Belson BSA-1520MP3 User manual

MODEL : BSA-1520MP3

MODEL BSA - 1520

IMPORTANT SERVICE SAFETY INFORMATION

1.SAFETY PRECAUTIONS

2. PRODUCT SAFETY NOTICE

some electrical andmechanical parts havespecial safety related

characteristics which areoften not evidentfrom visual inspection.

Nor can the protection they give necessarily be obtained by replacing

them with componentsrated for highervoltage , wattage,etc. Parts

that have special safety characteristics areidentified by a on

schematic and parts list. Use of a substitute replacement that dose not

have the same safety characteristics as the recommended replacement

part might createshock, fire, and/orother hazards. Productsafety is

under review continuouslyand new instructions are issued whenever

Appropriate.

3. Servicing precautions

caution: before servicing the unit covered by this service by this service

manual and its supplements. Read and follow the SAFETY PRECAUTIONS on

this page. NOTE: if unforeseen circumstances create a conflict between

the following servicingprecautions and anyof the safety precautions,

always follow thesafety precautions. Remember:safety first.

General servicing precautions.

A. Always unplugthe unit's AC powercord from theAC power source

(1) removing or reinstalling any component, circuit board, module or

any other unitassembly.

(2) disconnecting orreconnecting any unitelectrical plug or other

Electrical connection.

(3) connecting a test substitute in parallel with an electrical capacitor

caution: a wrongpart substitution or incorrect polarity installation

Of electrolytic capacitorsmay result in an explosion hazard.

B. Do notdefeat any plug/socketb+ voltage interlockswith which

the unit coveredby this service manual might be equipped.

C. Do not apply AC power to this unit and/or any its electrical assemblies

unless all solid-statedevice heat sinksare correctly installed.

D. Always connecta test unitinstrument's ground leadto the unit's

chassis ground before connecting the test instrument's positive lead

always remove thetest instrument's ground leadlast.

4. Laser precautions

Warning!!

1. When servicing.(In case itis necessary toconfirm laser beam

emission ) besure not toplace your eyes any closer than 1 or

30cm from thesurface of the objectivelens on theOptical

Pickup block.

HANDLING THE LASERPICKUP

2. Laser DiodesAre Extremely SusceptibleTo damage from static

electricity even ifa static dischargedies not ruin the diode, it can

shorten its lifeor cause itto work improperly.When replacing the

the pickup, usea conductive maton the floorand desk andwear

a wrist bandconnected to groundthrough a 1M ohm resistorto

protect the laserdiode from staticdamage. If thelens should get

dusty, blow off thedust carefully fromthe object.

3. There are no adjustable parts in the pickup assembly. If it is defective,

replace the wholepickup assembly.

CAUTION:

USE OF CONTROLS, ADJUSTMENTS OR PERFORMANCE OF PROCEDURES

HEREIN MAY RESULTIN HAZARDOUS RADIATION EXPOSURE.

DANGER:

IF INTERLOCK FAILS OR ISDEFEATED, THE LASER LIGHT IS ABLE TO

FUNCTION. THE LASERIS INVISIBLE, AVOID DIRECT EXPOSURE TO BEAM.

Before:

Before returning a unit to the customer, always make a safety check of the

Entire unit, including,but not limited to the followingitems:

a. Be sure that no built-in protective devices are defective and/or have been

defeated during servicing.

(1) protective shields are provided to protect both the technician and the

customer. Correctly replace all missing protective shields including any

removed for servicingconvenience.

(2) when reinstalling the chassis and/or other assemblies in the cabinet, be

sure to put back in place all protective devices, including , but not limited

to , nonmetalliccontrol knobs, insulating fishpapers,

adjustment and compartment covers/shields and isolating resistor/

capacitor networks. Do not operate this or permit it to beoperated

Without all protective devices correctly installed and functioning .

b . Be sure that there are no cabinet openings through which an adult or child

might be able to insert their fingers and contact a hazardous voltage. Such

openings include, butare not limited to, excessively widecabinet ventilation

slots, and an improperly fitted and/or incorrectly secured cabinet

back cover.

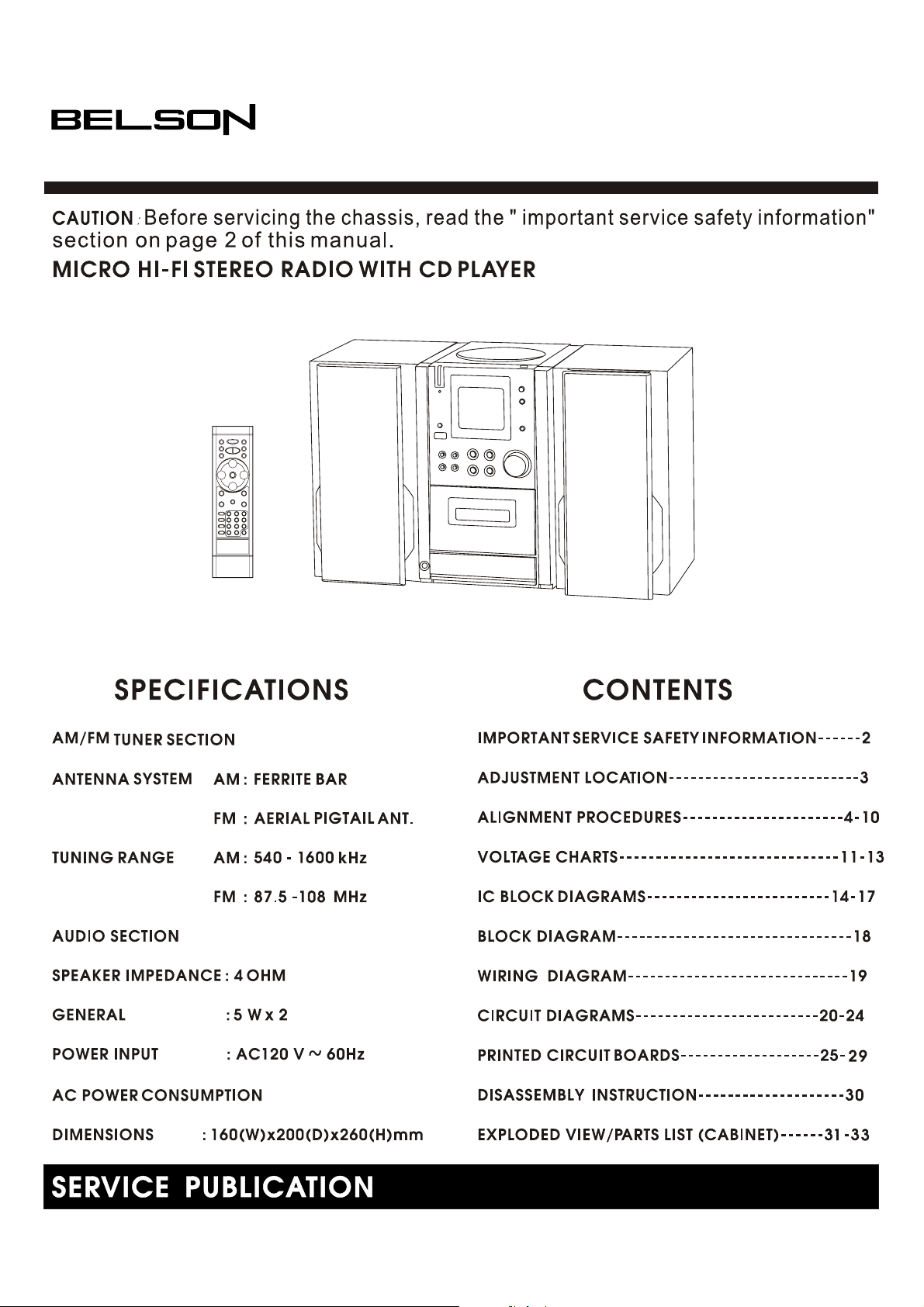

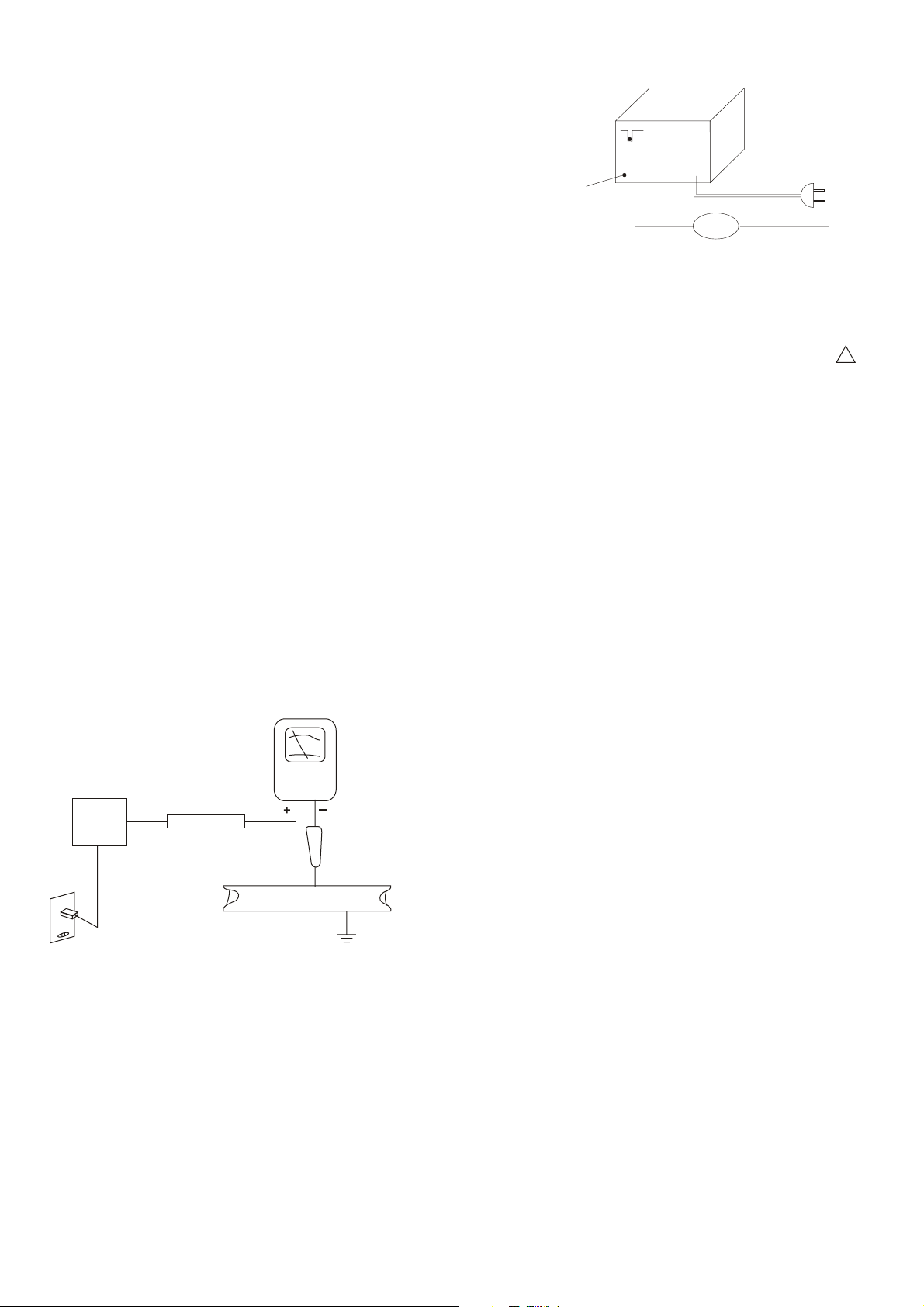

Leakage current hot check - with the unit completely reassembled ,plug the AC

line cord directly into a 120V AC outlet. (Do not use an isolation transformer

During this test.) Use a leakage current tester or a metering system that complies

with American Nationalstandards Institute (ANSI) C101.1"Leakage Current for

Appliances "and Underwriters Laboratories(UL) 1410 (50.7). WITH THE UNITAC

switch first in the ON position And then in the OFF position, measure from a known

earth ground (metal water pipe, conduit, etc.) To all exposed metal parts of the

Unit (antennas, handle bracket, metal cabinet, screw heads , metallic overlays,

control shaft, etc.) Especially any exposed metal parts that offer an

electrical return path to the chassis. Any current measured must not exceed 0.5

milliamp, reverse the unit power cord plug in the outlet and repeat test . ANY

MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HERENIN INDICATE A POTENTIAL

SHOCK HAZARD TAHT MUST BE ELIMINATED RETURNING THE UNIT TO THE CUSTOMER.

D. Insulation resistancetest cold check

unplug the power supply cord and connect a jumper wire between the two prongs

of the plug.

Turn on thepower switch ofthe unit.

Measure the resistance with an ohmmeter between jumpered AC PLUG AND EACH

Exposed metallic cabinet part on the unit, such as screw heads, antenna, control

shafts, handle brackets, etc. When the exposed metallic part has a return path to

the chassis , the reading should be between 1 and 5.2 megohms. When there is

no return path to the chassis, the reading must be "infinite". If it is not within the

limits specified, thereis the possibilityof a shock hazard, and theunit must be

repaired and recheckedbefore it isreturned to the customer.

TEST ALL

EXPOSED METAL

SURFACES

(READING SHOULD

NOT BE ABOVE

0.5mA)

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

DEVICE

UNDER

TEST

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

ANTENNA

TERMINAL

OHMMETER

OM

EXPOSED

METAL

PAR T

!

AC LEAKAGE TEST

2

BSA-1520

ADJUSTMENT LOCATION

3

MODEL:BSA-1520MP3

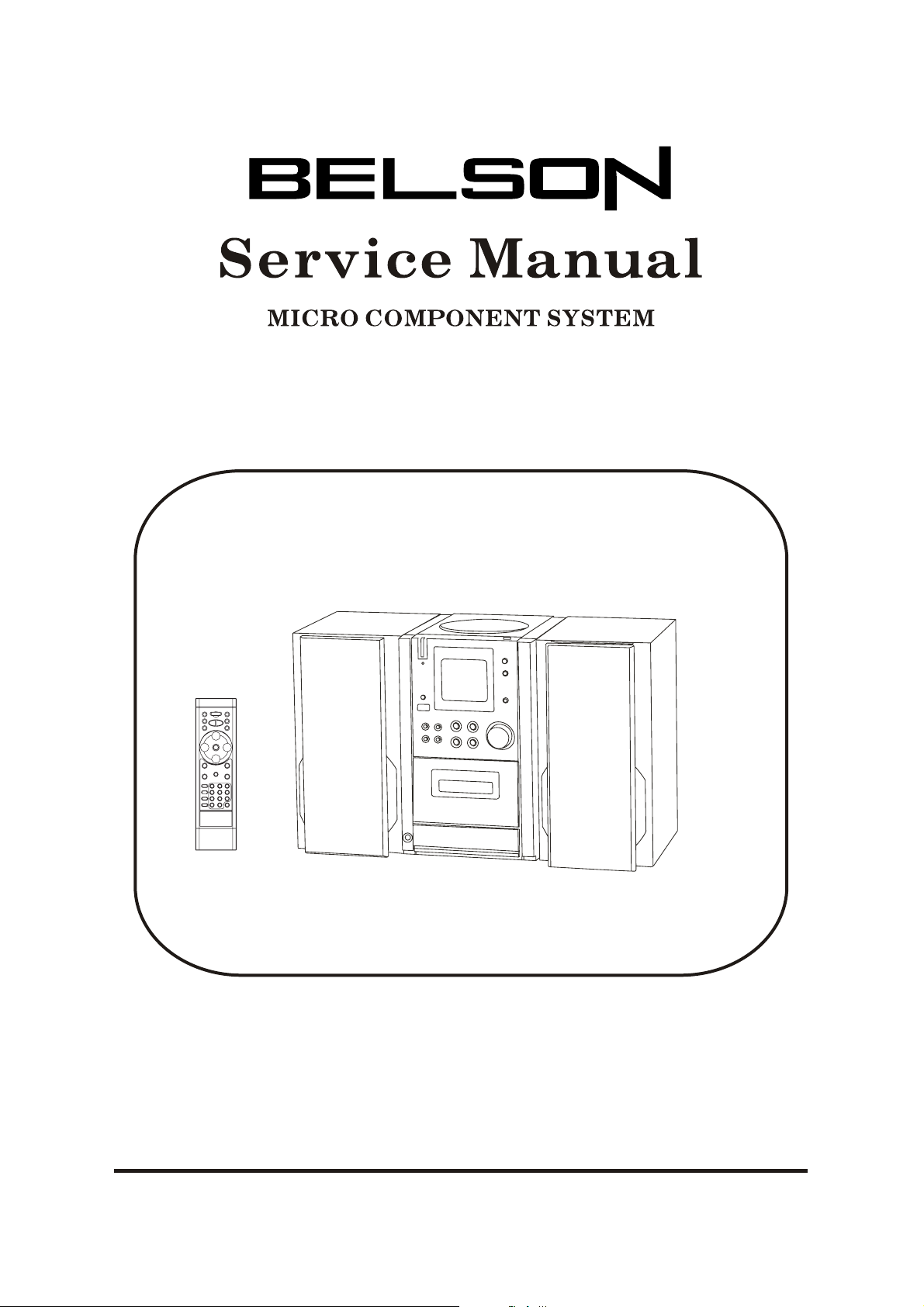

FM AND AM RF ALIGNMENT CHART ( IF ) ˗˴˸ˍ 28-Jul-04

Step item Input Circuit Output Circuit Tuner Adj - Adjustment

Setup Setup setting Point

Unless otherwise specified set switches as follows:

FM Function: FM

Adjust generator frequency to a center of the FM band where no FM broadcast exists

IF Connect FM IF Connect Co19 and GND FM in band Adjust for straight and

˄Adjustment sweep output IF-OUT terminal to end T304 symmetrical S-curve

terminal to IC302 IF sweep input terminal with max.amplitude.

˅FM Headphone jack or 87.5 MHz L303 Adjust L301 for max output

Band setup speaker terminal 108MHz Done

FM SG ANT. Headphone jack or 90.1 MHZ L302 Adjust for max.output and

ˆTracking (1) Terminal 90.1 MHz, speaker terminal MONO best waveform

1kHz, +-22.5kHz dev

ˇTracking (2) 106.1 MHz, 1 kHz Headphone jack or 106.1 MHz CT303 Same as above.

+-22.5 MHz dev speaker terminal

ˈRepeat steps 3 and 4.

MW

IF Connect standard loop Connect input terminal MW in band Adjust tor max. amplitude

˄Adjustment antenna to output ter- genescope to detector end ˧ˆ˃˅ with symmetrical 450 kHz.

minal of genescope output

˅MW Headphone jack or 522 kHz T301 Adjust L135 for max output

Band speaker terminal 1620 kHz CT302 Adjust CT133 for max output

ˆTracking (1) 612 kHz 400 kHz, Headphone jack or 612 kHz T303 Adjust for max.output and

3% mod speaker terminal best waveform

ˇTracking (2) 1404 kHz 400 kHz, Headphone jack or 1404 kHz CT301 Same as above.

3% mod speaker terminal

ˈRepeat steps 3 and 4.

TAPE SECTION

HEAD ADJUSTMENT (AZIMUTH)

10 kHz test tape (example:MTT-114N) must be used for this adjustment. Connect to VTVM or oscilloscope to the head-

phone JCK or speaker terminal Press the play button.

Adjust the azimuth by using a screw driver to maintain the maximum L & R output voltage. Adjust tape. Please secure the

azimuth position by using locking paint.

RECODING BIAS OSCILLATOR FREQUENCY ADJUSTMENT

Connect the frequency counter to of R601 two ends.

Press REC button of tape .

Adjust T201 obtain 60 kHz +-100 HZ

BSA-1520

ALIGNMENT PROCEDURE

4

Table of contents

Other Belson Stereo System manuals