Belt-Way Scales 45 User manual

Page 2 of 40

Conveyor Belt Scale

Product Manual

Safety and Warnings

All Belt-Way components MUST be used as described in this manual!

Please note the labels on the integrator and in the manual denote

dangerous voltage. Failure to take safety precautions may result in

serious injury or death.

The protective conductor terminal (Earth Ground) is signified by the

following label. It must be properly connected to earth ground per

local electrical codes.

Page 3 of 40

Conveyor Belt Scale

Product Manual

Table of Contents

Scale Accessories ...............................................................................5

Integrator Specs & Scale Components .............................................6-8

Mechanical Installation....................................................................9-15

Wiring the Sensors / Integrator Installation...................................................16-21

A. Sensor Board ...................................................................................................................................18

B. Terminal Board with AC Power Supply..............................................................................................19

C. Terminal Board with DC Power Supply..............................................................................................20

D. Integrator Board ..............................................................................................................................21

E. IO Board ..........................................................................................................................................21

Integrator Configuration................................................................ 22-36

A. Integrator Navigation.......................................................................................................................22

B. Setup Wizard ..................................................................................................................................23

C. C. Scale Setup .............................................................................................................................23-24

D. Scale Calibration .........................................................................................................................25-28

Zero Calibration....................................................................................................................................25

Test Weight Calibration ...................................................................................................................26-27

Material Test Calibration ......................................................................................................................28

E. Scale Totals .....................................................................................................................................29

F. Device Setup...............................................................................................................................29-30

Plant Connect.......................................................................................................................................31

G. Administration.................................................................................................................................32

Routine Maintenance .........................................................................33

Diagnostics / Troubleshooting ..................................................... 34-36

Message Icons / Error Messages ...........................................................................................................36

Calibration Logs ........................................................................... 37-38

Product Warranty ..............................................................................39

Page 4 of 40

Conveyor Belt Scale

Product Manual

Introduction

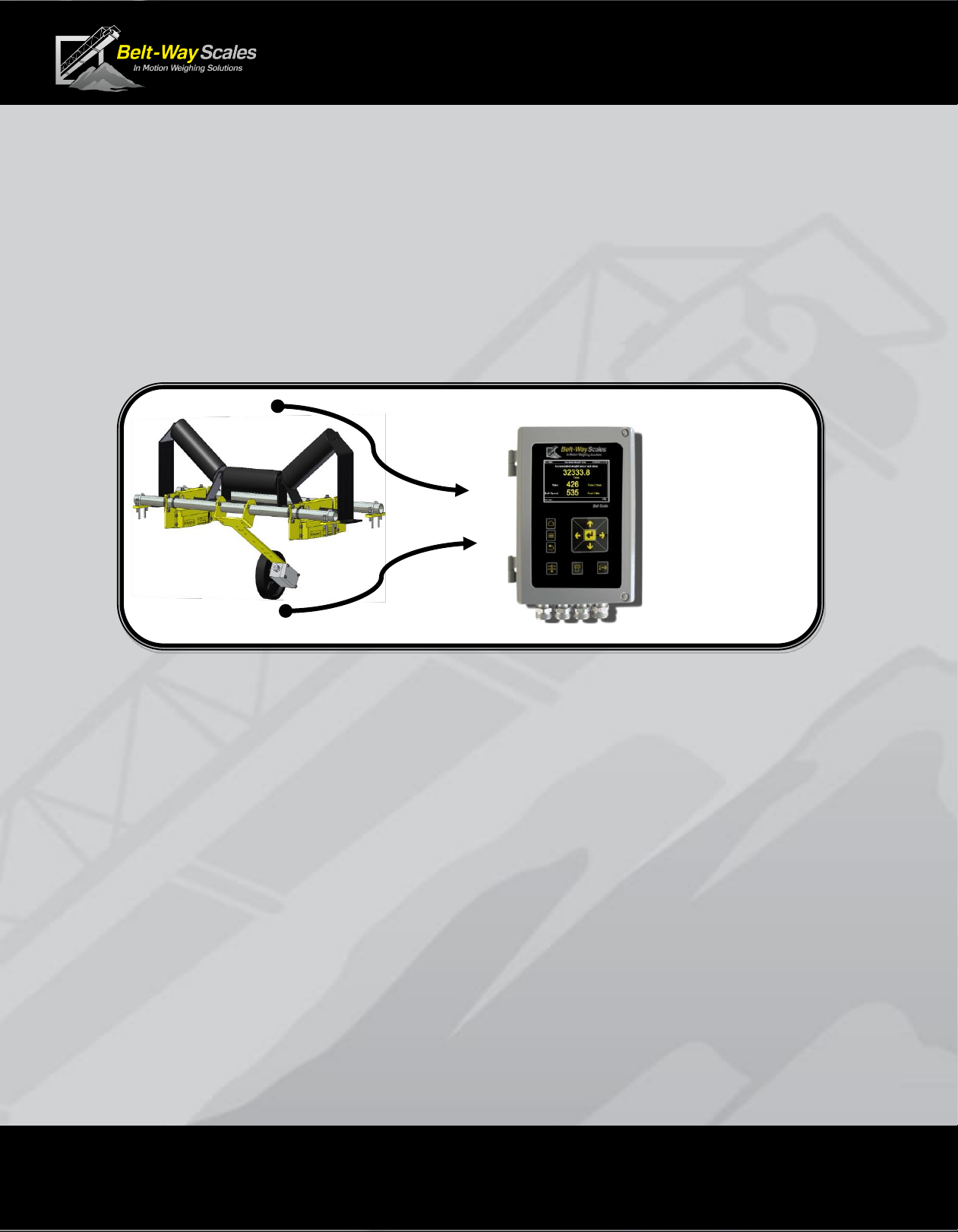

The Belt-Way conveyor belt scale is a highly accurate and cost effective in-

motion weighing system. It is designed to measure material flow over a

conveyor belt in real-time. The primary components are the integrator (AKA,

controller, display, indicator), load cell assemblies, and speed sensor. The

scale system processes speed and load signals to accumulate weight and

calculate flow rate.

This manual covers the following belt scale models:

•Model 45 (Low capacity)

•Model 100, Model 200 (Medium capacity)

•Model 350, Model 500, Model 1000 (High Capacity)

This manual pertains to scales operating on firmware 6.43 and above.

A manual for previous versions may be found at beltwayscales.com

BELT

LOAD

BELT

SPEED

ACCUMULATED

WEIGHT

+

FLOW RATE

Page 5 of 40

Conveyor Belt Scale

Product Manual

Scale Accessories

Call or visit beltwayscales.com for a complete list of all the accessories

that Belt-Way has to offer.

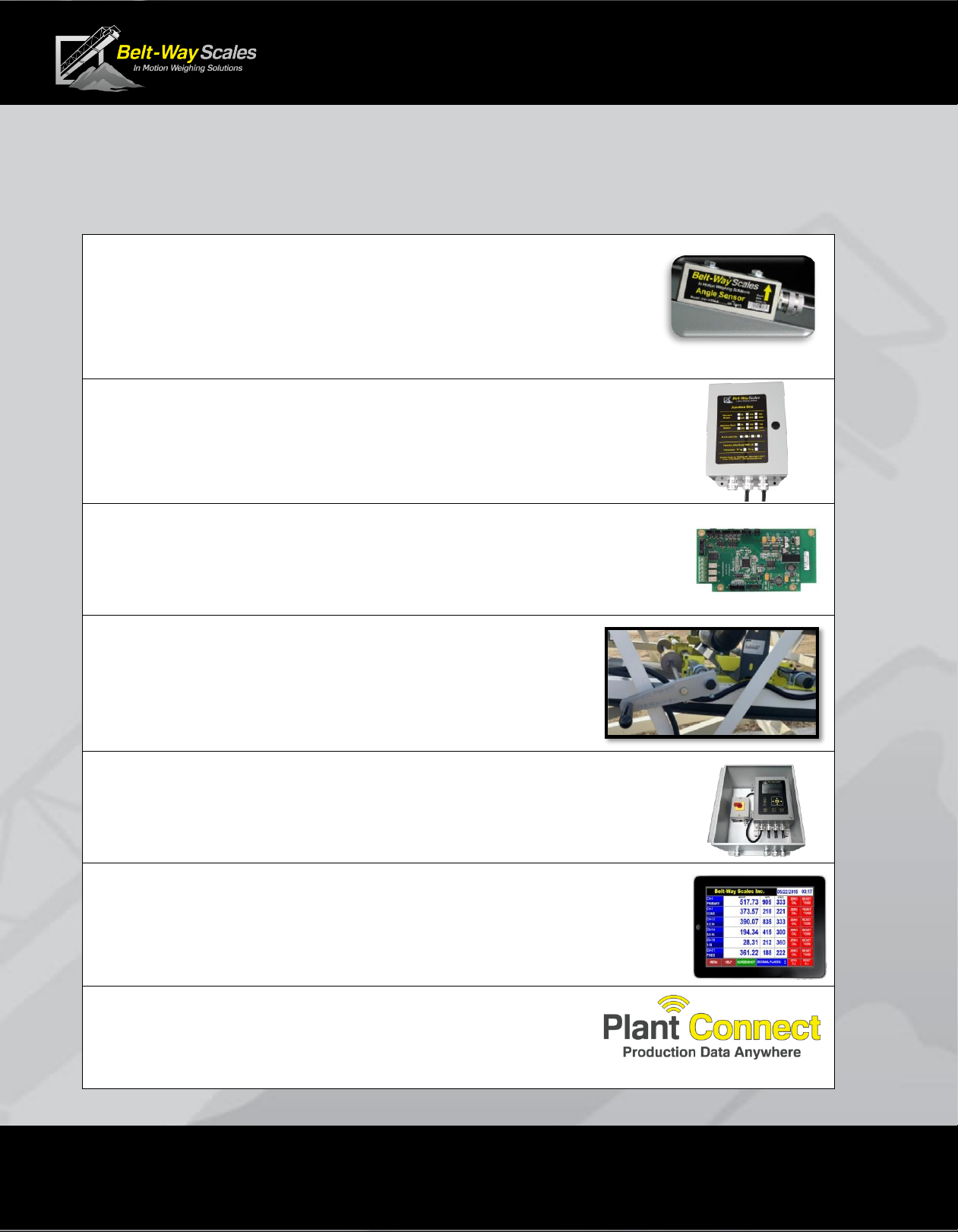

▪Angle Sensor

The angle sensor eliminates the need for constant recalibration

when the scale is installed on a variable angle conveyor or portable

machine.

▪RS485 Junction Box

A Smart junction box can be installed on the conveyor to place

the scale integrator up to 1000 ft. from the scale.

▪IO Board

The IO board allows the scale to interface with a PLC system, automate

loadout of trucks or rail cars, control a VFD, and blend multiple products.

▪Self-Storing Test Weight Kit

The test weight kit remains installed on the conveyor.

It is activated from one side for easy, safe calibration.

▪Outdoor Protection Enclosure

Heavy duty enclosure offers extra protection for the scale integrator.

Includes power switch.

▪Wireless Multi-Scale Remote Display

The remote display allows multiple scales to be viewed from one

location. Monitor production, clear weight, and perform zero calibrations.

Wireless communication makes installation simple and cost effective.

▪Plant Connect - Online Scale Production Reporting

Our Plant-Connect website allows users to monitor belt

scale production on a PC, tablet or smart phone.

Page 6 of 40

Conveyor Belt Scale

Product Manual

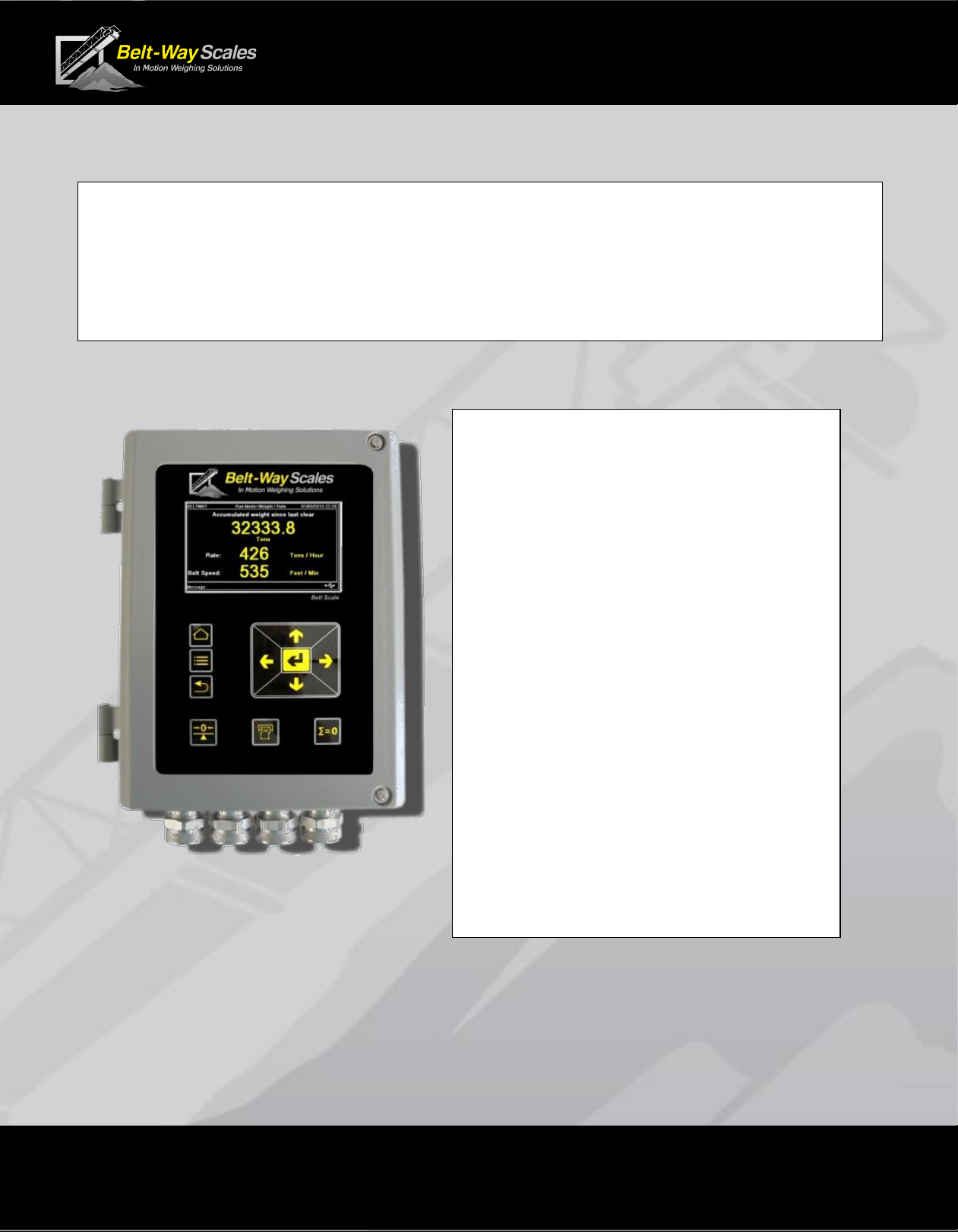

Integrator Specifications

Replacement Part Number: BWINT

100-240 AC Power Supply Factory Installed Part Number: BWPS-AC

100-240 AC Power Supply Field Installation Kit Part Number: BWPSKIT-AC

9-30 DC Power Supply Factory Installed Part Number: BWPS-DC

9-30 DC Power Supply Field Installation Kit Part Number: BWPSKIT-DC

IO Option Board Part Number: BWIO (Factory Installed)

IO Option Board Kit Part Number: BWIOKIT (Field Installed)

Display: 4.3" Color LCD

Enclosure: Cast Aluminum

Operating Temperature: -20C to 45C

Required Power: 12-24 VDC, 55 Watts

optional 110/240 AC power adapter

Inputs: 8 Load Cells (millivolts)

1 Speed Sensor (0-5 VDC Pulse)

1 Angle Sensor (0- 4 VDC)

Outputs: 1 RS232 (Printer Port)

1 RS232 (Display Port)

1 Ethernet Port (Modbus TCP)

1 USB 2.0 Client

Optional IO Outputs:

4-20 mA outputs (Tons Per Hour)

Digital Pulsed Output (Total Weight)

Min / Max Speed

Min / Max Tons Per Hour

Zero Calibration

Loadout

Optional IO Inputs:

Clear Weight

Print Ticket

Zero Calibration

Page 7 of 40

Conveyor Belt Scale

Product Manual

Electrical Ratings

Input Power to

Belt-Way Integrator:

12-30 VDC, 24 VDC 2.25A Max

AC Power option:

Input:100-240VAC 50/60Hz, 1A Max

Output: 24VDC, 2.25A Max

Use of the factory supplied AC Power option is recommended.

AC control power over-current protection with isolated circuit, and

disconnect point such as a breaker or switch box, is recommended.

Conformance to local electrical codes is required.

Digital Inputs:

(IO option installed)

12-24VDC, 50mA sink

Digital Outputs:

(IO option installed)

12 - 24VDC, 100mA sink

Analog Outputs:

(IO option installed)

4-20mA, 24VDC powered loop

Relay Outputs, UL

contact ratings:

(IO option installed)

220VDC, 0.24A, 60W

125VDC, 0.24A, 30W

250VAC, 0.25A, 62.5VA

125VAC, 0.5A, 62.5VA

30VDC, 2A, 60W

Environmental

▪Temperature: Normal operating range -20⁰C to +45⁰C.

▪Humidity: The unit is suitable for outdoor use.

▪Altitude: The unit is suitable for use to elevation of 2000m.

Page 8 of 40

Conveyor Belt Scale

Product Manual

Scale Components

The single idler scale consists of the following components

1 - Integrator

2 - Load Cell

Assemblies

2 - Mounting pipes

1- Hardware Kit

1 - Speed Sensor with

mounting arm

The dual idler scale consists of the following components

1 - Integrator

4 - Load Cell

Assemblies

4 - Mounting pipes

2 –Hardware Kits

1 - Speed Sensor with

mounting arm

Unpacking the Scale

Each scale is comprised of at least three boxes

26” x 10” x 8” - Integrator and Speed Sensor

26” x 10” x 8” - Load Cells and Hardware kit

48”, 60” or 72” long boxes for mounting pipe

and various sizes for angle sensors and other accessories

Page 9 of 40

Conveyor Belt Scale

Product Manual

Mechanical Installation

2D component and installation drawings are available at beltwayscales.com

3D drawings are available by request.

A. Recommended Tools

▪Cutting torch and grinder (remove idler mounting feet)

▪Heavy duty drill or magnetic drill press (drill u-bolt holes)

▪Tape Measure (measure idler distance)

▪Angle finder or phone app (measure conveyor angle)

▪1/2”socket and wrench (load cell and speed sensor brackets)

▪9/16” deep socket and wrench (V-block, u-bolts, leveling bolts)

▪String (to level weighbridge idlers)

▪Shim kit (to adjust idler height)

▪4 way screwdriver (integrator mounting, integrator door, hose clamps)

▪Small Belt-way screwdriver (integrator wiring)

B. Conveyor Design Recommendations

The following design suggestions are essential for best scale accuracy and repeatability.

▪Reduce speed whenever possible to maximize belt load. Slow moving, heavily loaded belts

work better than fast moving, lightly loaded belts.

▪Proper belt tension must result in 1%-2% deflection between idlers.

For example, 2% deflection is 1 inch sag in the belt over a 4 ft. idler spacing.

▪Lower trough angles, 0-35, are preferred. Avoid 45troughed idlers.

▪Install a belt scraper to keep the belt clean.

▪Cover the conveyor to shelter it from wind, rain and snow.

MOUNTING PIPE

AND

LEVELING

PLATES

MODIFIED

CEMA IDLER

LOAD CELL

ASSEMBLIES

SPEED

SENSOR

V-Block

CONVEYOR

FRAME

Page 10 of 40

Conveyor Belt Scale

Product Manual

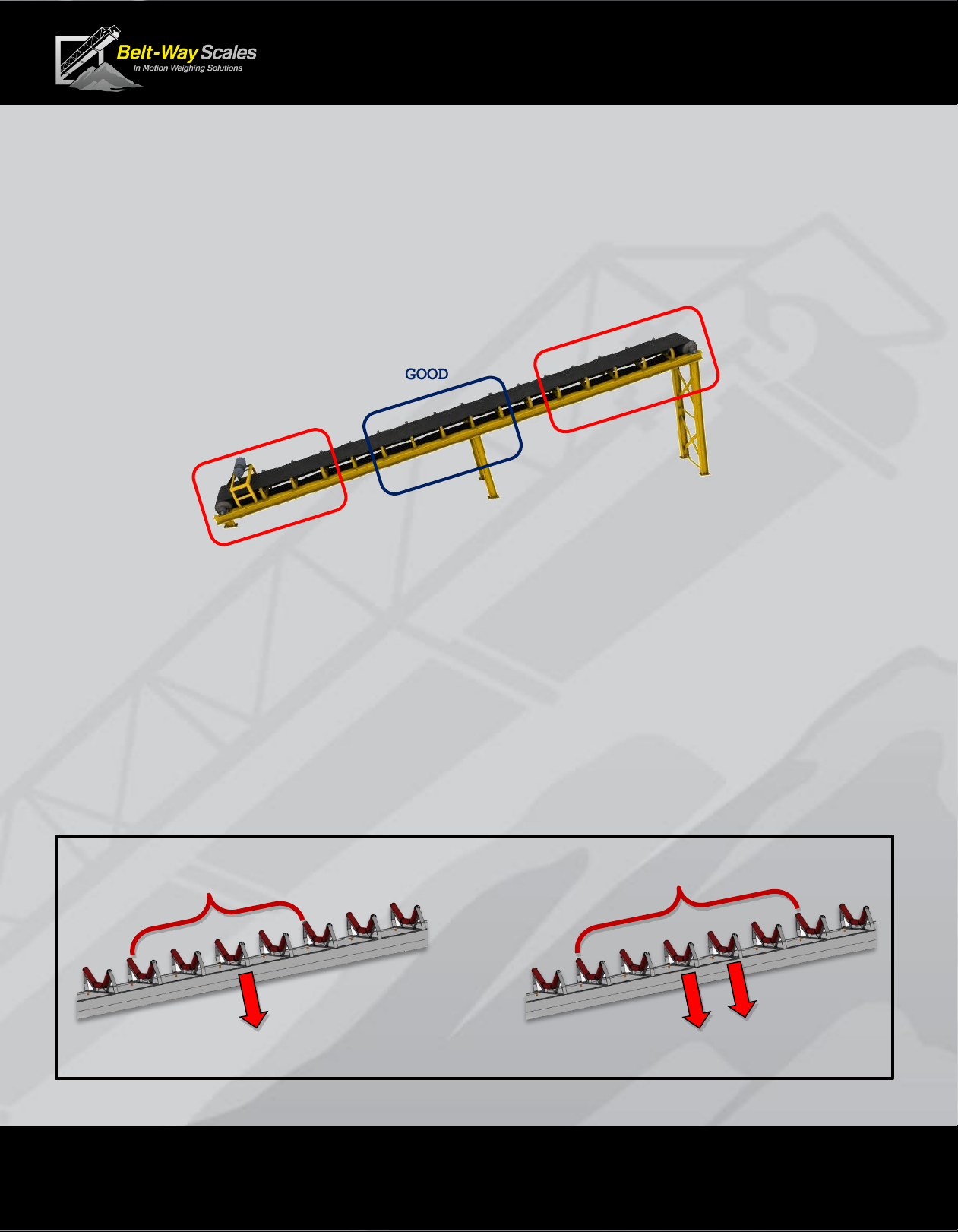

C. Scale Placement

▪Install the scale where it is easily accessible for maintenance purposes.

▪Choose a very rigid section of conveyor such as an idler over a brace.

▪The scale must be at least 40 ft. away from curves in the conveyor.

▪Stay at least three idlers away from the head pulley, tail pulley, and loading points.

Material must not impact the belt near the scale!

D. Define the Weighbridge

The Weighbridge is the section of belt actively being weighed by the scale.

▪The weighbridge idlers must be in good mechanical condition.

▪The weighbridge idlers must be the same trough angle, and diameter.

▪The weighbridge idlers should be an equal distance apart.

▪Skirting should not make contact with the belt in the weighing area.

▪A single idler weighbridge consists of 5 idlers.

Scale must be installed on the center idler

▪The dual idler weighbridge consists of 6 idlers.

The scale must be installed on the 2 center idlers.

GOOD

AVOID

AVOID

5 Idler Weighbridge

Single Idler Scale

6 Idler Weighbridge

Dual Idler Scale

Page 11 of 40

Conveyor Belt Scale

Product Manual

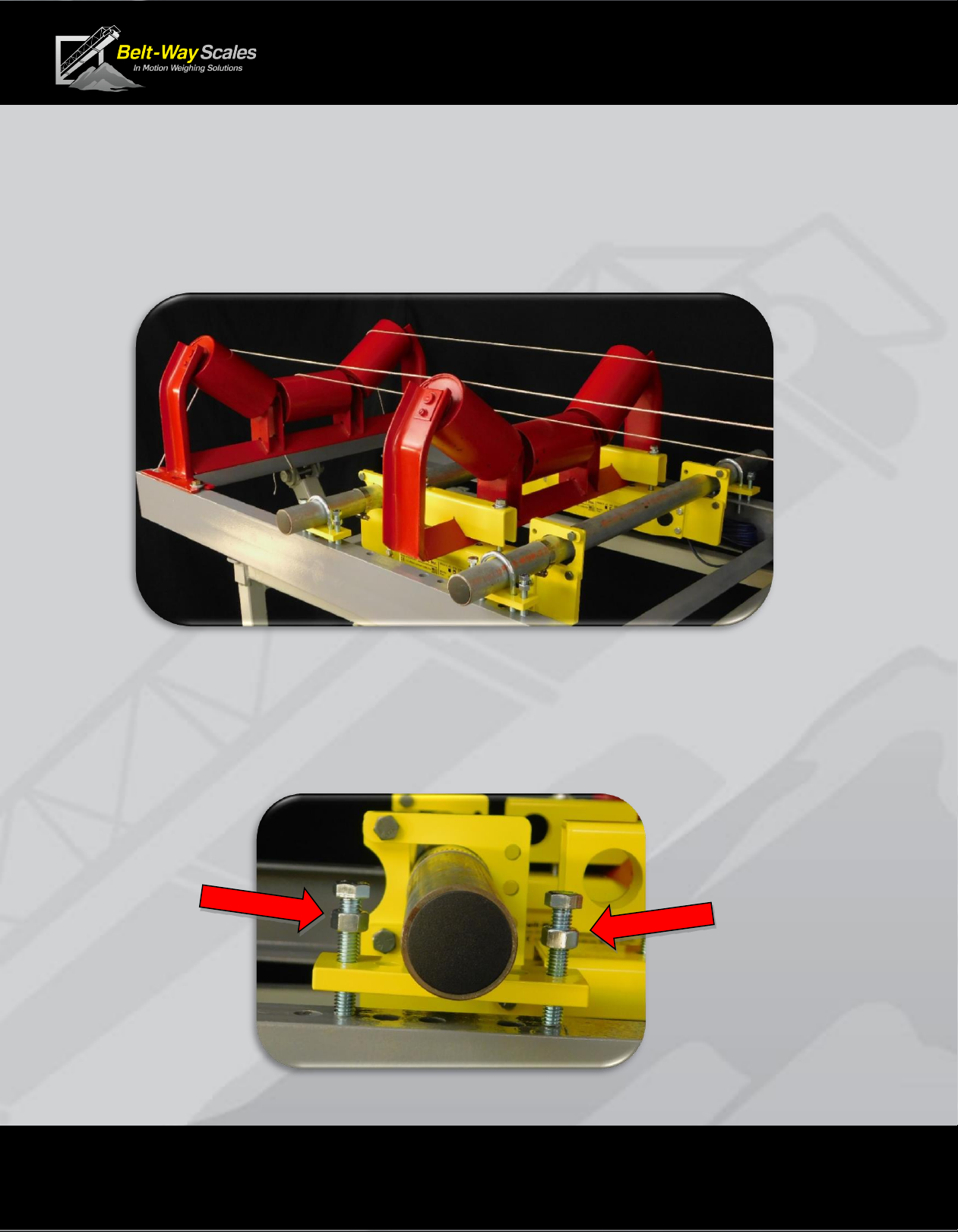

E. Attach Load Cell Assemblies to idler

▪Bolt the load cell assemblies to the idler as shown using the V-Block.

▪The load cell cable should point downhill.

▪Leave plenty of clearance between the load cell assembly and conveyor frame.

▪Do not overtighten the V-Block bolts.

▪The bolts should be tightened ¼ turn after compressing the lock washer.

▪Position the load cell assemblies an equal distance from the conveyor frame.

▪This balances the load of the belt evenly between the load cells.

NOTE: Stainless Steel Load Cells –Do not use a full thread bolt,

or over tighten the existing V-Block bolt on a stainless steel load cell.

This will damage the load cell cable.

Page 12 of 40

Conveyor Belt Scale

Product Manual

F. Install Scale Support Pipes

This step is extremely important to ensure long term scale accuracy.

▪The mounting pipe must touch the strap on the uphill side of load cell assembly.

▪The strap on the downhill side must create an oval opening.

▪Center the pipe in the oval hole.

▪The load cell assembly must be free to move up and down slightly on the pipes.

This eliminates torque on the conveyor frame, which allows automatic alignment

of the weighing elements.

▪Install the four hose clamps onto the pipe with the screw fitting directly over the

top of the pipe, but do not tighten the clamps at this time.

Uphill side:

Retaining strap

fits tightly around the pipe.

Downhill side:

Retaining strap

forms oval hole around the pipe.

Page 13 of 40

Conveyor Belt Scale

Product Manual

G. Drill U-bolt Holes

▪Use the leveling plate as a drill template for the U-bolts.

▪The leveling plates and pipe centers should measure 15”apart.

▪The holes should be at least 7/16” to clear the 3/8” -16 U-bolts.

H. Remove and Modify Idler

▪Unbolt idler from frame.

▪Remove the idler mounting feet to create clearance above the conveyor frame.

▪If the idler feet are not removed, all other weighbridge idlers must be shimmed up 3/8”.

▪Make sure the idler is centered from left to right on the conveyor.

15 inches

15 inches

Page 14 of 40

Conveyor Belt Scale

Product Manual

I. String-Line Idlers to level the Weighbridge:

This is an extremely important step in the installation process.

▪The empty belt must rest uniformly on all idlers within the weighbridge.

▪Use a minimum of three strings to align all 5 or 6 weighbridge idlers.

▪Shim idlers if necessary to bring them into alignment.

▪Use the 3/8-16 leveling bolts to adjust the scale idler height.

▪Tighten U-bolts evenly so pipes remain parallel and oval clearance

around bottom pipe is maintained.

▪Tighten the jam nuts against the leveling plate to lock the pipes in place.

Page 15 of 40

Conveyor Belt Scale

Product Manual

J. Install Hose Clamps:

▪Install the hose clamps on the outside of the load cell

assembly.

▪Leave clearance so the clamps don’t bind between the

pipe and load cell bracket.

▪Rotate the screw barrels away from the gaps between

the hanger brackets and the pipes.

K. Install Speed Sensor Assembly

▪The standard speed sensor assembly may hang

from either pipe. It must point downhill.

▪The wheel must ride smoothly on the belt.

▪Avoid installing it near return idlers that may cause the

wheel to bounce.

▪A small amount of weight may be added to the speed

wheel arm to hold the wheel firmly on the belt.

▪Use two hose clamps to retain the mounting arm .

▪Secure the cable to the arm with cable ties. Route the

cables carefully along the conveyor frame so they are

protected from falling debris and pinch points.

L. Optional Angle Sensor

Any conveyor that frequently changes angle must have an angle sensor installed.

▪Mount the Angle Sensor directly on the conveyor frame.

▪Mount in the direction of the head pulley.

▪Reference the UP arrow indicator on the sensor.

Caution: Excessive vibration

will interfere with Angle Sensor

performance.

Hose Clamps

Page 16 of 40

Conveyor Belt Scale

Product Manual

Wiring the Sensors

A. Extending the sensor cables

▪Standard load cells, speed sensors, and angle sensors have 30 ft cables.

▪50 ft. cables are available upon request for an additional charge.

▪Factory supplied cables may be extended up to 100 ft. in one of four ways:

1.Solder and waterproof a similar shielded cable onto the original.

2.Use a waterproof terminal strip. Do NOT sum multiple load cells into a single

cable. Each load cell must individually connect to the integrator.

3.Belt-Way RS485 Junction box.

4.Belt-Way RS485 Junction box with Quick Disconnect option

▪Distances greater than 100 ft should utilize the Belt-Way RS485 Junction box.

▪Use of any style crimp connector or wire nuts to extend sensor cables is

unacceptable and will void the warranty!

▪Use of unshielded cable is unacceptable and will void the warranty!

B. Connecting the sensors to the integrator or junction box.

C. Connecting the shield wire

Use a small screwdriver to gently pry the connector

out of the terminal strip.

Insert the connector at an angle to snap

It back into place

All sensor wires MUST be connected as shown below.

Properly terminating the shield wire is required to prevent electrical interference.

Route the cable through the rubber grommet

and loop the shield wire back out so it touches the aluminum connector.

Page 17 of 40

Conveyor Belt Scale

Product Manual

Always disconnect power before servicing the integrator.

Make sure you LOCK OUT, TAG OUT and TRY OUT the electrical system before any maintenance

or service. Please follow all Federal, State and Company Safety procedures and policies when

working with this product.

Integrator Installation

The mounting kit includes four mounting feet and four M6 x 1mm x 60mm screws with nuts to attach

mounting feet to the integrator. Customer must supply fasteners from mounting feet to mounting

location. Leave a minimum of 3”clearance on the hinge side to allow the door to open.

The integrator is weatherproof, but should be installed in a

protective enclosure whenever possible.

Physical damage to the integrator is not covered under warranty.

WARNING!

Do not install the integrator where it is subject to vibration.

Damage from vibration is not covered under warranty

Rubber or neoprene should be used to dampen the

effects of vibration. This is especially important on

portable machines. Vibration Mounting Kits are

available from Belt-Way.

Order part number BWVIBRATIONMT.

Integrator

Rubber Mount

Page 18 of 40

Conveyor Belt Scale

Product Manual

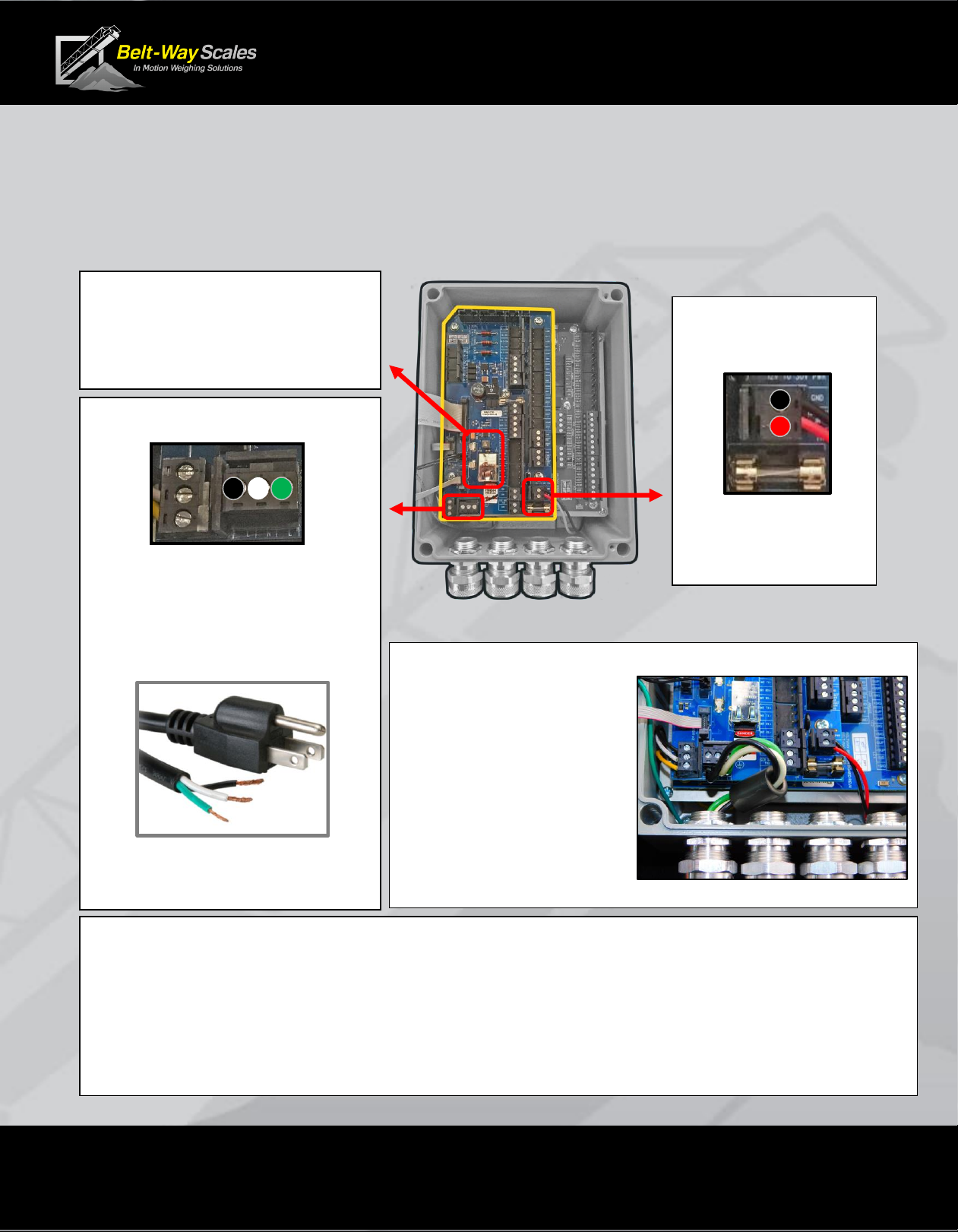

A.Sensor Board

The load cells, the speed sensor, and the angle sensor

all connect to the sensor board unless a junction box is required.

.80 A Fuse

Speed Sensor Wiring

SIGA –GREEN

+5V –RED

GND –BLACK & WHITE

Angle Sensor Wiring

SIG –GREEN

GND - WHITE

+5V –RED

GND - BLACK

Load Cell Wiring

-SUP –BLACK

+SUP –RED

-SIG - WHITE

+SIG –GREEN

A Single Idler Scale must use LC1 and LC2.

A Dual Idler Scale must use LC1 to LC4.

DO NOT SUM THE LOAD CELL WIRES BEFORE

CONNECTING TO THE INTEGRATOR!

The load cells are processed independently and require

individual wires for each load cell connector.

Summing the wires will cause the scale to malfunction.

Page 19 of 40

Conveyor Belt Scale

Product Manual

B.Terminal Board with 110 / 240 AC Power Supply

All power wiring must conform to local and national electrical codes.

Always disconnect power before servicing the integrator.

The AC Power supply is installed below the Sensor Board. It converts 110/240 AC to 24 VDC.

Ethernet Port

Power Over Ethernet 1.25 A Fuse

Only install this fuse when using

a wireless transmitter. See page 21

110 AC - To Power Supply

LINE –BLACK

NEUTRAL - WHITE

EARTH GROUND –GREEN

The user must supply a minimum

16-gauge 3 wire power cord.

Connect to a properly grounded

receptacle that is rated for at least

15 Amps at 110 VAC.

24 VDC

From Power Supply

GND = BLACK

+24V = RED

6 A Fuse

NOTE FOR GENERATOR POWER

A generator may produce unstable power during the startup or shutdown sequence.

The integrator is sensitive to power fluctuations and should be disconnected at startup and

shutdown to prevent data loss. Use a breaker or simply unplug the power cord from the

outlet until the generator is fully powered up.

Ferrite Bead Installation

Each scale includes a

Ferrite Bead to meet

CE emission requirements.

Run all AC wires through

it as shown to the right.

Page 20 of 40

Conveyor Belt Scale

Product Manual

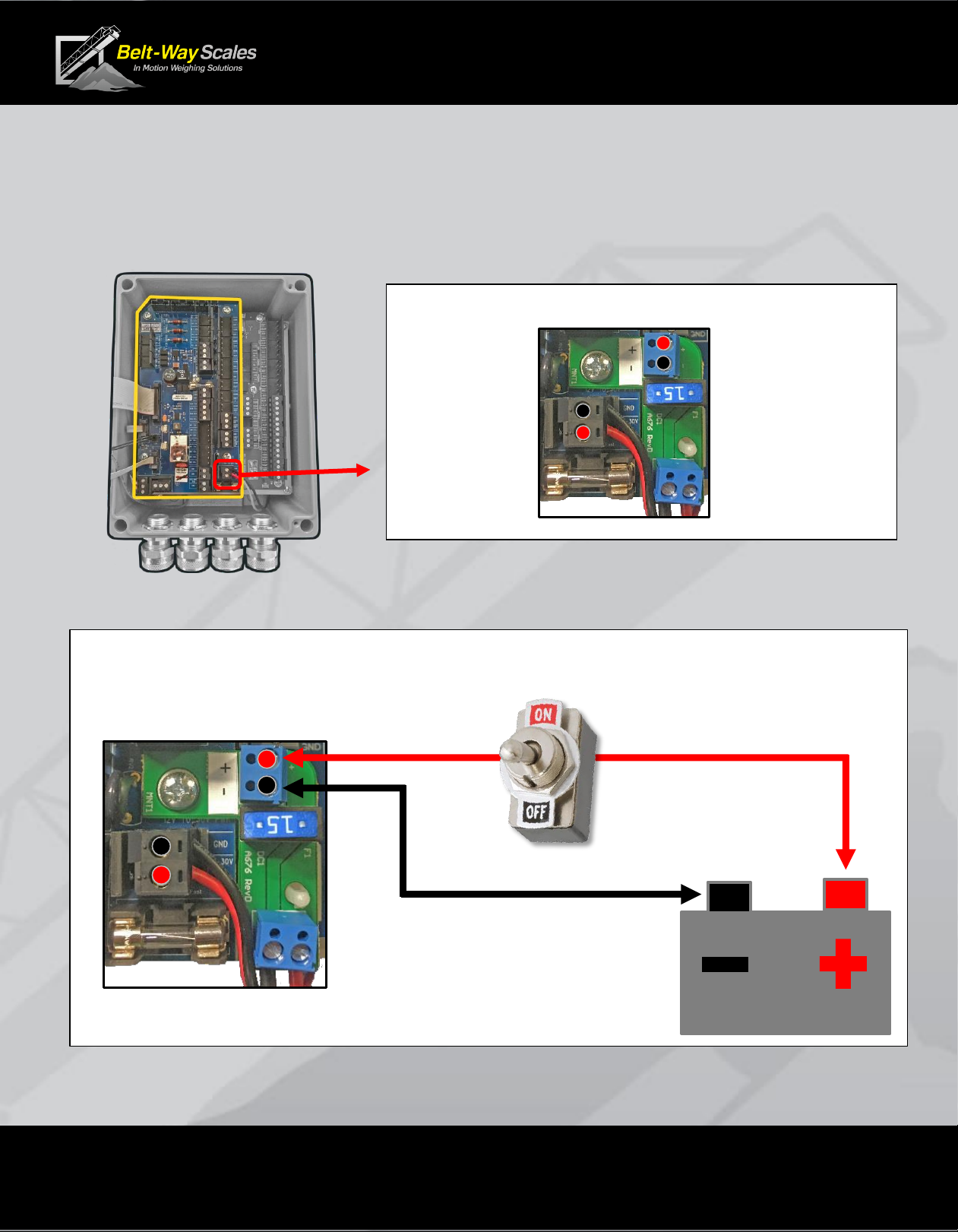

C.Terminal Board with DC Power Supply

The DC Power supply is installed below the Sensor Board.

It boosts 9-24 VDC up to 24 VDC and regulates the voltage during engine cranking.

User should supply a toggle switch to isolate the integrator from the battery.

9-24 VDC Landing Board

+ 9-24 VDC

- VDC

7.5 A Fuse

-VDC = BLACK

+24 VDC = RED Input from Battery

( Output from to Power Supply

Power Supply

To Integrator

This manual suits for next models

5

Table of contents

Other Belt-Way Scales Scale manuals