Belray 096 User manual

DENTAL X-RAY

INSTALLATION

INSTRUCTIONS

MODEL 096

·Wall Mount Type ....................WK

·Ceiling Mount Type................CK

·Floor Mount Type ..................FK1

·Mobil Type .............................FM

·Room Mount Type ..................RK II

IMPORTANT :

This manual provides information and instructions for the installation and calibration proce-

dures for the BELMONT model 096 dental x-ray.

The instructions contained in this book should be thoroughly read and understood before at-

tempting to install the x-ray unit. After the installation is completed, le this manual and

refer back to it when performing periodic maintenance.

REV.5

– 2–

INDEX

PAGE

SECTION ONE : TECHNICAL DATA

[1] ELECTRICAL AND RADIATION DATA......................................................... 3

[2] PHYSICAL DIMENSIONS ............................................................................... 4

[3] TUBE HEAD THERMAL CHARACTERISTICS ............................................ 6

SECTION TWO : PRE-INSTALLATION INSTRUCTIONS

[1] SUPPORT REQUIREMENTS ........................................................................... 7

[2] ELECTRICAL REQUIREMENTS .................................................................... 7

[3] LOCATION OF COMPONENTS ...................................................................... 8

SECTION THREE : INSTALLATION INSTRUCTIONS

[1] INSTALLATION REQUIREMENTS ................................................................ 8

[2] UNPACKING ..................................................................................................... 9

[3] INSTALLATION OF WK / CK / FK / RKII / FM ........................................... 10

[4] HEAD ASSEMBLY INSTALLATION ............................................................ 16

[5] CONTROL BOX INSTALLATION................................................................. 17

SECTION FOUR : POST INSTALLATION INSPECTION

[1] ARM ASSEMBLY............................................................................................ 19

[2] BALANCE ARM ASSEMBLY........................................................................ 19

[3] HEAD POSITIONING..................................................................................... 20

SECTION FIVE : CONTROL IDENTIFICATION AND OPERATION

[1] CONTROL IDENTIFICATION ....................................................................... 20

[2] FUNCTION OF CONTROLS.......................................................................... 21

[3] OPERATING PROCEDURES ......................................................................... 23

[4] ERROR CODES............................................................................................... 24

SECTION SIX : POST INSTALLATION CONFIRMATION

[1] CONFIRMATION OF POWER SUPPLY VOLTAGE..................................... 25

[2] CONFIRMATION OF TUBE CURRENT....................................................... 25

[3] CONFIRMATION OF EXPOSURE WARNING LAMP & BUZZER............ 25

[4] CONFIRMATION OF LINE VOLTAGE REGULATION .............................. 25

SECTION SEVEN : INITIAL SETTING

[1] FILM SPEED.................................................................................................... 26

[2] PRIORITY OF SELECTIONS......................................................................... 28

[3] ELECTRONIC CHIME ON/OFF .................................................................... 28

APPENDIX ONE : CIRCUIT DIAGRAM ........................................................... 29

APPENDIX TWO : PARTS IDENTIFICATION

[1] ARM AND HEAD ASSEMBLY ...................................................................... 30

[2] CONTROL BOX ASSEMBLY......................................................................... 30

– 3–

SECTION ONE : TECHNICAL DATA

[1]

ELECTRICAL AND RADIATION DATA

1. Nominal focal spot value ............................................ 0.8 mm (IEC)

2. Rated peak tube potential............................................ 70 kVp

3. Rated tube current....................................................... 10 mA

4. Maximum rated peak tube potential ........................... 70 kVp

5.

6. Power line frequency .................................................. 50/60 Hz

7. Exposure time ............................................................. 0.02 ~ 3 sec.

(ON and OFF are zero crossed.)

8. Timer accuracy............................................................ ±1 pulse (1/50sec. for 50Hz,1/60sec. for 60Hz)

9. Inherent ltration ........................................................ 1.3 mmAl Equivalent

10. Added ltration ........................................................... 0.8 mmAl

11. Minimum ltration permanently in useful beam ........ 2.1 mmAl Equivalent at 70 kVp

12. Nominal roentgen output

a. Distal end of regular cone ........................................... 8.2mGy/sec. + 30 %, - 40 %

b. Distal end of long cone ............................................... 3.7mGy/sec. + 30 %, - 40 %

13. Source to skin distance

a. Regular cone................................................................ 204 mm

b. Long cone.................................................................... 305 mm (OPTION)

14. Leakage technique factor ............................................ 70 kVp / 0.16 mA

0.16 mA is maximum rated continuous current

for 10 mA with a duty cycle 1: 60

15. Duty cycle ................................................................... 1: 60 (0.5 sec. exposure with 30 sec. interval)

16. Source to the base of cone distance ............................ 81 mm

17. Reference current time product................................... 30 mAs (70kVp, 10mA, 3sec.)

18. Maximum earth leakage current ................................. 0.5 mA

19. Field size ..................................................................... Round 58 mm

20. Tolerance of the focal spot marking............................ ±1 mm

21. Tolerance of target angle............................................. 1˚

22. Measurement base of technique factors

a. Peak tube potential ...................................................... Peak tube potential of conducting half cycle

b. Tube current ................................................................ Average of tube current during one cycle of

line frequency

c. Exposure time.............................................................. Impulese of power line frequency

Reference axis

Focal spot marking

Rated Line Voltage [Vac] 110 120 220 230 240

Minimum LinVoltage [Vac] 99 108 198 207 216

Maximum Line Voltage [Vac] 121 132 242 253 264

Rated Line Power [kVA] 1.3 1.3 1.3 1.3 1.3

Rated Line Current [Aac] 11.4 10.8 5.7 5.6 5.5

Maximum Line Current [Aac] 12.6 11.9 6.3 6.2 6.1

(Internal Resistance [ Ω] (0.19~0.46) (0.22~0.53) (1.12 max) (1.20 max) (1.27 max)

Range of Line Voltage Regulation [%] 2 ~ 5 2 ~ 5 0 ~ 3 0 ~ 3 0 ~ 3

-3A- From 2006 April

– 4–

[2] PHYSICAL DIMENSIONS

[unit : mm]

096-WK Wall Monut Type

220˚

600˚

1060

95 800

OPTION:

500 or 300

Horizontal Arm

is available.

300˚

1895

Min. 489

Max. 1589

Min. 879

Max. 1979

280

Max. 1190

Stroke : 1100 90

From 2004 July

– 5–

096-CK Ceiling Type 096-FK1 Floor Type

096-FM Mobile Type 096-RKII Room Type

[unit : mm]

600˚

106

300˚

Max. 650

Max. 1475

500

500

Stroke 700

450 Stroke

200

775

90

190

507

106

Max. 2140

400 350

180˚

260˚

From 2004 July

300˚

220˚

600˚

106

Max. 1190

Stroke 1100

90

300

(2300)

1965

1495

1350 75 692

Max. 1728

Stroke : 1100

280 300˚

(183)

220˚

600˚

106

Max. 1190

Stroke 1100

Max. 692

951335

300

300˚

280

Max. 1300

Max. 1734

Stroke : 1100

90

Max. 2122

220˚

90゚

825

680

536

106

90

Max. 2027

Max. 1639

1335

Max. 1190

Stroke : 1100

Max. 692

Stroke : 1100

600°

300°

– 6–

[3] TUBE HEAD THERMAL CHARACTERISTICS

A. Interval between each exposure

The temperature inside of the tube head rises, when an exposure is made. The value of the heat

generated is measured in Heat Unit (HU), which is the product of tube potential, tube current and

exposure time. Excessive heat will be accumulated inside of the tube head, if the x-ray is used

without a proper cool down interval between each exposure. The excessive heat may damage the

x-ray tube, high voltage generator or both.

B. Duty cycle

To avoid the accumulation of excess heat in an effort to prolong the tube head life, a cool down in-

terval of 60 seconds or more must be allowed between each 1 second exposure. or a 30 second

cool down must be allowed between each 0.5 second exposure.

C. Tube head cooling curve

1. Tube Housing cooling curve 2. Anode thermal characteristics

3. Maximum rating chart

3

1

5

H

U

/

S

2

5

H

U

/

S

1

7

5

H

U

/

S

TUBE MODEL D-088

ANODE THERMAL CHARACTERISTICS

Heat Storange (H.U.)

Time in Minutes

0123456

20000

18000

14000

10000

6000

2000

FOCAL SPOT 0.8mm

50 kV

60 kV

70 kV

80 kV

90 kV

Tube Current (mA)

Load Time (sec.)

0.10.20.30.50.71.02.03.05.0

30

20

10

Tube Housing Cooling Curve

Heat Storange (KH.U.)

Time in Minutes

020406080100120140

250

200

150

100

50

– 7–

SECTION TWO : PRE-INSTALLATION INSTRUCTIONS

[1] SUPPORT REQUIREMENTS

Control box:

When mounting the MODEL 096 WK control box, the wall and mounting hardware must be sufcient

to withstand a 12 kg shear load.

Arm and head:

(1) Wall mount type (WK)

The wall and mounting hardware for arm mounting bracket must be sufcient to withstand a 45 kg

shear load and a 200 kg withdrawal force at each of the three mounting bolts. If wall dose not have

enough strength, use the wall mounting plate(option). This plate is designed for mounting on two 2

X 4 wood studs with 16 inch center. With this plate, wall and mounting hardware must be sufcient

to withstand a 45 kg shear load and a 200 kg withdrawal force at each of the four mounting bolts.

(2) Ceiling mount type (CK)

The ceiling and mounting hardware for mounting plate must be sufcient to withstand a 150 kg (330

pounds) withdrawal force.

(3) Floor mount type (FK1)

The oor and mounting hardware for oor mounting plate must be sufcient to withstand a 100 kg

(220 pounds) withdrawal force.

CAUTION

:

If the MODEL 096 is to be mounted in a manner other than what is specied in this manual or if

the hardware to be used is other than what is supplied, the support capability of the wall and

the strength of the hardware must be checked and veried to be adequate.

[2] ELECTRICAL REQUIREMENTS

Power supply:

The MODEL 096 x-ray system will operate on a power supply of rated line voltage ± 10% with a three

wire (hot, neutral, earth) circuit, separately connected to the central distribution panel with an over cur-

rent protection device. Use sufcient wire size as the line voltage regulation should be within the range

of 2~5 % for 120V, 0~3% for 220~240V at rated current.

Concealed wiring for WK type:

Concealed wiring is accomplished by bringing conduit and wires into (2) ush mounted junction boxes

located (1) behind the control box and (1) behind the arm mounting bracket. Recommended heights for

the

ush junction boxes are : 131cm for behind control box and 113cm for behind arm mounting bracket.

Wiring done in this manner should extend 30cm beyond the wall surface to allow sufcient wire for

connections.

NOTE:

All connections, workmanship and materials used must comply with the local codes.

Junction

Boxes

FROM

POWER

SOURCE

Terminal Block

for Control Box

Pigtail for Arm

Mounting Bracket

(1) (2)

WALL

876543LN345678

– 8–

[3] LOCATION OF COMPONENTS

A. Arm and head assemblies for WK type:

Using the information provided in FIGURE 1, determine the correct location for the installation of

the arm and head assemblies for WK type. (unit : mm)

NOTE: Local requirements supersede guide lines indicated below.

B. Control box :

When determining the location for the control box the following radiation requirements concerning

operator positioning must be considered. The operator must;

1. have full view of the patient.

2. have full view of kVp, mA, timer selections and exposure warning light.

3. be a minimum of 1.8 meter away from the patient.

4. be out of line of the useful beam of radiation or be positioned behind a protective device with

X-ray protection equivalent of 1 mm of lead.

FIGURE 1

SECTION THREE : INSTALLATION INSTRUCTIONS

Within the installation and conrmation procedures are inspection/test steps which the installer must

perform to insure that the installation meets the manufacturer’s specications.

[1] INSTALLATION REQUIREMENTS

Tools:

Standard tool kit including wire crimping pliers (AMP, “Super Champ” or equivalent).

1.5 mm, 2 mm, 3 mm and 5 mm allen keys.

Instruments:

Digital multimeter with an accuracy of 1%, capable of measuring 300 V AC, and capable of indicat-

ing true RMS value within 1 second.

Standard calculator.

POWER SUPPLY:

Prior to starting the installation inspect the power supply and conrm that the power supply is with

rated line voltage ±10%, and that the supply is a 3 wire EARTHED circuit, separately connected to

the central distribution panel with an overcurrent protection device.

From 2004 July

95

1795

1895

520

420

1700

1800

1080

1180

220˚

( ) : WITH LONG CONE

– 9–

[2] UNPACKING

Unpack the entire contents of the shipping carton. Included within the shipping carton are:

Identication Quantity

Head............................................................................................................. 1/WK,FK,FM,CK,RKII

Regular Cone ............................................................................................... 1/WK,FK,FM,CK,RKII

Long Cone .....................................................................................(1)/WK,FK,FM,CK (OPTION)

Control Box ................................................................................................. 1/WK,FK,FM,CK,RKII

Head key...................................................................................................... 1/WK,FK,FM,CK,RKII

Collar ........................................................................................................... 1/WK,FK,FM,CK,RKII

Balance Arm ................................................................................................ 1/WK,FK,FM,CK

Balance Arm Wrench................................................................................... 1/WK,FK,FM,CK

Horizontal Arm W/ 2/Screw Cover ............................................................. 1/WK,FK

Arm Mounting Bracket W/3 Coach Bolt ø9, 3/Bolt cap............................. 1/WK

Wall Plate W/4 Coach Bolts, 3 bolts, Washers,7/bolt cap and template...... (1)/WK (OPTION)

Brake Screw (M6 x 6mm) ........................................................................... 2/WK,FK 1/FM,RKII

Brake Plug (Brass Plug) .............................................................................. 2/WK,FK 1/FM,RKII

Retaining Bolt (M6 x 35mm) ...................................................................... 2/WK

Stopper Screw (M6 x 15mm) ...................................................................... 1/WK,RKII 2/FK,FM

Control Box Mounting Screw (ø5.8 x 32mm)............................................. 4/WK,FK,CK,RKII

Pole.............................................................................................................. 1/FK,FM,CK

Mounting Plate (ø350mm) W/ 6 coach boltø9............................................ 1/FK,CK

Floor/Ceiling Cover..................................................................................... 1/FK,CK

Control Box Mounting Plate ....................................................................... 1/FK,FM

Back Supporter ............................................................................................ 2/FK,FM

FK/CK Mounting Bolt (M8 x 20mm) W/ 3 spring washer......................... 6/FK,CK

Brake Spring (ø5) ........................................................................................ 1/FK,FM,RKII

Leg............................................................................................................... 2/FM

Free Caster................................................................................................... 2/FM

Brake Caster ................................................................................................ 2/FM

Swing Arm................................................................................................... 1/CK

Light Arm .................................................................................................... 1/CK

Base ............................................................................................................. 1/RKII

Column ........................................................................................................ 1/RKII

Sliding Post.................................................................................................. 1/RKII

Swing Arm................................................................................................... 1/RKII

Gas Pump..................................................................................................... 1/RKII

Seat .............................................................................................................. 1/RKII

Lag Bolt (ø8 x 45mm) ................................................................................. 5/RKII

Manual......................................................................................................... 1/WK,FK,FM,CK,RKII

Inspect contents of shipping carton for damage or missing components.

– 10 –

FIGURE 2

Bottom Cover

ø9 x 75 Bolt

Bolt Cap

FIGURE 3

[3a] INSTALLATION OF WK TYPE

When mounting MODEL 096 arm bracket, the wall and the strength of the hardware used must be

checked and veried as being adequate to withstand a 45 kg shear load and 200 kg withdrawal force

at each of the three mounting bolts. When using concealed wiring, a ush mounted junction box

with the necessary conduit and wiring must be pre-installed at 113 cm from the oor.

1. ARM MOUNTING BRACKET (FIGURE 2):

1-1. Remove bottom cover from bottom of the arm mounting

bracket. Snake electrical interconnecting wires through brack-

et and out access hole.

1-2. Using ø 9 X 75 mm bolts in top and lower mounting holes,

mount arm mounting bracket on wall. DO NOT FULLY

TIGHTEN.

1-3. Placing a level across top edge of arm mounting bracket,

level bracket then tighten bolts securely.

1-4. Put the bolt cap to each head of bolt.

2. HORIZONTAL ARM (FIGURE 3):

2-1. Cut pull string on horizontal arm. DO NOT REMOVE STRING.

ALLOW ONE END TO EXTEND BEYOND MALE BARB AND THE OTHER END TO EX-

TEND BEYOND THE FEMALE MOUNT.

2-2. Place a thrust washer over the hole of arm mounting

bracket, and insert male barb into arm mounting bracket,

allowing pull string to extend through access opening on

bottom of the arm mounting bracket.

2-3. Insert two retaining bolts securely into upper threaded

holes of arm mounting bracket and tighten securely.

IMPORTANT: The retaining bolts must securely engage

the annular groove of horizontal arm. The removal of the

retaining bolts will allow the horizontal arm to rise verti-

cally, and out of, the arm mounting bracket.

2-4. Insert brake plug then brake screw (M6x6 mm) into the

lower threaded hole of the arm mounting bracket.

DO NOT FULLY TIGHTEN.

2-5. Place a level on the horizontal arm and conrm that the arm is level in its left and right swing

positions.

NOTE: Final leveling of horizontal arm is described on Page 19.

3. BALANCE ARM ASSEMBLY (FIGURE 4):

WARNING:

DO NOT RELEASE ARM HOLDING BAND UNTIL THE X-RAY HEAD HAS BEEN INSTALLED.

BALANCE ARM ASSEMBLY IS SPRING LOADED AND CAN CAUSE EQUIPMENT DAMAGE AND

INJURY IF NOT HANDLED IN THE PROPER MANNER.

3-1. DO NOT REMOVE ARM HOLDING BAND.

3-2. Secure pull string to cable and pulling the opposite end, snake cable through horizontal arm and

arm mounting bracket.

3-3. Insert brake plug then brake screw (M 6 X 6 mm) into the horizontal arm collar.

DO NOT FULLY TIGHTEN.

Brake Plug

Brake Screw

Thrust Washer

Retaining Bolts

Pull String

– 11 –

Arm Holding Band

Brake Plug

Brake Screw

End Cap

Screw Cover

Stopper Screw

Access Cover

Access Cover Screw

End Cap Screw

3-4. Remove end cap screw and open end cap.

3-5. Insert stopper screw into upper threaded hole inside

horizontal arm and tighten securely.

CAUTION: If stopper screw is not tightened

securely, the scissors arm can move vertically up

and out of the horizontal arm

3-6. Cut cable and interconnecting wires to a workable

length. Strip 10mm of wire insulation from each lead.

With wire crimping pliers use supplied wire nuts

to make wire connections.

3-7. Insert connected wires into the arm mounting

bracket and secure the bottom cover to the bottom

of the arm mounting bracket.

3-8. Secure end cap with end cap screw, and place a

screw cover.

FIGURE 4

[3b] INSTALLATION OF CK TYPE

1. Fix the mounting plate to the ceiling. Make sure the mounting plate is rmly xed and can with-

stand a 150 kg (330 pound) withdrawal force. (FIGURE 5)

6 x ø14Holes

Monuting Plate

P.C.D.300

ø350

FIGURE 5

From 2004 July

FIGURE 6

2. Attach the pole to the mounting plate by three mounting

bolts. Make the pole vertical by adjusting three adjust-

ment bolts and three mounting bolts. (FIGURE 6)

3. Set the cover and cover ring to the pole and tighten the set

screws of cover ring as the cover stays at the upper end of

the pole. (FIGURE 6)

4. Attach the swing post to the bottom end of the pole.

Monuting

Bolt

Cover

Set Screw

Cover Ring

Swing Post

Pole

Adjustment

Bolt

– 12 –

5. According to the desired rotation angle of swing

arm, set the stopper screw to the stopper ring. 9

different angles can be obtained by changing the

position of stop screws. Right table shows the re-

lation between the rotation angle of swing arm and

the position of stopper screws. (FIGURE 7)

6. Set the stopper ring, swing arm and keys to the

swing post. After the swing arm is lowered to the

limit, make sure the stopper ring is in contact with

the swing arm. (FIGURE 7)

7. Fix the stopper ring to the swing post by the set

screws. Start position of the rotation of swing arm

is decided by these set screws. (FIGURE 8)

300˚

90˚

270˚

150˚

210˚

60˚

300˚

120˚

240˚

Swing Angle

Stopper

Ring

Stopper

Screw

Swing Arm

Keys

FIGURE 7

Stopper Ring

Stopper Screw

Brake Screw

Brake Plug

Keys

Swing Post

Swing Arm

Set Screw

FIGURE 8

8. Insert the shaft of balance arm to the swing arm.

Set a brake plug then brake screw into the top

threaded hole of the swing arm. Do not fully tight-

en. Set a stopper screw into lower threaded hole

of swing arm and tighten securely. (FIGURE 9)

9. Connect the cables from the balance arm and the

cables from the control box under the pole. Then

put the cables into the swing arm. (FIGURE 10)

10. Refer to page 16 for Head assembly installation.

11. Refer to page 17 for Control box installation.

12. Perform the post installation inspection.(page 19~20).

Swing Post

Swing Arm

FIGURE 9

FIGURE 10

WARNING:

DO NOT RELEASE ARM

HOLDING BAND UNTIL

THE X-RAY HEAD HAS

BEEN INSTALLED.

BALANCE ARM

ASSEMBLY IS SPRING

LOADED AND CAN

CAUSE EQUIPMENT

DAMAGE AND

INJURY IF NOT HANDLED

IN THE PROPER MANNER.

Arm Holding Band Balance Arm

Brake Plug

Brake Screw

Stopper Screw

Swing Arm

From 2004 July

– 13 –

Brake Plug

Brake Screw

Mounting Screw

Pole Bushing

Holizontal Arm

Brake Spring

Stopper Screw

Power Cable

ø350

P.C.D 300

Ø14-6Holes Mounting Plate

[3c] INSTALLATION OF FK1 TYPE

1. Fix the mounting plate to the floor. Make sure the

mounting plate is firmly fixed and can withstand a

150kg(330 pound) withdrawal force.(FIGURE 11)

2. Attach the pole to the mounting plate by three mount-

ing bolts. Make the pole vertical by adjusting three

adjustment bolts and three mounting bolts. Then set

the cover to the pole. (FIGURE 12)

3. Set the control box mounting plate to the pole by two

mounting plate screws, then slide the back supporter

of mounting plate and x two back supporter screws

from the control box mounting plate.(FIGURE 13)

4. Through the cable from balance arm to the horizontal

arm, then Joint balance arm and horizontal arm by

stopper screw, brake plug and brake screw. (FIG-

URE 14)

5. Insert the pole busing into the shaft of horizontal arm.

Set stopper screw, brake plug, brake spring and brake

screw. (FIGURE 15)

6. Insert the pole bushing into the pole as the wires go

through the access hole of control box mounting

plate. (FIGURE 15)

7. Then adjust swing range of the arm and x the two

mounting screws for pole busing. Conrm the swing

range of arm is as physical dimension.(Page 5)

8. Refer to page 16 for Head assembly installation.

9. Refer to page 17 for Control box installation.

FIGURE 13

FIGURE 12

Back Supporter

Mounting Plate

Screws

Back Supporter

Screws

Back Supporter

Screws

Control Box

Mounting Plate

Adjustment

Bolts

Mounting

Bolts

Cover

FIGURE 11

From 2004 July

Arm Holding Band

Brake Plug

Brake Screw

End Cap

Screw Cover

Stopper Screw

End Cap Screw

Power Cord

WARNING:

DO NOT RELEASE ARM

HOLDING BAND UNTIL

THE X-RAY HEAD HAS

BEEN INSTALLED.

BALANCE ARM

ASSEMBLY IS SPRING

LOADED AND CAN

CAUSE EQUIPMENT

DAMAGE AND

INJURY IF NOT HANDLED

IN THE PROPER MANNER.

FIGURE 14

FIGURE 15

10. Perform the post installation inspection.(page 19~20).

– 14 –

[3d] INSTALLATION OF RKII TYPE

1. Fix the base on the oor with lag bolts (supplied)

or with appropriate means.

CAUTION

:MAKE SURE THE BASE IS

FIXED ON THE FLOOR FIRMLY.

2. Insert the sliding post with column cover into the

column.

3. Install the column on the base with mounting

bolts. Make it vertical with adjusting bolts.

4. Put the thrust washer to top of the sliding post and

install the swing arm assembly to sliding post.

5. Set the stopper screw into lower threaded hole of

swing arm 2.

6. Set the brake plug then brake spring and brake

screw into the upper hole of swing arm 2.

Tighten the brake screw IF ARM DRIFTS.

DO NOT FULLY TIGHTEN.

7. Run the cable from swing arm 1 through a cable

guide.

8. Slide up the backrest cushion to the top of column.

9. Insert the gas pump into the gas pump bracket.

Mount the seat on the gas pump.

10. Refer to page 16 for Head assembly installation.

11. Refer to page 17 for Control box installation.

FIGURE 16

12. Perform the post installation inspection.(page 19~20)

(SEE FIGURE 16)

– 15 –

FIGURE 19

[3e] INSTALLATION OF FM TYPE

1. POLE ASSEMBLY INSTALLATION

(FIGURE 17)

1-1. Attach four legs bars to the pole base and secure them by

hex socket head bolts. (Align the hole on bottom of base

with the threaded hole on the leg bar.).

CAUTION

:

TWO LONGER LEG BARS MUST BE ATTACHED TO

THE WIDER ENDS OF THE BASE.

2. Attach the caster to each leg end.

2. CONTROL BOX MOUNTING PLATE

(FIGURE 18)

2-1. Set the control box mounting plate over the access hole

of the pole at the short leg side, as 3 wires of power sup-

ply come out from access hole. Secure two screws above

and below the access hole.

2-2. Slide the supporter of mounting plate down to the oppo-

site side of mounting plate, and secure with two screws

beside the access hole.

3. ARM ASSEMBLY INSTALLATION

FIGURE 17

FIGURE 18

WARNING

:

DO NOT RELEASE ARM HOLDING BAND UNTIL

THE X-RAY HEAD HAS BEEN INSTALLED. BAL-

ANCE ARM ASSEMBLY IS SPRING LOADED AND

CAN CAUSE EQUIPMENT DAMAGE AND INJURY

IF NOT HANDLED IN THE PROPER MANNER.

3-1. Insert the shaft of balance arm with pole

bushing attached into the pole as the wires

go through the access hole of control box

mounting plate.

3-2. Keeping the arm at the position (a) of FIGURE 20.

3-3. Fix the pole bushing by two mounting screws on the pole.

3-4. Conrm the swing range of the arm is as FIGURE 20.

4. HEAD INSTALLATION

Refer to page 16.

5. CONTROL BOX INSTALLATION

Refer to page 17.

6. ADJUSTMENT

6-1. Tighten the brake screw if arm drifts.

6-2. Perform the post installation

inspection.(page 19~20)

M8 X 20

Cap Bolts

Leg Bar

(Short)

Leg Bar

(Long)

Pole Bushing

Pole

Pole Base

Caster

Long Leg

Short Leg

80˚

Position (a)

From 2004 July

Arm Holding

Band

Shaft of

Balance Arm

Pole Bushing

Stopper Screw

Mounting

Screws

Mats

Mats

Brake Plug

Brake Spring

Brake Screw

Back Supporter

Mounting Plate

Screws

Back Supporter

Screws

Back Supporter

Screws

Control Box

Mounting Plate

FIGURE 20

– 16 –

21mm

Head Key

Arm Collar

Balance Arm

Balance Arm

Wiring

Head Shaft

Stopper Ring

Head Yoke

Terminal

27mm

Yoke Inside

Cover

Arm Holding Band

(a)

(b)

[4] HEAD ASSEMBLY INSTALLATION (FIGURE 21):

FIGURE 21

3

4

5

6

7

8

Small Diameter

Screw Driver

Earth Terminal

Wirings of Balance

Arm Assembly

3 Blue

4 Brown

5 Red

6 Yellow

7 Gray

8 Green/Yellow

FIGURE 22

1. Remove a screw (a) on arm collar, and place the arm

collar over the stopper ringon the head shaft.

(Direction of arm collar is shown in FIGURE 21.)

2. Remove the yoke inside cover by loosening

screw(b).

3. Making sure the stopper ring and arm collar is

placed on the head shaft, insert the wirings of bal-

ance arm through the head shaft to the head yoke.

4. Insert the head shaft into balance arm assembly, and

while holding the head in position, install head key

securely into retaining groove.

5. Slide the arm collar upward to proper position and

secure it in place with a screw (a).

6. Loosen 5 screws on the terminal using a small dia.

screw driver, and insert the wirings of balance arm

assembly into the terminal according to the color.

(FIGURE 22)

7. Retighten the screws on the terminal and confirm

that the wirings are xed on the terminal.

8. Remove M5 Phillips head screw from earth terminal

and secure No.8 wiring together to earth terminal.

9. Reattach the yoke inside cover with a screw.

10. Remove arm holding band.

From 2004 July

– 17 –

[5] CONTROL BOX INSTALLATION

The wall and the strength of the hardware used must be checked and veried as being adequate to

withstand a 10 kg shear load.

A flush mounted junction box with the necessary conduit and wiring must be pre-installed at

1310mm from the oor.

NOTE: Refer to the control box template, and:

1. Be certain the electrical wire entry hole is aligned with the junction box.

2. That there is adequate support in the wall to secure the control box.

A. CONTROL BOX - MOUNTING for WK type0 (FIGURE 23):

1. Tape the control box template to the wall at the recommended height.

1a. Conrm relationship of access hole in for the electric wires with the entry hole for the wires in

the back of the control box.

2. Using a 2.4mm drill, drill a pilot hole 50mm deep for each mounting screw.

2a. The method of drilling the pilot hole and, the hardware use to secure the control box depend

upon the structure.

3. Drive two wood screws into upper two holes remaining about 20mm undriven. (Fig.23a)

4. Remove two M3 Phillips head screws from top of the control box and open front panel. (Fig.23b)

5. Remove a restriction plate. (Fig.23c)

6. Snake power supply cable lines and interconnecting wires through access hole in back panel.

7. Hook the control box chassis to wood screws driven in step 3 above through two mounting holes

on upper side of chassis. Tighten screws slightly.

8. Attach two wood screws to mounting holes on lower side of back panel. (Do not fully tighten.)

(Fig.23d)

9. Placing level across top edge of the control box, level, then tighten four screwes securely.

a

c

b

d

FIGURE 23

– 18 –

FIGURE 25

B. CONTROL BOX, WIRING (FIGURE 24-a & 24-b).

WARNING: MAKE SURE THE POWER SUPPLY IS TURNED OFF AT THE CENTRAL

DISTRIBUTION PANEL.

1. Strip approximately 10mm of insulation off the power supply leads and interconnecting cables.

2. Following wiring diagram, connect those wires to the terminal block of control box.

3. Set the restriction plate to the original place.

C. CLOSING FRONT PANEL (FIGURE 25).

CAUTION:BEFORE CLOSING THE FRONT PANEL, PERFORM POST INSTALLATION

CONFIRMATION(PAGE 25 ).

1. Conrm all the post installation conrmation are performed.

2. Close the front panel and secure two M3 phillips head screws on the top panel.

JunctionBoxes

From

Power

Source

Terminal Block

for Control Box

Pigtail for Arm

Mounting Bracket

WALL

LN345678

876

543

GREEN/YELLOW

BLUE(WHITE)

BROWN(BLACK)

BLUE

RED

GRAY

GREEN/YELLOW

YELLOW

BROWN

FIGURE 24-a

3

4

5

6

7

L

N

8

FIGURE 24-b

– 19 –

SECTION FOUR: POST INSTALLATION INSPECTION

[1] ARM ASSEMBLY

1. Incorrect levelling of the wall bracket can cause arm drift. First, check level with arms in position

#l . If not correct, bracket must be adjusted by placing shims behind the arm mounting bracket or

the wall plate (FIGURE 26-a).

IMPORTANT:

If the end of the horizontal arm #1 is pitched below level, then the tubehead will drift away from

the wall. If the end of the horizontal arm #1 is pitched above level, then the level arm will require

only minimum adjustment of brake (friction) screw.

2. Check level in position #2. If not correct, adjust as follows: (FIGURE 26-b)

a) Remove bolt caps on mounting bolts.

b) SLIGHTLY loosen two top mounting bolts.

c) Shift the bracket left or right up to the arms arc accurately levelled.

d) Move the horizontal arm to position #1.

e) Fully tighten two top mounting bolts.

f) Fully tighten bottom mounting bolt.

g) Put the bolt cap to each head of mounting bolt.

NOTE: SLIGHT TENDENCIES TO DRIFT CAN BE CORRECTED BY TIGHTENING

BRAKE SCREWS IN HORIZONTAL ARM AND/OR WALL BRACKET.

DO NOT TIGHTEN BEYOND WHAT IS REQUIRED TO PREVENT DRIFT.

Adjustment Nut

less tension

LOOSEN

more tension

TIGHTEN

Balance Spring

Cover

FIGURE 27

[2] BALANCE ARM ASSEMBLY

1. Place the balance arm assembly into position.

2. If either balance arm drifts either higher or lower from the set position, remove the spring adjuster

covers and with the supplied wrench adjust the balance arm springs (FIGURE 27).

Bolt Cap

Top Mounting Bolt

Bottom Mounting Bolt

Brake Screw

LEVEL

#2

#1

FIGURE 26-b

FIGURE 26-a

LEVEL

Wall error adjustment;

install shims behind

the wall plate

– 20 –

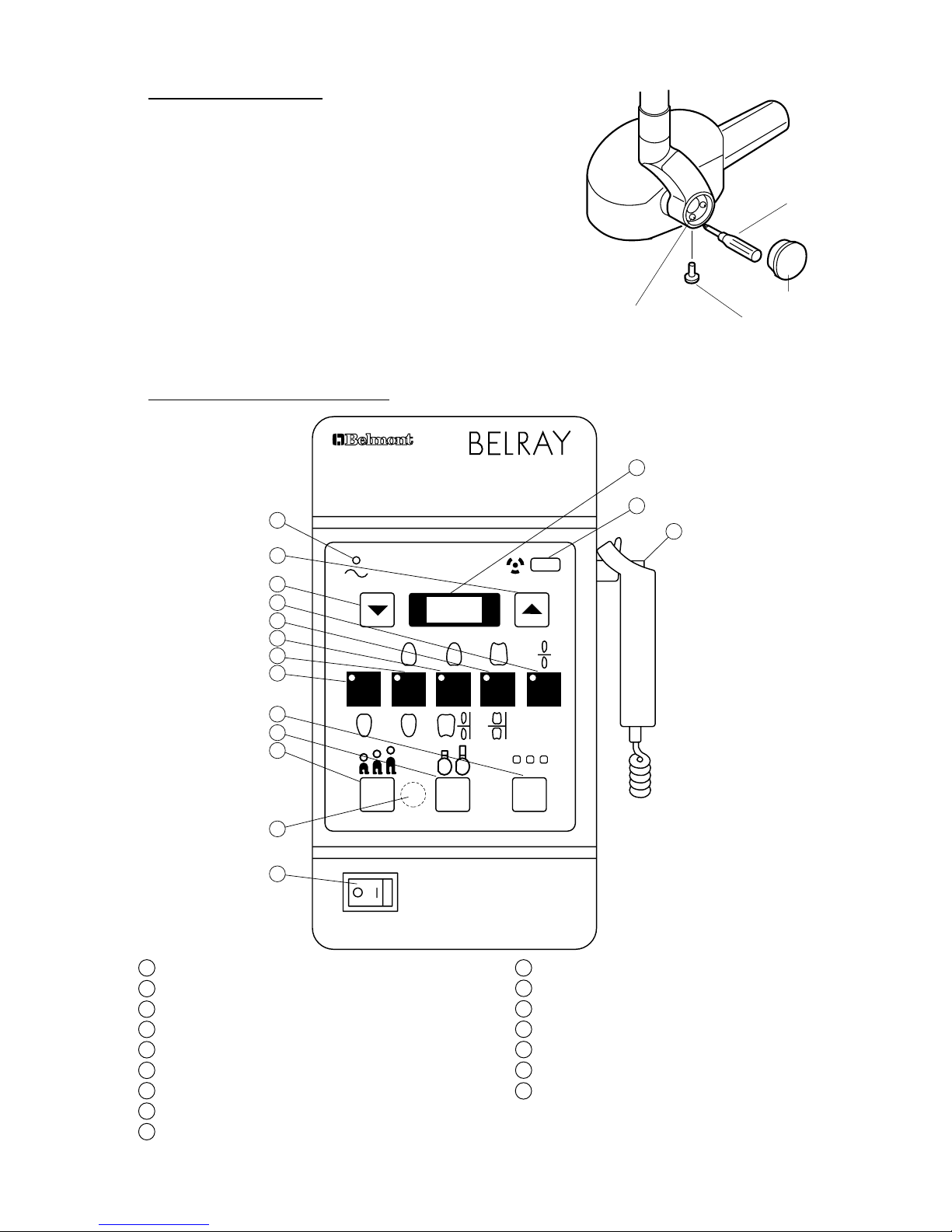

SECTION FIVE : CONTROL IDENTIFICATION AND OPERATION

[1] CONTROL IDENTIFICATION

1

Main Power switch

10

Patient Size Selection Switch

2

Ready Lamp

11

Cone Type Selection Switch

3

Exposure Time Adjusting Sw.(Up)

12

Film Speed Selection Switch

4

Exposure Time Adjusting Sw.(Down)

13

Exposure Time Display Window

5

Tooth Selection Switch (T1)

14

Exposure Warning Light

6

Tooth Selection Switch (T2)

15

Exposure Switch

7

Tooth Selection Switch (T3)

16

Technical Switch

8

Tooth Selection Switch (T4)

9

Tooth Selection Switch (T5)

W A R N I N G

THIS X-RAY UNIT MAY BE DANGEROUS

TO PATIENT AND OPERATOR UNLESS SAFE EXPOSURE FACTORS

AND OPERATING INSTRUCTIONS ARE OBSERVED.

MODEL 096 70kVp 10mA

P C F

T1 T2 T3 T4 T5

abc

15

14

2

3

4

9

8

7

6

12

11

10

16

5

1

13

[3] HEAD POSITIONING

A. Place head into position.

B. If head drifts from the set position, adjust the brake screws

according to the following procedures.

1. Remove the yoke outside cover by loosening cover

screw.

2. Adjust 6 brake screws using phillips screw driver.

3. After adjustment, reattach the yoke outside cover with

the cover screw.

FIGURE 28

Phillips Screw Driver

Yoke Outside Cover

Cover Screw

Brake Screw

Table of contents