Belle Group 20-90 User manual

1

- Spare Parts Book

- Pièces détachées

- Libro Despiece

- Lista de Peças

- Onderdelen Boekje

- Reservedele Skrift

- Ersatzteilhandbuch

- Manuale dei ricambi

- Bruksanvisning

- Varaosaluettelo

- Lista Części Zamiennych

- Запасные части Книга

- Varuosade nimekiri

- Rezerves daļu saraksts

- Atsarginiu daliu sarašas

- Част Списък

- Část Barevný pruh

- Lista Pieselor de Schimb

- Část Barevný pruh

- Rezervni djelovi Knjiga

Operators Manual

Operators Manual

Manuel De L'Opérateur

Manual del Operador

Manual de Operação

Handleiding

Betjeningsvejledning

Bedienungshandbuch

Manuale Dell'Operatore

Bruksanvisning

Käyttöohje

Instrukcja Obsługi

Рyкoвoдcтвo для oпepaтopa

Kasutusjuhend

Lietotāja rokasgrāmata

Naudojimo Instrukcija

Oпepaтop Pъчeн

Na’vod K Obzluze

Manualul Operatorului

Kezelõk Kézi

Uputstvo za rukovatelja

GB

F

E

P

NL

DK

D

I

S

US

SF

PL

RUS

EST

LV

LT

BG

6

14

22

30

38

46

54

62

70

78

86

94

102

110

118

126

134

174

870/40000/1

142

HUN

HR

150

CZ

RO

158

166

2

Signed by: Managing Director - On behalf of BELLE GROUP (SHEEN) UK.

Signature: Le Directeur Général - Pour le compte de la SOCIETE BELLE GROUP (SHEEN) UK.

Medido por: Director Gerente - En nombre de BELLE GROUP (SHEEN) UK.

Assinado por: Director-Geral - Em nome de BELLE GROUP (SHEEN) UK.

Getekend door: Algemeen Directeur - Namens BELLE GROUP (SHEEN) UK.

Uunderskrevetaf: Administrerende direktør – På vegne af BELLE GROUP (SHEEN) UK.

PRODUCT TYPE ................. TYPE DE PRODUIT.............. TIPO DE PRODUCTO.......... TIPO DE PRODUCTO .........

MODEL................................. MODELE............................... MODELO .............................. MODELO..............................

SERIAL No........................... N° DE SERIE........................ N° DE SERIE........................ NO. DE SÉRIE .....................

DATE OF MANUFACTURE. DATE DE FABRICATION ..... FECHA DE FABRICACIÓN.. DATA DE FABRIC

SOUND POWER LEVEL NIVEAU DE PUISSANCE NIVEL DE POTENCIA NIVEL DE POTÊNCIA

MEASURED......................... SONORE MESUREE............ ACÚSTICA MEDIDO............ DE SOM MEDIDO................

(GUARANTEED).................. (GARANTIE)......................... (GARANTIZADO) ................. (GARANTIDO) .....................

WEIGHT............................... POIDS................................... PESO.................................... PESO ...................................

We, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, hereby certify that if the product described within this certificate is bought from an

authorised Belle Group dealer within the EEC, it conforms to the following EEC directives: 98/37/EC (This directive is a consolidation of the original machinery directive

89/392/EEC), Electromagnetic Compatibility Directive 89/336/EEC (as amended by 92/31/EEC & 93/68 EEC). The low voltage directive 73/23/EEC, BS EN ISO

12100-1:2003 Safety of machinery and associated harmonised standards, where applicable. Noise emissions conform to directive 2000/14/EC Annex VI, for machines

under article 12 the notified body is AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

Noise Technical Files are held at the Belle Group Head Office address which is stated above.

Nous soussignons, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, GB, certifions que si le produit décrit dans ce certificat est acheté chez un

distributeur autorisé Belle Group au sein de la CEE, il est conforme aux normes CEE ci-après: 98/37/CE (Cette norme est une codification des normes de la machine

d'origine 89/392/CEE), Norme compatible pour l'électromagnisme 89/336/CEE (modifié par 92/31/CEE et 93/68/CEE). Caractéristiques basse tension 73/23/CEE, BS EN

ISO 12100-1:2003, Norme de sécurité des machines et des critères associés et configurés, si applicable. Les émissions de bruit sont conformes à la directive

2000/14/EC Annexe VI pour machines , article 12, l’objet mentionné est AV Technology Mimited, AVTECH House, Birhall Lane, Cheadle Heath, Stockport, Cheshire,

SK3 0XU, GB.

Les dossiers techniques sur les émissions sonores des machines sont détenus au siège social de BELLE GROUP à l’adresse ci-dessus.

La Sociedad, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK 17 OEU, GB, por el presente documento certifica que si el producto descrito en este

certificado es comprado a un distribuidor autorizado de Belle Group en la CEE, este es conforme a las siguientes directivas: 98/37/CE de la CEE (Esta directiva

consolida la directiva inicial sobre maquinaria 89/392/CEE), Directiva 89/336 CEE sobre Compatibilidad Electromagnética (según enmiendas 92/31/CEE y 93/68 CEE),

Directiva sobre Bajo Voltaje 73/23/CEE, BS EN ISO 12100-1:2003 de Seguridad de Maquinaria y Niveles armonizados estándares asociados donde sean aplicables.

Emisión de Ruídos conforme a la Directiva 2000/14/CE Anexo VI para máquinas bajo artículo 12 la mencionada unidad está AV Technology Limited, AVTECH House,

Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 OXU, GB.

En La Sede Central de Belle Group existen Archivos Técnicos con contenido referente a Niveles de Ruido.

O signatário, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK 0EU, GB, pelo presente, declara que se o produto descrito neste certificado foi adquirido a

um distribuidor autorizado do Belle Group em qualquer país da UE, está em conformidade com o estabelecido nas seguintes directivas comunitárias: 98/37/EC (esta

directiva é uma consolidação da directiva de maquinaria original 89/392/EEC), Directiva de Compatibilidade Electromagnética 89/336/EEC (conforme corrigido pelas

92/31/EEC & 93/68 EEC). A directiva de baixa voltagem 73/23/EEC, BS EN ISO 12100-1:2003 Segurança da maquinaria e às normas harmonizadas afins se aplicáveis.

As emissões de ruído respeitam e estão dentro das directivas para máquinas 2000/14/EC Anexo VI, artigo 12, sendo o organismo notificado AV Technology Limited,

AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

A informação técnica sobre níveis sonoros está disponivel na Sede da Belle Group na morada acima mencionada.

Ondergetekende, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 OEU, GB, verklaren hierbij dat als het product zoals beschreven in dit certificaat is

gekocht van een erkende Belle Group dealer binnen de EEG, het voldoet aan de volgende EEG richtlijnen: 98/37/EC (Deze richtlijn is een opvolger van de orginele

Machinerichtlijn 89/392/EEG), Electromagnetische Compatability Richtlijn 89/336/EEG ( geamendeerd door 92/31/EEG & 93/68 EEG). De Laagspannings Richtlijn

72/23/EEG, BS EN ISO 12100-1:2003 Veiligheid van Machines en hieraan gekoppelde geharmoniseerde Standaarden, waar deze van toepassing is. Rumoer emissions

passen voor richtlijn EC Zijgebouw VI , voor toestel onder stuk 12 naar de notified troep zit AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath,

Stockport, Cheshire, SK3 OXU, GB

Worden de Technische Dossiers van het lawaai gehouden op het adres van het Hoofdkantoor van de Groep Belle dat hierboven ' wordt verklaard.

Vi, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, erklærer hermed, at hvis det i dette certifikat beskrevne produkt er købt hos en autoriseret

Belle Group forhandler i EU, er det i overensstemmelse med følgende EØF-direktiver: 98/37/EF, 73/23/EØF (som ændret ved 93/68/EØF), 89/336/EØF (som ændret ved

92/31/EØF), 93/68/EØF og tilknyttede, harmoniserede standarder, hvor relevant. Støjniveauet er i overensstemmelse med direktiv 2000/14/EF, bilag VI gældende for

maskiner under paragraf 12. Det bemyndigede organ er AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU,

Storbritanien.

EC DECLARATION OF CONFORMITY / DECLARATION CE DE CONFORMITE /

DECLARACIÓN DE CONFORMIDAD CE / DECLARAÇÃO CE DE CONFORMIDADE /

EG-VERKLARING VAN OVEREENSTEMMING / EF

OVERENSSTEMMELSESERKLÆRING

Ray Neilson

PRODUCTTYPE .................. PRODUKTTYPE...................

MODEL................................. MODEL .................................

SERIENUMMER................... SERIENR. .............................

FABRICAGEDATUM............ FREMSTILLINGSDATO .......

GEMETEN LYDEFFEKTNIVEAU

GELUIDSSTERKTENIVEAU MÅLT....................................

(GEGARANDEERD) ............ (GARANTERET)...................

GEWICHT............................. VÆGT...................................

GB

F

E

P

NL

DK

14

How To Use This Manual

This manual has been written to help you operate and service the Hydraulic Power Pack safely.

This manual is intended for dealers and operators of theHydraulic Power Pack.

Foreword

The ‘Machine Description’ section helps you to familiarise yourself with the machine’s layout and controls.

The ‘General Safety’ and ‘Health and Safety’ sections explain how to use the machine to ensure your safety and the safety of the

general public.

The ‘Operating Instructions’ section helps you with the setting up and use of the

machine.

The ‘Trouble Shooting’ guide helps you if you have a problem with your machine.

The ‘Service & Maintenance’ section is to help you with the general maintenance and servicing of your machine.

The ‘Warranty’ section details the nature of the warranty cover and claims procedure.

The ‘Declaration Of Conformity’ section shows the standards that the machine has been built to.

Directives with regard to the notations.

Text in this manual to which special attention must be paid are shown in the following way:

The life of the operator can be at risk.

WARNING

The product can be at risk. The machine or yourself can be damaged or injured if procedures are not

carried out in the correct way.

CAUTION

WARNING

Contents

KNOW how to safely use the unit’s controls and what you must do for safe maintenance.

(Be sure that you know how to switch the machine off before you switch on, in case you get into difficulty.)

ALWAYS wear or use the proper safety items required for your personal protection.

If you have ANY QUESTIONS about the safe use or maintenance of this unit, ASK YOUR SUPERVISOR OR CONTACT THE BELLE

GROUP +44 (0)1298 84606

Before you operate or carry out any maintenance on this machine YOU MUST READ and STUDY

this manual.

WARNING

Belle Group reserves the right to change machine specification without prior notice or obligation.

How to use this manual........................................................................................................................................................................... 14

Warning ................................................................................................................................................................................................... 14

Machine Description................................................................................................................................................................................ 15

Applications ............................................................................................................................................................................................. 15

Technical Data......................................................................................................................................................................................... 16

General Safety ........................................................................................................................................................................................ 17

Health and Safety.................................................................................................................................................................................... 17

Pre-Start Safety Checks.......................................................................................................................................................................... 17

Operating Instructions ............................................................................................................................................................................. 18

EHTMA - Code Of Practice ..................................................................................................................................................................... 19

Service & Maintenance ........................................................................................................................................................................... 20

Trouble Shooting Guide .......................................................................................................................................................................... 21

Warranty .................................................................................................................................................................................................. 21

15

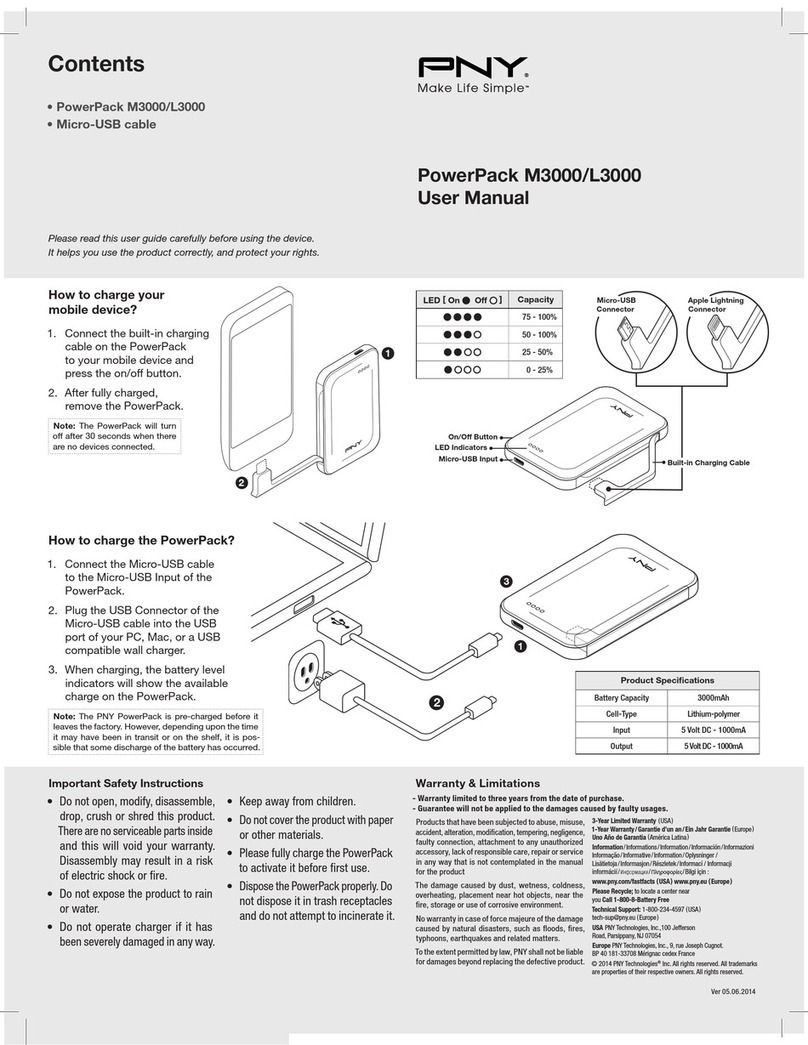

Machine Description

1. Frame

2. Cowl

3. Fuel Tank

4. Air Filter

5. Exhaust

6. Oil Cooler

7. Valve Block

8. Transport Handle

9. Pump

10. Water Tank

11. Transport Wheels

7

9

6

1

5

4

8

2

3

10

11

Applications

The Belle Cub Power Pack is suitable to power the following Belle hydraulic tools.

a) 2012 PAN 26.5lb. Hand held Pick. b) 2018 PAN 39.7lb. Hand held breaker.

c) 2322-C PAN Submersible Water Pump.

The Cub Power Pack can safely be connected to any tool which carries the EHTMA Category ‘C’ ( Green Triangle ), however the

operator should be aware that tools requiring operating pressures above the 90 Bar supplied may perform at a lower efficiency. (ie:- a

disc cutter will stall more easily ). If in doubt regarding the correct and safe connection of a tool please consult Belle Group. or your

local Agent for advice.

The Belle Midi Power Pack is suitable to power the following Belle hydraulic tools.

a) 2012 PAN 26.5lb. Hand held Pick. b) 2018 PAN 39.7lb. Hand held breaker.

c) 2023 PAN 50.7lb Hand held breaker. d) 2025 PAN 55.1lb. Hand held breaker.

e) 2025X 25 Kg. Hand Held Breaker f) 2322-S Submersible Water Pump.

The Midi Power Pack can safely be connected to any tool which carries the EHTMA Category ‘C’ ( Green Triangle ). If in doubt

regarding the correct and safe connection of a tool please consult Belle Group, or your local Agent for advice.

The Belle Major Power Pack MAJOR/20-140X & MAJOR/20-140D is suitable to power the following Belle hydraulic tools EHTMA Cat. ‘C’.

a) 2012 PAN 26.5lb. Hand held Pick. b) 2018 PAN 39.7lb. Hand held breaker.

c) 2023 PAN 50.7lb Hand held breaker. d) 2025 PAN 55.1lb. Hand held breaker.

e) 2025X 25 Kg. Hand Held Breaker f) 2322-S Submersible Water Pump.

The Belle Major Power Pack MAJOR/30-140 is suitable to power the following Belle hydraulic tools EHTMA Cat. ‘D’.

a) 3025 PAN 55.1lb. Hand held Pick. b) 2311 PAN Disc Cutter

The Major Power Pack can safely be connected to any other tool which carries the relevant EHTMA Category ‘D’ ( Brown Triangle ).

If in doubt regarding the correct and safe connection of a tool please consult Belle Group or your local Agent for advice.

16

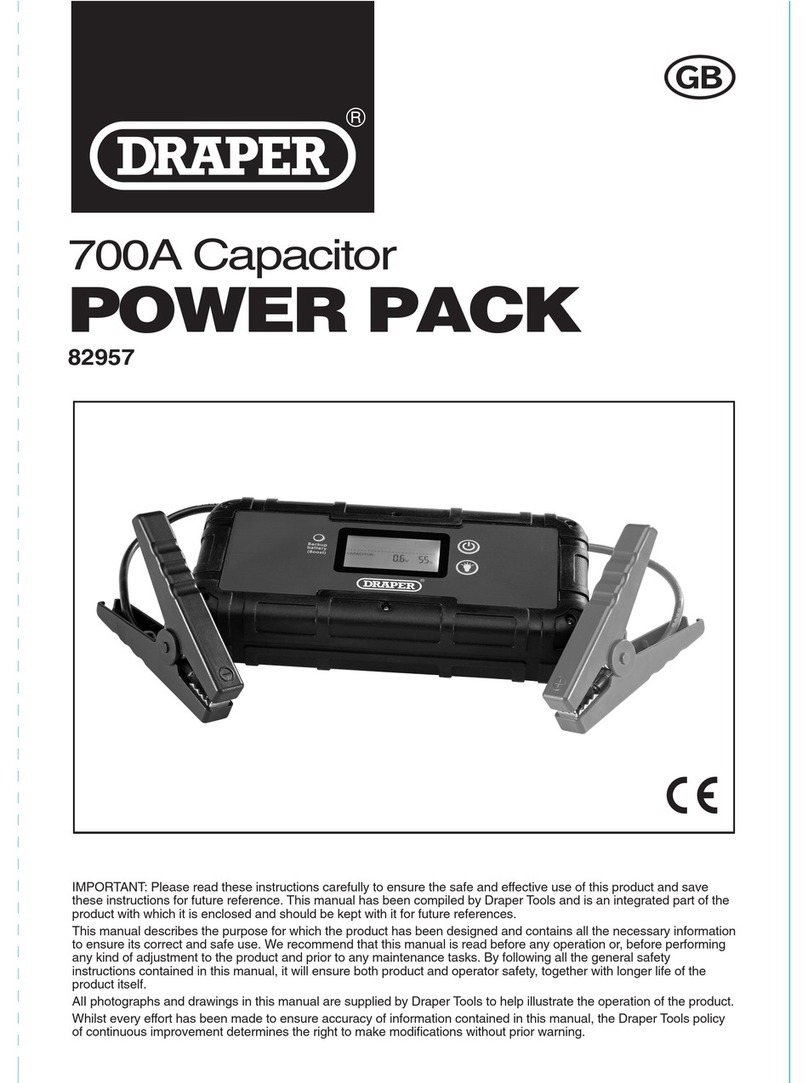

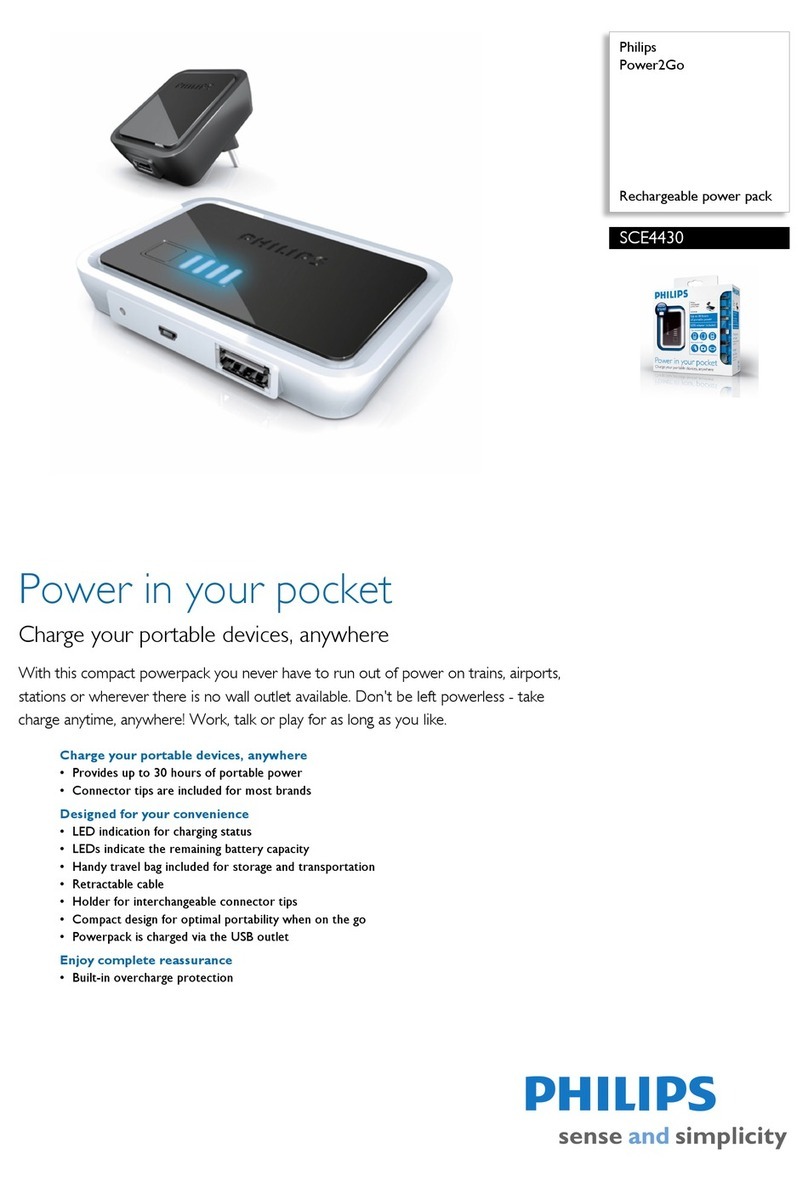

Technical Data

*= Not CE Approved

Model 20-90 20-110D* 20-140

Type Cub Midi Midi

Engine Honda GX160 Lombardini Honda GX270 &

15LD 350 Robin EX27

Engine Power (Hp) 5.5 7.5 9

Hydraulic Flowrate (Gals/Min) 5.3 5.3 5.3

Working Pressure (Bar) 90 110 140

Length (in) 22.4 29.2 29.2

Width (in) 17.3 20.9 20.9

Height (in) 17.7 22.4 22.4

Hydraulic Connections 3/8” / 1/2” 3/8” / 1/2” 3/8” / 1/2”

Hydraulic Oil Type

Dry Weight (lbs) 82.7 147.7 132.3

Weight Including Oils (lbs) 92.6 160.9 145.5

Oil Tank Capacity (Gals) 1.19 1.68 1.68

Fuel Type Unleaded Diesel Unleaded

Fuel Tank Capacity (Gals) 0.95 1.14 1.59

Noise Level (dB(A)) 101 104 101

Flat faced, quick release, Non-drip couplings

- Below 30º = ISO VG T32. - Above 30º = ISO VG T46

Model 20-140X 20-160X 30-140

Type Major Major Major

Engine Honda GX390 Honda GX390 Honda GX390

Engine Power (Hp) 5.5 5.5 7.5

Hydraulic Flowrate (Gals/Min) 5.3 5.3 7.9

Working Pressure (Bar) 140 160 140

Length (in) 30.7 30.7 30.7

Width (in) 21.3 21.3 21.3

Height (im) 24.2 24.2 24.2

Hydraulic Connections 3/8” / 1/2” 3/8” / 1/2” 3/8” / 1/2”

Hydraulic Oil Type

Dry Weight (lbs) 158.7 158.7 158.7

Weight Including Oils (lbs) 172.0 172.0 172.0

Oil Tank Capacity (Gals) 1.64 1.64 1.72

Fuel Type Unleaded Unleaded Unleaded

Fuel Tank Capacity (Gals) 1.72 1.72 1.72

Noise Level (dB(A)) 101 101 101

Flat faced, quick release, Non-drip couplings

- Below 30º = ISO VG T32. - Above 30º = ISO VG T46

17

Health and Safety

General Safety

Never attempt to add fuel or oil when the engine is running. Use only the correct grade, and do not

overfill.

WARNING

The following precautions should be taken before operating Belle Hydraulic Power Units and Road Breaking Tools.

a) Read this Operators Guide and the operating handbook for the tool to be connected and run. Observe the manufacturers

recommendations.

b) Never operate the power units and tools without the correct Personal Protection Equipment. Belle recommend the use of protective

goggles and/or face shield, ear defenders, protective footwear, gloves, and hand hat.

c) Ensure that the ‘STEEL’ is securely locked into the breaker.

d) Only operate the Power unit in a well Ventilated area ensuring adequate flow of air for the cooling fan and the removal of the

exhaust gases.

e) Ensure that a safe operating work position (Workstation) is selected. Belle recommend that tools are operated at the extremity of

the transmission hoses connecting the tool to the power unit.

f) Ensure that the hydraulic tool is compatible with the hydraulic power supply to be used. It is DANGEROUS to use a hydraulic tool

with an incompatible flow rate and pressure.

NOTE:- Hydraulic power units and tools supplied by EHTMA member companies carry range identification labels and it is

essential to check that the tools and power unit have the same identification label.

g) Check the power unit, hoses and tools frequently for damage and/or leaks.

h) Do not adjust the power pack settings, ie:- the engine speed/flow rate, Relief Valve pressure setting etc. Operating with flows and

pressures outside the specifications can be dangerous.

j) Use only Belle replacement parts. It can Prove dangerous to fit obscure parts.

Vibration

Some vibration from the machines operation is transmitted through the handle to the operator’s hands. The Belle Group Hydraulic Tool

range has been specifically designed to reduce hand/arm vibration levels. Refer to specifications & technical data for vibration levels

and usage times (recommended maximum daily exposure time). DO NOT exceed the maximum usage times.

PPE (Personal Protective Equipment)

Personal injury or property damage may be caused by knocks, crushing, slipping, tripping, falling, or by flying chips due mainly to the

improper or careless handling of the machine, or working in a confined area.

Suitable PPE must be worn when using this equipment i.e. Safety Goggles, Gloves, Ear Defenders, Dust Mask and Steel Toe capped

footwear. Wear clothing suitable for the work you are doing. Tie back long hair and remove any jewellery which may catch in the

equipment’s moving parts.

Dust

Many of the tools which can be used with this Power Pack can produce dust, which may be hazardous to your health. Always wear a

mask that is suited to the type of dust being produced.

2) Ensure that the engine exhaust is not obstructed and that there is adequate ventilation to disperse the exhaust gases.

3) Ensure that the transmission hoses are positioned to avoid damage by vehicles etc., and that they will not be understrain when the

accessory tool is in use.

4) Check engine fuel and oil level, and top up as necessary. Refer to the engine manuals for details of grade.

5) Check hydraulic oil level and top up as necessary.

NOTE:- When topping up the hydraulic tank it is advisable to use a strainer. Do not overfill.

Do not operate the machine at an angle of greater than 20 degrees, otherwise the engine lubricating

system may fail, causing extensive damage to the engine.

CAUTION

Pre-start Checks

1) Ensure that the Power Unit is standing on stable ground or where necessary that it is suitable chocked for stability.

Ensure that the hose couplings to the accessory tool are thoroughly cleaned before ceonnecting. Failure to

do so may cause damage to the seals.

CAUTION

18

Operating Instructions

Starting the Engine

NOTE:- Refer to the engine manual for details. Always ensure the Bypass lever is in the Bypass position.

Petrol Engines

1) Open the fuel tap.

2) Close the choke on the carburetter.

3) Set the engine ignition switch to ‘ON’.

4) Start the Engine by pulling on the recoil starter rope.

5) As the engine warms up, gradually return the choke to ‘OPEN’.

NOTE:- Midi and Major petrol Power Packs are fitted with a Power On Demand device and the engine will run at idle speed until

pressure is generated in the hydraulic system.

Diesel Engines

1) Open the fuel tap.

2) Set the engine speed control to the ‘START’ position.

3) Set the decompressor lever to the ‘START’ position.

4) Start the engine by pulling the recoil starter rope.

Operating Checks

Before commencing operation with the accessory tool connected, the following checks should be carried out.

1) Bypass lever is in the “FLOW’ position.

2) Check that there is no excessive engine vibrations.

3) Ensure that there are no hydraulic leaks from hoses or couplings.

4) Check that the filter condition indicator is not within the clogging sector. When this sector is indicated, the return line filter should be

replaced.

Depending on the ambient temperature, optimum performance is usually achieved after 5-10 minutes operation, this is the time

required for the hydraulic oil to reach its correct operating temperature.

Stopping the Engine

NOTE:- Refer to the engine manual for details.

Petrol Engines.

1) Set the bypass lever to the ‘BYPASS’ position.

2) Set the ignition switch to ‘OFF’.

3) Switch off the fuel tap.

Diesel Engines.

1) Set the bypass lever to the ‘BYPASS’ position.

2) Set the engine speed control to the ‘STOP’ position.

3) Switch off the fuel tap.

19

EHTMA - Code Of Practice

EUROPEAN HYDRAULIC TOOL MANUFACTURERS ASSOCIATION CODE OF PRACTICE – HYDRAULIC POWER SYSTEMS

Before Starting. Refer to manufacturer’s operating instructions.

Compatibility. Hydraulic Power Systems are designed to operate at a specific Flow and Pressure. Equipment produced by EHTMA

members carries a triangular colour coded range identification label. Check that both the tool and power unit have

the same identification label before operation. It is imperative that power systems and tools having

different colour codings are not interconnected as this practice is both inefficient and dangerous.

For reference the EHTMA colour code is as follows:-

If in doubt consult the equipment manufacturer.

Characteristics. Operators not familiar with the use of hydraulic tools should note the following points:-

1) Hydraulic breakers are usually more powerful than the equivalent weight pneumatic tools.

2) The body of the hydraulic breaker and the supply hoses will become quite warm during normal operation.

3) As the breaker has no exhaust it is generally much quieter in operation. This should not be taken as a lack of power.

Safety Points.

1) Always wear safety footwear when operating breaking equipment.

2) Eye protection is strongly recommended, particularly on hard surfaces.

3) Ensure that the ‘steel’ is securely locked into the breaker.

4) Check hoses for deep cuts or exposed braiding; replace any damaged hose.

Classification Colour Code. Flow 1/min Max pressure Bar.

A Yellow 5.5 – 6.5 180

B Blue 13.5 – 16.5 172

C Green 18.0 – 22.0 138

D Brown 27.0 – 33.0 138

E Red 36.0 – 44.0 138

F Black 45.0 – 55.0 138

G Orange 54.0 – 66.0 138

Z Grey 9.0 – 11.0 180

20

Service & Maintenance

The following schedule details the attentions considered necessary to ensure satisfactory operation of the power unit.

NOTE:- The attentions and periods summarised in the schedule are the initial recommendations and should be revised to suit the

Power Unit working conditions.

System Pressure and Flow Checks

1. Connect a suitable hydraulic test unit to the powerpack. The unit should comprise a high pressure flowmeter 0-13.2 gals/min, a

gauge 0-200 bar (0-3000psi), a temperature gauge, and a load valve. Suggested unit available from UCC (UC4120).

2. Connect the test unit to the power pack with the load valve and the By-Pass lever in the by-pass position and start the power pack.

Allow the engine to warm up, set the by-pass lever to the flow position. Close the load valve completely and check that the

relief valve setting is correct. The hydraulic oil will tend to get quite hot during this operation and therefore the checking should be

carried out as quickly as possible and the load valve opened before excessive temperatures are reached.

3. Carefully close the load valve to raise the pressure to 100 Bar (70 Bar for Cub). Check that the flow rate is between

4.8 and 5.3 gals/min (7.4 and 7.9 gals/min for Major 30-140). Adjust the engine speed to give the correct flow.

DO NOT EXCEED 3600 RPM (2900 RPM for Major 30-140)”on load” . If correct flow cannot be obtained within max engine

speed then the pump must be replaced

Item Attention First 50 10 100 300

Hours Hrs Hrs Hrs

Complete Unit Keep all areas clean and free from dust, debris etc. 9

Check security of all fasteners especially on engine mountings. 9

Wheels and Feet Examine for damage. 9

Transmission Hoses Examine for leaks or damage. 9

Check for the correct positioning of the protective sleeves. 9

Engine Check oil level. 9

Examine mountings. 9

Examine exhaust silencer for damage of deterioration. 9

Check for excess vibration when running. 9

Change Oil/Service (Refer to manufacturers instructions).

Hydraulic Tank Check oil level. 9

Replace Filter. 99

Change Hydraulic Oil. 9

Oil Cooler. Externally clean using compressed air. 9

DO NOT USE A WIRE BRUSH.

Return Line Filter Replace filter 9

Hydraulic pipes Examine for oil leaks. 9

/ connectors

21

Warranty

Your new Belle Group Hydraulic Power Pack is warranted to the original purchaser for a period of one-year (12 months) from the

original date of purchase.

The Belle Group warranty is against defects in design, materials an workmanship.

The following are not covered under the Belle Group warranty:

1. Damage caused by abuse, misuse, dropping or other similar damage caused by or as a result of failure to follow assembly,

operation or user maintenance instructions.

2. Alterations, additions or repairs carried out by persons other than Belle Group or their recognised agents.

3. Transportation or shipment costs to and from Belle Group or their recognised agents, for repair or assessment against a warranty

claim, on any machine.

4. Materials and/or labour costs to renew, repair or replace components due to fair wear and tear.

The following components are not covered by warranty.

· Engine air filter

· Engine spark plug

Belle Group and/or their recognised agents, directors, employees or insurers will not be held liable for consequential or other damages,

losses or expenses in connection with or by reason of or the inability to use the machine for any purpose.

Warranty Claims

All warranty claims should firstly be directed to Belle Group, either by telephone, by Fax, by Email, or in writing.

For warranty claims:

Belle Group Inc

3959 Electric Rd,

Suite 360, Roanoke,

VA, 24018,

USA.

Troubleshooting Guide

Problem Cause Remedy

Engine stops or Fuel tap switched off. Switch on fuel tap.

will not start. Fuel shortage. Refuel.

Fuel line blocked. Clean filters/pipes.

Air vents in filter cap blocked. Clean.

Air cleaner blocked. Clean or renew element. Refer to engine manual.

Engine malfunctions. Refer to engine manual.

Low engine oil. (Petrol only).

Top up to correct level. Refer to engine manual for correct grade.

Insufficient oil in hydraulic tank.(Petrol only). Top up to correct level (Refer to Technical Data Section)

Engine Ignition switch or connecting wires Check for earth leak, and renew worn or damaged parts.

damaged (Petrol units only).

Hydraulic tank float switch wires damaged Renew worn or damaged parts.

(Petrol units only).

Hydraulic pump seized. Renew pump.

Hydraulic oil Bypass lever is in the ‘BYPASS’ position. Set to ‘FLOW’.

pressure low. Relief valve set low or worn. Check relief valve setting and adjust.

Pump worn or damaged. Check system oil flow. Renew pump as necessary.

Engine power low. Refer to engine manual.

Accessory tool running Radiator fins blocked. Clean using air blast.

hot or loose. Oil cooler fan damaged. Tighten or renew as necessary.

Hydraulic pump worn or damaged. Renew pump.

Relief valve set low or worn. Check setting and renew as necessary.

Hydraulic oil contaminated. Drain oil tank and transmission hoses and replenish with

clean oil. Replace filters.

Engine speed remains P.O.D. Cylinder seized in retracted position. Check the cylinder and replace as necessary

at idle when tools are P.O.D. Cable adjustment Re-adjust as necessary.

operated. (20-140X & Throttle lever incorrectly set at low speed. Reset engine speed and lock throttle lever.

20-160X only)

Engine speed remains P.O.D. Cylinder seized in extended position. Check cylinder and replace as necessary.

at full when off load/ P.O.D. Cable adjustment incorrect. Re-adjust as necessary.

Bypass.

174

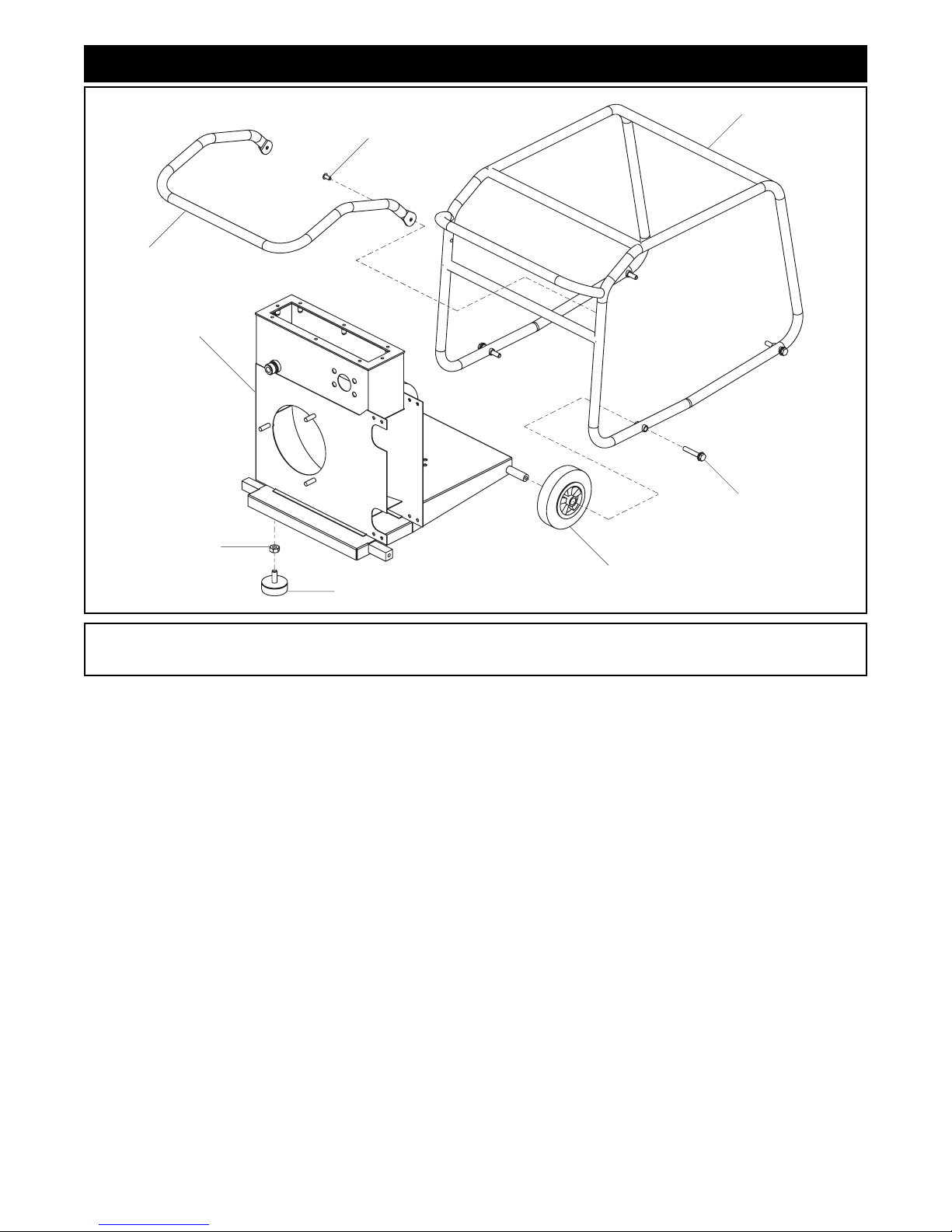

CUB - 20/90

1-01

08

01

03

02

04

05

06

07

1-01

Chassis Assembly, Ensemble Châssis, Conjunto de Chasis, Conjunto do Chassis

1 01056.................. Frame ................................ Châssis ..............................Estructura .......................... Estrutura ............................................................................. 1

2 01542.................. Handle ............................... Poignee..............................Manillar.............................. Punho ................................................................................. 1

3 01160.................. Rivet................................... Rivet...................................Roblon ............................... Rebite ................................................................................. 2

4 01060.................. Chassis..............................Châssis ..............................Chasis ............................... Chassis............................................................................... 1

5 10-300-1000........ Nut .....................................Ecrou..................................Tuerca ............................... Porca ............................................... M10........................... 2

6 00525.................. Feet.................................... Pieds ..................................Patas ................................. Pés ..................................................................................... 2

7 00523.................. Wheel................................. Roue ..................................Rueda................................ Roda ................................................................................... 2

8 01419.................. Bolt..................................... Boulon................................Perno................................. Perno .................................................................................. 4

175

CUB - 20/90

1-01

08

01

03

02

04

05

06

07

1-01

Chassis, Chassisbaugruppe , Chassisenhed, Gruppo dello Chassis

1 01056.................. Frame ................................Rahmen .............................Stel .................................... Telaio.................................................................................. 1

2 01542.................. Hendel ............................... Griff ....................................Håndtag............................. Impugnatura ....................................................................... 1

3 01160.................. Klinken...............................Niet.....................................Klinke................................. Biglietto non vincente ......................................................... 2

4 01060.................. Chassis..............................Chassis ..............................Chassis.............................. Chassis............................................................................... 1

5 10-300-1000........ Moer................................... Mutter.................................Møtrik ................................ Dado ................................................ M10........................... 2

6 00525 .................. Voeten ............................... Pieds ..................................Fod .................................... Piede .................................................................................. 2

7 00523.................. Wiel.................................... Rad ....................................Hjul .................................... Ruota.................................................................................. 2

8 01419 .................. Bouten ............................... Bolzen ................................Skruebolt ........................... Bullone................................................................................ 4

176

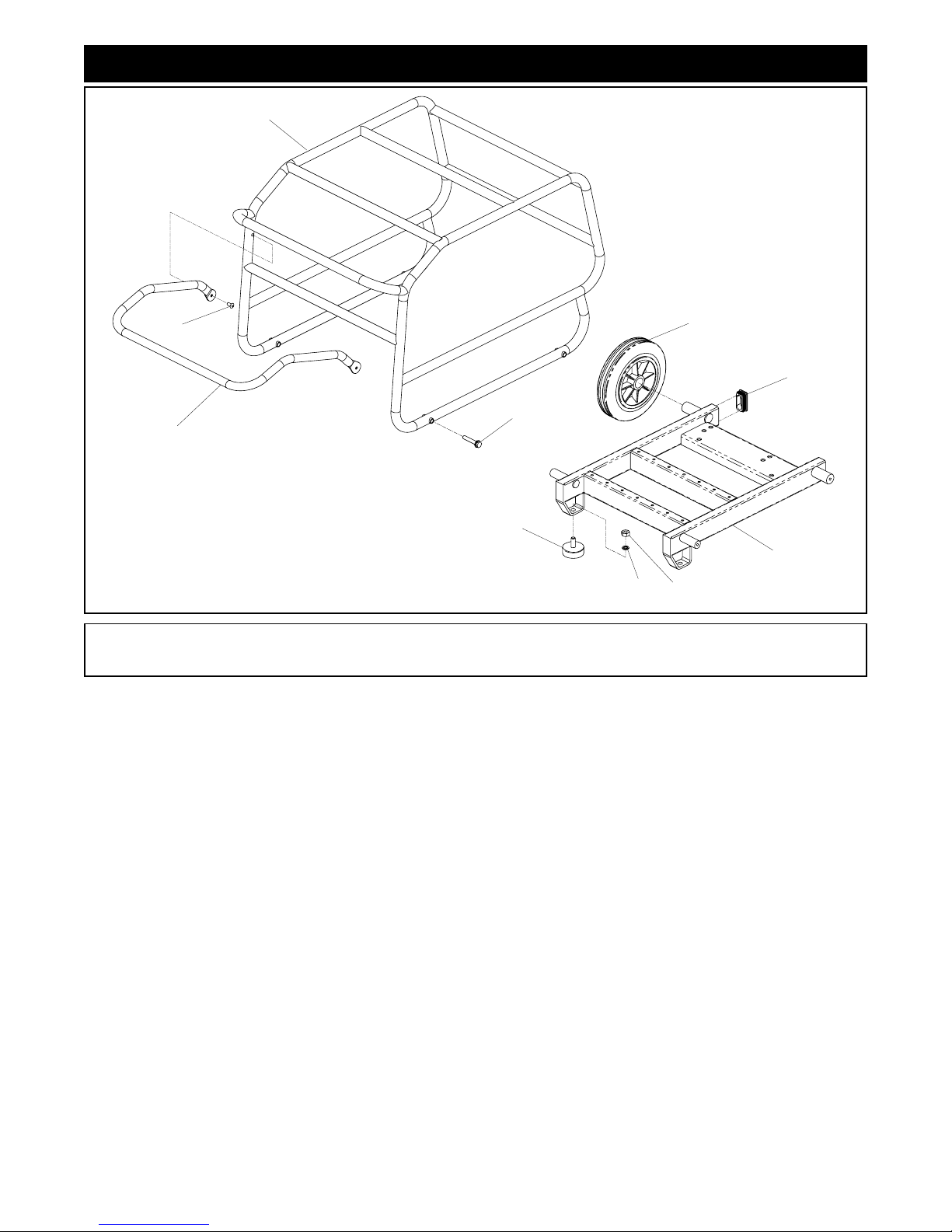

Chassis Assembly, Ensemble Châssis, Conjunto de Chasis, Conjunto do Chassis

MIDI - 20/110D, 20/140 & MAJOR - 20/140X, 20/160X, 30/140

01

04

03

10

02

09

06

07 08

05

1-02

1-02

1 01455.................. Frame ................................ Châssis ..............................Estructura .......................... Estrutura.........................20/140 - Honda & Robin EX27 ......... 1

1 01493.................. Frame ................................ Châssis ..............................Estructura .......................... Estrutura.........................20/140 - Robin EH41DU .................. 1

1 01455.................. Frame ................................ Châssis ..............................Estructura .......................... Estrutura .........................20/110D............................................ 1

1 01493.................. Frame ................................ Châssis ..............................Estructura .......................... Estrutura.........................20/140X, 20/160X & 30/140 .............1

2 7/8037 ................. Screw................................. Vis ......................................Tornillo............................... Parafuse .........................20/140, 20/110D............................... 4

2 01419 .................. Screw................................. Vis ......................................Tornillo............................... Parafuse .........................20/140X, 20/160X & 30/140 ............. 4

3 01476.................. Handle ............................... Poignee..............................Manillar.............................. Punho ....................................................................................... 1

4 01160.................. Rivet................................... Rivet...................................Roblon ............................... Rebite ....................................................................................... 2

5 01436-B .............. Chassis ..............................Châssis ..............................Chasis ............................... Chassis..................................................................................... 1

6 00525-B .............. Feet.................................... Pieds ..................................Patas ................................. Pés .................................20/140, 20/110D ............................... 2

6 01525-B .............. Feet.................................... Pieds ..................................Patas ................................. Pés .................................20/140X, 20/160X & 30/140 ............. 2

7 4/1003................. Washer .............................. Rondelle.............................Arandela............................ Anilha..............................M10................................................... 2

8 8/10003............... Nut .....................................Ecrou..................................Tuerca ............................... Porca ..............................M10................................................... 2

9 00013.................. Plug.................................... Bouchon.............................Tapón ................................ Bujão ........................................................................................ 2

10 60/0285............... Wheel.................................Roue ..................................Rueda................................ Roda......................................................................................... 2

177

Chassis, Chassisbaugruppe , Chassisenhed, Gruppo dello Chassis

MIDI - 20/110D, 20/140 & MAJOR - 20/140X, 20/160X, 30/140

01

04

03

10

02

09

06

07 08

05

1-02

1-02

1 01455.................. Frame ................................Rahmen .............................Stel .................................... Telaio..............................20/140 - Honda & Robin EX27 ........ 1

1 01493.................. Frame ................................Rahmen .............................Stel .................................... Telaio..............................20/140 - Robin EH41DU ................. 1

1 01455.................. Frame ................................Rahmen .............................Stel .................................... Telaio..............................20/110D ........................................... 1

1 01493.................. Frame ................................Rahmen .............................Stel .................................... Telaio..............................20/140X, 20/160X & 30/140 ............1

2 7/8037................. Schroef .............................. Schraube............................Skrue................................. Vite .................................20/140, 20/110D.............................. 4

2 01419.................. Schroef .............................. Schraube............................Skrue................................. Vite .................................20/140X, 20/160X & 30/140 ............ 4

3 01476.................. Hendel ............................... Griff ....................................Håndtag............................. Impugnatura ............................................................................ 1

4 01160.................. Klinken...............................Niet.....................................Klinke................................. Biglietto non vincente .............................................................. 2

5 01436-B .............. Chassis ..............................Chassis ..............................Chassis.............................. Chassis.................................................................................... 1

6 00525-B .............. Voeten ............................... Pieds ..................................Fod .................................... Piede ..............................20/140, 20/110D .............................. 2

6 01525-B .............. Voeten ............................... Pieds ..................................Fod .................................... Piede ..............................20/140X, 20/160X & 30/140 ............ 2

7 4/1003 ................. Afdichtring ..........................Scheibe ..............................Spændeskive..................... Rondella .........................M10.................................................. 2

8 8/10003............... Moer................................... Mutter.................................Møtrik ................................ Dado ...............................M10.................................................. 2

9 00013.................. Plug.................................... Verschlusschraube ............Prop................................... Candela ................................................................................... 2

10 60/0285............... Wiel.................................... Rad ....................................Hjul .................................... Ruota ....................................................................................... 2

178

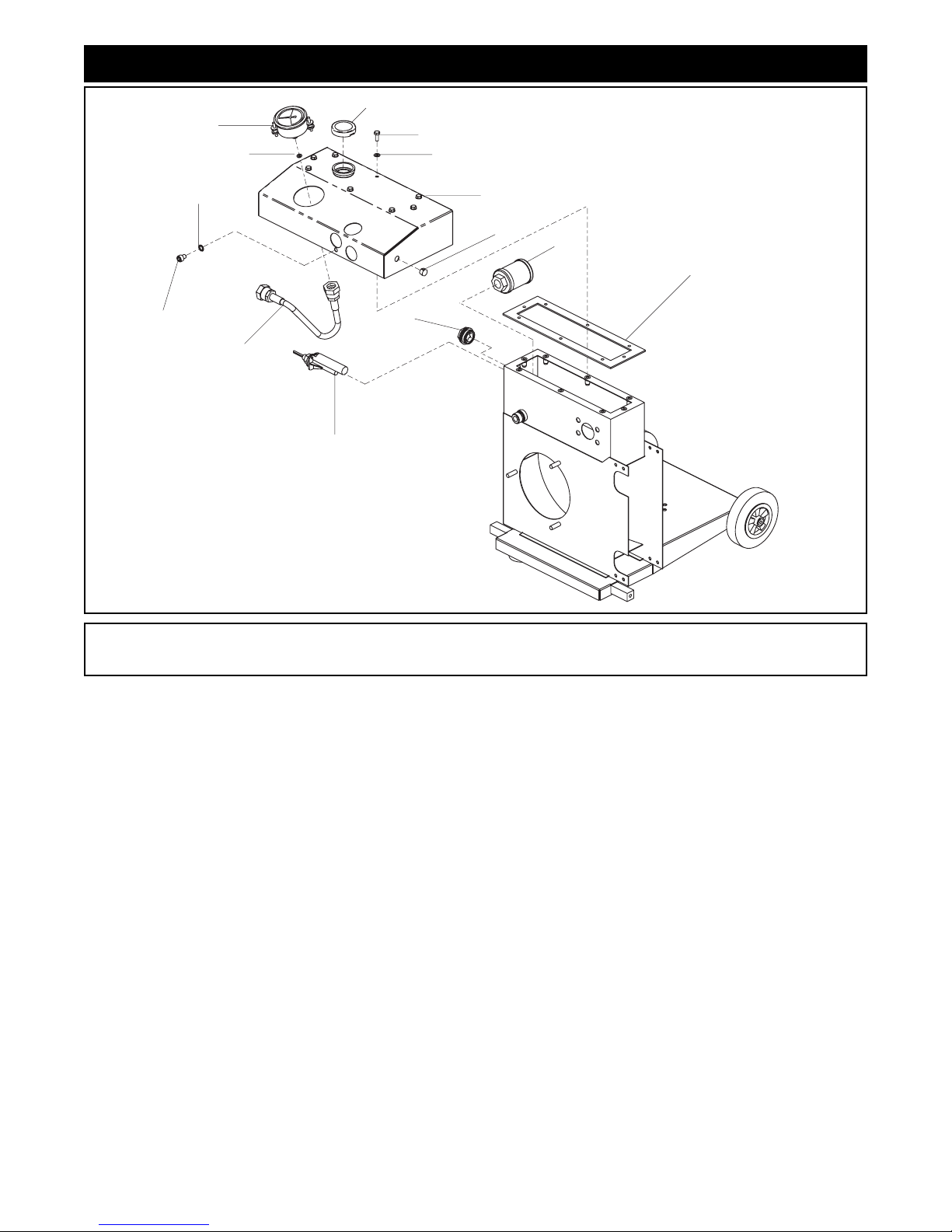

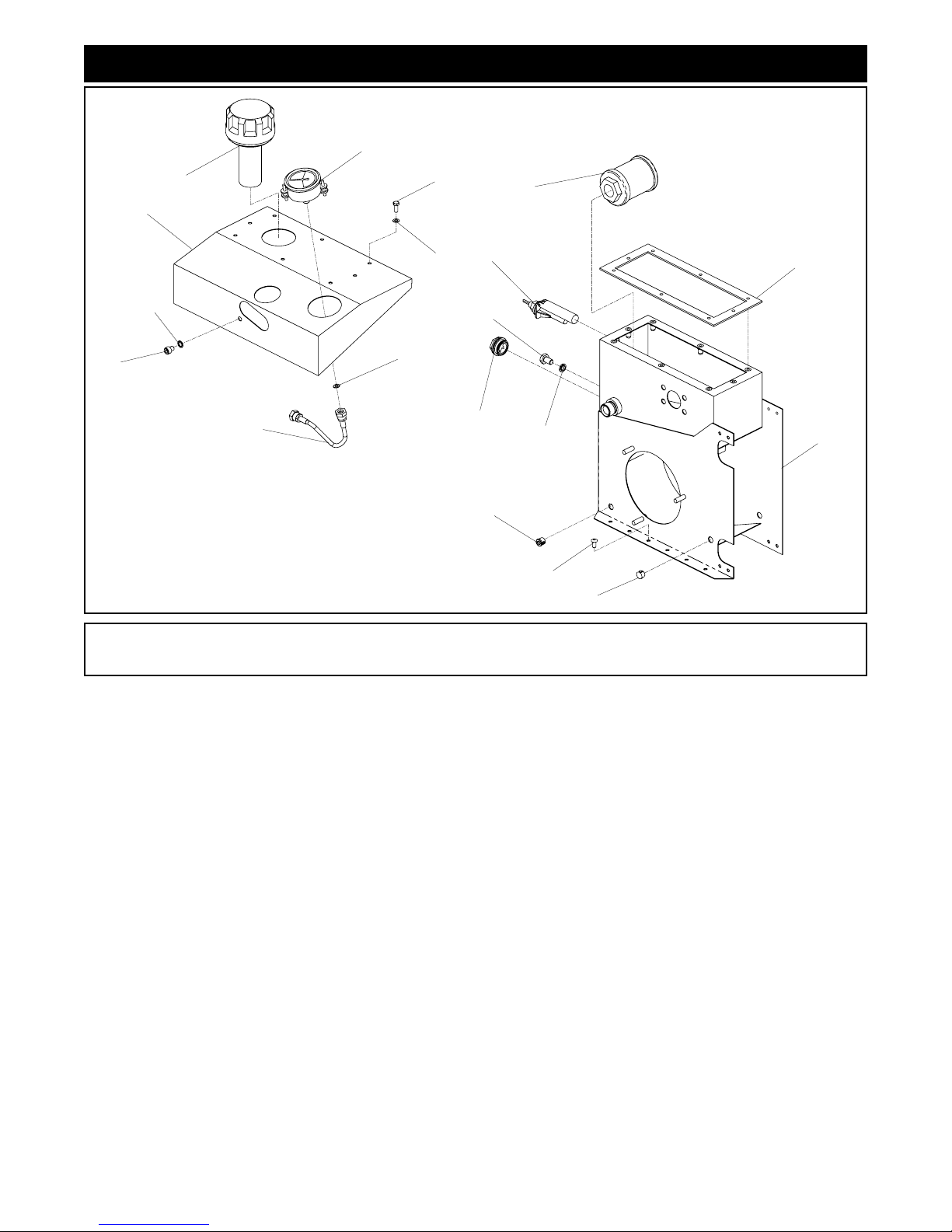

CUB - 20/90

2-01

Tank Assembly, Ensemble Réservoir, Conjunto Tanque, Conjunto do Depósito 2-01

1 01064................Suction Strainer......Filtre d’aspiration ou crépine d’aspiration...... Tamiz de la Succión......................... Filtro de Sucção............................................ 1

2 01466................Gauge.....................Jauge.............................................................Calibrar ............................................ Ajuizar........................................................... 1

3 00790................Switch .....................Bouton ........................................................... Parada ............................................. Paragem ....................................................... 1

4 01063................Gasket ....................Joint...............................................................Junta ................................................ Gaxeta .......................................................... 1

5 00005/3.............Gauge.....................Jauge.............................................................Calibrar ............................................ Ajuizar........................................................... 1

6 00006................Seal ........................Joint d’étanchéité .......................................... Obturador......................................... Vedação........................................................ 1

7 00007................Hose .......................Durit...............................................................Flexible............................................. Tubagem....................................................... 1

8 00129................Cap .........................Capuchon ...................................................... Casquete.......................................... Tampa........................................................... 1

9 01059................Cowl........................Capot............................................................. Caperuza ......................................... Cobertura...................................................... 1

10 9-6001...............Screw......................Vis.................................................................. Tornillo ............................................. Parafuse ........................M6 x 16.................. 8

11 4-6003...............Washer ...................Rondelle ........................................................ Arandela........................................... Anilha.............................M6 ......................... 8

12 01036................Grommet.................Passe-fil.........................................................Anillo ................................................ Anel Isolante................................................. 1

13 10-405-0800 .....Washer ...................Rondelle ........................................................ Arandela........................................... Anilha.............................M8 ......................... 1

14 4-8002...............Screw......................Vis.................................................................. Tornillo ............................................. Parafuse ........................8mm ...................... 1

05

14

07

03

02

04

01

08

10

11

12

06

13 18

179

CUB - 20/90

2-01

Tank bouwdeel, Öltank Bauteil, Tank Komplet, Gruppo Serbatoio 2-01

1 01064................Zeef ........................Saugfilter ....................................................... Sugefilter.......................................... Filtro d’aspirazione........................................ 1

2 01466................Maat........................Breite ............................................................. Hydrauliktrykmanometer .................. Indicatore...................................................... 1

3 00790................Schakelaar..............Schalter .........................................................Oliestandsføler ................................ Interruttore .................................................... 1

4 01063................Tætningsring...........Flachdichtung ................................................ Pakking ............................................ Gaurnizione .................................................. 1

5 00005/3.............Maat........................Breite ............................................................. Hydrauliktrykmanometer .................. Indicatore...................................................... 1

6 00006................Afdichtring...............Dichtung ........................................................Tætning............................................ Tenuta........................................................... 1

7 00007................Slang ......................Schlauchstück ...............................................Slange.............................................. Flessible........................................................ 1

8 00129................Kap .........................Kappe ............................................................ Hætte ............................................... Cappuccio..................................................... 1

9 01059................Vat ..........................Wasserbehaelter ........................................... Hætte ............................................... Cappuccio..................................................... 1

10 9-6001...............Schroef ...................Schraube ....................................................... Skrue................................................ Vite.................................M6 x 16.................. 8

11 4-6003...............Afdichtring...............Scheibe ......................................................... Spændeskive ................................... Rondella.........................M6 ......................... 8

12 01036................Rubberen ring.........Auge .............................................................. Kordelstrop....................................... Anello in gomma........................................... 1

13 10-405-0800 .....Afdichtring...............Scheibe .........................................................Spændeskive ................................... Rondella.........................M8 ......................... 1

14 4-8002...............Schroef ...................Schraube ....................................................... Skrue................................................ Vite.................................8mm ...................... 1

05

14

07

03

02

04

01

08

10

11

12

06

13 18

180

MIDI - 20/110D

2-02

Tank Assembly, Ensemble Réservoir, Conjunto Tanque, Conjunto do Depósito 2-02

1 01441................Tank........................Réservoir ....................................................... Tanque............................................. Depósito........................................................ 1

2 00065................Suction Strainer......Filtre d’aspiration ou crépine d’aspiration...... Tamiz de la Succión......................... Filtro de Sucção............................................ 1

3 5-0018...............Seal ........................Joint d’étanchéité .......................................... Obturador......................................... Vedação........................................................ 1

4 7-10013.............Bolt .........................Boulon ...........................................................Perno ............................................... Perno ............................................................ 1

5 01466................Gauge.....................Jauge.............................................................Calibrar ............................................ Ajuizar........................................................... 1

6 10-601-0400 .....Plug ........................Bougie ...........................................................Tapón............................................... Bujão............................................................. 1

7 10-100-0511 .....Seal ........................Joint d’étanchéité ..........................................Obturador......................................... Vedação........................................................ 1

8 00021/1.............Nut ..........................Ecrou ............................................................. Tuerca.............................................. Porca ............................................................ 1

9 10-330-0810 .....Screw......................Vis..................................................................Tornillo ............................................. Parafuse ....................................................... 1

10 4-8002...............Washer ...................Rondelle ........................................................ Arandela........................................... Anilha............................................................ 1

11 01449................Cowl........................Capot............................................................. Caperuza ......................................... Cobertura...................................................... 1

12 01472................Cap .........................Capuchon ...................................................... Casquete.......................................... Tampa........................................................... 1

13 9-6001...............Screw......................Vis.................................................................. Tornillo ............................................. Parafuse ....................................................... 8

14 4-6003...............Washer ...................Rondelle ........................................................ Arandela........................................... Anilha............................................................ 8

15 00858................Gasket ....................Joint...............................................................Junta ................................................ Gaxeta .......................................................... 1

16 00005/3.............Gauge.....................Jauge.............................................................Calibrar ............................................ Ajuizar........................................................... 1

17 00006................Seal ........................Joint d’étanchéité .......................................... Obturador......................................... Vedação........................................................ 1

18 00007................Hose .......................Durit...............................................................Flexible............................................. Tubagem....................................................... 1

19 01160................Rivet .......................Rivet ..............................................................Roblon.............................................. Rebite ......................................................... 12

20 01545................Cable ......................Cable ............................................................. Cable................................................ Cabo ............................................................. 1

21 01036................Plug ........................Bougie ...........................................................Tapón............................................... Bujão............................................................. 4

12

11

14

13

16

17

10

09

19

18

05 03

04

07

08

06

01

15

02

21

20

181

MIDI - 20/110D

2-02

Tank bouwdeel, Öltank Bauteil, Tank Komplet, Gruppo Serbatoio 2-02

1 01441................Tank........................Öltank ............................................................ Tank ................................................. Serbatoio ...................................................... 1

2 00065................Zeef ........................Saugfilter ....................................................... Sugefilter.......................................... Filtro d’aspirazione ....................................... 1

3 5-0018...............Afdichtring...............Dichtung ........................................................ Tætning............................................ Tenuta........................................................... 1

4 7-10013.............Bouten ....................Bolzen ........................................................... Skruebolt.......................................... Bullone.......................................................... 1

5 01466................Maat........................Breite ............................................................. Hydrauliktrykmanometer .................. Indicatore...................................................... 1

6 10-601-0400 .....Plug ........................Verschlussschraube ...................................... Prop ................................................. Candela ........................................................ 1

7 10-100-0511 .....Afdichtring...............Dichtung ........................................................Tætning............................................ Tenuta........................................................... 1

8 00021/1.............Moer .......................Mutter ............................................................ Møtrik ............................................... Dado ............................................................. 1

9 10-330-0810 .....Schroef ...................Schraube ....................................................... Skrue................................................ Vite................................................................ 1

10 4-8002...............Afdichtring...............Scheibe ......................................................... Spændeskive ................................... Rondella........................................................ 1

11 01449................Vat ..........................Wasserbehaelter ........................................... Hætte ............................................... Cappuccio..................................................... 1

12 01472................Kap .........................Kappe ............................................................ Hætte ............................................... Cappuccio..................................................... 1

13 9-6001...............Schroef ...................Schraube ....................................................... Skrue................................................ Vite................................................................ 8

14 4-6003...............Afdichtring...............Scheibe ......................................................... Spændeskive ................................... Rondella........................................................ 8

15 00858................Tætningsring...........Flachdichtung ................................................ Pakking ............................................ Gaurnizione .................................................. 1

16 00005/3.............Maat........................Breite ............................................................. Hydrauliktrykmanometer .................. Indicatore...................................................... 1

17 00006................Afdichtring...............Dichtung ........................................................Tætning............................................ Tenuta........................................................... 1

18 00007................Slang ......................Schlauchstück ...............................................Slange.............................................. Flessible........................................................ 1

19 01160................Klinken....................Niet ................................................................ Klinke ............................................... Biglietto non vincente.................................. 12

20 01545................Kabel ......................Kabel .............................................................Kabel................................................ Cavo ............................................................. 1

21 01036................Plug ........................Verschlussschraube ...................................... Prop ................................................. Candela ........................................................ 4

12

11

14

13

16

17

10

09

19

18

05 03

04

07

08

06

01

15

02

21

20

182

MIDI - 20/140 & MAJOR - 20/140X, 20-160X

01

04

07

08

06

09

02

10

11

13

17

18

19

16

03

05

12

15

14

2-03

Tank Assembly, Ensemble Réservoir, Conjunto Tanque, Conjunto do Depósito 2-03

1 01441................Tank........................Réservoir ....................................................... Tanque............................................. Depósito........................................................ 1

2 01160................Rivet .......................Rivet ..............................................................Roblon.............................................. Rebite ......................................................... 12

3 00065................Suction Strainer......Filtre d’aspiration ou crépine d’aspiration...... Tamiz de la Succión......................... Filtro de Sucção............................................ 1

4 00858................Gasket ....................Joint...............................................................Junta ................................................ Gaxeta .......................................................... 1

5 00790................Switch .....................Bouton ........................................................... Parada ............................................. Paragem ....................................................... 1

6 5/0018...............Seal ........................Joint d’étanchéité .......................................... Obturador......................................... Vedação.........................1/8” ........................ 1

7 7/10013.............Screw......................Vis..................................................................Tornillo ............................................. Parafuse ........................M10 x 16................ 1

8 01466................Gauge.....................Jauge.............................................................Calibrar ............................................ Ajuizar........................................................... 1

9 01031................Clamp .....................Serrage.......................................................... Mordaza ........................................... Grampo......................................................... 2

10 01036................Grommet.................Passe-fil.........................................................Anillo ................................................ Anel Isolante..................1/2” ........................ 2

11 01449................Cowl........................Capot............................................................. Caperuza ......................................... Cobertura...................................................... 1

12 9/6001...............Screw......................Vis..................................................................Tornillo ............................................. Parafuse ........................M6 x 16.................. 8

13 4/6003...............Washer ...................Rondelle ........................................................ Arandela........................................... Anilha.............................M6 ......................... 8

14 01472................Cap .........................Capuchon ...................................................... Casquete.......................................... Tampa........................................................... 1

15 00005-3.............Gauge.....................Jauge.............................................................Calibrar ............................................ Ajuizar............................M6 ......................... 1

16 00006................Seal ........................Joint d’étanchéité ..........................................Obturador......................................... Vedação........................................................ 1

17 4/8003...............Washer ...................Rondelle ........................................................ Arandela........................................... Anilha.............................M8 ......................... 1

18 10-330-0810 .....Screw......................Vis..................................................................Tornillo ............................................. Parafuse ........................M8 x 10.................. 1

19 00007................Hose .......................Durit............................................................... Flexible............................................. Tubagem....................................................... 1

183

MIDI - 20/140 & MAJOR - 20/140X, 20-160X

01

04

07

08

06

09

02

10

11

13

17

18

19

16

03

05

12

15

14

2-03

Tank bouwdeel, Öltank Bauteil, Tank Komplet, Gruppo Serbatoio 2-03

1 01441................Tank................................ Öltank .................................... Tank.......................................... Serbatoio .................................................................................. 1

2 01160................Klinken............................ Niet ........................................ Klinke........................................ Biglietto non vincente ............................................................. 12

3 00065................Zeef ................................ Saugfilter................................ Sugefilter .................................. Filtro d’aspirazione ..................................................................1

4 00858................Tætningsring................... Flachdichtung ........................ Pakking..................................... Gaurnizione .............................................................................. 1

5 00790................Schakelaar...................... Schalter.................................. Oliestandsføler ........................ Interruttore ................................................................................ 1

6 5/0018...............Afdichtring....................... Dichtung................................. Tætning .................................... Tenuta ............................................. 1/8” ................................. 1

7 7/10013.............Schroef ........................... Schraube ............................... Skrue ........................................ Vite .................................................. M10 x 16......................... 1

8 01466................Maat................................ Breite ..................................... Hydrauliktrykmanometer........... Indicatore.................................................................................. 1

9 01031................Klem ............................... Schelle................................... Klemme .................................... Morsetto.................................................................................... 2

10 01036................Rubberen ring................. Auge ...................................... Kordelstrop ............................... Anello in gomma.............................. 1/2” ................................. 2

11 01449................Vat .................................. Wasserbehaelter.................... Hætte........................................ Cappuccio................................................................................. 1

12 9/6001...............Schroef ........................... Schraube ............................... Skrue ........................................ Vite .................................................. M6 x 16........................... 8

13 4/6003...............Afdichtring....................... Scheibe.................................. Spændeskive............................ Rondella .......................................... M6................................... 8

14 01472................Kap ................................. Kappe .................................... Hætte........................................ Cappuccio................................................................................. 1

15 00005-3.............Maat................................ Breite ..................................... Hydrauliktrykmanometer........... Indicatore.................................................................................. 1

16 00006................Afdichtring....................... Dichtung................................. Tætning .................................... Tenuta ...................................................................................... 1

17 4/8003...............Afdichtring....................... Scheibe.................................. Spændeskive............................ Rondella .......................................... M8................................... 1

18 10-330-0810 .....Schroef ........................... Schraube ............................... Skrue ........................................ Vite .................................................. M8 x 10........................... 1

19 00007................Slang .............................. Schlauchstück........................ Slange ...................................... Flessible ................................................................................... 1

Other manuals for 20-90

1

This manual suits for next models

2

Table of contents

Other Belle Group Power Pack manuals