Bell&Howell FILMSOUND 302 User manual

Disclaimer

This scanned document is provided as a courtesy. We make

no representation for its accuracy. It is for use by qualified

personnel only. There are high voltage and mechanical

hazards present in this equipment. Do not attempt repair

unless you are fully aware of the safety precautions to be

taken. Use this information at your own risk.

www.paulivester.com

SERVICE

INSTRUCTIONS

DESIGN

INDEX

CHART

Design

Number

Model

Letter

Parts

List

Code

Letter

Description

302

L

A

16

-mm

Filmosound

magnetic

and

optical

sound

projector,

120

-volt,

50-60

cycle,

oval

case

-mounted

speaker,

sapphire

shuttle

and

film

guide,

grey

wrinkle

finish.

302

M

B

Same

as

Design

302L,

except

grey

smooth

finish

and

loopsetter

(item

4-31)

added.

8302

A

C

Same

as

Design

302M,

except

made

in

Japan.

Most

notable

difference

in

amplifier

and

door

-mounted

speaker.

8302

AO

Same

as

Design

8302A,

except

with

oil

cup

lubrication

system

parts

(Parts

List

Fig.

5)

added.

8302

AP

Same

as

Design

8302A,

except

with

3

-wire

power

cord

8302

APO

(part

no.

32051)

added.

Same

as

Design

8302A,

except

with

3

-wire

power

cord

and

oil

cup

lubrication

system

parts

(Parts

List

Fig.

5)

added.

8302

AT

Same

as

Design

8302A,

except

tropicalized.

8302

ATO

Same

as

Design

8302AT,

except

with

oil

cup

lubrication

system

parts

(Parts

List

Fig.

5)

added.

8302

B

D

Same

as

Design

8302A,

except

220

-volt.

8302

BO

Same

as

Design

8302AO,

except

220

-volt.

8302

BP

Same

as

Design

8302AP,

except

220

-volt.

8302

BPO

Same

as

Design

8302APQ,

except

220

-volt.

8302

BT

Same

as

Design

8302AT,

except

220

-volt.

8302

BTO

Same

as

Design

8302ATO,

except

220

-volt.

8302

C

E

Same

as

Design

8302A,

except

with

insulation

specification

for

CSA

added.

8302

CO

Same

as

Design

8302AO,

except

with

insulation

specifica-

tion

for

CSA

added.

8302

D

Same

as

Design

8302A,

except

without

silent

speed

opera-

tion

(switch,

item

11-53,

not

included).

8302

DO

Same

as

Design

8302D,

except

with

oil

cup

lubrication

system

parts

(Parts

List

Fig.

5)

added.

8302

E

Same

as

Design

8302B,

except

without

silent

speed

opera-

tion

(switch,

item

11-53,

not

included).

8302

EO

Same

as

Design

8302E,

except

with

oil

cup

lubrication

system

parts

(Parts

List

Fig.

5)

added.

8302

L

F

Same

as

Design

8302AO,

except

with

UL

approved

parts

and

front

speaker

case

assembly.

FILMOSOUND

PROJECTORS

DES.

302/8302

Introduction

This

Instruction

Book

has

been

prepared

to

aid

the

serviceman

in

the

repair

and

servicing

of

the

Bell.

&

Howell

16

-mm

Filmosound

Projectors,

Designs

302

and

8302.

An

illustrated

parts

catalog

is

included

at

the

rear

of

the

manual

to

identify

replacement

parts

for

all

projectors.

All

parts

in

the

exploded

view

illustrations

are

indexed

in

their

suggested

order

of

removal.

Where

disassembly

and

reassembly

of

parts

is

quite

obvious,

no

attempt

has

been

made

to

elaborate

on

the

removal

or

installation

of

such

parts.

When

making

specific

re-

pairs

or

replacements,

the

serviceman

must

use

his

own

judgement

in

eliminating

unnecessary

steps

of

procedure.

Projector

models

covered

by

these

instructions

(302L,

302M,

8302A,

8302B,

8302C

and

8302L)

are

almost

identical

in

design

and

construction.

Specific

differences

are

noted

in

the

instructions

and

in

the

Usable

on

Code

column

of

the

parts

lists

at

the

rear

of

the

manual.

It

is

also

important

to

note

that

some

302M

and

8302

model

projectors

are

equipped

with

oil

cups

installed

in

the

top

of

the

gear

case,

while

others

are

of

the

"factory

sealed

lubrication"

design.

Except

for

this

difference

in

lubricating

parts

and

in

the

gear

case

casting,

oil

cup

projectors

and

permanently

lubri-

cated

projectors

are

identical.

Projector

design

var-

iations

are

listed

in

the

Design

Index

Chart,

preceding

page.

•

SPECIAL

MAINTENANCE

PRECAUTIONS.

For

the

most

part,

disassembly

and

reassembly

of

the

projectors

is

relatively

simple.

Before

attempting

repairs,

however,

it

is

suggested

that

the

serviceman

run

an

operating

test

to

verify

customer

complaint

and

then

check

the

Trouble

Shooting

section

to

determine

the

possible

cause

of

the

trouble.

LUBRICATION.

Proper

lubrication

of

parts

is

of

vital

importance.

When

overhauling

projectors,

always

clean

parts

thoroughly

of

old

lubricant

and

relubricate

during

reassembly

only

with

recommended

Bell

&

Howell

projector

oil

and

grease.

Do

not

over

-lubricate,

and

be

sure

to

wipe

away

any

excess

lubricant

with

a

lint

-free

cloth.

Proper

lubricants

are

indicated

in

paragraph

22.

SPECIAL

SERVICE

TOOLS.

Special

service

tools

available

from

Bell

&

Howell

for

use

in

servicing

Filmosound

Projectors

are

illus-

trated

in

figure

B.

Refer

to

the

accompanying

tool

list

for

tool

numbers

and

applications.

The

tool

number

is

stamped

in

each

Bell

&

Howell

tool.

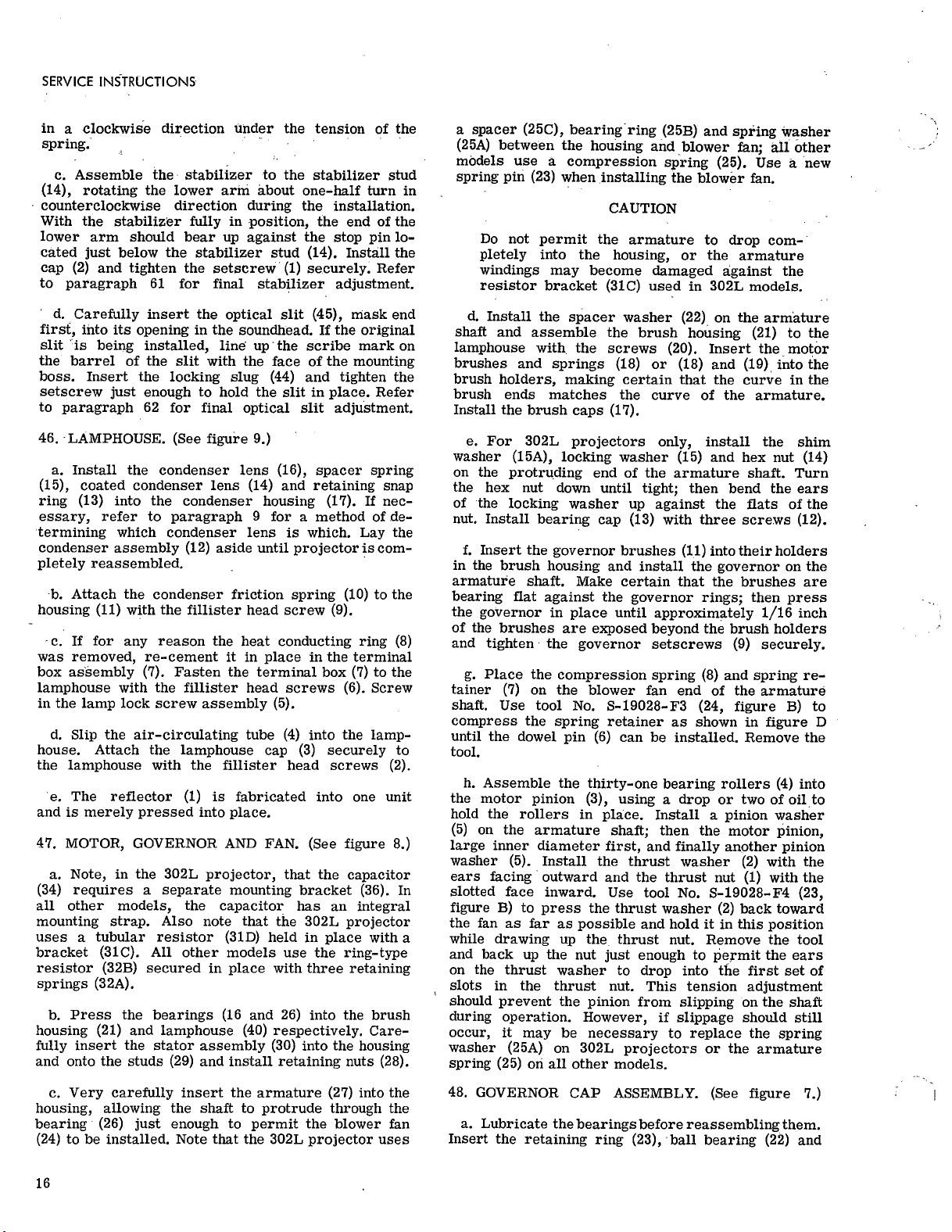

Figure

A.

16

-MM

Filmosound

Projector

1

SERVICE

INSTRUCTIONS

Fl

2

3

8

9

10

11

G

4

C

5

6

12

13

14

15

16

17

18

19

20

21

22

duN

23

24

25

Figure

B.

Special

Service

Tools

INDEX

NO.

TOOL

NO.

FUNCTION

1

ST-

244-

F1

Fan

housing

bearing

removal

2

S

-10309-F1

Lens

carrier

adjustment

3

S

-4529-N4

Shuttle

tooth

height

gage

4

S

-4007-F14

Quills

(use

with

Index

No.

7)

5

S

-4007-F5

Sleeve

(use

with

Index

No.

7)

6

No.

1459

Clip

(use

with

Index

No.

7)

7

S-4007-

1

Fixture

(for

assembling

shutter

and

counter

shaft

parts)

8

S

-15177-N4

Shim

gage

(for

gear

clearance)

9

S

-4007-F6

Sleeve

(use

with

Index

No.

7)

10

S

-15638-N6

Film

guide

clearance

gage

11

G

-165-F3

Setscrew

wrench

12

G

-167-F3

Setscrew

wrench

(Bristo)

INDEX

NO.

TOOL

NO.

FUNCTION

13

S

-14986-X1

Setscrew

wrench

(Bristo)

14

S

-15177-F3

Cone

(sprocket

installation)

15

S

-15177-N2

Gage

(sprocket

adjusting)

16

S

-15177-N1

Gage

(sprocket

shaft

adj.

)

17

S

-14878-F1

Drift

punch

(bearing

removal)

18

S

-10310-F2

Wrench

(shuttle

shaft

holding)

19

G

-167-X2

Setscrew

wrench

(Bristo)

20

G

-167-F1

Handle

(for

Index

No.

19)

21

G

-165-X2

Setscrew

wrench

(Bristo)

22

G

-165-F1

Handle

(for

Index

No.

21)

23

S

-19028-F4

Wrench

(for

clutch

disassembly)

24

S-19028-

F3

Wrench

(for

clutch

disassembly)

25

S

-12264-F3

Wrench

(for

governor

cap)

2

FILMOSOUND

PROJECTORS

DES.302/8302

AND

NOTE

Disassembly

procedures

are

keyed

and

cross-

referenced

to

the

exploded

views

located

in the

Parts

Catalog

section

of

this

book.

The

ex-

ploded

views

can

be

folded

outward

beyond

the

edge

of

the

book

so

that text

and

illustrations

can

be

referred

to

simultaneously.

Follow

the

procedures

as

outlined,

eliminating

unneces-

sary

steps

where

desired.

1.

AMPLIFIER

PROJECTOR.

(See

figure

1.)

a.

Remove

the

case

feet

(1),

lock

washers

(2)

and

bottom

plate

(3).

Remove

four

screws

(4)

and

carefully

withdraw

the

amplifier

(5)

from

the

projector

case.

Be

sure

to

disconnect

all

connecting

cable

plugs

from

the

amplifier.

NOTE

No

specific

disassembly

instructions

are

given

for

the

amplifier.

Refer

to

the

appropriate

schematic

diagram

at

the

end

of

the

Parts

Catalog

section

for

proper

voltage

and

parts

replacement

information.

Correct

amplifier

troubles

by

normal

circuit

tracing

techniques.

b.

Remove

the

screws

(6),

flat

washers

(7),

cushions

(8)

and

spacers

(9)

and

withdraw

the

projector

(10)

from

the

projector

case

(11).

c.

The

reel

arms

(14)

and

(15)

are

normally

stored

in

the

projector

case.

Remove

the

reel

arm

spring

belts

(12)

and

(13)

by

disconnecting

the

ends

and

carefully

pulling

them

free

of

the

case.

Refer

to

paragraph

15

for

disassembly

instructions

relevant

to

the

rear

reel

arm

and

to

paragraph

16

for

the

front

reel

arm.

2.

PROJECTOR

MAIN

COMPONENTS.

(See

figure

2.)

a.

Remove

the

condenser

assemblies

(1)

and

(2)

and

projection

lens

(3)

from

the

projector.

Refer

to

paragraph

6b

for

disassembly

of

the

relay

condenser

and

to

paragraph

9e

for

disassembly

of

the

45-50mm

condenser.

Do

not

attempt

to

disassemble

the

pro-

jection

lens.

b.

Loosen

the

knurled

screw

(4)

and

remove

the

exciter

lamp

cover

(5).

Press

down

slightly

on

the

exciter

lamp

(6),

twist

the

lamp

and

remove

it

from

its

socket.

c.

The

gear

case

assembly

(14),

blower

housing

(17),

governor

cap

assembly

(19)

and

lamphouse

and

motor

assembly

(20)

can

be

removed

as

a

unit

by

removing

two

screws

(7)

or

(7A)

and

two

Sems

screws

(8);

The

Procedure

screws

(7)

are

used

in

302L

projectors

only;

screws

(7A)

and

support

bracket

(7B)

are

used

in

all

other

models.

d.

Free

the

gear

case

assembly

by

removing

screws

(9)

and

(11),

the

latter

also

serving

to

attach

the

guide

rail

(12)

and

spacer

washers

(13).

Separate

the

gear

case

(14)

from

the

blower

housing,

being

careful

not

to

damage

the

teeth

of

the

counter

gear

(22,

figure

5)

as

it

passes

the

thrust

nut

(1,

figure

8).

When

as-

sembled,

the counter

gear

engages

the

motor

pinion

(3,

figure

8).

e.

Remove

the

screws

(15

and

16)

and

separate

the

blower

housing

(17)

from

the

lamphouse

(20).

Remove

two

screws

(18)

and

separate

the

governor

cap

assem-

bly

(19)

from

the

lamphouse.

3.

GEAR

CASE

-

FRONT

COVER

AND

CLUTCH

MECHANISM.

(See

figure

3.)

a.

Remove

the

pressure

plate

assembly

(1)

from

the

rear

of

the

lens

carrier

and,

if

necessary,

disassemble

as

follows:

Press

in

on

the

spring

cups

(1A)

until

the

cups

and

springs

(1B)

can

be

removed.

Remove

screws

(1C)

and

disassemble

the

remaining

parts.

b.

Remove

the

rubber

knob

(2).

Unscrew

the

hex

nut

(3)

and

partially

unscrew

the

clutch

knob

assembly

(4)

until

the

retaining

ring

(5)

can

be

removed.

Unscrew

the

knob

assembly

completely

and

catch

the

spacer

(6)

as

it

drops

free.

c.

Note

that

a

small

pin

in

the

plate

and

shaft

as-

sembly

(13)

engages

a

hole

in

the

gate

operating

block

(9).

These

two

parts

must

be

disengaged

while

the

front

cover

assembly

(8)

is

being

removed.

Lift

out

the

gate

operating

block

(9).

d.

Unscrew

the

fillister

head

screw

(10)

and

remove

the

gate

operating

lever

(11).

Loosen

the

setscrew

(12)

and

disassemble

the

plate

and

shaft

assembly

(13)

and

eccentric

bushing

(14)

from

the

front

cover.

Unscrew

the

special

screw

(19)

and

carefully

remove

the

idler

gear

shaft

(15),

idler

gear

(16),

eighteen

steel

balls

(17)

and

large

fl

at

washer

(18)

from

the

boss

on

the

rear

of

the

front

cover.

e.

Loosen

the

pilot

screw

(20)

and

disengage

the

tip

of

the

clutch

lever

stud

(21)

from

the

hole

in

the

clutch

lever

(22).

Remove

the

clutch

lever,

torsion

spring

(23)

and

clutch

plunger

(24).

4.

GEAR

CASE

-

SPROCKETS

AND

GEARS.

(See

figure

4.)

a.

Remove

the

two

screws

(1)

and

film

strippers

(2).

3

SERVICE

INSTRUCTIONS

b.

Remove

the

sprocket

guard

screw

(3),

sprocket

guard

assembly

(4),

spring

(5)

and

tension

washer

(6)

from

the

end

of

each

sprocket

shaft.

Use

the

Bristo

wrench

and

handle

(21

and

22,

figure

B)

to

loosen

the

setscrews

(7).

Remove

sprocket

assemblies

(8),

being

careful

not

to

damage

the

felt

washers

located

inside

the

sprockets.

c.

Remove

screws

(9)

and

film

guides

(10).

Remove

screws

(11)

and

lens

carrier

retainers

(12)

and

lift

off

the

lens

carrier

(20).

Remove

the

screw

(13),

ball

retaining

spring

(14)

and

steel

ball

(15)

from

the

lens

carrier.

Unscrew

the

two

screws

(16)

from

the

pressure

plate

adjustment

nuts

(17)

and

disassemble

the

pressure

plate

carrier

(18)

from

the

lens

carrier.

CAUTION

The

inner

tip

of

the

lens

lock

screw

(19)

is

peened

and

this

screw

should

not

be

removed

from

the

lens

carrier.

d.

Note

that

an

ear

on

each

film

tension

clip

(22)

engages

a

slot

in

the

aperture

plate.

Remove

the

screws

(21),

the

film

tension

clips

(22),

the

thrust

spring

(23)

and

the

aperture

plate

(24).

The

302L

projector

is

equipped

with

a

variable

aperture

plate

(see

inset,

figure

4);

all

other

models

are

equipped

with

a

fixed

-aperture

plate.

Remove

the

framer

shaft

assembly

(25).

e.

Loosen

setscrews

(26)

with

the

Bristo

wrench

and

handle

(19

and

20,

figure

B).

Turn

the

setscrews

out

far

enough

to

permit

removal

of

the

sprocket

shafts

(27).

Remove

the

sprocket

shafts,

upper

gear

(28),

and

the

worm

wheel

(29)

with

its

spacer

washer

(30).

Note

that

each

sprocket

shaft

is

drilled

to

re-

ceive

a

felt

oil

wick

(27A).

These

should

be

discarded

and

replaced.

NOTE

All

8302

Models

and

the

302M

are

equipped

with

a

loopsetter

assembly

(31)

which

is

held

in

place

by

the

screw

(21)

which

holds

the

lower

tension

clip

(

22), and

an

adjacent

screw

(9)

which

attaches

the

lower

film

guide

(10).

Do

not

disassemble

unless

the

spring

(31B)

is

in

need

of

replacement.

5.

GEAR

CASE

-

SHUTTER

AND

SHUTTLE.

(See

figure

5.)

a.

Insert

the

special

wrench

(18,

figure

B)

behind the

shutter

supports

as

shown

in

figure

C.

The

wrench

must

engage

the

flats

on

the

shuttle

shaft

(13).

Re-

move

shutter

retaining

nut

(1)

with

an

open-end

wrench

and

lift

out

the

shutter

supports

(2)

and

the

shutter

(3).

The

oil

baffle

(4)

and

lubricator

assem-

bly

(5)

should

be

removed

together,

as

a

unit.

Re-

moval

of

the

special

screws

(7)

will

free

the

lubricator

assembly

(5),

shuttle

(8)

and

shuttle

pins

(9).

A

"class

-

fit"

number

is

etched

into

each

shuttle

in

the

location

indicated

by

the

letter

A

in

figure

5.

If

the

shuttle

requires

replacement,

be

sure

that

the

new

shuttle

has

the

same

class

fit

number

as

the

old

one.

b.

Before

removing

the

parts

indexed

10

through

24,

note

the

location

of

the

steel

balls

(12,

14,

21

and

23).

When

repairs

necessitate

the

complete

disassembly

of

the

gear

case,

these

steel

balls

must

be

discarded

and

replaced

with

new

ones.

NOTE

Steel

balls

used

by

Bell

&

Howell

are

carefully

graded

and

balls

of

different

grades

must

not

be

intermixed.

When

ordered

in

quantities

of

1000

or

more,

the

grade

is

indicated

on

the

bottle.

When

ordered

in

quantities

of

less

than

1000,

the

balls

are

all

of

one

grade

and

must

not

be

intermixed

with

any

steel

balls

you

already

may

have

on

hand.

c.

Remove

the

shoulder

'screw

(10A),

spring

(10B)

and

collar

(11)

and

remove

and

discard

the

steel

balls

(12).

Withdraw

the

shuttle

shaft

(13)

from

the

rear

of

the

gear

case

and

remove

and

discard

the

steel

balls

(14).

All

steel

balls

(12)

and

(14)

must

be

replaced

with new

ones

when

the

gear

case

parts

are

reassem-

bled.

Remove

the

oil

felt

(15)

which

wraps

around

the

shuttle

shaft.

If

excessively

dirty,

replace

this

felt.

d.

Loosen

two

setscrews

(16)

and

remove

the

worm

drive

extension

(17).

Loosen

the

setscrews

(18

and

19)

and

withdraw

the

worm

gear

(20).

Discard

the

steel

balls

(21).

From

the

rear

of

the

gear

case,

re-

move

the

counter

gear

(22),

steel

balls

(23),

and

the

oil

felt

(24).

Discard

the

steel

balls.

e.

Remove

the

flat

head

screw

(25)

and

the

spring

clamp

(26).

Remove

the

oiler

felt

(27)

from

the

hole

between

the

two

bearings

(28)

with

a

tweezers.

If

either

or

both

of

the

bearings

(28)

are

in

need

of

replacement,

they

can

be

removed

by

driving

them

out

with

the

special

drift

punch

(17,

figure

B).

Be

sure

to

save

the

shims

(29)

located

behind

the

shoulder

of

the

bearings.

6.

BLOWER

HOUSING.

(See

figure

6.)

a.

Note

that

Design

302L

projectors

are

equipped

with

the

adjustable

fire

shutter

(items

1

through

5);

all

other

models

are

equipped

with

the

manually

controlled

heat

filter

(items

15

through

20).

Disas-

semble

parts

as

necessary

for

replacement.

b.

When

disassembling

the

condenser

assembly

(9),

note

that

the

condenser

for

Design

302L

projector

has

a

one-piece

condenser

holder

and

handle;

in

all

other

models,

the

condenser

handle

is

removable.

7.

GOVERNOR

CAP

ASSEMBLY.

(See

figure

7.)

a.

Unscrew

the

special

nut

(1)

with

a

spanner.

wrench.

Then

unscrew

the

fillister

head

screw

(2)

and

remove

the

radial

bearing

(3).

Remove

the

worm

shaft

and

drive

blade

(4)

and

felt

washer

(5).

Use

the

special

tool

(25,

figure

B)

to

remove

screw

(6).

Remove

clutch

cover

(7)

and

bronze

washer

(8),

taking

care

not

to

dislodge

the

spring

(9)

or

steel

balls

(11).

b.

Note

how

the

parts

indexed

9

through

12

are

4

FILMOSOUND

PROJECTORS

DES.

302/8302

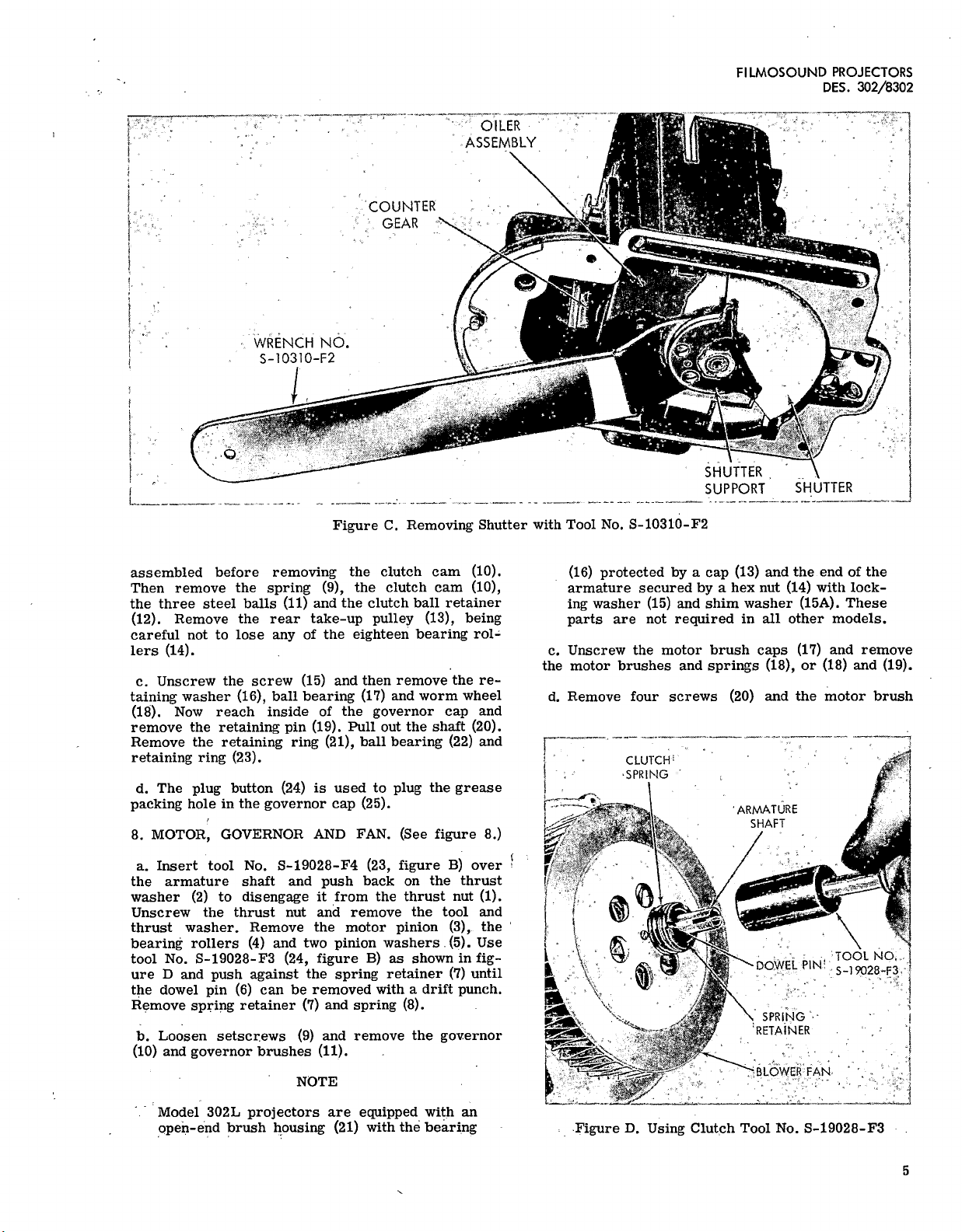

OILER

ASSEMBLY

COUNTER

GEAR

WRENCH

NO.

S

-10310-F2

V

SHUTTER

SUPPORT

SHUTTER

Figure

C.

Removing

Shutter

with

Tool

No.

S

-10310-F2

assembled

before

removing

the

clutch

cam

(10).

Then

remove

the

spring

(9),

the

clutch

cam

(10),

the

three

steel

balls

(11)

and

the

clutch

ball

retainer

(12).

Remove

the

rear

take-up

pulley

(13),

being

careful

not

to

lose

any

of

the

eighteen

bearing

rol-

lers

(14).

c.

Unscrew

the

screw

(15)

and

then

remove

the

re-

taining

washer

(16),

ball

bearing

(17)

and

worm

wheel

(18).

Now

reach

inside

of

the

governor

cap

and

remove

the

retaining

pin

(19).

Pull

out

the

shaft

(20).

Remove

the

retaining

ring

(21),

ball

bearing

(22)

and

retaining

ring

(23).

d.

The

plug

button

(24)

is

used

to

plug

the

grease

packing

hole

in

the

governor

cap

(25).

8.

MOTOR,

GOVERNOR

AND

FAN.

(See

figure

8.)

a.

Insert

tool

No.

S

-19028-F4

(23,

figure

B)

over

the

armature

shaft

and

push

back

on

the

thrust

washer

(2)

to

disengage

it

from

the

thrust

nut

(1).

Unscrew

the

thrust

nut

and

remove

the

tool

and

thrust

washer.

Remove

the

motor

pinion

(3),

the

bearing

rollers

(4)

and

two

pinion

washers

(5).

Use

tool

No.

S

-19028-F3

(24,

figure

B)

as

shown

in

fig-

ure

D

and

push

against

the

spring

retainer

(7)

until

the

dowel

pin

(6)

can

be

removed

with

a

drift

punch.

Remove

spring

retainer

(7)

and

spring

(8).

b.

Loosen

setscrews

(9)

and

remove

the

governor

(10)

and

governor

brushes

(11).

NOTE

Model

302L

projectors

are

equipped

with

an

open-end

brush

housing

(21)

with

the

bearing

(16)

protected

by

a

cap

(13)

and

the

end

of

the

armature

secured

by

a

hex

nut

(14)

with

lock-

ing

washer

(15)

and

shim

washer

(15A).

These

parts

are

not

required

in

all

other

models.

c.

Unscrew

the

motor

brush

caps

(17)

and

remove

the

motor

brushes

and

springs

(18),

or

(18)

and

(19).

d.

Remove

four

screws

(20)

and

the

motor

brush

CLUTCH

SPRING

'ARMATURE

SHAFT

TOOL

NO,

DOWEL

PIN

S

-19028-F3

SPRING

'RETAINER

"BLOWER

FAN

Figure

D.

Using

Clutch

Tool

No.

S

-19028-F3

5

SERVICE

INSTRUCTIONS

housing

(21).

Press

the

bearing

(16)

from

the

motor

brush

housing

and

remove

the

spacer

washer

(22)

from

the

armature

shaft.

e.

Tap

out

and

discard

the

spring

pin

(23)

and

re-

move

the

blower

fan

assembly

(24).

Remove

the

spring

(25)

from

the

armature

shaft

(all

models

except

302L).

On

the

302L,

remove

the

spring

washer

(25A),

bearing

ring

(25B)

and

spacer

(25C)

from

the

armature

shaft.

Withdraw

the

armature

assembly

(27)

from

the

motor

housing,

being

careful

that

it

does

not

slip

forward

during

removal.

f.

Unscrew

the

stator

retaining

nuts

(28)

from

the

four

studs

(29)

and

carefully

withdraw

the

stator

as-

sembly

(30)

from

the

motor

housing.

9.

LAMPHOUSE.

(See

figure

9.)

a.

Remove

the

reflector

assembly

(1)

from

the

lamp

-

house.

The

retaining

ring

(1A)

on

the

reflector

holds

the

unit

in

position.

b.

Unscrew

the

fillister

head

screws

(2)

and

remove

the

lamphouse

cap

(3)

and

the

air

-circulating

tube

(4).

c.

Unscrew

the

lamp

lock

screw

assembly

(5).

Re-

move

the

fillister

head

screws

(6)

to

detach

the

terminal

box

assembly

(7).

Do

not

remove

the

heat

conducting

ring

(8)

unless

necessary

for

replacement.

d.

Unscrew

the

fillister

head

screw

(9)

and

remove

the

condenser

friction

spring

(10)

from

the

lamphouse

and

motor

housing

(11).

e.

The

condenser

assembly

(12),

which

was

removed

in

paragraph

2,

is

disassembled

by

removing

the

lens

retaining

snap

ring

(13).

Be

careful

that

the

spring

(15)

does

not

release

suddenly

and

cause

possible

damage

to

the

lens

(14).

Remove

the

condenser

lens

(14),

spacer

spring

(15),

and

a

second

condenser

lens

(16)

from

the

condenser

lens

housing

(17).

f.

When

removing

the

condenser

lenses,

wrap

them

separately

and

mark

them

"inner"

and

"outer"

to

insure

proper

reassembly.

If

the

two

lenses

should

become

intermixed

accidentally,

place

them

side

by

side,

fl

at

surface

down,

on

a

piece

of

white

paper.

When

looking

straight

down

at

the

lenses,

note

that

each

has

a

circular

reflection.

The

lens

with

the

smaller

circle

of

reflection

is

the

outer

lens

(14).

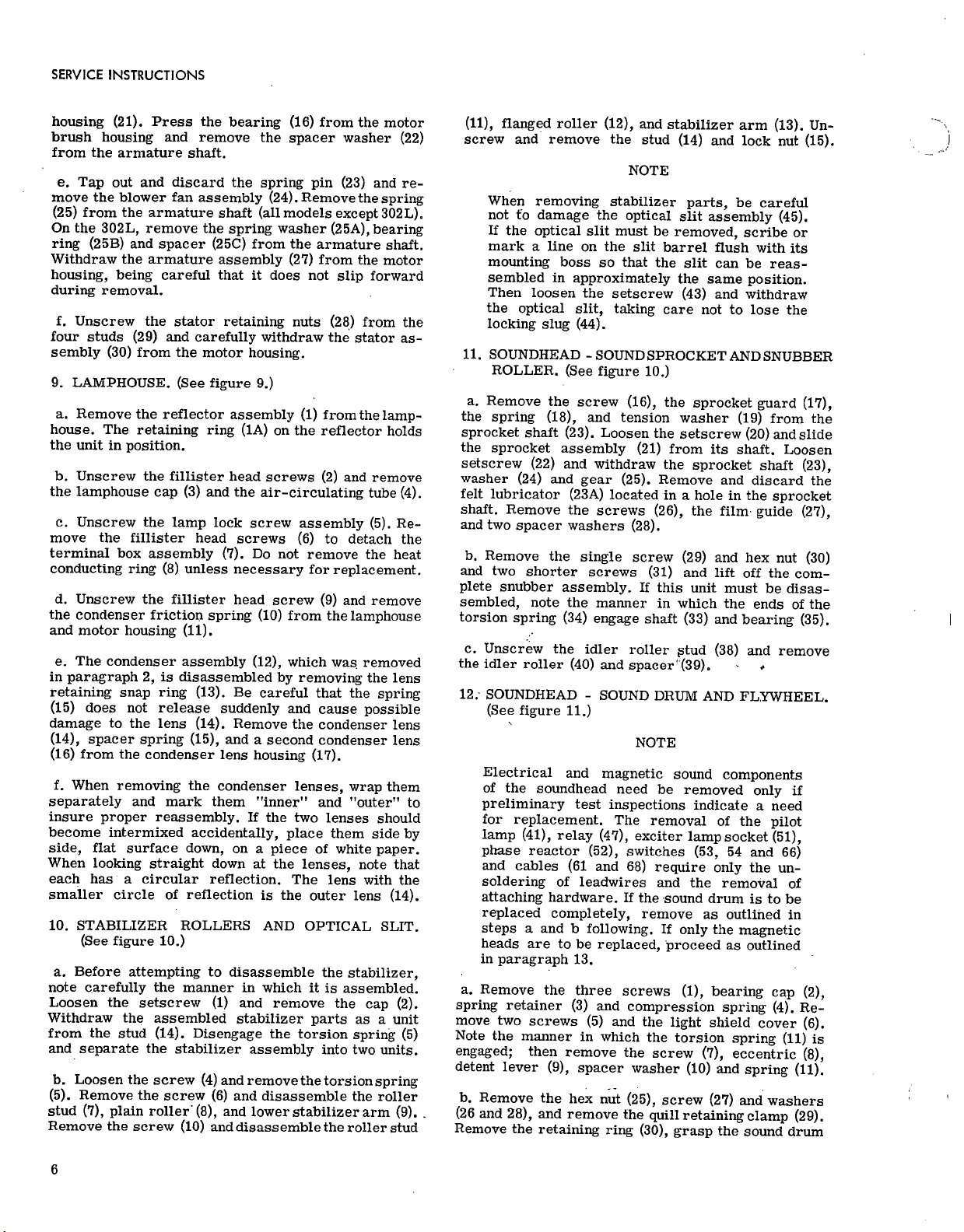

10.

STABILIZER

ROLLERS

AND

OPTICAL

SLIT.

(See

figure

10.)

a.

Before

attempting

to

disassemble

the

stabilizer,

note

carefully

the

manner

in

which

it

is

assembled.

Loosen

the

setscrew

(1)

and

remove

the

cap

(2).

Withdraw

the

assembled

stabilizer

parts

as

a

unit

from

the

stud

(14).

Disengage

the

torsion

spring

(5)

and

separate

the

stabilizer

assembly

into

two

units.

b.

Loosen

the

screw

(4)

and

remove

the

torsion

spring

(5).

Remove

the

screw

(6)

and

disassemble

the

roller

stud

(7),

plain

roller

(8),

and

lower

stabilizer

arm

(9).

Remove

the

screw

(10)

and

disassemble

the

roller

stud

(11),

fl

anged

roller

(12),

and

stabilizer

arm

(13).

Un-

screw

and

remove

the

stud

(14)

and

lock

nut

(15).

NOTE

When

removing

stabilizer

parts,

be

careful

not

to

damage

the

optical

slit

assembly

(45).

If

the

optical

slit

must

be

removed,

scribe

or

mark

a

line

on

the

slit

barrel

fl

ush

with

its

mounting

boss

so

that

the

slit

can

be

reas-

sembled

in

approximately

the

same

position.

Then

loosen

the

setscrew

(43)

and

withdraw

the

optical

slit,

taking

care

not

to

lose

the

locking

slug

(44).

11.

SOUNDHEAD

-

SOUND

SPROCKET

AND

SNUBBER

ROLLER.

(See

figure

10.)

a.

Remove

the

screw

(16),

the

sprocket

guard

(17),

the

spring

(18),

and

tension

washer

(19)

from

the

sprocket

shaft

(23).

Loosen

the

setscrew

(20)

and

slide

the

sprocket

assembly

(21)

from

its

shaft.

Loosen

setscrew

(22)

and

withdraw

the

sprocket

shaft

(23),

washer

(24)

and

gear

(25).

Remove

and

discard

the

felt

lubricator

(23A)

located

in

a

hole

in

the

sprocket

shaft.

Remove

the

screws

(26),

the

film

guide

(27),

and

two

spacer

washers

(28).

b.

Remove

the

single

screw

(29)

and

hex

nut

(30)

and

two

shorter

screws

(31)

and

lift

off

the

com-

plete

snubber

assembly.

If

this

unit

must

be

disas-

sembled,

note

the

manner

in

which

the

ends

of

the

torsion

spring

(34)

engage

shaft

(33)

and

bearing

(35).

c.

Unscrew

the

idler

roller

stud

(38)

and

remove

the

idler

roller

(40)

and

spacer'

(39).

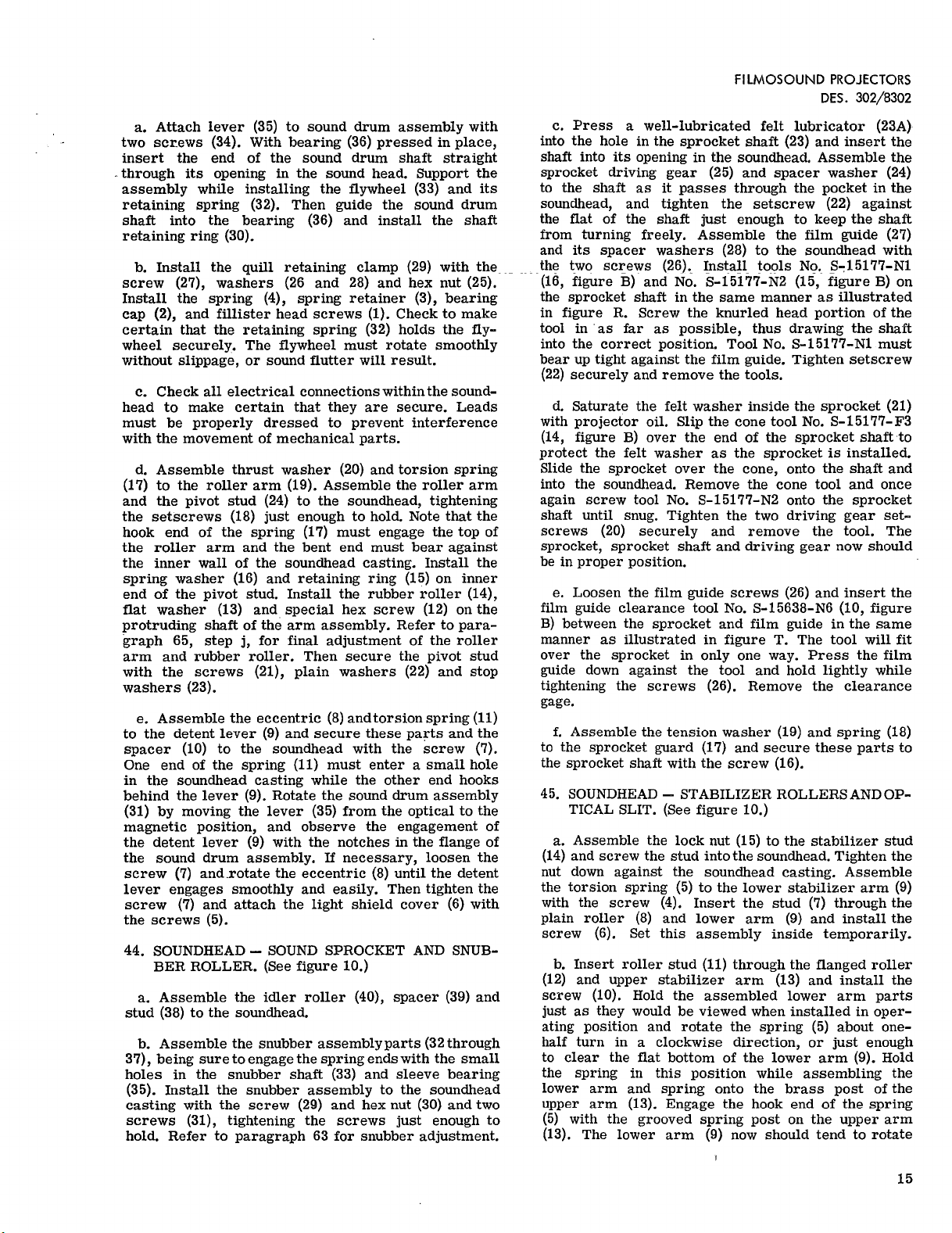

12.

-

SOUNDHEAD

-

SOUND

DRUM

AND

FLYWHEEL.

(See

figure

11.)

NOTE

Electrical

and

magnetic

sound

components

of

the

soundhead

need

be

removed

only

if

preliminary

test

inspections

indicate

a

need

for

replacement.

The

removal

of

the

pilot

lamp

(41),

relay

(47),

exciter

lamp

socket

(51),

phase

reactor

(52),

switches

(53,

54

and

66)

and

cables

(61

and

68)

require

only

the

un-

soldering

of

leadwires

and

the

removal

of

attaching

hardware.

If

the

sound

drum

is

to

be

replaced

completely,

remove

as

outlined

in

steps

a

and

b

following.

If

only

the

magnetic

heads

are

to

be

replaced,

proceed

as

outlined

in

paragraph

13.

a.

Remove

the

three

screws

(1),

bearing

cap

(2),

spring

retainer

(3)

and

compression

spring

(4).

Re-

move

two

screws

(5)

and

the

light

shield

cover

(6).

Note

the

manner

in

which

the

torsion

spring

(11)

is

engaged;

then

remove

the

screw

(7),

eccentric

(8),

detent

lever

(9),

spacer

washer

(10)

and

spring

(11).

b.

Remove

the

hex

nut

(25),

screw

(27)

and

washers

(26

and

28),

and

remove

the

quill

retaining

clamp

(29).

Remove

the

retaining

ring

(30),

grasp

the

sound

drum

6

FILMOSOUND

PROJECTORS

DES.

302/8302

and,

while

supporting

the

weight

of

the

flywheel,

with-

draw

the

sound

drum

from

the

soundhead

until

the

rear

end

of

the

shaft

is

free

of

the

bearing

(36).

Re-

move

the

fl

ywheel

retaining

spring

(32)

and

withdraw

the

sound

drum

assembly

completely

from

the

sound

-

head

casting,

meanwhile

lifting

out

the

fl

ywheel

(33).

Do

not

remove

the

lever

(35)

unless

in

need

of

re-

placement.

13.

MAGNETIC

HEADS

AND

COILS.

(See

figure

11A.)

NOTE

The

magnetic

heads

and

coils

of

the

sound

drum

assembly

can

be

replaced

by

following

the

pro-

cedure

outlined

below.

The

sound

drum

need

not

be

removed

from

the

sound

head

casting

to

make

these

replacements.

Unless

damaged

by

rough

handling

or

improper

adjustment,

the

heads

have

a

relatively

long

life.

Be

sure

to

check

out

other

possible

causes

of

improper

magnetic

sound

reproduction

(dirt

on

heads

or

film,

old

or

damaged

film,

improper

magnetic

striping)

before

replacing

heads.

a.

Inspect

the

faces

of

the

heads

(figure

E)

with

a

mag-

nifying

glass.

Fine

scratches

in

the

direction

of

film

travel

will

seldom

affect

sound

quality.

Deep

grooves

or

steps,

usually

caused

by

extensive

operation

with

quarter

or

half-track

film,

will

prevent

proper

track

contact

area

and

are

cause

for

head

replacement.

•-

rf

STABILIZER

ASSEMBLY.

•

ERASE

HEAD

•

RECORD

-PLAYBACK

HEAD

•

Figure

E.

Magnetic

Heads

and

Sound

Drum

b.

Use

a

low

-voltage

AC

supply

and

an

AC

voltmeter

to

check

the

continuity

of

the

head

coils.

A

DC

powered

ohmmeter

will

magnetize

the

heads.

(See

figure

F

for

terminal

configuration.)

Open

head

circuits,

unless

traceable

to

broken

leads

at

the

terminal

ring,

will

require

replacement

of

the

damaged

coil,

as

outlined

in

the

following

steps.

FINISH

START

ERASE

HEAD

COMMON

LOAD

ON

LATE

CODE'

Z

HEADS

START

FINISH

START

BIAS

8 Ohm

3

FOR

CODE

W

AND

X

UNITS

FINISH

2

S

F

•

3

4

RECORD

4.5

2

5

ERASE

1 Ohm

RECORD

HEAD

I

ERASE

2

CODE

S

-START

OF

WINDING

F

-FINISH

OF

WINDING

•

5

4

S S

FOR

CODE

Y

AND

Z

UNITS

4.5 Ohm

RECORD

Figure

F.

Magnetic

Head

Coil

Identification

and

Connections

7

SERVICE

INSTRUCTIONS

c.

Shift

the

function

lever

to

the

OPT

(optical)

posi-

tion

and

remove

the

screw

(12,

figure

11),

washer

(13),

and

roller

(14).

Remove

two

screws

(5)

and

the,

light

shield

cover

(6).

d.

Refer

to

figure

11A

and

remove

the

screw

(6)

and

washer

(7).

Shift

the

function

lever

to

the

MAG

(mag-

netic)

position

and

remove

the

screw

and

washer

at

the

opposite

end

of

the

hum

shield.

Place

the

function

lever

at

a

point

mid

-way

between

the

optical

and

magnetic

positions,

and

carefully

lift

off

the

shield

cover

(5).

Remove

the

remaining

screw

(6)

and

washer

(7)

and

lift

off

the

hum

shield

(4).

e.

Loosen

the

screw

(10,

figure

11A),

and

carefully

lift

the

record

-playback

arm

(16)

as

far

as

possible

but

without

placing

a

strain

on

the

coil

leads.

While

holding

the

arm

in

this

position,

tighten

the

screw

(10).

f.

Shift

the

function

lever

to

a

position

such

that

the

record

-playback

head

(figure

E)

is

facing

directly

up.

Carefully

apply

a

drop

or

two

of

acetone

at

the

points

where

the

head

pole

pieces

enter

the

coil

forms.

CAUTION

Do

not

apply

acetone

to

the

coils.

If

acetone

runs

onto

the

coil

windings,

remove

at

once

with

a

clean,

lint

-free

cloth.

g.

Allow

approximately

30

seconds

for

the

acetone

to

soften

the

cement.

Then,

while

holding

the

arm

(16,

figure

11A)

firmly

in

place,

insert

a

jeweler's

screwdriver

between

the

pole

piece

(11)

and

the

coil

form

and

carefully

pry

the

coils

(12)

from

the

arm.

As

soon

as

one

coil

begins

to

loosen,

shift

the

screw-

driver

to

the

other

coil

and

begin

to

loosen

this

one.

.

When

both

coils

are

loose,

slip

them

away

from

the

pole

piece.

h.

With

the

function

lever

in

mid

-position,

loosen the

center

screw

in

the

arm

(16)

and

remove

the

record

-

playback

head.

i.

The

erase

head

is

removed

in

the

same

manner

as

the

record

-playback

head

(steps

e

through

h,

preceding).

j.

With

the

heads

(pole

pieces)

removed,

the

resist-

ance

of

the

coils

can

be

checked

without

danger

of

magnetization.

Remove

twine

and

tape

(2)

from

the

terminal

ring

(3)

carefully

unsolder

the

coil

leads

from

their

terminals.

The

resistance

of

the

coils

should

be

approximately

as

indicated

in

figure

F.

Shorted

coils

must

be

replaced.

k.

Should

it

be

necessary

to

replace

a

coil,

care-

fully

disconnect

the

coil

leads

from the

terminal

ring.

Coil

leads

must

be

connected

as

shown

in

figure

F.

Coils

and

their

leads

can

be

identified

as

follows:

Erase

coil

-

wound

with

heavier

gage

wire

than

the

record

-playback

coil.

The

longest

of

its

two

tinned

leads

is

the

start

of

the

winding.

Bias

coil

(not

in

8302L

Projectors)

7

part

of

re-

cord

-playback

coil

assembly.

Wound

with

heavier

gage

wire

than

record

coil

and

the

longest

of

its

two

leads

is

the

start

of

the

winding.

Record

coil

-

part

of

record

-playback

coil

as-

sembly.

Wound

with

lighter

gage

wire

than

the

erase

coil.

NOTE

Refer

to

paragraph

42

for

head

and

coil

reas-

sembly

instructions.

14.

PROJECTOR

CASE.

(See

figure

12).

Except

for

the

carrying

handle,

tilt

mechanism

and

speaker,

it

is

doubtful

that

projector

case

parts

will

require

replacement.

Merely

refer

to

the

ex-

ploded

view

illustrations

and

remove

damaged

parts

in

indexed

order.

Inspect

speaker

cone

for

damage.

In

Design

8302L

Projector,

the

speaker

is

mounted

in

the

front

of

the

projector

case.

15.

REAR

REEL

ARM.

(See

figure

13.)

a.

Remove

the

fabric

take-up

belt

(1).

Press

out

the

shaft

(2)

and

remove

the

take-up

arm

assembly

(3

through

14).

b.

Remove

the

screw

(3)

and

twist

the

cover

(4)

slightly

to

disengage

the

return

spring

(6)

from

the

lock

pin

(14A).

Lift

off

the

cover

and

return

spring.

c.

Remove

the

screw

(7),

plunger

(8),

and

rewind

gear

(9).

Unscrew

the

hex

nut

(10)

and

the

bearing

retaining

ring

(11).

Remove

the

nineteen

steel

balls

(13),

take-up

pulley

(12)

and

nineteen

more

steel

balls

(13)

from

the

take-up

arm

assembly

(14).

Be

careful

not

to

lose

any

of

the

steel

balls.

d.

Unscrew

the

rewind

drive

gear

(15)

from

the

shaft

of

the

take-up

drive

pulley

assembly

(16)

by

turning

clockwise

to

loosen

the

left-hand

thread.

If

necessary,

wrap

tape

around

the

rewind

drive

gear

(15)

and

drive

pulley

(16)

so

that

they

may

be

firmly

grasped

to

unscrew

one

from

the

other.

Remove

take-

up

drive

pulley

slowly,

cupping

hand

around

it

to

catch

the

plunger

(17)

and

compression

spring

(18)

which

will

pop

out

as

the

pulley

is

removed.

e.

Carefully

remote

the

spring

(22).

Unscrew

the

shoulder

screw

(20)

to

remove

the

rewind

lock

lever

(21).

The

headless

setscrew

(19)

acts

as

a

plug

for

the

grease

packing

hole

and

is

easily

removed.

f.

The

bearing

retainer

ring

(23)

is

press

fitted

in

place

and

will

have

to

be

pried

out

if

it

ever

be-

comes

necessary

to

remove

the

sixteen

roller

bear-

ings

(24)

from

the

rear

reel

arm

(25).

g.

To

disassemble

the

take-up

spindle

pulley

assem-

bly

(12),

support

the

reel

end

of

the

spindle

in

a

"Vee"

block

and

use

a

straight

punch

to

drive

out

the

roll

pin

(12A).

Separate

the

reel

clip

(12B)

from

the

spindle.

8

FILMOSOUND

PROJECTORS

DES.

302/8302

16.

FRONT

REEL

ARM.

(See

figure

14.)

a.

Unscrew

the

clutch

cover

screw

(1)

and

remove

the

cover

(2)

and

bronze

washer

(3).

Carefully

remove

the

three

steel

balls

(4),

clutch

cam

(5)

and

clutch

ball

retainer

(6).

b.

Lift

the

pulley

(7),

with

bearing

rollers

(8),

the

shim

or

shims

(9)

and

the

spindle

washer

(10)

from

the

reel

spindle

(13).

The

same

number

of

shims

(9)

must

be

installed

during

reassembly

of

the

reel

arm.

c.

Remove

split

retaining

washer

(11)

and

disas-

semble

the

reel

spindle

(13)

and

washers

(12

and

14)

from

the

front

reel

arm.

d.

Unscrew

the

bearing

retainer

(15)

and

press

the

bearing

(16)

from

the

front

reel

arm.

e.

Support

the

reel

end

of

the

spindle

in

a

"V"

block

and

drive

out

roll

pin

(13A)

with

a

straight

punch

to

free

the

reel

clip

(13B),

plunger

(13C)

and

spring

(13D).

18.

CLEANING

OPTICAL

PARTS.

Clean

the

projection

lens,

both

condenser

as-

semblies

and

the

reflector

with

Bell

&

Howell

lens

cleaning

tissue

and

Optikleen

lens

cleaning

fluid.

First

remove

accumulated

dust

with

a

camel's

hair

brush;

then

wipe

on

lens

cleaning

fluid

with

a

clean,

soft

cloth

and

polish

with

lens

tissue.

Be

careful

not

to

leave

fingerprints

on

lens

surfaces,

and

do

not

at-

tempt

to

disassemble

the

projection

lens.

Clean

only

the

exposed

lens

elements.

19.

CLEANING

OPTICAL

SLIT

AND

MAGNETIC

HEADS.

a.

Clean

the

exposed

elements

of

the

optical

slit

as-

sembly

(45,

figure

10)

with

lens

tissue

wrapped

about

a

toothpick.

If

lens

cleaning

fluid

is

necessary,

dampen

the

lens

tissue

sparingly.

Do

not

disassemble

the

optical

slit

assembly.

b.

Clean

the

mirror

on

the

sound

drum

assembly

(31,

figure

11)

in

the

same

manner

as

the

optical

slit

assembly,

being

careful

not

to

disturb

the

mir-

ror

mounting

in

the

process.

c.

Clean

the

magnetic

heads

with

a

piece

of

linen

wrapped

about

a

toothpick

and

dipped

in

denatured

alcohol.

Do

not

flood

the

heads

with

alcohol;

moisten

only

enough

to

remove

foreign

materials.

CAUTION

Only

alcohol

should

be

used

as

a

cleaning

agent

for

the

magnetic

heads.

17.

AMPLIFIER.

(See

figure

15.)

a.

Normally,

the

replacement

of

tubes

and

the

fuse

is

the

only

disassembly

necessary.

b.

To

remove

tubes,

simply

pull

them

straight

up

from

the

sockets,

taking

care

not

to

damage

tube

pins,

particularly

on

miniature

tubes.

c.

The

knobs

on

the

front

panel

are

secured

with

set-

screws.

The

microphone

jack

is

secured

with

a

nut.

d.

To

gain

access

to

internal

parts

of

the

amplifier,

unscrew

four

sheet

metal

screws,

from

the

bottom

and

remove

the

base

plate

assembly.

Take

care

not

to

pull

the

leads

which

are

solder

grounded

to

a

terminal

on

the

inside

of

the

base

assembly.

Refer

to

the

schematic

diagrams,

figures

17

and

18

for

complete

amplifier

service

and

parts

replacement

information.

20.

CLEANING

FILM

PATH

PARTS.

Film

path

parts

are

those

components

(aperture

plate,

pressure

plate,

sprockets,

film

rollers)

which

are

contacted

by

the

film

during

operation.

In

addi-

tion

to

the

normal

accumulation

of

dirt,

such

parts

may

also

acquire

a

build-up

of

film

emulsion.

Clean

with

a

soft

cloth

dampened

with

carbon

-tetrachloride.

If

deposits

of

hardened

emulsion

remain,

scrape

a-

way

such

deposits

with

a

toothpick

or

sharpened

orange

stick.

An

aperture

brush

or

toothpick

can

be

used

to

remove

foreign

matter

from

between

sprocket

teeth.

21.

CLEANING

MECHANICAL

PARTS.

Blow

dust

and

dirt

from

chassis

and

housings

with

compressed

air,

and

wipe

electrical

compo-

nents

(tubes,

transformers,

motors)

with

a

clean,

soft

cloth.

All

other

mechanical

parts

should

be

cleaned

with

carbon

tetrachloride

to

remove

old

grease

and

lubricating

oil.

Dry

parts

thoroughly

with

compressed

air

or

with

soft,

lint

-free

cloths.

During

reassembly,

be

sure

to

lubricate

parts

as

necessary.

22.

LUBRICATION

INSTRUCTIONS.

a.

Whenever

it

is

necessary

to

disassemble

the

intermittent

mechanism

or

to

perform

extensive

major

repairs

to

the

gear

housing,

all

oil

storage

pads

should

be

removed

and

discarded.

Cover

the

bottom

of

a

small

pan

with

about

1/4

-inch

of

oil

(Bell

&

Howell

Spec.

No.

1543)

and

insert

one

end

of

the

new

wick

or

pad

in

this

oil.

Do

not

immerse

9

SERVICE

INSTRUCTIONS

pads

in

oil.

Allow

wicks

to

stand

until

they

are

completely

saturated

with

oil;

then

remove

them

from

the

pan

and

allow

the

excess

to

drain

away.

NOTE

When

installing

the

lubricator

assembly

(5,

figure

5),

make

certain

that

the

tongue

of

the

pad

is

firmly

in

contact

with

the

shuttle

cam

before

tightening

shuttle

pin

retaining

screws.

b.

Place

a

light

film

of

oil

(Spec.

No.

1543)

on

all

rotating

shafts

during

reassembly

and

speck

all

gear

teeth

with

grease

(Spec.

No.

1544).

c.

After

reel

arms

are

reassembled,

remove

the

grease

plug

and

pack

the

cavity

around

the

spindle

parts

with

grease

(Spec.

No.

345).

d.

When

governor

cap

is

reassembled,

remove

the

grease

cup

and

pack

the

housing

with

grease

(Spec.

No.

345).

23.

GENERAL

REPAIR

INSTRUCTIONS.

Except

as

noted

below,

reconditioning

of

projec-

tor

parts

for

possible

re

-use

is

impractical.

When

a

part

is

obviously

damaged,

or

its

condition

is

doubtful,

replace

with

a

new

part.

Specific

repair

instructions

for

the

amplifier

and

sound

system

will

be

found

in

paragraphs

24

through

37,

follow-

ing.

Refer

to

the

wiring

diagrams

at

the

end

of

the

parts

list

for

electrical

circuitry

and

proper

re-

placement

parts.

a.

Film

path

components

should

be

inspected

for

signs

of

scratches

or

rough

burrs

that

might

dam-

age

the

film.

Minor

defects

can

sometimes

be

re-

moved

by

polishing

with

fine

emery

cloth.

b.

Binding

in

the

heat

filter

or

fire

shutter

com-

ponents

(figure

6)

can

sometimes

be

attributed

to

bent

parts.

Straighten

parts

as

necessary

and

check

operation.

c.

Be

sure

to

inspect

all

wiring

for

frayed

insula-

tion

or

bare

spots.

Such

wiring

should

be

replaced.

Make

certain

that

all

solder

connections

are

secure.

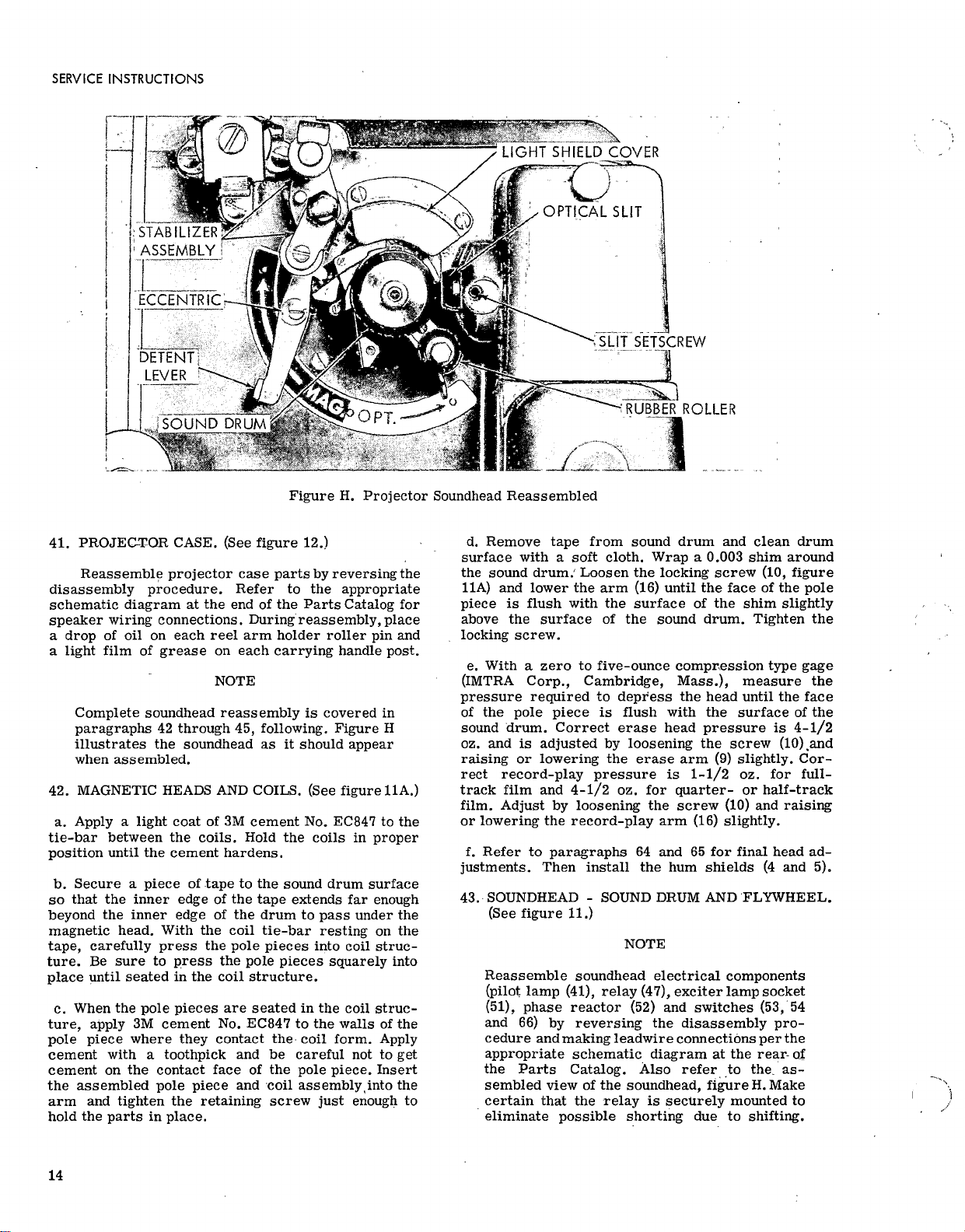

24.

ERASE

FAILURE.

a.

With

projector

and

amplifier

set

for

magnetic

recording,

measure

the

RF

voltage

across

pins

1

and

3

on

rear

amplifier

receptacle

connector

J6.

All

RF

measurements

should

be

made

with

a

suit-

able

vacuum

tube

voltmeter.

With

the

record

inter-

lock

in,

reading

should

be

6

volts

across

the

erase

winding

and

0.3

volts

across

the

bias

winding

(5.5

and

1.5

volts

respectively

for

8302L

Projectors).

b.

If

no

voltage

is

present,

or

if

voltage

is

incor-

rect,

check

for

continuous

ground

or

open

up

to

the

interlock

relay.

Make

certain

that

relay

con-

tact

is

functioning

properly.

Check

to

see

that

neon

indicator

lights

and

stays

lit

with

the

projector

running

forward

and

the

V1.

record

button

pressed

in.

c.

Check.

RF

voltages

at

terminal

strip

mounted

inside

the

soundhead

casting.

Check

continuity

with

an

ohmmeter.

NOTE

Any

tools

used

in

the

vicinity

of

the

mag-

netic

head

should

be

demagnetized

immedi-

ately

before

use.

If

a

DC

ohmmeter

is

used,

the

input

transformer

and

head

must

be

de-

magnetized;

therefore,

use

only

a

low

-volt-

age

AC

supply

and

AC

voltmeter

for

con-

tinuity

checks.

25.

NOISE

CAUSED

BY

TUBES

OR

TRANSISTOR.

S

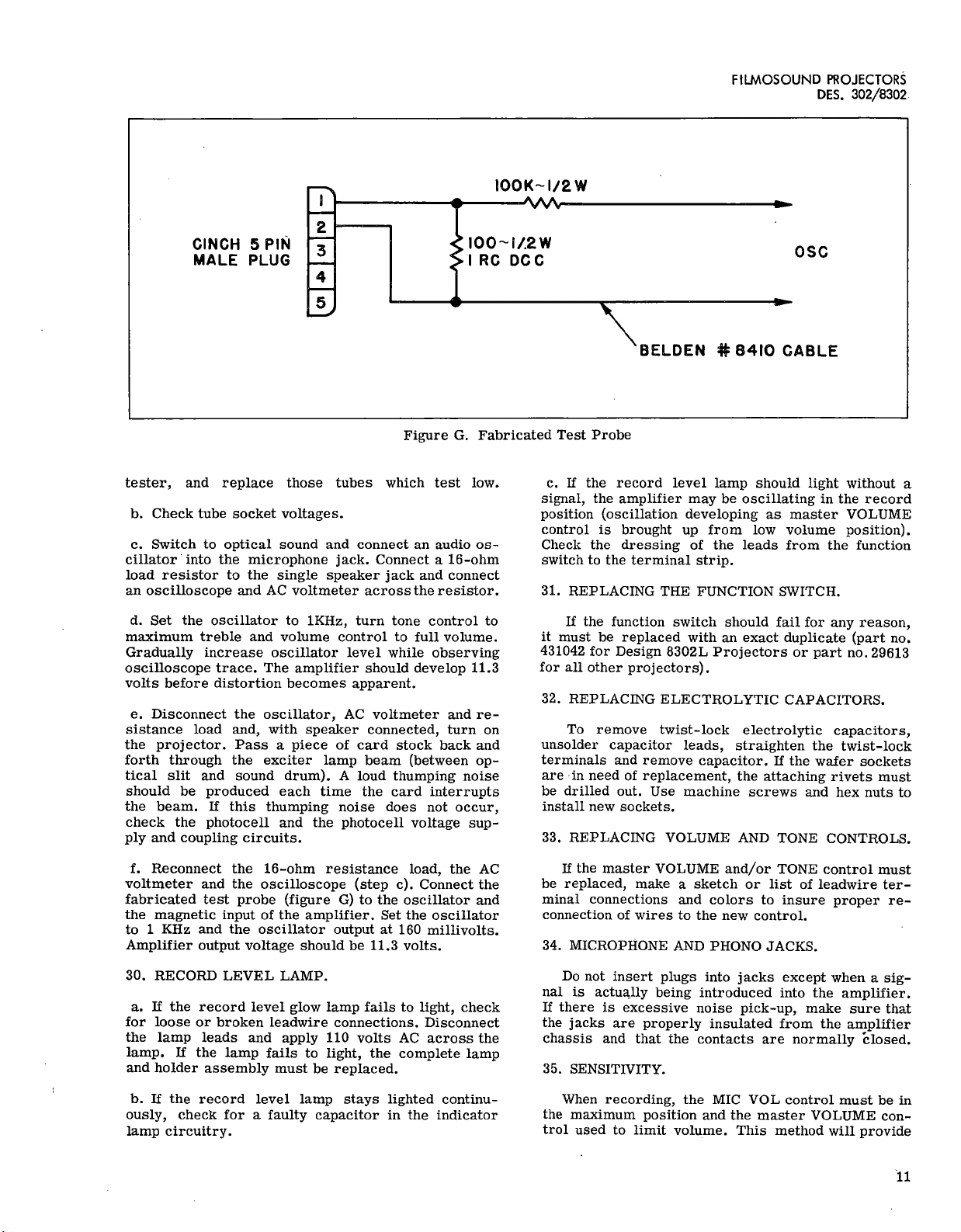

a.

Mica

leakage

generates

a

frying

or

has

noise.

If

this

noise

occurs

when

the

amplifier

r

is

in

the

op-

tical

position,

replace

tube

Ho

ever,

first

make

certain

no

stray

lite

is

striking

the

photocell.

b.

If

the

noise

occurs

only

when

in

the

magnetic

playback