Bell&Howell AUTOLOAD FILMOSOUND 2585 User manual

Disclaimer

This scanned document is provided as a courtesy. We make

no representation for its accuracy. It is for use by qualified

personnel only. There are high voltage and mechanical

hazards present in this equipment. Do not attempt repair

unless you are fully aware of the safety precautions to be

taken. Use this information at your own risk.

www.paulivester.com

SERVICE

INSTRUCTIONS

AUTOLOAD®

FILMOSOUND 16mm

PROJECTOR

(AUTOMATIC

THREADING

j

MODELS

2585,

2590,

2592

©

1980

Bell

&

Howell

Company

All

Rights

Reserved.

In]

BELL

s

HOWELL

GENERAL

SERVICE

DEPT.

7100

McCORMICK

ROAD

CHICAGO,

ILLINOIS

60645

PART

NO.

74421

REVISED

PRINTED

IN

U.S.A.

DECEMBER

1980

r

FACTORY

SERVICE

RECEIVING

ADDRESS

1

Bell

&

Howell

Company

General

Service

Department

Audio

-Visual

Division

7100

No.

Central

Park,

Dock

1

Chicago,

IL

60645

L

FOR

PARTS,

ORDERS

AND

SERVICE

INFORMATION

Bell

&

Howell

Company

General

Service

Department

Audio

-Visual

Division

7100

No.

McCormick

Road

Chicago,

IL

60645

(312)

262-1600

I I-

TABLE

OF

CONTENTS

Section/Paragraph

Page

Section/Paragraph

Page

INTRODUCTION

ADJUSTMENTS

AND

TESTS

1.

General

1

30.

General

Instructions

29

2.

Description

of

Models

1

31.

Optical

Alignment

29

3.

Automatic

Loading

Operation

. .

1

32.

Adjusting

the

Intermittent

4.

Special

Maintenance

Precautions

3

Mechanism

30

5.

Cleaning

Instructions

3

33.

Lens

Carrier

Adjustment

35

6.

Lubrication

Instructions

3

34.

Still

-Run

Clutch

Adjustment

.

35

7.

General

Replacement

Data

3

35.

Automatic

Loading

System

8.

Fuse

Replacement

4

Adjustments

—

General

37

9.

Lamp

Replacement

4

36.

Adjusting

the

Loading

Guides

38

37.

Checking

and

Adjusting

the

DIS

ASSEMBLY/REASSEMBLY

Loop

Restorer

39

PROCEDURES

38.

Timing

the

Sprockets

39

10.

General

Precautions

9

39.

Adjusting

the

Reel

Arms

and

11.

Projector

Rear

Cover

Removal.

9

Rewind

Clutch

41

12.

Drive

Belt

Replacement

9

40.

Adjusting

the

Sound

System

42

13.

Projector

Top

Cover

and

41.

Projector

Speed

Checks

43

Handle

Removal

10

42.

Checking

Clearance

for

the

14.

Internal

Speaker

Replacement

.

.

11

Exciter

Lamp

Cover

43

15.

End

Cap

Removal

11

43.

Gear

Shift

Tension

Adjustment

44

16.

Blower

Repairs

11

44.

Idler

Gear

Backlash

17.

Main

Switch

Replacement

12

Adjustment

44

18.

Drive

Motor

Replacement

12

45.

Circuit

Explanation

for

the

19.

Transformer

Replacement

14

20

Watt

Amplifier

(With

or

20.

Rear

Reel

Arm

Replacement

.

.

14

Without

Dual

Tone

Control)

.

.

44

21.

Front

Reel

Arm

Replacement

. .

15

22.

Still-Run/Animation

Clutch

and

Heat

Shutter

Linkage

Repair

16,

TROUBLE

SHOOTING

23.

Amplifier

and

Controls

Repair

.

16

24.

Soundhead

Replacement

17

46.

Miscellaneous

Troubles

and

25.

Soundhead

Positioning

19

Remedies

49

26.

Mechanism

Assembly

Replacement

19

47.

Picture

Troubles

and

Remedies

51

27.

Disassembly

of

Mechanism

48.

Film

Transport

Troubles

and

Components

19

Remedies

52

28.

General

Mechanism

Components

49.

Sound

System

Troubles

and

Reassembly

Precautions

22

Remedies

53

29.

Reassembly

of

Mechanism

50.

Trouble

Shooting

the

Automatic

Components

22

Loading

System

55

LIST

OF

ILLUSTRATIONS

Section

Page

INTRODUCTION

Figure

A.

Automatic

Loading

Operation

2

Figure

B.

Service

Tools

7

DISASSEMBLY/REASSEMBLY

PROCEDURES

Figure

C.

Projector

Rear

Cover

(Multi

-Line

Voltage

Models

Shown)

10

Figure

D.

Removing

the

Top

Cover

an

d

Handle

10

Figure

E.

Front

End

Cap

and

Speaker

Removal

11

Figure

F•

Blower

Repairs

12

Figure

G•

Replacing

the

Main

Switch

13

Figure

H.

Replacing

the

Drive

Motor

13

Figure

J.

Replacing

the

Transformer

(Single

-Line

Voltage

Model)

14

Figure

K.

Replacing

the

Rear

Reel

Arm

15

Figure

L.

Replacing

the

Front

Reel

Arm

16

Figure

M.

Amplifier

and

Controls

Repair

1

.

7

Figure

N.

Replacing

the

Soundhead

and

Mechanism

Assemblies

18

Figure

P.

Positioning

the

Soundhead

19

ADJUSTMENTS

AND

TESTS

Figure

Q.

Aligning

the

Optical

System

29

Figure

R.

Aperture

Plate

and

Shuttle

Tooth

Clearance

30

Figure

S.

Shuttle

Arms

and

Cam

Assembly

31

Figure

T.

Adjusting

Shuttle

Tooth

Height

31

Figure

U•

Adjusting

Fit

of

Shuttle

Arms

to

Pull

-Down

Cam

32

Figure

V.

Center

Shuttle

Tooth

Travel

Adjustment

33

Figure

W.

Still

-Rim

Clutch

Adjustments

34

Figure

X.

Automatic

Loading

System

Adjustments

36

Figure

Y.

Threading

Lever

Clearance

Adjustment

38

Figure

Z.

Adjusting

the

Loop

Restorer

-

40

Figure

AA.

Adjusting

the

Reel

Arms

41

Figure

AB.

Positioning

the

Sound

Drum

and

Silicon

Photocell

42

Figure

AC.

Stabilizer

Roller

Adjustment

42

Figure

AD.

Adjusting

Gear

Shift

Tension

and

Backlash

44

Ilk

•

11

"SI

Model

2592A

16mm

Automatic

Threading

Projectors

FEATURE

DESCRIPTION

LIST

Color

Charcoal

gray

Input

Voltage

—

2585A/AML

120VAC,

60Hz

2585AX/AXU

.

120/220/240V,

50/60Hz

2590A,

2592A

120VAC,

60Hz

2592AX/ASX

.

120/220/240V,

50/60Hz

Film

Threading

Fully

automatic

Film

Speeds

—

Sound

24fps

in

forward

and

reverse

Silent

18fps

in

forward

and

reverse

Projector

Controls

-

2585,

2590

Forward/Reverse

2592AX/ASX

Forward/Reverse/Still-Run

2592A

Forward/Reverse/Still-Run

and

Directamotion

Projection

Lamp

—

2585,

2592.

. .

Type

ELC,

24V/250W/50

hr

2590'

Type

BHB,

120V/250W/25

hr

Projection

Lens

—

2585

2590,

2592

2

inches

(51mm)

f/1.6

2

inches

(51mm)

f/1.2

Shutter

—

2585A/AML,

2590A,

2592A

Rotating

threeblade

2585

AX/AXU,

2592AX/ASX

Rotating

two

blade

Exciter

Lamp

. . .

Type

BAK,

4V/0.75

Amp,

300

hr

(approx.)

Amplifier

Output

. . . . . . . .

20

Watts

RMS

Built

In

Speaker

x

permanent

magnet

16

ohm

(over-

load

protected)

Amplifier

Controls

-

2585,

2590

Volume/Tone

2592

Volume/Treble/Bass

Dimensions

. .

.14-1/4"w

x

16"h

x

10-1/4"d

Approximate

Weight

—

2585A/AML

33

pounds

(15Kg)

2585AX/AXU

35.5

pounds

(16Kg)

2590A

29

pounds

(13.2Kg)

2592A

34

pounds

(15.4Kg)

2592AX

36

5

pounds

(16.5Kg)

2592ASX

39.5

pounds

(17.9Kg)

11

RECOMMENDED

SPARE

PARTS

LIST

FOR

REPAIR

OF

50

MODEL

2585,

2590

AND

2592

AUTOMATIC

THREADING

16MM

SOUND

PROJECTORS

REFERENCE:

SERVICE

MANUAL

NO.

74421

PART

NO.

DESCRIPTION

QTY

24047

Belt,

Take-up

6

34884

Lamp,

Exciter,

Type

BAK

6

44223

Lamp,

Projector,

Type

BHB

2

44459

Belt,

Drive

6

45695

Switch,

Rotary

1

49945

Switch,

Rotary

2

117172

Fuse,

Slo-Blo,

4

amp

6

305792

Fuse,

Slo-Blo,

2

amp

6

308638

Fuse,

Slo-Blo,

3/4

amp

6

710396

Lamp,

Projector,

Type

ELC

6

710660

Switch,

Rotary

2

707257

Motor,

Drive

1

015569

Photodiode

Assembly

1

015921

Thermal

Fuse

and

Sleeve

Assembly

6

077195

PCB

Amplifier

Assembly

2

077632

Thermal

Fuse

and

Sleeve

Assembly

6

078577

PCB

Amplifier

Assembly

2

iii

16mm

Sound

Projectors

Models

2585/2590/2592

INTRODUCTION

1.

GENERAL.

This

Service

Manual

provides

the

neces-

sary

information

for

the

repair

and

adjust-

ment

of

the

Bell

&

Howell

Company

16mm

Automatic

Loading

Sound

Projectors,

Models

2585,

2590

and

2592.

Major

design

and

oper-

ating

characteristics

are

listed

in

the

Fea-

ture

Description

List

on

the

preceding

page.

An

illustrated

Parts

Catalog

is

included

at

the

rear

of

the

manual

to

identify

replace-

ment

parts

and

to

assist

in

the

disassembly

and

reassembly

of

these

projectors.

2.

DESCRIPTION

OF

MODELS.

As

noted

in

the

following

chart,

this

manual

covers

several

variations

of

the

basic

2500

-

series

automatic

loading

projectors.

Each

model

is

"letter

-coded"

in

the

Parts

Catalog

so

that

replacement

parts

which

are

not

common

to

all

projectors

can

be

readily

identified.

Parts

peculiar

to

Canadian

ver-

sions

are

so

indicated

in

the

parts

lists.

MODEL

CODE

2585A

2585AML

2585AX

2585AXU

2590A

2592A

2592AX

2592ASX

H

A

B

C

D

E

F

G

Except

for

differences

in

operating

voltages

(single

-line

or

multi

-line)

and

certain

spe-

cial

features,

all

projector

models

covered

in

this

service

manual

are

basically

identical.

The

single

-line

voltage

units

(suffix

letter

"A"

in

the

model

designator)

operate

on

120VAC,

60Hz

and

are

equipped

with

a

line

cord

that

is

wired

into

the

projector.

The

multi

-line

voltage

units

(all

"AX"

models)

are

equipped

with

a

voltage

selector

switch

which

provides

a

means

for

varying

input

voltages

(120

-

240V,

50/60Hz)

and

to

match

input

voltages

with

those

available

globally.

A

male

plug

is

supplied

to

mate

with

a

fe-

male

receptacle

located

on

the

rear

cover

for

accommodation

of

global

requirements.

Model

2585AML

is

a

militarized

version

of

the

2585A

unit

and

is

further

identifiable

by

two

5

amp

Slo-Blo

fuses

mounted

on

the

top

cover.

The

2585AXU

and

2592ASX

models

are

the

only

projectors

in

this

series

that

are

equipped

with

a

front

cover

containing

speakers.

The

sound

system

control

knobs

located

on

the

operating

side

of

the

base

are

not

the

same

for

all

models.

The

2585/2590

models

are

equipped

with

a

volume

control

and

a

single

tone

control.

All

2592

models

are

equipped

with

a

volume

control

and

two

tone

controls;

one

for

treble

and

one

for

bass.

All

of

the

2592

models

are

designed

for

"still"

projection,

however,

only

the

2592A

model

is

equipped

with

the

Directamotion

®

(animation)

feature.

To

activate

the

anima-

tion

feature

place

the

main

switch

in

the

"forward

project"

or

"reverse

proj

ect"

posi-

tion.

Then,

with

the

projector

running,

place

the

run/still

lever

in

the

"still??

position.

To

advance

film

frame

-by

-frame,

press

and

release

the

animation

lever

located

at

the

top

left

corner

of

the

projector

mechanism

housing.

To

advance

several

frames

of

film

(or

a

length

of

film

at

regular

projection

speed)

press

and

hold

the

animation

lever

down.

Release

the

lever

to

stop

film

motion.

To

resume

normal

film

projection

return

the

run/still

lever

to

the

"run"

position.

3.

AUTOMATIC

LOADING

OPERATION.

The

automatic

loading

system

consists

of

a

series

of

film

guides,

loopformers

and

rollers

designed

to

advance

and

guide

the

film

smoothly

and

precisely

through

the

film

path

to

the

take-up

reel.

This

is

ac-

complished

when

the

system

is

in

the

"load"

(closed)

position.

When

the

system

is

in

the

"open"

(run)

position,

all

guides

are

clear

of

the

film

path.

All

projectors

are

1

Service

Instructions

C)

FWD.

4

PROJ.

5

6/

C=I

2

Figure

A.

Automatic

completely

gear

-driven,

with

shifting

from

forward

to

reverse

accomplished

by

means

of

a

rocker

plate/idler

gear

arrangement.

The

upper

and

lower

guides

are

connected

by

a

mechanical

linkage

with

a

locking

lever

at

the

lower

end

to

actuate

(close)

the

sys-

tem.

A

film

escape

mechanism

is

included

at

the

upper

end

of

the

linkage

to

prevent

damage

to

the

film

due

to

jamming.

When

a

film

jam

occurs,

the

film

will

fold

and

flow

out

through

the

kickplate

of

the

escape

mechanism

until

the

operator

has

had

an

opportunity

to

stop

the

projector.

To

thread

film

using

the

system,

refer

to

Figure

follows:

Step

1:

Check

the

leader

film)

for

defects.

damaged

or

torn,

film

trimmer

(1)

automatic

loading

A

and

proceed

as

(first

three

feet

of

If

the

film

end

is

insert

it

into

the

and

trim

the

end.

Loading

Operation

Step

2:

Push

the

auto

-load

lever

(2)

forward

until

it

locks.

(Note:

If

the

projector

being

threaded

is

equipped

with

the

still

feature,

place

the

run

-still

lever

in

the

"run"

position.)

Step

3:

Step

4:

Turn

the

main

switch

to

the

"forward

project"

position

(3).

Insert

the

leader

into

the

film

chan-

nel

under

roller

(4).

Push

the

leader

in

until

it

engages

the

sprocket

and

the

automatic

loading

system

begins

to

thread

the

film.

After

two

feet

of

leader

has

passed

through

the

pro-

jector,

pull

lightly

on

the

leader

end

until

a

"click"

is

heard

signaling

the

release

of

the

threading

mechanism.

Step

5:

Turn

the

main

switch

"off

."

Attach

the

leader

end

to

the

take-up

reel

and

rotate

the

reel

in

a

clockwise

direc-

tion

to

take

up

film

slack.

2

16mm

Sound

Projectors

Models

2585/2590/2592

4.

SPECIAL

MAINTENANCE

PRECAUTIONS.

Before

beginning

repairs,

check

specific

customer

complaints

against

the

trouble

shooting

charts

in

this

service

manual

for

the

most

probable

causes

and

suggested

remedies.

When

repairs

have

been

made,

be

sure

to

clean

and

lubricate

the

projector

before

it

is

returned

to

the

customer.

The

removal

and

installation

of

most

pro-

jector

components

can

be

accomplished

with

tools

normally

found

in

an

audio-visual

equip-

ment

repair

shop.

Although

most

wiring

connections

are

made

by

quick

disconnects,

a

soldering

gun

should

be

available

for

some

repairs.

Special

tools

and

gages

necessary

for

projector

alignments

and

adjustments

are

illustrated

and

listed

in

Figure

B

and

its

accompanying

chart.

The

setscrew

wrenches

and

test

films

are

listed

in

separate

charts

and

are

not

shown

in

Figure

B.

Keep

your

work

bench

clean

and

uncluttered.

As

parts

are

removed,

group

them

together

in

an

orderly

fashion

and

reassemble

attach-

ing

parts

loosely

to

the

parts

they

attach.

Note

or

tag

electrical

wires

or

connectors

so

that

they

can

be

properly

reconnected.

If

there

is

any

doubt

as

to

the

connection

of

leadwires,

refer

to

the

proper

wiring

diagram

at

the

rear

of

the

Parts

Catalog.

5.

CLEANING

INSTRUCTIONS.

Keep

film

path

areas

free

of

dirt

and

emul-

sion

build-up;

otherwise

film

jamming

may

occur

during

loading

operations

and

pro-

jection.

Use

isopropyl

alcohol

and

the

spe-

cial

cleaning

pad

(P/N

48478)

to

remove

hardened

emulsion,

and

be

careful

not

to

scratch

the

surfaces

that

contact

the

film.

Pay

particular

attention

to

the

sound

drum

and

the

soundhead

rollers.

Use

isopropyl

alcohol

to

clean

plastic

parts

and

be

careful

not

to

remove

lubricants

from

critical

areas,

especially

in

the

film

thread-

ing

linkage.

These

lubricants

are

applied

during

the

assembly

of

the

projector

and,

in

many

cases,

it

would

be

necessary

to

partially

disassemble

the

projector

to

re

-

lubricate

these

parts.

Blow

away

dust

and

film

chips

with

a

low-pressure

jet

of

com-

pressed

air

and

wipe

with

a

soft,

lint

-free

cloth.

If

the

projector

is

especially

dirty,

the

transport

mechanism

should

be

removed

from

the

mainplate

and

thoroughly

cleaned.

Brush

or

blow

out

all

accumulations

of

dirt

and

film

chips.

Wash

"Oilite"

bear-

ings

and

cams

with

naphtha.

If

cleaning

does

not

remove

old

lubricant

from

the

felt

wiper

and

wick,

these

items

should

be

replaced.

Clean

all

other

moving

parts

with

isopropyl

alcohol

and

dry

all

parts

with

a

low-pressure

jet

of

compressed

air.

As

soon

as

all

parts

have

been

cleaned

and

dried,

apply

a

light

film

of

the

specified

lubricants

and

reinstall

the

transport

mechanism.

6.

LUBRICATION

INSTRUCTIONS.

The

Lubrication

Chart

in

this

section

indi-

cates

those

parts

and

areas

requiring

lub-

rication.

These

are

also

pointed

out

in

the

Parts

Catalog

illustrations

by

means

of

ballooned

letters

"L"

(for

oil)

and

"G"

(for

grease).

Specified

lubricants

are

available

from

the

Bell

&

Howell

Company.

Be

sure

that

the

part

or

area

to

be

lubricated

is

clean

before

lubricant

is

applied,

and

be

careful

not

to

over

-lubricate.

A

drop

or

two

of

oil

or

a

very

light

film

of

grease

will

be

adequate.

Apply

grease

with

a

cam-

el's

hair

brush

and

wipe

away

excess

lub-

ricant

with

a

lint

-free

cloth.

Felt

pads

and

wicks

should

be

placed

in

a

shallow

pan

containing

the

specified

grease

and

allowed

to

stand

until

they

are

com-

pletely

saturated.

Wipe

away

excess

grease

before

installing

these

felt

parts.

7.

GENERAL

REPLACEMENT

DATA.

These

projectors

are

designed

for

easy

accessibility,

removal

and

replacement

of

most

major

components.

Routine

inspection,

trouble

shooting

and

lubrication

generally

can

be

accomplished

by

the

removal

of

the

front

cover,

the

rear

cover

and

the

two

covers

located

on

the

underside

of

the

base.

Most

of

the

wiring

connections

3

Service

Instructions

for

the

major

electrical

components

are

made

by

means

of

quick

disconnect

con-

nectors

or

screw

-on

wire

nuts,

thus

mini-

mizing

unsoldering

operations.

Wiring

con-

nections

and

leadwire

colors

are

indicated

in

the

wiring

diagrams

at

the

rear

of

the

Parts

Catalog.

The

front

cover

is

easily

removed

by

un-

latching

the

two

top

cover

latches

and

lifting

the

cover

from

the

projector.

The

rear

cover

is

secured

to

the

projector

base

with

three

screws

and

to

the

end

caps

with

two

screws

each

(see

Figure

C).

When

these

seven

screws

have

been

removed,

carefully

work

the

cover

free

from

the

projector

to

the

limit

of

the

interconnecting

leadwires.

The

covers

on

the

underside

of

the

base

are

secured

by

screws

and

can

be

removed

to

expose

the

amplifier

and

its

controls.

8.

FUSE

REPLACEMENT.

a.

Single

-Line

Voltage

Models.

The

ampli-

fier

power

input

circuit

and

the

audio

system

of

these

models

is

protected

by

a

Slo-Blo

fuse

located

adjacent

to

the

rotary

switch

on

the

gear

side

of

the

mainplate.

Remove

the

projector

rear

cover

(paragraph

11)

to

gain

access

to

this

fuse.

Additional

pro-

tection

is

provided

for

the

2585AML

units

by

two

Slo-Blo

fuses

mounted

on

the

top

cover

of

the

projector.

b.

Multi

-Line

Voltage

Models.

The

ampli-

fier

power

input

circuit

of

these

models

is

protected

by

a

Slo-Blo

fuse

located

adjacent

to

the

rotary

switch

on

the

gear

side

of

the

mainplate.

The

audio

system

of

these

models

is

protected

by

three

Slo-Blo

fuses

that

are

mounted

on

a

fuseboard/support

assembly

attached

to

the

power

transformer

assembly.

To

gain

access

to

all

fuses,

remove

the

rear

cover

as

instructed

in

paragraph

11.

NOTE:

Refer

to

the

appropriate

schematic

wiring

diagram

in

the

Parts

Catalog

for

correct

values

when

replacing

fuses.

c.

All

Models.

The

electrical

system

of

all

projectors

is

protected

against

acciden-

tal

overheating

by

a

special

thermal

fuse.

This

fuse

is

installed

on

the

bracket

located

just

above

the

drive

motor.

The

projector

rear

cover

must

be

removed

(paragraph

11)

and

the

wire

nuts

disconnected

from

the

fuse

leads

for

replacement.

9.

LAMP

REPLACEMENT.

a.

Projection

Lamp.

With

the

line

cord

disconnected

and

the

front

cover

removed,

swing

open

the

lamphouse

cover

an

d

press

in

on

the

top

of

the

lamp

retainer

spring

to

unlock

the

spring,

then

swing

the

spring

down

to

release

the

tension

on

the

projec-

tion

lamp.

Pull

the

lamp

straight

out

from

its

socket

(do

not

twist

or

wiggle

the

lamp

during

removal).

Assemble

the

new

lamp

into

the

socket

and

swing

the

lamp

retainer

spring

up

into

place.

Close

the

lamphouse

cover

and

replace

the

front

cover.

b.

Exciter

Lamp.

Disconnect

the

line

cord.

Loosen

the

thumbscrew

on

the

exciter

lamp

cover

and

remove

the

cover.

Rotate

the

lamp

release

ring

until

the

exciter

lamp

can

be

turned

and

lifted

from

the

lamp

socket

pins.

Install

the

new

lamp

in

the

lamp

socket.

Then

press

down

on

the

release

ring

and

rotate

to

close

the

ring.

Remove

fingerprints

from

the

lamp

with

lens

tissue

or

a

lint

-free

cloth

and

reinstall

the

covers.

4

LUBRICATION

CHART

Parts

To

Be

Lubricated

16mm

Sound

Models

2585/2590/2592

Lubricant

Projectors

Non-bearing

machined

surfaces

of

castings

Oil

P/N

07003

(L1)

Upper

sprocket

shaft

Oil

P/N

08963

(L2)

Framer

shaft

Oil

P/N

04978

(L3)

Bearing

face

of

worm

gear

Oil

P/N

04978

(L3)

Lower

sprocket

shaft

Oil

P/N

078215

(L4)

Felt

pads

Oil

P/N

070032

(L5)

Friction

surfaces

of

all

sliding

parts

(not

otherwise

specified)

Oil

P/N

070032

(L5)

Worm

gear

and

sprocket

gear

teeth

Grease

P/N

070043

(G1)

All

other

gear

and

pinion

teeth

Grease

P/N

070034

(G2)

Reel

arm

lock

buttons

Grease

P/N

070034

(G2)

Shuttle

link

bearings

Grease

P/N

070034

(G2)

In

-out

cam,

cam

follower

and

cam

wicks

Grease

P/N

070034

(G2)

All

pivot

posts

and

bearings

(in

the

mechanism

housing)

Grease

P/N

070034

(G2)

MULTI

-SPLINE

SETSCREW

TOOL

CHART

TOOL

NO.

DESCRIPTION

USED

FOR

G1271

-F1

G1271

-X2

Setscrew

Wrench

and

Handle

Setscrew

Wrench

4-40

multi

-spline

setscrews

4-40

multi

-spline

setscrews

STK3852-B

STK3863-B

Setscrew

Wrench

and

Handle

Setscrew

Wrench

6-32

multi

-spline

setscrews

6-32

multi

-spline

setscrews

G165

-F1

G165

-X2

Setscrew

Wrench

and

Handle

Setscrew

Wrench

8-32

multi

-spline

setscrews

8-32

multi

--spline

setscrews

G165

-F3

Special

Setscrew

Wrench

For

setscrews

in

wrench

handles

TEST

FILM

CHART

PART

NO.

DESCRIPTION

USE

TFL-55

NX1

Test

Film

Loop

Adjust

centering

and

framing

TFL-37

NX1

Test

Film

Loop

Check

buzz

track

TFL-26

NX3

Test

Film

Loop

Check

7KHz

azimuth

TFL-23

NX1

Test

Film

Loop

Check

400Hz

power

output

TFL-D1580

NX2

Test

Film

Loop

Adjust

centering

and

framing

TFR-D550

NX5

Test

Film

Roll

Final

audio/centering/framing

TFS-D550

NX1

Test

Film

Strip

(bad

holes)

Check

loop

restorer

function

TFS-D550

NX5

Test

Film

Strip

(elongated

holes)

Check

loop

restorer

function

5

Service

Instructions

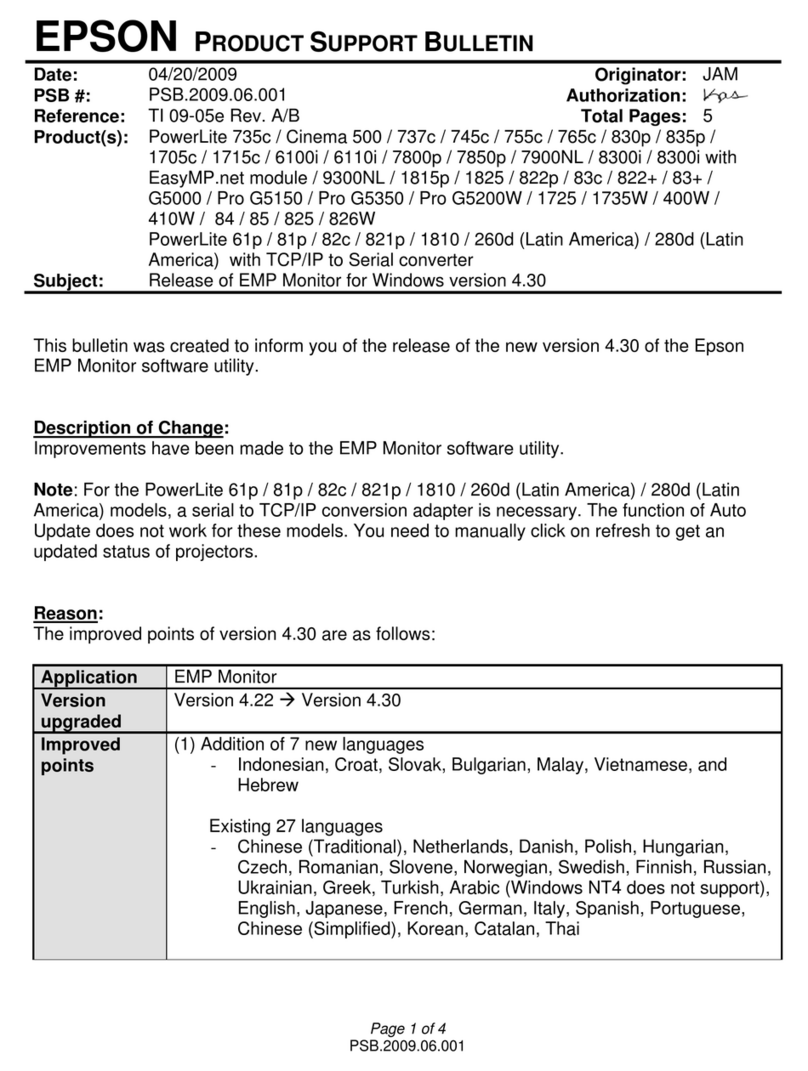

SERVICE

TOOLS

AND

SUPPLIES

CHART

Figure

B

Index

No.

Tool

No.

Tool

Description

Tool

Usage

1

S-078175-6

Fl

Lamp

Plug

(ELC

Lamp)

Optical

system

alignment

(Fig.

Q).

lA

S-1552-1

N1

Lamp

Plug

(BLB

Lamp)

Optic

al

system

alignment

(Fig.

Q).

2

S-550-2

N1

Lens

Plug

Optical

system

alignment

(Fig.

Q).

3

5-550-2

N2

Alignment

Rod

Optic

al

system

alignment

(Fig.

Q).

4

S-550-2

N3

Aperture

Plug

Optic

al

system

alignment

(Fig.

Q).

5

P/N

44507

Tension

Spring

Optical

system

alignment

(Fig.

Q).

6

Make

in

Shop

Torque

Wrench

Adjust

rewind

torque

(para.

38).

7

P/N

710365

Rewind

Torque

Reel

Adjust

rewind

torque

(para.

38).

Purchase

Push

-Pull

Torque

Scale

(Chatillon

#LP

-72,

Master

Gage

Co.,

Chicago,

IL

60622)

Adjust

rewind

torque

(para.

38).

8

S-09701-35

N2

Shuttle

Height

Gage

Check

shuttle

protrusion

(Fig.

T).

9

S-550-8

N1

Alignment

Tool

Align

sound

drum

(Fig.

AC).

10

Make

in

Shop

Adjustment

Tool

Remove

play

from

sprocket

plate.

11

S-552-1

N1

Timing

and

Alignment

Plate

Timing

the

sprockets

(para.

37).

12

S-552-2

N1

Loop

Restorer

Roller

Gage

Adjusting

loop

restorer

(para.

36).

13

Make

from

707588

Decal

Removal

Tool

Remove

decals.

14

P/N

48478

Cleaning

Tool

Clean

film

path

area.

P/N

70507

Adhesive

(Al)

See

parts

catalog

illustrations.

P/N

70910

Heat

Sync

Compound

(HS)

See

paragraph

23.

6

16mm

Sound

Projectors

Models

2585/2590/2592

1A

5

2

3

4

3/4

IN.

1/ 1

6

.1

.

4v.

Cp

s

13

r

e___

1/16

1

/

8

I -

CD

P LIE-

3/16

IN.

@SPROCKET

PLATE

ADJUSTING

TOOL

MAKE

FROM

ALUMINUM

ROD

(5/16

IN.

OD

BY

3

IN,

LONG)

8

6

14

9

7

12

11

Figure

B.

Service

Tools

7-8

16mm

Sound

Projectors

Models

2585/2590/2592

DISASSEMBLY/REASSEMBLY

PROCEDURES

10.

GENERAL

PRECAUTIONS.

a.

Be

sure

to

use

the

proper

size

tools

for

disassembly

and

reassembly

procedures.

After

removing

attaching

parts

(screws,

nuts,

etc.),

loosely

assemble

these

parts

to

the

removed

component

or

to

the

tapped

holes

in

the

major

casting

to

prevent

their

loss.

b.

Cemented

or

adhesive

-backed

parts

are

so

noted

in

the

parts

lists

and

can

be

removed

by

carefully

prying

up

one

edge

with

a

decal

removal

tool.

Be

careful

not

to

scratch

surrounding

areas

and

remove

traces

of

old

adhesive

with

solvent

before

installing

new

labels

or

nameplates.

If

the

new

item

is

to

be

cemented

in

place,

use

Bell

&

Howell

Company

P/N

70507

cement.

If

the

new

item

is

adhesive

-backed,

peel

off

the

protective

tissue

and

smooth

the

item

in

place.

c.

When

disconnecting

leadwires

prior

to

the

removal

of

electrical

components,

tag

the

leads

or

make

a

rough

sketch

of

more

complicated

connections

to

assist

in

re-

installation.

Where

unsoldering

is

neces-

sary,

use

a

soldering

gun

and

a

heat

sink

to

avoid

the

transfer

of

heat

to

adjacent

parts.

Leadwire

colors

and

connections

are

shown

in

the

wiring

diagrams

at

the

rear

of

the

Parts.

Catalog

section.

d.

When

removing

riveted

parts

for

re-

placement,

drill

out

the

old

rivets

with

a

drill

equal

in

size

or

slightly

smaller

than

the

diameter

of

the

rivets.

Use

screws

and

nuts

of

corresponding

size

to

attach

the

replacement

part,

making

sure

that

these

parts

do

not

interfere

with

the

proper

oper-

ation

of

the

equipment.

e.

The

instructions

contained

in

this

sec-

tion

are

limited

to

the

replacement

and/or

repair

and

adjustment

of

major

projector

components.

If

further

disassembly

is

re-

quired,

refer

to

the

Parts

Catalog

section

for

a

more

complete

breakdown.

All

parts

listings

are

arranged

in

a

suggested

order

of

disassembly

to

assist

service

personnel

in

the

removal

and

replacement

of

worn

or

damaged

parts.

11.

PROJECTOR

REAR

COVER

REMOVAL

(Figure

C).

The

lower

end

of

the

rear

cover

is

secured

to

the

base

of

the

projector

with

three

screws

and

to

each

end

cap

with

two

screws.

When

these

seven

screws

have

been

re-

moved,

the

rear

cover

can

be

carefully

pulled

away

from

the

projector

base

and

end

caps

to

the

limit

of

the

interconnecting

leadwires.

Normally,

this

will

be

enough

to

expose

all

projector

mainplate

and

base

-

mounted

components

for

inspection,

clean-

ing,

lubrication

and

parts

replacement.

If

it

is

necessary

for

the

rear

cover

to

be

completely

removed,

all

leadwires

to

the

rear

cover

components

must

be

disconnected.

When

reinstalling

the

rear

cover,

be

sure

that

no

leadwires

have

become

caught

and

that

the

cover

is

fully

seated

before

in-

stalling

the

mounting

screws.

12.

DRIVE

BELT

REPLACEMENT.

a.

Remove

the

projector

rear

cover

(para-

graph

11),

top

cover

(paragraph

13)

and

rear

end

cap

(paragraph

15,

step

b).

b.

If

the

drive

belt

is

badly

worn

and

in

need

of

replacement,

cut

the

old

belt

and

remove

it

from

the

projector.

Unplug

the

motor

lead

connector.

Loosen

the

screw

at

the

upper

end

of

each

motor

bracket

strap

and

disengage

the

straps

from

the

motor

mounting

bracket.

Remove

the

four

screws

that

secure

the

motor

brackets

to

the

pro-

jector

base

and

raise

the

motor

just

enough

to

permit

the

new

belt

to

be

passed

around

the

motor

toward

the

blower.

Be

careful

not

to

lift

the

motor

so

high

as

to

damage

the

blower

fan.

Clean

both

belt

pulleys

with

isopropyl

alcohol

and

loop

the

belt

around

the

pulleys

with

as

little

stretching

as,

pos-

sible.

Reassemble

the

bracket

straps

to

the

9

Service

Instructions

°

a

tt

LINE

CORD

RECEPTACLE

REAR

COVER

TO

END

CAP

SCREWS

REAR

COVER

TO

BASE

SCREWS

VOLTAGE

SELECTOR

Figure

C.

Projector

Rear

Cover

(Multi

-Line

Voltage

Models

Shown)

motor

brackets

and

tighten

the

screws

se-

curely.

Secure

the

motor

mounting

brackets

to

the

projector

base

with

the

four

screws

and

reconnect

the

motor

lead

connector.

Reinstall

the

rear

end

cap

and

projector

covers

-

13.

PROJECTOR

TOP

COVER

AND

HANDLE

REMOVAL

(Figure

D).

Remove

the

rear

cover

(paragraph

11).

The

top

cover

is

secured

by

two

screws

which

are

inserted

through

the

upper

sides

of

the

mainplate

and

threaded

into

tapped

mounting

brackets

on

the

underside

of

the

top

cover

(see

Figure

D).

Remove

these

two

screws

and

lift

the

top

cover

from

the

projector.

To

'

-

'replace

the

carrying

handle,

the

two

handle

screws

and

cover

mounting

brackets

must

be

disassembled

from

the

top

cover.

CARRYING

HANDLE

TOP

COVER

COVER

MOUNTING

BRACKET

HANDLE

SCREWS

COVER

MOUNTING

SCRE

WS

MODEL

2585AML

ONLY

Figure

D.

Removing

Top

Cover

and

Handle

10

16mm

Sound

Projectors

Models

2585/2590/2592

14.

INTERNAL

SPEAKER

REPLACEMENT

(Figure

E).

The

internal

speaker

is

mounted

to

the

front

end

cap

an

d

can

be

removed

without

disassembling

the

front

end

cap

from

the

projector.

Remove

the

rear

cover

(paragraph

11)

to

expose

the

speaker,

and

disconnect

the

two

leads

from

the

speaker

terminals.

Remove

the

four

speed

nuts

from

the

mount-

ing

studs

in

the

end

cap

and

lift

the

speaker

out

from

the

projector.

Reinstall

the

speaker

in

reverse

fashion,

pressing

the

leadwire

lug

connectors

firmly

in

place

on

the

speaker

terminals.

Redress

any

leadwires

whichmay

have

been

disturbed

during

speaker

removal.

15.

END

CAP

REMOVAL

(Figure

E).

If

it

should

become

necessary

to

remove

the

front

or

rear

end

caps

from

the

pro-

jector,

either

for

replacement

or

to

gain

access

to

other

components,

proceed

in

the

following

manner.

a.

Front

End

Cap.

Remove

the

rear

cover

(paragraph

11)

and

top

cover

(paragraph

13)

from

the

projector.

Disconnect

the

lead

-

wires

from

the

internal

speaker

terminals

and

tip

the

projectorso

that

the

underside

of

the

base

is

exposed.

Rotate

the

tilt

knob

until

its

setscrew

is

visible

through

the

cut-

out

in

the

collar

surrounding

the

tilt

knob.

Loosen

this

setscrew

and

withdraw

the

tilt

knob.

Disassemble

the

screw

and

washer

from

the

tilt

bar

assembly

and

from

the

projector

rubber

foot

and

remove

these

parts

from

the

base.

Remove

the

two

screws

that

are

inserted

through

the

base

and

threaded

into

the

lower

Tinnerman

nuts

assembled

to

the

underside

of

the

end

cap.

Remove

the

two

screws

that

are

inserted

through

the

mainplate

and

threaded

into

the

Tinnerman

nuts

assembled

to

the

front

edge

of

the

end

cap.

Reinstall

the

end

cap

in

reverse

fashion

and

reconnect

the

speaker

leads

to

the

speaker

terminals.

Reassemble

the

top

and

rear

covers

to

the

projector.

b.

Rear

End

Cap.

Remove

the

rear

cover

(paragraph

11)

and

top

cover

(paragraph

13)

from

the

projector.

Tip

the

projector

so

that

the

underside

of

the

base

is

exposed

and

remove

the

two

screws

that

are

inserted

FRONT

END

CAP

TILT

KNOB

SCREWS

(4)

5/64

IN.

ALLEN

SETSCREW

WIRE

-TIE

HEX

NUTS

SPEAKER

LEADS

Figure

E.

Front

End

Cap

and

Speaker

Removal

through

the

base

and

threaded

into

the

lower

Tinnerman

nuts

assembled

to

the

underside

of

the

end

cap.

Remove

the

two

screws

that

are

inserted

through

the

main

-

plate

and

threaded

into

the

Tinnerman

nuts

assembled

to

the

front

edge

of

the

end

cap.

If

the

rear

end

cap

is

to

be

replaced,

move

the

end

cap

far

enough

away

from

the

pro-

jector

so

that

the

leadwires

to

the

end

cap

receptacles

can

be

disconnected.

Reinstall

the

end

cap

in

reverse

fashion,

making

certain

that

all

leadwires

are

properly

connected.

16.

BLOWER

REPAIRS

(Figure

F).

a.

Remove

the

rear

cover

(paragraph

11),

top

cover

(paragraph

13)

and

the

rear

end

cap

(paragraph

15,

step

b)

from

the

pro-

jector.

Move

the

covers

far

enough

away

from

the

projector

to

clear

the

blower

housing

without

placing

strain

on

the

inter-

connecting

leadwires.

11

Service

Instructions

SCREWS

(3)

RIGHT-HAND

HOUSING

SCREWS

(2)

SETSCREWS

BLOWER

FAN

LEFT-HAND

HOUSING

O

Figure

F.

Blower

Repairs

b.

The

right-hand

blower

housing

is

at-

tached

to

the

left-hand

housing

with

three

screws

and

to

the

projector

base

with

two

screws.

Remove

these

five

screws

and

sep-

arate

the

two

housings

to

expose

the

blower

fan.

If

the

blower

fan

is

to

be

replaced,

loosen

the

two

setscrews

and

disassemble

the

blower

fan

from

the

motor

shaft.

c.

When

reassembling

the

blower

assem-

bly,

it

is

important

that

the

fan

be

posi-

tioned

so

as

not

to

strike

against

the

two

housings.

Assemble

the

new

fan

to

the

motor

shaft.

Press

the

motor

shaft

to

the

left

(to

remove

end

play)

and

tighten

the

setscrews

just

enough

to

hold.

Assemble

the

right-hand

housing

and

hold

in

mounted

position

(screw

holes

aligned)

while

spinning

the

fan.

Reposition

the

fan

as

necessary

until

there

is

clearance

between

the

fan

and

both

housings;

then

tigthen

both

set-

screws

securely.

d.

Install

the

five

housing

mounting

screws

and

check

to

make

certain

that

all

leadwires

are

properly

dressed.

Reassemble

the

rear

end

cap

and

projector

top

and

rear

covers.

17.

MAIN.SWITCH

REPLACEMENT

(Figure

G).

Remove

the

rear

cover

(paragraph

11)

from

the

projector

to

expose

the

switch.

Swing

open

the

lamphouse

and

remove

the

switch

knob

and

grip

ring

from

the

front

end

of

the

switch

shaft.

Unscrew

the

lock

nut

that

secures

the

switch

to

the

mounting

bracket.

Withdraw

the

switch

from

the

bracket,

catch-

ing

the

lock

nut

and

lockwasher

as

they

become

free.

NOTE:

Some

single

-line

voltage

units

have

capacitors

wired

across

the

switchterminals

(see

inset,

Figure

G)

which

must

be

discon-

nected

from

the

old

switch

and

reconnected

to

the

replacement

switch.

Be

sure

to

in-

clude

the

insulating

sleeving

on

the

capa-

citor

lead

to

the

fuseholder

above

the

switch.

Insert

the

shaft

of

the

new

switch

through

the

hole

in

the

bracket

and

assemble

the

lockwasher

and

lock

nut

to

the

shaft

before

inserting

it

through

the

mainplate.

Slide

the

lockwasher

up

against

the

switch

boss

and

tighten

the

lock

nut

securely.

Assemble

the

grip

ring

and

switch

knob

to

the

end

of

the

switch

shaft

and

close

the

lamphouse.

Re-

install

the

projector

rear

cover.

18.

DRIVE

MOTOR

REPLACEMENT

(Figure

H).

Remove

the

projector

rear

cover

(para-

graph

11),

top

cover

(paragraph

13)

and

rear

end

cap

(paragraph

15,

step

b)

and

disconnect

the

motor

leads.

Remove

the

blower

right-hand

housing

and

blower

fan

(paragraph

16).

Loosen

the

screw

in

the

upper

ears

of

each

motor

bracket

strap

and

disengage

the

straps

from

the

tongues

of

the

mounting

brackets.

Remove

the

two

screws

from

the

left-hand

mounting

bracket

only

and

slide

the

motor

and

bracket

for-

ward

and

out

of

the

projector,

while

dis-

engaging

the

drive

belt

from

the

motor

12

16mm

Sound

Projectors

Models

2585/2590/2592

MAINPLATE

GRIP

RING

SWITCH

KNOB

a)

0

CAPACITOR

P/N

077148

•

O

?Si

INSULATING

SLEEVE

CAPACITOR

P/N

077149

SINGLE

-LINE

VOLTAGE

MODELS

ONLY

LOCK

NUT

IL

SCRE

WS

WIRE

CLAMP

FUSEHOLDER

MOUNTING

LOCK

WASHER

BRACKET

MAIN

SWITCH

Figure

G.

Replacing

the

Main

Switch

pulley.

If

the

motor

is

to

be

replaced,

remove

the

pulley

from

the

motor

shaft.

Assemble

the

new

motor

and

left-hand

bracket

to

the

projector

base,

with

the

pulley

loosely

installed

on

the

motor

shaft,

and

the

drive

belt

looped

around

the

pulley.

Rest

the

motor

end

bell

in

the

cradle

of

the

right-hand

mounting

bracket

and

position

the

left-hand

bracket

so

that

the

mounting

screws

can

be

installed.

Assemble

the

motor

bracket

straps

to

the

end

bells

and

mounting

bracket

ears

and

tighten

the

strap

screws.

Insure

that

the

thermal

fuse

and

sleeve

assembly

is

properly

positioned

and

retained

against

the

motor.

Reassemble

the

right-hand

blower

housing

and

blower

fan

to

the

motor

shaft

(paragraph

16).

Position

the

drive

pulley

so

that

the

drive

belt

is

perpendicuar

be-

tween

drive

pulley

and

mechanism

pulley.

Then

tighten

the

two

pulley

setscrews

se-

curely

and

reconnect

the

motor

leads.

Re-

place

the

rear

end

cap

and

projector

top

and

rear

covers.

END

BELL

0

0

0

MOTOR

PULLEY

SETSCREWS

(2)

MOTOR

BRACKET

STRAP

(2)

•

.ss•

0

OQ

0

o,Y

00

au

00

It)

MOTOR

MOUNTING

SCREW

(4)

MOUNTING

BRACKET

(2)

Figure

H.

Replacing

the

Drive

Motor

13

Service

Instructions

"PIGGY

-BACK"

LAMP

AND

TRANSFORMER

ASSEMBLY

FRONT

SCREWS

(2)

PROJECTOR

BASE

REAR

SCREWS

(2)

Figure

J.

Replacing

the

Transformer

(Single

-Line

Voltage

Models

Shown)

19.

TRANSFORMER

REPLACEMENT

(Figure

J).

a.

Single

-Line

Voltage

Models.

Although

the

2585/2592

units

are

equipped

with

a

"piggy

-back"

power

and

lamp

transformer

and

the

2590

unit

is

equipped

with

a

power

transformer

only;

transformer

replacement

procedure

for

all

single

-line

voltage

units

is

the

same.

To

gain

excess

to

the

trans-

former,

remove

the

rear

cover

(paragraph

11),

top

cover

(paragraph

13)

and

rear

end

cap

(paragraph

15,

step

b).

To

replace

the

transformer,

first

remove

the

two

screws

closest

to

the

mainplate

installed

from

the

underside

of

the

projector

base.

Then

re-

move

the

two

remaining

screws

installed

from

the

top

of

and

down

into

the

left-hand

and

right-hand

transformer

brackets

into

the

projector

base.

See

Parts

Catalog

Fig-

ures

9A

and

9B

if

further

breakdown

of

the

transformer

is

required.

Reinstall

the

transformer

by

reversing

the

removal

pro-

cedure.

Refer

to

the

appropriate

wiring

diagram

in

the

Parts

Catalog

for

proper

wiring

connections.

Replace

the

rear

end

cap

and

projector

covers.

b.

Multi

-Line

Voltage

Models.

These

models

are

equipped

with

a

power

trans-

former

only.

To

replace

the

power

trans-

former

remove

the

rear

cover

(paragraph

11),

top

cover(paragraph

13)

and

rear

end

cap

(paragraph

15,

step

b).

Next

remove

the

four

screws

that

are

installed

from

the

top

of

the

transformer

mounting

bracket

and

down

into

the

projector

base.

Remove

the

two

hex

nuts

to

disassemble

the

fuse

-

board

support

from

the

transformer.

Re-

verse

the

removal

procedure

to

reinstall

the

transformer.

Refer

to

the

appropriate

wiring

diagram

in

the

Parts

Catalog

for

proper

wiring

connections.

Replace

the

rear

end

cap

and

projector

covers.

20.

REAR

REEL

ARM

REPLACEMENT

(Figure

K).

a.

Remove

the

projector

rear

cover

(par-

agraph

11)

and

top

cover

(paragraph

13)

and

disassemble

the

retaining

rings,

gear

and

washer

from

the

rear

reel

arm

shaft..

Note

the

manner

in

which

the

reel

arm

disc

is

oriented

in

regard

to

the

mainplate.

Re-

move

the

three

screws

and

disassemble

the

disc

and

reel

arm

from

the

mainplate.

The

lock

button

and

its

spring

will

'pop"

from

position

when

the

reel

arm

is

re-

moved.

Be

careful

not

to

lose

these

parts.

NOTE:

If

further

reel

arm

repair

is

re-

quired,

refer

to

Parts

Catalog

Figure

12

for

a

complete

breakdown

of

reel

arm.

parts.

When

reassembling

the

reel

arm,

be

sure

to

maintain

a

backlash

of

0.005

to

0.018

inch

(0.127mm

to

0.460mm)

between

the

upper

face

gear

and

its

mating

spur

gear.

b.

Apply

a

light

film

of

grease

(B&H

P/N

070034)

to

the

mounting

flange

of

the

reel

arm

and

around

the

reel

arm

hole

in

the

mainplate.

Assemble

the

tension

spring

to

the

shaft

of

the

lock

button

and

insert

the

button

shaft

into

the

small

hole

adjacent

to

the

reel

arm

hole.

Depress

the

button

while

assembling

the

reel

arm

to

the

main

-

plate.

With

the

reel

arm

in

the

Mown?'

posi-

tion,

release

the

button

and

assemble

the

reel

arm

disc

to

the

reel

arm

shaft.

Install

the

three

disc

mounting

screws

and

tighten

to

14

inch

-pounds.

Manually

depress

the

14

16mm

Sound

Projectors

Models

2585/2590/2592

REAR

REEL

ARM

ASSEMBLY

LOCK

BUTTON

e

TENSION

SPRING

REEL

ARM

DISC

FLAT

WASHER

SCREWS

(3)

Oka

RETAINING

RING

(2)

SPUR

GEAR

Figure

K.

Replacing

the

Rear

Reel

Arm

lock

button

and

raise

an

d

lower

the

reel

arm

to

check

for

freedom

of

movement.

Assemble

a

retaining

ring,

flat

washer

and

spur

gear

to

the

reel

arm

shaft

and

secure

these

parts

with

the

second

retaining

ring.

Lightly

brush

the

gear

teeth

with

grease

and

manually

rotate

the

spur

gear

to

check

engagement

with

the

mating

idler

gear.

There

should

be

a

barely

perceptible

amount

of

backlash

between

gears.

21.

FRONT

REEL

ARM

REPLACEMENT

(Figure

L).

a.

Remove

the

projector

rear

cover

(para-

graph

11).

Note

the

manner

in

which

the

clutch

gearing

is

assembled

to

the

reel

arm

shaft.

Remove

the

retaining

ring

and

disassemble

the

gearing