Bend-Pak Autostacker PL-6SR User manual

1645 Lemonwood Dr.

Santa Paula, CA, 93060 USA

Toll Free (888) 977-8225

Tel: (805) 933-9970

autostacker.com

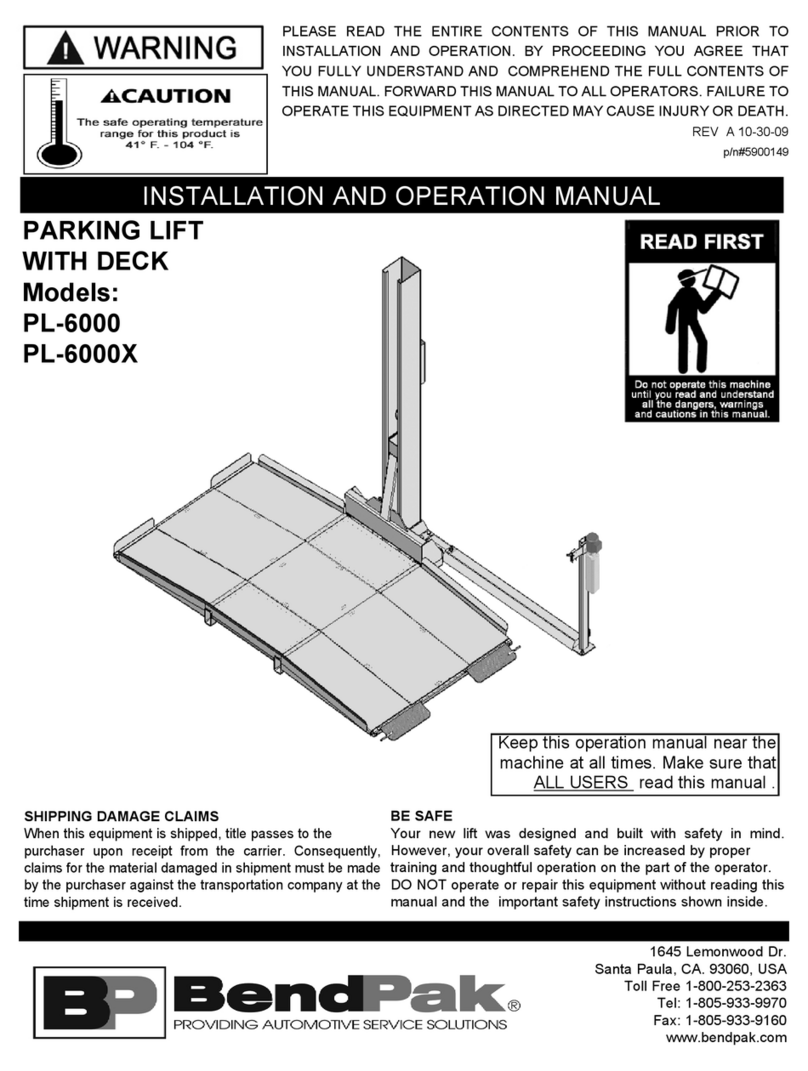

Autostacker™ Parking Lift

Installation and Operation Manual

Manual P/N 5900002 — Manual Revision D — August 2019

Models:

• PL-6SR

• PL-6SRX

U.S. Design Patent No. D814,736

Autostacker is designed and engineered by BendPak Inc. in Southern California, USA. Made in China.

⚠

DANGER

Read the

entire

contents of this Manual

before

using this product. Failure

to follow the instructions and safety precautions in this manual can result in

serious injury or death. Make sure all other operators also read this manual. Keep

the manual near the product for future reference. By proceeding with setup and

operation, you agree that you fully understand the contents of this manual.

Manual. Autostacker Parking Lift, Installation and Operation Manual, Manual P/N 5900002, Manual Revision D,

Released August 2019.

Copyright. Copyright © 2019 by BendPak Inc. All rights reserved. You may make copies of this document if you

agree that: you will give full attribution to BendPak Inc., you will not make changes to the content, you do not gain

any rights to this content, and you will not use the copies for commercial purposes.

Trademarks. BendPak and the BendPak logo are registered trademarks of BendPak Inc. Autostacker is a

trademark of BendPak Inc. All other company, product, and service names are used for identification only. All

trademarks and registered trademarks mentioned in this manual are the property of their respective owners.

Limitations. Every effort has been made to ensure complete and accurate instructions are included in this

manual. However, product updates, revisions, and/or changes may have occurred since this manual was

published. BendPak reserves the right to change any information in this manual without incurring any obligation for

equipment previously or subsequently sold. BendPak is not responsible for typographical errors in this manual.

You can always find the latest version of the manual for your product on the Autostacker website.

Warranty. The Autostacker warranty is more than a commitment to you: it is also a commitment to the value of

your new product. For full warranty details, contact your nearest Autostacker dealer or visit

autostacker.com/support/warranty.

Safety.Your product was designed and manufactured with safety in mind. Your safety also depends on proper

training and thoughtful operation. Do not set up, operate, maintain, or repair the unit without reading and

understanding this manual and the labels on the unit;

do not use this product unless you can do so

safely!

Owner Responsibility. In order to ensure operator safety and maintain your product properly, it is the

responsibility of the product owner to read and follow these instructions:

• Follow all setup, operation, and maintenance instructions.

• Make sure product setup conforms to all applicable local, state, and federal codes, rules, and regulations,

such as state and federal OSHA regulations and electrical codes.

• Read and follow all safety instructions. Keep them readily available for operators.

• Make sure all operators are properly trained, know how to safely operate the unit, and are properly supervised.

• Do not operate the product until you are certain that all parts are in place and operating correctly.

• Carefully inspect the product on a regular basis and perform all maintenance as required.

• Service and maintain the unit only with approved replacement parts.

• Keep all instructions permanently with the product and make sure all labels are clean and visible.

• Only use this product if it can be used safely!

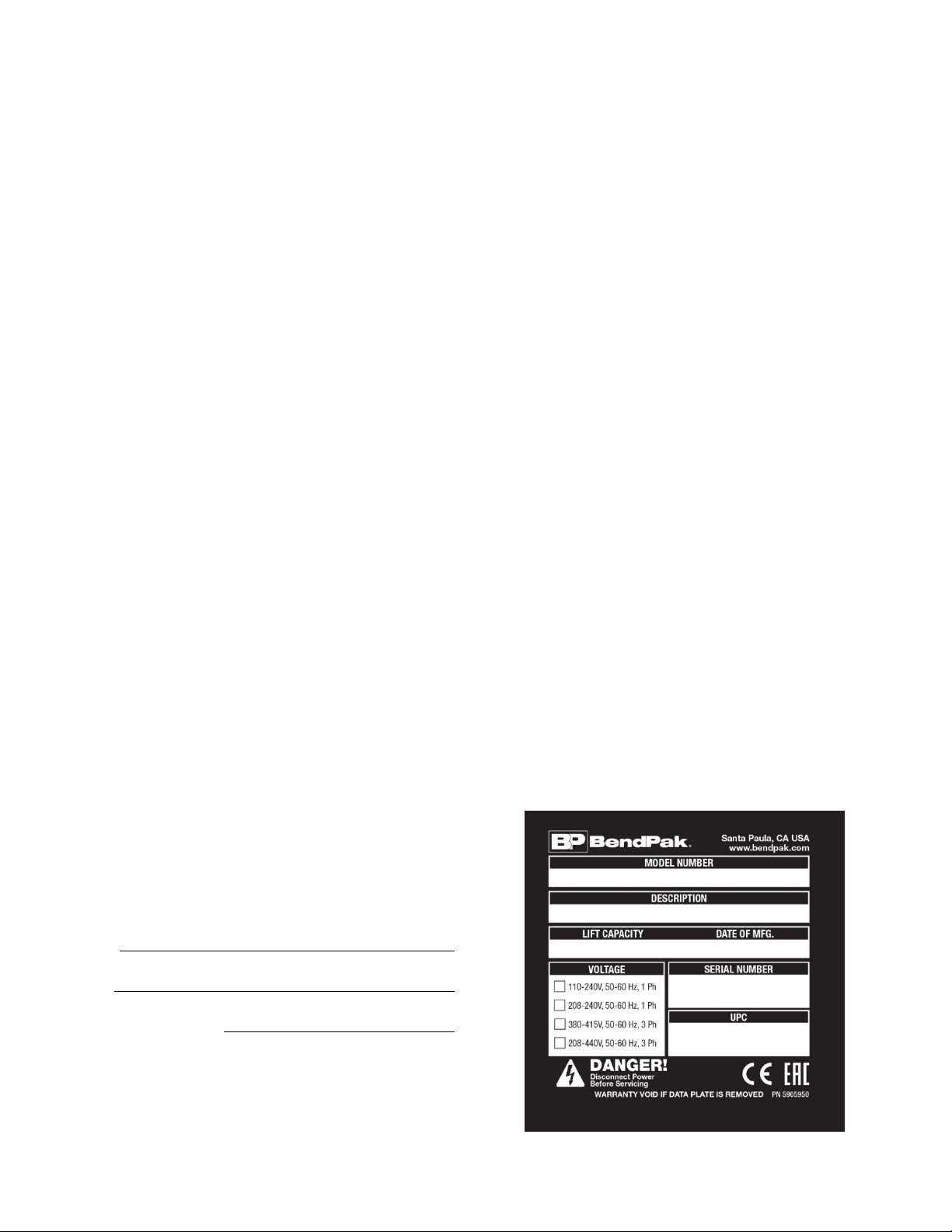

Unit Information. Enter the Model Number, Serial

Number, and the Date of Manufacture from the label

on your unit. This information is required for part or

warranty issues.

Model:

Serial:

Date of Manufacture:

Autostacker™ Parking Lift 3P/N 5900002 — Rev. D — August 2019

Table of Contents

Introduction 3 Installation 13

Shipping Information 4 Operation 41

Safety Considerations 4 Maintenance 47

FAQ 6 Troubleshooting 48

Specifications 7 Multi-Autostacker 51

Components 8 Wiring Diagrams 68

Will My Cars Fit? 10 Labels 74

Orientation 11 Parts Diagrams 80

Installation Checklist 12

Introduction

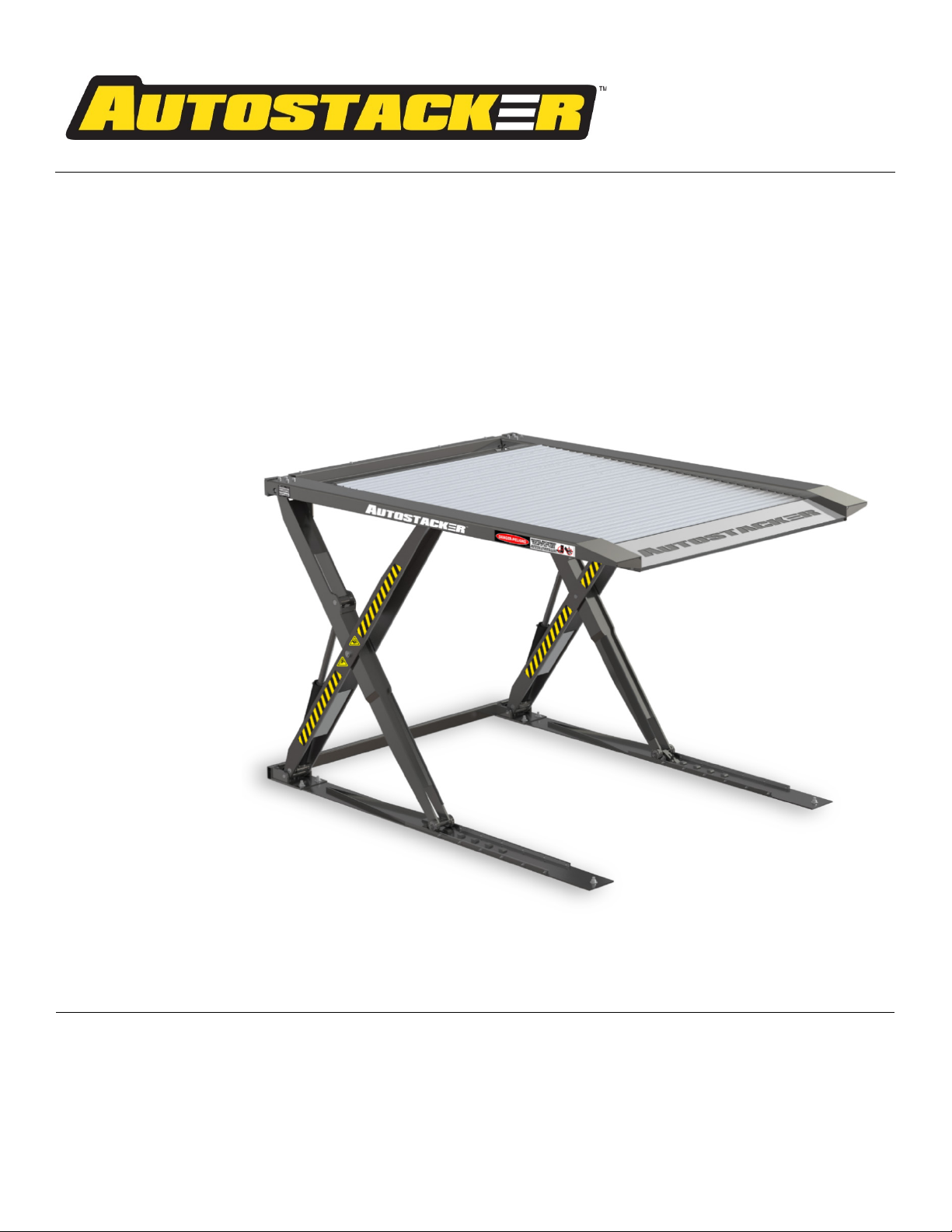

This manual describes both Autostacker versions, which can easily and quickly raise a Vehicle so that

you can park a second Vehicle underneath.

Autostacker raises Vehicles up to 6,000 lbs (2,722 kg). For more information about Autostacker, visit

autostacker.com.

Autostacker is available in two versions:

•PL-6SR. Parking Lift that allows you to make a parking spot that holds just one Vehicle into a

parking spot that holds two Vehicles, lifting vehicles up to 6,000 lbs (2,722 kg).

•PL-6SRX. Wide version of the PL-6SR, with an extra 8 inches of width for your Vehicles.

Autostacker is available in a

Multi-Lift

configuration, where you can control up to 12 Lifts using a

single Master Power Unit.

Unless specifically stated, the setup for each Autostacker in a Multi-Lift configuration follows the same

installation process as a single Autostacker. The main differences include separate procedures for

routing the Hydraulic Hoses and Return Line to a Master Power Unit, in addition to installing a Control

Stand to each Lift that allows you to operate a specific Lift in your lineup; see Multi-Autostacker

towards the end of this manual for those modified procedures and any additional information.

After you have completed those modified procedures, continue the remainder of the installation as you

would with a single Autostacker; see the Installation Checklist for an overview of the installation

process.

This Manual is mandatory reading for

all Autostacker Lift installers and users

.

Autostacker™ Parking Lift 4P/N 5900002 — Rev. D — August 2019

⚠DANGER Be very careful when setting up, operating, maintaining, or repairing this equipment;

failure to do so could result in property damage, product damage, injury, or (in very

rare cases) death. Make sure only authorized personnel operate this equipment. All

repairs must be performed by an authorized technician. Do not make modifications

to the unit; this voids the warranty and increases the chances of injury or property

damage. Make sure to read and follow the instructions on the labels on the unit.

Keep this manual on or near the equipment so that anyone who uses or services it can read it.

Technical support for your product is available directly from your distributor or you can contact

parts (please have the serial number and model number of your unit available).

Shipping Information

Your equipment was carefully checked before shipping. Nevertheless, you should always thoroughly

inspect the shipment before you sign to acknowledge that you received it.

When you sign the bill of lading, it tells the carrier that the items on the invoice were received in good

condition.

Do not sign the bill of lading until

after

you have inspected the shipment.

If any of the

items listed on the bill of lading are missing or damaged, do not accept the shipment until the carrier

makes a notation on the bill of lading that lists the missing and/or damaged goods.

If you discover missing or damaged goods

after

you receive the shipment and have signed the bill of

lading, notify the carrier at once and request the carrier to make an inspection. If the carrier will not

make an inspection, prepare a signed statement to the effect that you have notified the carrier (on a

specific date) and that the carrier has failed to comply with your request.

It is difficult to collect for loss or damage after you have given the carrier a signed bill of lading. If this

happens to you, file a claim with the carrier promptly. Support your claim with copies of the bill of

lading, freight bill, invoice, and photographs, if available. Our willingness to assist in helping you

process your claim does not make us responsible for collection of claims or replacement of lost or

damaged materials.

Safety Considerations

Read this manual carefully before using your new product.

Do not set up or operate

the product until you are familiar with all operating instructions and warnings. Do not allow anyone else

to operate the product until they are also familiar with all operating instructions and warnings.

General Safety Information

Please note the following:

•The product is a Parking Lift. Use it only for its intended purpose. Do not make any

modifications.

•The product must only be operated by authorized personnel.

•Always wear appropriate protective clothing when installing, servicing, or repairing your

Autostacker.

Autostacker™ Parking Lift 5P/N 5900002 — Rev. D — August 2019

•Keep loads centered and balanced on the Platform. Do not overload the rear side; Autostacker is

designed to support an equal load.

•Use caution when driving onto the Platform with a Vehicle with wet tires.

•When the product is in use, keep all body parts away from it.

•Do not leave the area or the Autostacker without confirming that each Leg Base is secured on a

Safety Lock.

•Make sure all operators read and understand the Installation and Operation Manual. Keep the

manual near the device at all times.

•Make a visual inspection of the product before using it. Check for damaged or missing parts. Do

not use the product if you find any issues. Instead, take it out of service, then contact your

distributor, or Autostacker at autostacker.com/support or support@autostacker.com.

•Make a thorough inspection of the product at least once a year. Replace any damaged or severely

worn parts, decals, or warning labels.

Symbols

Following are the symbols used in this manual:

⚠DANGER Calls attention to an immediate hazard that will result in injury or death.

⚠WARNING Calls attention to a hazard or unsafe practice that could result in injury or death.

⚠CAUTION Calls attention to a hazard or unsafe practice that could result in minor personal

injury, product, or property damage.

NOTICE Calls attention to a situation that, if not avoided, could result in product or property

damage.

Tip Calls attention to information that can help you use your product better.

Liability Information

BendPak Inc. assumes no liability for damages resulting from:

• Use of the product for purposes other than those described in this manual.

• Modifications to the equipment without prior, written permission from BendPak Inc.

• Damage to the equipment from external influences.

• Incorrect operation of the equipment.

Autostacker™ Parking Lift 6P/N 5900002 — Rev. D — August 2019

Frequently Asked Questions

Question: What kinds of Vehicles is Autostacker designed for?

Answer: Autostacker is designed for cars, light trucks, and SUVs.

Q: Why is the Platform angled?

A: The angled Platform allows low-profile Vehicles to drive directly onto the Platform without scraping.

Q: How high does my garage ceiling have to be to use Autostacker?

A: Autostacker works great with ceilings as low as 10 feet. However, the height of the ceiling does

impact what cars you can park on the Lift. Refer to Will My Car Fit? for complete information.

Q: Can I put the Console on either side of the Autostacker?

A: Yes. The included Hydraulic Hoses are long enough to support the Console being up to 30 inches

away on either side. If you want, you could go to your local hydraulics shop and get longer, custom-

made Hydraulic Hoses that give you greater latitude for where you put your Console. Remember that

the operator

must

be able to see both the Autostacker and the area around it, for safety purposes.

Make sure to cover the Hydraulic Hoses once they are installed.

Q: Does it matter if I drive my vehicles in straight or back them in?

A: No, Autostacker works great either way. For the Vehicle

on

the Platform, make sure the wheels are

in the Tire Trough, whichever direction you drive it on. For the Vehicle

under

the Platform, put it in

whichever direction makes it easier to open the doors. Note that it is not required that you drive your

under Vehicle all the way underneath the Platform; for some Vehicles, opening the doors is easier if you

only drive part way in.

Q: Can Autostacker be installed outside?

A: Yes, but the Lift is designed for indoor installation, so there are some additional things you will need

to do; cover the Console, put a canopy over the Lift, keep it clean and dry, and increase maintenance.

Contact BendPak Customer Service (via the web bendpak.com/support, via email

techsupport@bendpak.com, or via phone (800) 253-2363 for additional information.

Q: How long can I leave a Vehicle raised on the Autostacker?

A: As long as you want,

if it is engaged on a Safety Lock

. Autostacker is great for storage in any

condition, long or short-term.

Q: Can I change the oil on the Vehicle raised on the Autostacker?

A: Yes; the optional Access Panel gives you access to the underside of the Vehicle that is raised,

making your parking lift into a service lift as well. Each Access Panel works in place of three Platform

sections and you can install up to two access panels per Autostacker.

Q: How many Lifts can be supported by the Master Power Unit?

A: The Master Power Unit can support up to 12 Autostacker Lifts, although

only one Lift can be

raised and lowered at a time

.

Autostacker™ Parking Lift 7P/N 5900002 — Rev. D — August 2019

Specifications

Specifications PL-6SR PL-6SRX

Lifting capacity 6,000 lbs. / 2,722 kg

ATotal width 103" (8.6 feet) / 2,620 mm 111" (9.3 feet) / 2.815 mm

BPlatform width 83.75" (7 feet) / 2,127 mm 91.75" (7.7 feet) / 2,331 mm

CDrive-thru width 83" (7 feet) / 2,112 mm 90.75" (7.7 feet) / 2,305 mm

DOverall length 143" (12 feet) / 3640 mm

EPlatform plus ramp 143" (12 feet) / 3,632 mm

Platform only 129" (10.7 feet) / 3,274 mm

Maximum wheelbase 132" (11 feet) / 3,352 mm

Maximum underclearance 80" (6.7 feet) / 2,032 mm

Top Safety Lock 81" (6.9 feet) / 2,057 mm

Ramp height 2" / 50.75 mm

Rise/Lower Speed 55 seconds / 35 seconds

Motor • 220 VAC at 50 Hz, 208-230 VAC at 60 Hz, 1 Ph

• 380 VAC at 50 Hz, 3 Ph

• 110 VAC at 50/60Hz, 1 Ph

If you have a

Multi-Lift

setup, see Multi-Autostacker for modified specifications.

Autostacker™ Parking Lift 8P/N 5900002 — Rev. D — August 2019

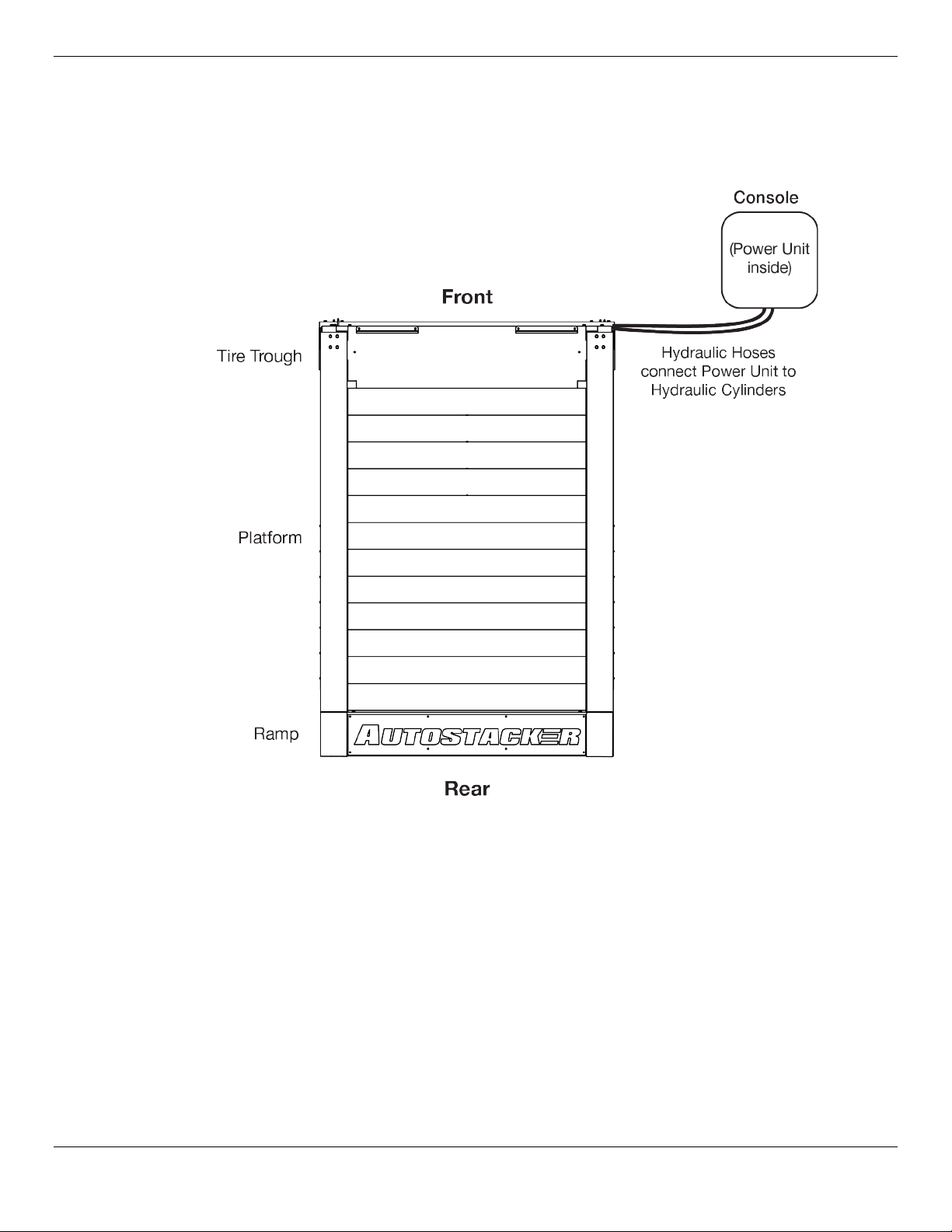

Components

Autostacker components include:

•Console. Hosts the Controls for your Autostacker and the Power Unit. The Console is designed

to go on either side of the front of the Autostacker. The included Hydraulic Hoses let you put the

Console up to 30 inches away from the Autostacker. For a Single-Lift setup.

•Platform. Angled metallic deck that holds Vehicles. The Platform has the Tire Trough at one end

(the front) and the Drive-Up Ramp at the other end (the back).

•Drive-Up Ramp. Gives you access to the Platform. Note that the Tires of the Vehicle you are

parking on the Platform can be placed on the Drive-Up Ramp.

•Tire Trough. Lowered section of the Platform that holds the Vehicle’s tires. The Tire Trough

functions as tire chocks, so it is very important that the wheels of the Vehicle sit fully in the Tire

Trough.

•Patented Door-sentry™ car door protectors. Protects the car doors of the Vehicle parked

under the Platform. You should carefully open the car doors of the Vehicle parked under the

Platform, but the car-door protectors are there in case of contact.

•Leg Assemblies. The Autostacker comes partially assembled, making installation easier and

faster. There are two Leg Assemblies, left and right. Each Leg Assembly has a Platform Arm, Leg,

Cylinder, and Base. Note that the two Leg Assemblies are heavy and can damage materials like

tile, sandstone, and brick if not handled correctly; you must use a lifting device like a Forklift or

Shop Crane to move the Leg Assemblies.

•Left and Right Legs. Part of a Leg Assembly, they raise and lower the Platform.

•Safety Locks. Hold the Platform in place while it is raised. Multiple Safety Locks let you select

the right Platform height for your needs.

Only leave your Autostacker on the ground or

on the Safety Locks.

•Top Safety Lock. Provides the most space for the Vehicle under the Platform. The heights of all

six Safety Locks are listed in Raising a Vehicle.

•Lowest Safety Lock. Provides the most space for the Vehicle on the Platform.

•Left and right Cylinders. Also part of a Leg Assembly, they move the Legs up and down using

hydraulic power. The Cylinders are synchronized so that raising and lowering the Platform is even,

smooth, and rapid.

•Top and Bottom Connector Tubes. Located at the front of the Lift, the Connector Tubes

hold the Autostacker superstructure together. The Bottom Connector Tube is hollow; the Hydraulic

Hoses and the Return Lines are routed to the Console through the Bottom Connector Tube.

•Hydraulic Hoses. The Hydraulic Hoses provide hydraulic power to the Hydraulic Cylinders,

which they use to raise and lower the Lift.

•Return Line. Returns extra Hydraulic Fluid to the reservoir on the Power Unit. Connect to the top

of the Hydraulic Cylinders.

•Velocity Fuse. Prevents the Hydraulic System from failing in the event of a sudden, catastrophic

loss of Hydraulic Fluid pressure; if a Hydraulic Hose were accidentally cut, for example, while the

Platform was raised with a Vehicle on it.

•Rubber Padding. Offers padded protection if you accidentally bump your head into the Platform

Arm when passing underneath the Platform. One per Leg Assembly.

•Conduit Tube. Not shown. Used for routing electrical wiring if you have a Control Stand at the

Rear of the Lift. For a Multi-Autostacker setup; see Multi-Autostacker for additional information.

•Control Stand. Not shown. Holds the Controls to operate a specific Lift in a Multi-Lift setup, and

can be placed at the Front or Rear of the Lift. See Multi-Autostacker for additional information.

•Safety Placard. Not shown. Includes safety and operation instructions; attaches to the Control

Stand. See Multi-Autostacker additional information.

Autostacker™ Parking Lift 9P/N 5900002 — Rev. D — August 2019

The following drawing shows the two possible locations for the Lift Controls: The Console for a

Single-Lift configuration versus the Control Stand for a Multi-Lift configuration.

Console:

Control Stand:

Autostacker™ Parking Lift 10 P/N 5900002 — Rev. D — August 2019

Will My Cars Fit?

The Autostacker accommodates a wide variety of cars, light trucks, and SUVs. This section describes

how to get wider, longer, and taller Vehicles onto your Autostacker.

Width

Considerations for Vehicle width include:

•Platform width. The width from the outside of the left tires to the outside of the right tires cannot

exceed the width of the Platform. The tires

must

fit on the Autostacker Platform.

•Mirrors. Mirrors and other accessories may mean that some parts of a Vehicle are much wider

than the tires of the Vehicle. This is generally not a problem on a raised Vehicle, but should be

taken into consideration for Vehicles being parked under the Autostacker.

•Doors. Opening car doors makes the Vehicle wider while they are open. If opening Vehicle doors

is an issue, try driving in the Vehicle in the other direction. Autostacker Legs have Door-sentry car

door protectors, which limit problems if a door does contact an Autostacker Leg.

Length

Considerations for Vehicle length include:

•Vehicle wheelbase. Vehicles that get raised on the Platform must have one set of wheels in the

Tire Trough and the other set on the Platform itself.

•Overhang. If a Vehicle’s wheelbase fits on the Platform, then any overhanging parts of the Vehicle

outside the wheelbase are not an issue.

Height

Considerations for Vehicle height include:

•Ceiling height. The height of the ceiling determines how much space you have for the two

Vehicles. If you want to park both a tall Vehicle on and under your Autostacker, your ceiling needs

to be higher than if you want to park two low-slung Vehicles.

•Formula. There’s a formula for figuring out how high a ceiling you need.

Height of Vehicle on Platform +16 inches +Safety Lock height

For example: Say you have a 2017 Camaro and a 2017 Toyota Camry. The Camry is 58 inches

high, the Camaro is 53 inches. If you want the Camry under the Platform and the Camaro on it, the

formula would be 53 +16 +65.75 (fourth Safety Lock) = 134.75 inches. If you have a 12 foot high

ceiling, you have 144 inches to use, so this combination would fit fine.

The 16 inch figure includes the height of the Platform plus the height needed to raise the Lift off of

the Safety Lock. Note this figure is a rough estimate, for calculation purposes only.

⚠CAUTION We recommend double checking your ceiling and Vehicle heights before raising a

Vehicle on the Autostacker Platform.

Be especially vigilant the first time

you raise a particular Vehicle!

No one wants to see the roof of their Vehicle

make contact with the ceiling. Use the Emergency Stop button if necessary.

Autostacker™ Parking Lift 11 P/N 5900002 — Rev. D — August 2019

Orientation

The following diagram shows the Console on the right side; it can be placed on either side up to 30

inches away from the Lift.

Not all components are shown. Drawing not necessarily to scale.

Autostacker™ Parking Lift 12 P/N 5900002 — Rev. D — August 2019

Installation Checklist

Following are the steps needed to install an Autostacker; perform them in this order.

☐1. Review the installation Safety Rules.

☐2. Make sure you have the necessary Tools.

☐3. Plan for Electrical Work.

☐4. Select the installation site.

☐4. Check Clearances around the Lift.

☐5. Create a floor plan.

☐6. Position the Leg Assemblies and other components.

☐7. Attach the Bottom and Top Connector Tubes.

*

☐8. Anchor the Bases to the ground.

☐9. Set up the Console and attach the Power Unit.

*

☐10. Connect the Hydraulic Hoses.

*

☐11. Connect the Return Lines.

*

☐12. Connect the Power Unit.

*

☐12. Attach the Conduit Tube.

*

☐12. Install the Control Stands.

*

☐13. Wiring a Power Disconnect Switch.

☐14. Install a Thermal Disconnect Switch.

☐15. Test the Autostacker.

☐16. Add the Tire Trough and Tire Stops.

☐17. Add the Platform sections and Drive-Up Ramp.

☐18. Lubricate the Autostacker.

☐19. Review the Final Checklist.

*

Procedures modified and/or specific to a

Multi-Lift

configuration only. See Multi-Autostacker for

more information.

Autostacker™ Parking Lift 13 P/N 5900002 — Rev. D — August 2019

Installation

This section describes how to install your Autostacker. Perform the steps in the order listed.

⚠WARNING

Only use the factory-supplied parts that came with your Lift

. If you

use parts from a different source, you void your warranty and compromise the

safety of everyone who installs or uses the Lift. If you are missing parts, visit

autostacker.com/support or call (888) 977-8225.

Safety Rules

When installing your Autostacker, your safety depends on proper training and thoughtful operation.

⚠WARNING Do not install this equipment unless you have automotive lift installation training.

Always use proper lifting tools, such as a Forklift or Shop Crane, to lift heavy

components. Do not install this equipment without reading and understanding

this manual and the safety labels on the unit.

Only fully trained personnel should be involved in installing this equipment.

Pay attention at all

times.

Use appropriate tools and lifting equipment, when needed. Stay clear of moving parts.

BendPak recommends referring to the current version of the ANSI/ALI ALIS Standard Safety

Requirements for Installation and Service for more information about safely installing, using, and

servicing your Lift.

⚠WARNING You must wear appropriate protective equipment

at all times

during

installation: gloves, steel-toed work boots, eye protection, back belts, and

hearing protection.

Tools

You may need some or all of the following tools:

•Rotary hammer drill or similar

•3/4", 3/8" masonry bits

•Hammer and crow bar

•Open-end wrench set

•Socket and ratchet set

•Medium crescent wrench

•Chalk line and tape measure

•Medium flat screwdriver

•Fork lift or Shop Crane

Autostacker™ Parking Lift 14 P/N 5900002 — Rev. D — August 2019

Electrical Work

You will need to have a licensed, certified Electrician available at some point during the installation.

⚠DANGER All wiring

must

be performed by a licensed, certified Electrician.

The Electrician needs to do these things:

•Connect the selected power source to the bottom of the Power Disconnect

Switch. Required. This is generally done when the Power Unit is being connected.

•Connect the Power Unit to the top of the Power Disconnect Switch. Required. This is

generally done when the Power Unit is being connected.

•Install a

Thermal

Disconnect Switch. Optional. BendPak recommends connecting a

Thermal Disconnect Switch or overload device (not supplied) to make sure the equipment shuts

down in the event of an overload or an overheated motor. Refer to Install a Thermal

Disconnect Switch for more information.

Select a Site

Keep the following in mind when selecting a site for your Autostacker:

•Enough space. Make sure there is adequate space for the Autostacker on all four sides, plus

enough height for the Vehicles you will be lifting. If architectural plans are available, use them to

make sure there is adequate space for your planned layout.

•No overhead obstructions. Make sure the site is free of overhead obstructions such as

heaters, building supports, electrical lines, lights, and so on.

•Concrete specifications. Do not install the lift on cracked or defective Concrete. Make sure

the concrete is at least 4.25 inches thick, 3,000 psi, and cured for at least 28 days if recently

poured. Make sure the floor is defect-free, dry, and level.

⚠WARNING Do not install your Autostacker on a surface with 3° or more of slope. A 3° degree

slope or greater could lead to property damage, personal injury, or death.

•Power. You will need a power source available near the Console. For a 220 VAC, single-phase

circuit, use a 25 amp or greater fuse. For a 380 VAC, three-phase circuit, use a 20 amp or greater

fuse.

•Operating temperature. Autostacker is designed to be used between temperatures of 0°F to

104°F (-20°C to 40°C).

•Indoor installation. Autostacker is designed for indoor installations.

•Outdoor installation. Autostacker is not designed for outdoor use. It has an operating ambient

temperature range of 0ºF to 104ºF (-20ºC to 40ºC). If operation below this temperature is required,

contact autostacker.com/support for more information. Do not operate your Autostacker in

rain or extremely damp locations. It is water resistant, not waterproof, and water damage is not

covered under the warranty. Outdoor installations can be accommodated in certain regions

if

optional moisture preventative devices are ordered and installed. Coastal locations often require

additional maintenance due to highly corrosive airborne ocean salt. Although parts of your Lift are

made of galvanized metal and protected by commercial-grade powder coat, take additional

precautions by damp washing all exposed surfaces approximately every three months. Do not

allow grass clippings, leaves, or other debris to accumulate on your Autostacker. If you use your

Autostacker outdoors, clean it daily and lubricate it every week.

•Second floor installs. Do not install the Autostacker on a second floor or elevated floor without

first consulting the building architect and getting their approval.

Autostacker™ Parking Lift 15 P/N 5900002 — Rev. D — August 2019

•Dress properly. Wear protective gear (like safety goggles, helmet, heavy gloves, suitable

working clothes, safety boots, ear protection, and so on) when installing Autostacker. Do not wear

loose clothing or jewelry; contain long hair; keep hair and clothing away from moving parts.

⚠WARNING

Always

wear appropriate protective gear when working on the Autostacker.

Important: Your Autostacker Lift is supplied with installation instructions and concrete fasteners

that meet the criteria set by the current American National Standard “Automotive

Lifts – Safety Requirements for Construction, Testing, and Validation” ANSI/ALI

ALCTV. Lift buyers are responsible for any special regional, structural, or seismic

anchoring requirements specified by any other agencies or codes, such as the

Uniform Building Code or International Building Code.

Create a Floor Plan

You need to plan out, in advance, where the Autostacker is going to go. Be sure to work with the

Autostacker owner on this:

•Access. The Autostacker is a Parking Lift, so be sure you can drive Vehicles onto it.

•Side clearance. Consider whether or not you want enough room on the sides for people to walk

around the Autostacker.

•Front clearance. Vehicles parked on the Autostacker Platform may extend over the front. If the

Vehicle you want to place on the Platform is longer than average (a light truck or a Cadillac, for

example), make sure you have enough room between the Autostacker and any obstacles (such as

a wall).

•Rear clearance. You are not required to park the Vehicle under the Autostacker all the way

underneath the Platform. Depending on the Vehicle, it may be easier to get in to and out of the

Vehicle if you only go partway under the Platform, as shown below. If this is a consideration, make

sure to allow adequate room at the rear of the Autostacker (the drive-up end) for you to park the

Vehicle and for the garage door to close.

This image shows an Autostacker using some of the space at the rear (by the garage door) for the

Vehicle underneath the Platform to be only partway in.

Autostacker™ Parking Lift 16 P/N 5900002 — Rev. D — August 2019

•Console. The Console must be located near the Autostacker; the Hydraulic Hoses that come with

the Autostacker are optimized for up to 30 inches between the Autostacker and the Console.

Tip If you want the Console further than 30 inches from the Autostacker, you can use

custom Hydraulic Hoses. Keep in mind that the Console

must

have a full,

unobstructed view of the Autostacker and be near the power source.

•Operator. The operator at the Console must have a full, unobstructed view of the Autostacker.

•Power. The Console must also be positioned near the power source.

Autostacker™ Parking Lift 17 P/N 5900002 — Rev. D — August 2019

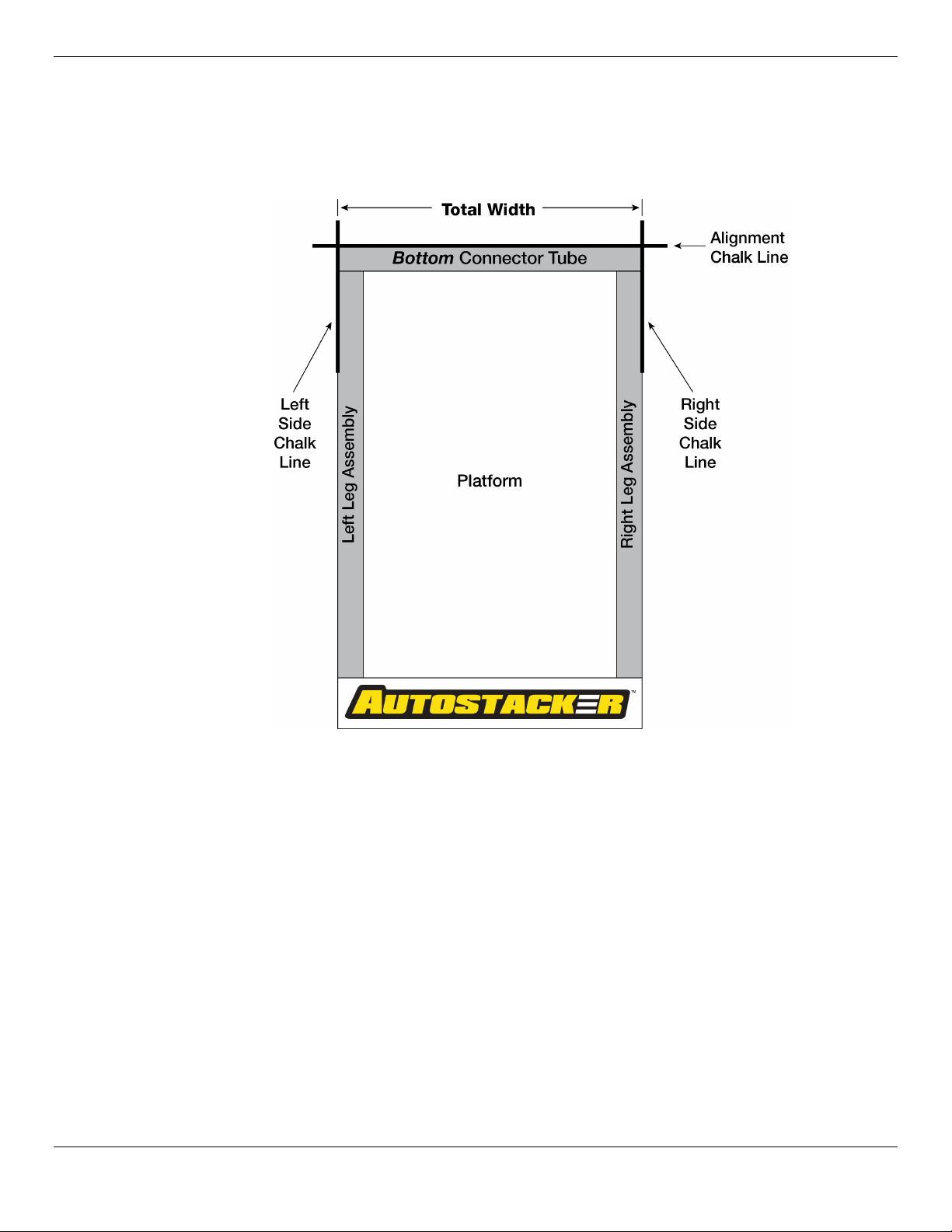

Create Chalk Lines Guides

Using Chalk Line Guides makes it easy to position the Autostacker components for installation.

Note: The front of the Autostacker is the end

opposite

the Drive-Up Ramp. The Tire Trough is at

the front of the Autostacker and the Drive-Up Ramp is at the back.

Autostacker™ Parking Lift 18 P/N 5900002 — Rev. D — August 2019

To add Chalk Line Guides:

1. Decide where you want to place the Autostacker.

2. Create an Alignment Chalk Line where you want the front of the Autostacker.

Make the Alignment Chalk Line

longer

than the Total Width setting for the Autostacker.

3. Create two perpendicular chalk lines at 90° angles to the Alignment Chalk Line.

Make the distance between the Left Side Chalk Line and the Right Side Chalk Line the distance of

the Total Width setting for the Autostacker, found in Specifications.

For a

Multi-Lift

setup, see Multi-Autostacker for modified specifications. If you plan to

position the Control Stand at the

Rear

of the Lift, use the Total Width (A); do not use the A1 figure.

4. When you want to move the components into position, put the Bottom Connector Tube against

the Alignment Chalk Line and between the Left and Right Side Chalk Lines.

Put the Leg Assemblies up against the Bottom Connector Tube and inside the Left and Right Side

Chalk Lines, respectively.

The Leg Assemblies are

not

interchangeable; the Door Sentry car-door protectors go on the

inside.

Autostacker™ Parking Lift 19 P/N 5900002 — Rev. D — August 2019

Position the Autostacker Components

When the Lift components are delivered to the site, try to have them placed near where you will be

installing the unit. For example, if you are installing Autostacker in a garage, you might want to have the

components unloaded on the garage’s driveway or inside the garage.

⚠CAUTION Some of the Autostacker components are heavy and can damage materials like tile,

sandstone, and brick if not handled correctly. Try to handle the Autostacker

components only twice: once when delivered and once when moved into position.

Once delivered, remove the packaging and prepare for installation.

⚠WARNING Some of the Autostacker components are very heavy. You must have a Forklift or

Shop Crane to move them into position. Use care when moving them around.

Autostacker components include:

•Two Leg Assemblies: Each Leg Assembly includes a Base, Leg, Hydraulic Cylinder, and

Platform Arm.

•Bottom Connector Tube: Connects to the Leg Assembly Bases. The Hydraulic Hoses and the

Return Line are routed through the hollow Bottom Connector Tube.

•Top Connector Tube: Connects to the Leg Assembly Platform Arms. Also attaches to the Tire

Trough.

•Tire Trough: A single piece with a lowered portion (to hold the Vehicle’s tires from moving, which

holds the Vehicle in place). Attaches to the Top Connector Tube and the first Platform section at

the front of the Autostacker.

•Platform: Made up of galvanized steel sections that are bolted together.

•Ramp: A single piece, angled for easy drive-up.

To move the Leg Assemblies into position:

1. Use a Forklift or Shop Crane to move the Leg Assembles into position based on the Chalk Lines.

The Leg Assemblies go on the

inside

of the Chalk Lines.

⚠CAUTION Some of the Autostacker components are heavy and can damage materials like tile,

sandstone, and brick if not handled correctly. Move the Leg Assemblies with care

so that you do not cause damage to the surface.

2. Double check to make sure the Leg Assemblies are correctly positioned with the Door-Sentry car-

door protectors on the inside; the Leg Assemblies are

not

interchangeable.

Autostacker™ Parking Lift 20 P/N 5900002 — Rev. D — August 2019

Attach the Bottom and Top Connector Tubes

The Bottom Connector Tube holds the bottom of the Autostacker structure together. It is hollow,

allowing the Hydraulic Hoses and the Return Line to be routed through it.

Each end of the Bottom Connector Tube connects to the corresponding end of a Leg Assembly base.

The Top Connector Tube holds the top of the Autostacker structure together. Each end of the Top

Connector Tube connects to the corresponding end of a Platform arm.

If you have a

Multi-Autostacker

setup and plan to position the Control Stand at the Rear of the Lift,

the Bottom Connector Tube has a Window on one end that needs to be oriented correctly to fit your

floor plan; see Multi-Autostacker for more information.

To attach the Bottom and Top Connector Tubes:

1. Move the Bottom Connector Tube into position: on the ground at the front of the Lift.

The Bolt locations on the Bottom Connector Tube need to line up with the holes on the Base of

each Leg Assembly.

Important: The Bottom Connector Tube must be oriented so that the smaller gap (from the

top Bolts to the top of the tube) must be at the top and the larger gap (from the

bottom Bolts to the bottom of the tube) must be at the bottom.

If you cannot

push the Bolts through the Bottom Connector Tube and into the

holes on the base of the Leg Assembly, it is probably because you

have the Bottom Connector Tube oriented wrong.

Not all components shown. View is front of Autostacker facing towards Rear.

2. Take four Bolts from the Parts Box, then use them to connect one end of the Bottom Connector

Tube to the base of one of the Leg Assemblies.

3. Take four more Bolts from the Parts Box, then use them to connect the other end of the Bottom

Connector Tube to the base of the other Leg Assembly.

4. Use a Forklift or Shop Crane to lift the two Leg Assemblies onto the lowest Safety Lock.

Raising the Leg Assemblies gives you some extra room as you continue installing the Autostacker.

5. Take three Bolts from the Parts Box, then use them to connect one end of the Top Connector

Tube to the corresponding end of a Platform arm.

Tip The Top Connector Tube is heavy; you need at least two people to connect it (one

person to hold the tube in place, one to connect the tube using the Bolts) or use a

Forklift or Shop Crane to hold it in place while you connect it.

6. Take three more Bolts and use them to connect the other end of the Top Connector Tube to the

corresponding end of a Platform Arm.

This manual suits for next models

1

Table of contents

Other Bend-Pak Automobile Electronic manuals

Popular Automobile Electronic manuals by other brands

BMW

BMW Apollo 84 61 0 143 955 installation instructions

Xpresskit

Xpresskit PKUCG2X installation guide

Double Intelligence Technology

Double Intelligence Technology PSA quick start guide

Dometic

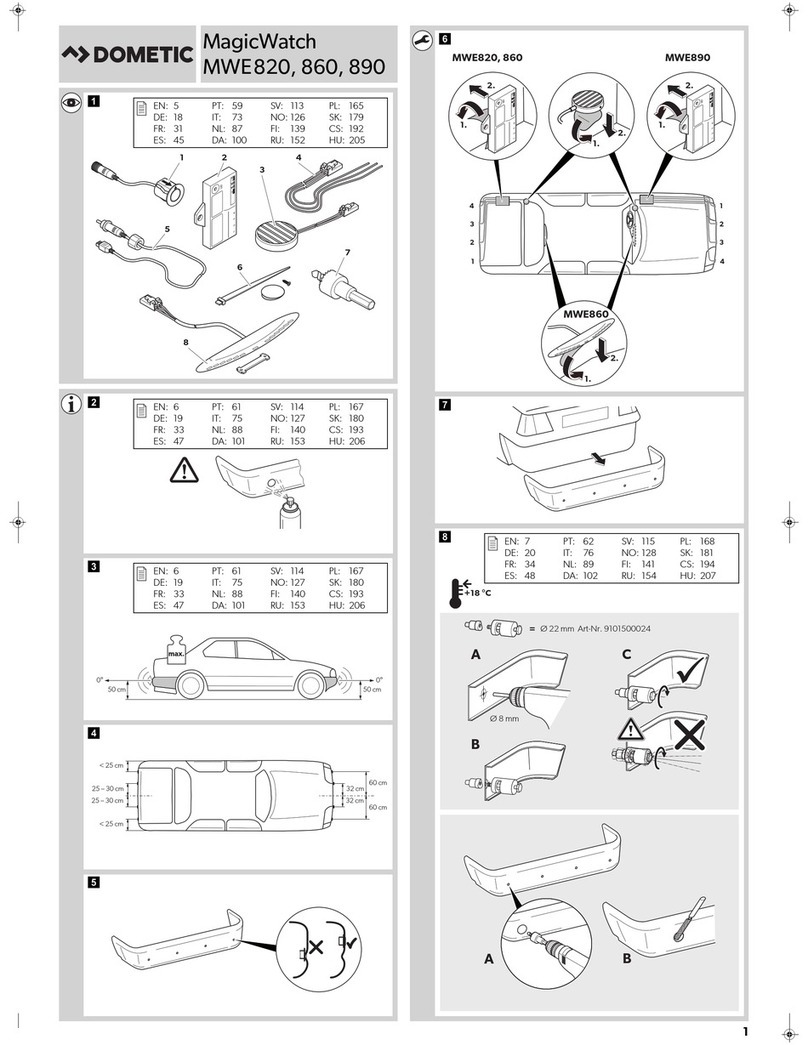

Dometic MAGICWATCH MWE820 Installation and operating manual

VDO

VDO TEMPERATURE GAUGE installation instructions

Dynojet

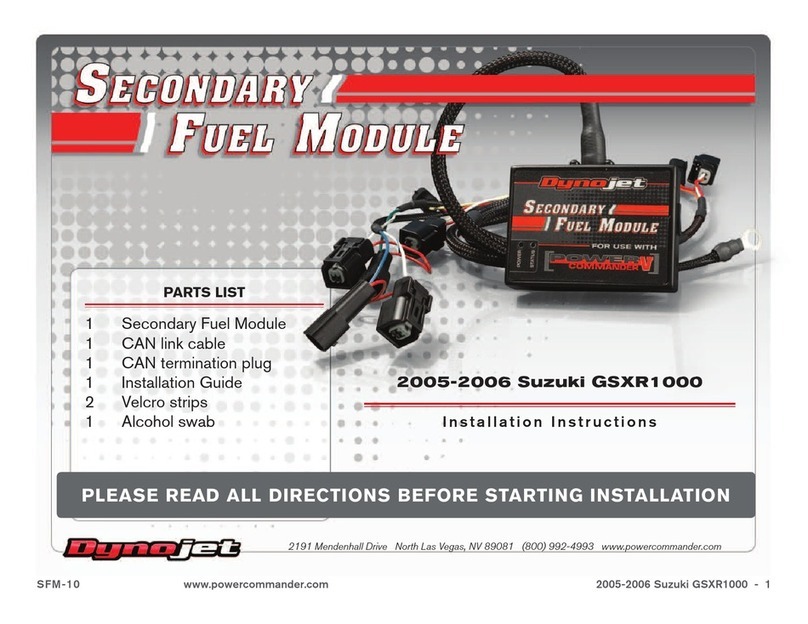

Dynojet SFM-10 installation instructions