right spindle. Play or

record channel 3.

5. Place the channel seleetor in the l-4 position.

6. Again place thefull reel of tape onthe left spin-

dleand theempty reelon the right spindle. play

or reeord track 4.

Stereophonic Playback

I. Connect a high impedance input of an auxiliary

amplifier to the stereo output jack at the right

rear of the tape recorder chassis.

2. Place the channel selector inthe stereo position.

3. Tracks I and 3 will play back with side number

one of the reel up.

4. After the recording has been played through,

turn the full reel over so the number two side

will be up and place it on the left spindte.

5. With the number two side up, tracks 4 and 2 will

be reproduced.

O

I

Frl

n

Page 3

Rewind and Fast Forward

When a tape has been completely played or re-

eorded, press the stop button to stop the recorder.

To return the tape to the original supply reel, press

the rewind button. To advance the tape rapidly, press

the forward button. Be sure to take up any slack tape

before operating either of these controls to prevent

breaking the tape since it travels at a high rate of

speed in these modes of operation.

CAUTI 0N: Always stop the recorder complete-

ly when going from rewind or forward to

another mode.

Program lndicator

This permits the logging of material as it is

DISASSEMBLY

To Remove Recorder from Case

l. Remove the two reel spindles held in place by

Philtips head machine screws.

2. Remove the control knobs.

Remove the top plate (6) secured in place by 4

Phillips head rnachine screws.

Remove the plastic carrying handle.

Place the recorder ln an upright position and

remove the two plastic feet at the back of the

case.

6. Remove the bottom grille.

?. Remove thetwo Phillips headscrews accessible

through the openings in the metal plastic handle

channel support.

8. Carefully lift the recorder from the case.

To Remove the tape Transport Mechanism

1. Disconnect the drive motor (80).

ADJUSTMENTS

Pressure Roller

1. Connect an inch-ounce scale to the end of pres-

sure roller lever assembly (37).

2. Pull pressure roller free of capstan.

3. If reading is less than 16 in-o2., bend the long

spring to increase the pressure.

Take Up Tension

l. Place an empty 7" reel on the take-up splndle.

2. Attach a short loop of string to the outside edge

of the reel.

3. Connect agramscale with aminimum readingof

60 grams to the string.

Page 4

recorded, or relocating previously logged material.

The indicator should be set at "000" at start of the

tape, then any desired point on the tape can be logged

or relocated.

Public Address

To use there,ggrder asa publicaddress system,

plug a microphone..into the microphone input jack and

turnthe poweron. Remove alltape from therecorder.

Set the monitor switch to the monitor position. De-

press the record button and lock it in place by de-

pressing the play button.

Keep the microphone well away fromthe speak-

ers to prevent acoustic feed-back squeal.

I NSTRUCTI ONS

2. Remove the input and output jacks, function se-

lector switch, and monitor switch.

3. Disconnect the head leads.

4. Remove the six self-tapping screws holding

transport to the speaker mounting plates.

5. Carefully lift thetransport mechanism from the

speaker mounting plates.

To Remove the Amplif ier

l. Disconnect all plug-in leads.

2. Disconnect the slide switch wire link from the

slide switch.

3. Unsolder the leads to the muting switch.

4. Remove the volume and tone control locking

nuts.

5. Remove the self-tapping screws and washers

along thetop and bottom edgeof the printed cir-

cuit board.

6. Carefully remove the amplilier assembly.

HoId the scale parallel to the recorder and at a

right angle to the take-up spindle.

Depress the play button and note the reading.

ff the reading is over or below 60 grams, re-

move themechanism from thecase asdescribed

under "Disassembly In gtructions".

Remove the mechanism plate held in place by

six Phillips head sheet metal screws.

8. Disengage the counter drive belt (65) from

clutch pulley (?l).

Remove the clutch pulley (71).

Slip the tension spring (69) and felt lining (67)

off the take-up spindle.

3.

4.

5.

4.

5.

6.

7.

9.

10.

:,,|--E.it.:;3 , '.'i

H ,i -&ilE

FIG.2 BOTTOM VIEW OF MECHANISM

ll. If the reading was over 60 grams, saturate the Play-Record Head

felt llning (6?) in a solution of one part turbine

oil and 15 parts carbon tetrachloride. Allow to l. Thread a good prerecorded tape onto the re-

dry for 30 minutes before reassembling the corder.

clutch. 2. Place the reeorder in the playback mode with

L2. If reading was less than 30 grams, replace the normal volume.

tension spring and/ ot the felt lining. 3. Adjust the head (33) for up and down position by

Tape Reel Spindles loosening the nuts in the side and i[aing the

head (33) up or down so the top of the pole piece

The supply and take-up spindles should be ad- is in line with the top of the tape.

iusted so the tape does not scrape on the edge of the

reels. If they are worn, remove the spindles from

flange shaft and add shim washers until the reels are

aligned.

CLEAN ING LUBRICATION

The play-record }ead (33) erase head (34), The beart€s ofthis recorder were lubllcated

pressure roller (22), andthe capstan should be cleaned before leaving the factory. No furthe! lubllcetion

periodicaUy. Use a aoft cloth and alcohol to clean x'lll be n€ceasary.

tleee parts.

Page 5

o

SEED CHANGE

3'A uP

7 Y2 Do\|r

e-----e

Be[U g D{esnze0ll

.@ @@@

- AMPLIFITR SPEAKER RADIO PHONO MICRoPHONE

Oi A e \

RECORD : PAUSE

€\'(:a (:=\ --

v l.-/

PLAY NEWINO FORWARD sIOP

| - { -cMNNrL sELEooR 11.9iP

N.RMAL A

@'"'ut'-'^"

A PHOTOFACT "EXPLODED" VIEW

@Howrrd W. Srns & Co., lnc. 196?

FIG.3A EXPLODED V IEW OF PARTS ABOVE PLATE ASSEMBLY

Page 6

i

t;

t.@

\.v,

c--tll9

A PHOTOFACT "EXPLODED" VIE\(

@How..d W. S.m' a Co., tic. r t

F IG.3 B EXPLODED V I EW OF PARTS BELOW PLATE AS SEM BLY

Page 7Page 9

STEREO PREAMP

ECC83

AMP CHASS IS - TOP V IEW

't

2

7

1

7

.t A Howard w. somr !$$lS rr'oro PRINTED BOARD ARROWS INDICATING TUSE I.OCA,TIONS ARE

POINTING TO PIN I UNIESS OIHERWISE INDICATED

Page l0

=

ul

o-

o

F

I

a

E.

o

6

6

ul

z.

E,

o-

h\

l"

{

fi

lFr

:i.,i..::!

!#t'',:e

;e.,

X

F{

F

s

r;q

.*

&

s

&

#

t.

\4

{F

'+*

{/

@

2

#

.:

N#

@

s

@

e

qit

{:1

{*

ir"

qf

w

r

s'

:

$

t

€

E

U

€

\f

t4

\o

E

|lt

F

\F

Er

F

\I

\o

t{

3F

r'F

.sB

:{o

EH

Xr

r lfl

\\

o oti

[$'

{\

ul oo

gr

6

o

Ef

rfl

n

Page I I

6

r

o

z

I

H

.u)

>r@

40

o '6

an Fl

Fr@

iF

€d

-6

6!aS

dH-

6{ r

:;E

^6F

&Is

FO O

Hdd

- oo

E>>

Fg.g.

trFF

rdoo

E996

€i6gs

h€t;

E g-g,E

o.=,:L

":AAT/

d*+ h

C t k.lj

E O O.C

qlooh

5#&!

oi

zz

EFe

€<

dA

q)

o

FO

388=

€NO@

orFo

FOOF

trl

z

4

q

OC'OG)

EEFB

thtnaD@

E* -N o

>E

lz

UJ

o-

tn

u

F

o

z

F

o

F

z

U

=

u

U

J

L

U

&

o

2z

-oZ

cNN

@6

o.

Fo

oZ

F

.Bd

=f,

c)

rl

6 (Ct

$s

oo

oo

@6

U

g

F

L

=

U

t${r

tt

60

6

J

u

LEE

AA

u

N

6

fre dN

AA

TA 'A

U)

!

F

o

z

F

o

F

z

u

:

U

U

L

U

d

o

nZ

OL

,d

F<c

at

!p

Yd

o<

Jd

F

rO

8z

CL

oiY

,;<

L

d

'=L

OF

<eL

iu-

EO

6ZF

€t

=a

(,

o

@

@

6

o

o

o

u

U

z

o

q

L

=&

c

oI

aO

o

o

@

frt N

H

d

6

€

F

'ri.l

o-r

F tia

fiE

€P

os

EH

a6

.TF

o

Bo

tz

F

rtE

=f;

o

la

F

o

o

z

-

d,

=

ct

3

o

ul

z

J

J

trl

\J

!a

c,

EI

F

f

o-

F

f

o

I

o

f

g

c,

tlt

=

4

o

II

r/t

z

c,

F

d,

tu

3

o

g

4

ltl

=

4

o

II

at,

z

4

h

t!I

TL

c

t/t

J

6

U

!t

ot

6

=

qt

6

'=

q,

o

ta

IA

ot

vtE

ea

9s

FO

t/t -

;;b

lll v'

sE

s

tag

,€

-'o

4\-

va

I

l-

G

I

sl

(,

la

EI

A

?

o

a

ts

I

@

6

rc)

qE

E>

k

3.'i

igo

*Z

o

z

h

|a

I

J

UI

t-

4

&a

h

(,

lr|

-l

trt

{i I

H

TA

6

@

F

lt

G

€

F

o

6

6

F

@

@

F

o

ru

E

o

€

{)

(0

u

o

ttl

F

o

o

6

t

6t

F{

o

h'

o

lr

I

rd

d

o

t{

o

d

b

Evt

"-t

EO

E4

.TF

iz

?o

E(J

()

.l:

d

aB

.{

o

o

@

o

i.

o

a

t

-.j6

6rt

pa^

s Z'a

od:

!>=

.9eE

aFb

.5tr

9<z

o

at

d

_o

5F

bo

E<

'dr

E<

t(J

t

k

fo

O III

Ex

t-

dt!

=<

H*

$o

go

bi

ES

i€r

€ot

o!to

t -dt

o*Z

u.?F

gdE

JIEO

L KP

A9r.

o 1'9

EEE

v,

c,

o

=

I

o-

(\,

(J

F

J

o

c,

t-

.9

.b uJ

EJ

.Xur

t{

$I

6

6

F

o

€

o

=H

€

(,

6

p

;

o

o

2

vt

llr

Co

3

l-

v,

u

F

o

z

F

o

F

z

Fo

cz

o-

EF

!E

bs

=

.d

8z

Cg

oit

6<

q

o

rZ

<d d

d

OL

{ia

g.e

Elp

4

o;!

o

m

o

o

o

5

D

ut

tn

o

D

o

{:

ul,

bz J

F

o

F

z

q

t

u

(.l

c

U

e

$ 6 (t r @ @ O r N o!i. n q)F OO O < N

NNdNNNmOOOOOO60A$$$

*

g

o

d

N

KsfHHHHgxHErHrsHHrEx

!'i@@r oo 9 = I=E E9!99RF S R

i,fr e c4trtr d d tr tr tr fi tl d tr tr d tr !( d

at,

U

F

o

z

z

o

F

I

F

ln

z

tr

3E

ooa

qk

!$ee

ooot

>Atirt

Bt

=5

|JO

47

tF

o4

b{

F

<d

oz

Op

ed

da.

co

<d

4z

dL

Fiy

z<

qd

U

E

E

-oo

frz

€E

=<

od

E

o

3Ee

o o;{

N N=

e eP

o

tr

4

v,

F

)

ju

au

iz

g< v-9Ic:

o.coo

o Eoo

6qlON

f;-e

)-a <co

j No

d dd

F

6

F

u

=

u

U

J

a

u

4

u;

Ei

SE

G<

U'A $E agEHHA$ H HEgmgEEgEEgEaHH

i_d

o.-

it E; =+s++x* t *ntuH Hq;ien:+E

oo Hqoncao<

o,

U;

UF

=t

EA 5E q++r$+i i leqq+ee+:iq+qF3

gg gggggga. a. aggggttggagggg!i

is;

!Er

Jlo; gg gFEHf;EB g HsHHEHEHggfrEHHE

6

<d

Er

6f s: q+fi$+q E Fq+q F9qqq ee

EH tt88t8 A tte8 8H388 8d

6e

9E

U<

<a

FrNR

r$$N-=

SeeqHeE Z EseqE cqF EEEqE

iEiEai$ $ gIie: sRF RSlR€

aantrqQA A aQoEO =OZ !a6iloA.

o

oo

Ni

FF

^o

XP

zz

v,

Y

4

=

q

eN

o

++

-A

ER

(!)

o

z

o

z

F

4

€H -H-** 5

sEeH : ,:!E.ii-H sufl E= :H e

9<9Nae$a! e!oQNiooN dooNd

oQioOOooooroOOoOoOoOOo <OOOOO

Ei <{6 (o r o o g = S P g I I IP gR RS R S K R F RR g d

a()C)()C)()()()()()9()()C)()()Qooo9()C)()c)(Joo

z

H.i

oL

*i

r

ct

@{r

60

$N

3i

Ha

oci

=z

{r

44

rf o

NI

ct

I

n

tr

t_d

oL

=i

d

N

L)

tr

ie9

44L

UF

sH5 6I

H

@

D

I

D

i')

r(

=ryE

gai @

dI

o

&

!q

E

gt

9p

u<

<A

o

6

d

TA

c

ft

=

fle

o1

o{

4A

o

gl

3eo

te3

too

iFF

ts

J

o)o oo

o@600@@@

l.odo6NNN

4

I>OOOOooA

a@$<$6n=

al al.

f;-e

FZ 5tre*tr(JQa

)(r()

z.

J

t/,

t

z.

O

l!

!

tr

e.

t

(J

E,

F

C.)

lrl

J

trl

J

E

l4l

z.

lrt

(9

tL

o tt)

c! E!

E Ee

<< a

EF '

<<o

PAGE 12

TROUBLT CHART

Symptom Cause Remedy

Clicking noise when recorder

isin fast forward or rewind. l. Damaged counter. l. Check springs in counter or lub-

ricate.

Noisy pushbutton operation. l. Lack of lubrlcation. l. Lubricate the neoprene pads on

push-button shafts.

Volumeor tone controlsbind

and are difficult to turn. Prlnted circuit board not cen-

tered.

Lack of lubrication or tacky

condition of rubber grommets.

l. Reposition the board ao the

shafts are properly aligned in

rubber grommets.

2. Check condition of rubber grom-

mets and lubricate with silicon

grease.

2.

Speed change shaft binds. l. Lack of lubrication. l. Lubricate with anon-melting lub-

ricant.

Take-up reel does not re-

volve in faet forward posi-

tion.

Oil onrim of fast forward idler

wheel (i8).

Fast forward lever spring (li2)

off or broken.

Fast forward idler spring (84)

off or broken.

Clean rimwith a softcloth mois-

tened with alcohol.

Replace.

Replace.

l.

2.

3.

l.

2.

3.

Erratic drive onboth speeds. l. Drive pulley's (77) position in-

correct. l. The bottom of drive pulley (77)

should be /32" from top of

motor shell.

Take-upreel doesnot rotate

in play or record position. l. Take-up idler spring (8?) off or

broken.

2. Oil on rimof take-up idler (66).

3. Clutch slipping onclutch wheel.

l. Replace.

2. Clean with cloth moistened with

alcohol.

3. Reposition clutch pulley(71) and

tighten.

F

llt

F

\F

tr

l+

\o

s{

9F

r'F

.5=

\o

EH

Xr

i gll

\v

oai

!,t 9,

F

{\

ra qi

lrt

rr

Counter does not operate. Counter defective.

Counter belt (65) off or broken. l.

2.

I.

2. Replace.

Replace.

Supply reel does not rotate in

rewind position. OII on rewind idler wheel (43)

or rewind drive wheel (44).

Rewind idler spring (f0?) off or

broken.

Clean with cloth moistened in

alcohol.

Replace.

I.

2.

l.

2.

Pitch of sound is Iow from

prerecorded tape, 1. Capstan drive mechanism slip-

pinc. l. Removetop panel (6) and clean all

driving surfaces with alcohol.

Reels do not stop when stop

button is depressed. Brake actuating spring (39) off

or broken.

Brake lining worn.

Brake lever (98) loose on shaft.

Replace.

Replace.

Reposition brake lever (98) and

tighten.

l.

2.

3.

1.

2.

3-

Wow or flutter t.

2.

3.

Motor shaft bent.

Idler wheel (93) worn.

Flywheel shaft (73) or bearings

scored.

Pressure roller (22) binding on

shaft.

Pressure pads (31) and (35)

dirty.

Excessive takeup tension.

Improper pressure between

capstan (73) and pressure roller

(22).

Replace motor (80).

Replace idler wheel (93).

If shaIt is lightly scored, polish

with crocus cloth. If bearings

are scored, replace.

Remove pressure roller (22) and

clean bearing with alcohol. If

ehaft is scored, polish with cro-

cus cloth.

Saturate with alcohol and brush

contact surfaces in direction of

tape travel.

See ttAdjustments".

See "Adjustments".

l.

2.

3.

6.

7.

4.

5.

4.

5.

6.

7. n

o

(f

n

{

Page 13

MECHANICAL PARTS LIST

4-40 x 1,/4 Truss Head Phillips

Screw

. 116 x . 281 x. 020 Washer

Reel Spindle

Removable Cover

4-40 x l/4 Truss Head Screw

Top Plate Assembly

"8" Ring, .18?

Brake Assembly

Brake Spring

Counter Mounting Clips

4-40 x L/4 FIat Head Screw

Counter Assembly

Hex Head Screws

Mechanism Plate Assry.

Volume, Tone & Channel Selector

Knobs

"E" Ring, .187

.l9l x ?[6 Fibre Washer

Fast Forward Idler Wheel

. t9l x ?/16 Fibre Washer

"E" Ring, .187

. 191 x . 3?5 x . 015 Nylon Washer

Pressure Roller

.257 x. 437 x . 015 Nylon Washer

.l9I x 7/16 Fibne Washer

"8" Ring, . 250

"8" Ring

Azimuth Spring

?ape Guide

Head Mtg. Bracket Assembly

Hex Head Screws

Pressure Pad

Record & PIay Arm & Pad Ass'y.

Record & Play Head

Erase Head

Pressure Pad

Erase Arm & Pad Assembly

Pressure Roller Lever Assembly

Speed Change Shaft Spring

Brake Actuating Spring

"E" Ring, .187

Rewind Idler Arm Assembly

. l9I x.7/16 Fibre Washer

Second Rewind Idler

Rewind Drive Idler Wheel

"E" Ring .187

.191 x 7/6 Fibre Washer

"E" Ring, .250

. 265 x l/2 x .030 Fibre Washer

Pause Knob

Neon Plastic Cap

Record Button

9/16 - 2? Hex Nut

Pushbutton

Stop Button

"E" Ring, .18?

Brake Lining

Brake Spring

Remote Control Link

.191 x Z/t6 f iure Wa,sher

l/16 x3/8 Cotter Pin

I

2

3

4

5

6

7

I

I

l0

1l

L2

l3

l4

15

l6

17

l8

19

20

2T

22*

23

24

25

26

27

28

29

30

3t

32

33

34

35

36

37

38

39

40

4L

42

43

44

45

46

47

48

49

50

5l

52

53

54

55

56

5?

58

59

60

?00245

700?16

800423

800?95

?00245

0?6343

700890

0 ?6190

800536

800599

700088

076261

?00348

0 76189

701508

700890

700?97

0 7623 I

700797

?00890

700806

800714 *

?00807

700?97

?00889

700897

800540

070202

700343

800564

076274

70607

70608

800564

076273

076185

800587

800572

700890

07619r

700797

0?6183

076180

700890

?00?97

?00889

700?98

076265

800574

800440

700477

800439

800441

700890

8004?8

800536

800607

?00797

?00553

6l

62

63

64

65*

66

67

68

69

70

7r

72

73

74

75

76

77

78

?9

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

9?

98

99

100

l0l

102

r03

t04

r05

r06

107

108

r09

lt0

111

Il2

113

I14

ll5

u6

ll?

1r8

ll9

120

121

r22

?0r3 67

800?28

800461

700797

800544 *

076196

800459

800458

800460

800655

800542

700424

07623r

800568

700734

700230

800462

700420

70671

70670

700348

70671

701587

800548

076260

076192

700896

0?6204

700797

800545

700890

0 ?6180

8005?6

700894

700895

0?6199

800624

700438

076198

?00806

?00806

700890

700420

800520

070219

80047?

700345

076200

700712

700890

800547

800479

700?98

?00889

076184

076186

076263

076202

076201

070219

700424

Rubber Grommets

Jack Lock Nuts

Take-up Spindle Shaft

. 191 x 7/L6 x.015 Fibre Washer

Counter BeIt

Clutch Wheel Assembly

Clutch Lining

Clutch Plate

Clutch Spring

. 484 x 3/4 x .010 Fibre Washer

Clutch Pulley

Set Screw

Capstan & Flywheel Assembly

Ball Bearing, . 18?5 Dia"

#10 Ext. Tooth Washer

#10-32 x 3/8 Hex Head Screw

Drive Pulley

#8-32 x L/4Set Screw

Grommets

Motor-Fasco

#10-1/4 Screw

Grommets

Fan

Fast Forward Idler Spring

Forward Idler Lever Assembly

Take-up Idler Lever Assembly

Take-up Idler Lever Spring

"E" Ring, .437

Take-up Assembly Idler Wheel

Fibre Washer

Take-up Idler Spring

"E" Rlng, .187

Speed Change Idler Wheel

Retractor

"E" Ring, .3?5

"E" Ring, , 312

Speed Change Shaft Assembly

Brake Lever

#6-32 x 3/tO Cone Pt. Set screnr

Speed Change Link Assembly

. l9l x . 375 x .015 Nylon Washer

. l9I x . 375 x .015 Nylon Washer

"E" Ring, .187

#8 - 32 x 1/4 Set Screw

Forward & Rewind Pulley

Mrtor Mtg. Plate Assembly

Rewind ldler Spring

*LA xI/4 Hex Head Screws

Forward Lever Link Assembly

.196 x 7AG x.030 Steel Washer

"E" Ring, .18?

Fast Forward Lever Spring

Rewind Spindle Shaft

. 265 x I/2 Fitde Washer

"E" Ring, .250

Rewind Lever Assembly

Take-up Arm Assembly

Pushbutton Assembly

Rewind Lever Link Assembly

Pressure Roller Link Assembly

Mctor Mounting Plate

Set Serew

* Pregsure Roller WALSCO Part No. 1488

* Counter Bett WALSCO Part No. 1410-54

Page 14

This manual suits for next models

5

Table of contents

Popular Voice Recorder manuals by other brands

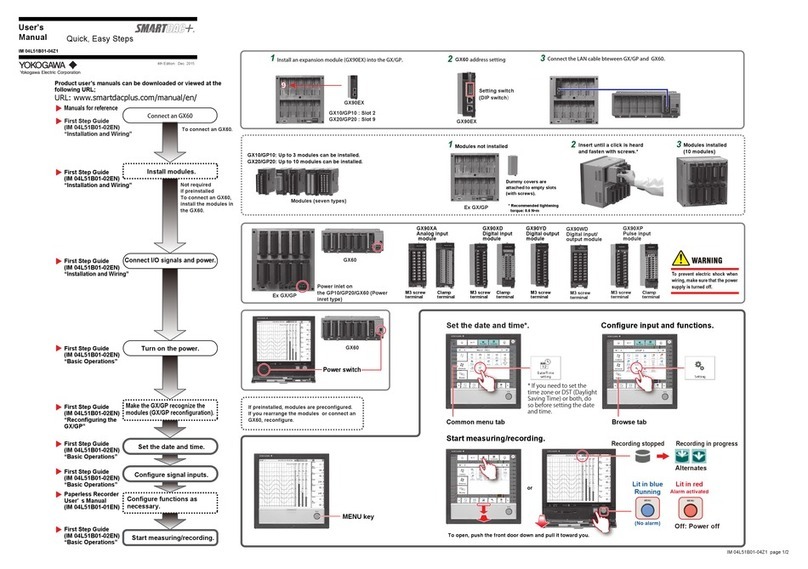

YOKOGAWA

YOKOGAWA SMARTDAC+ GX user manual

Safety Basement

Safety Basement Platinum Nano SB-VR9920 instruction manual

Sony

Sony ICD-P630F operating instructions

Olympus

Olympus DM-5 Detailed instructions

Siemens

Siemens SICAM Q80 System manual

Sony

Sony ICD-MX20 - Memory Stick Pro Duo Digital Voice... operating instructions