BENDEL TORNADOR FOAM Z-011S User manual

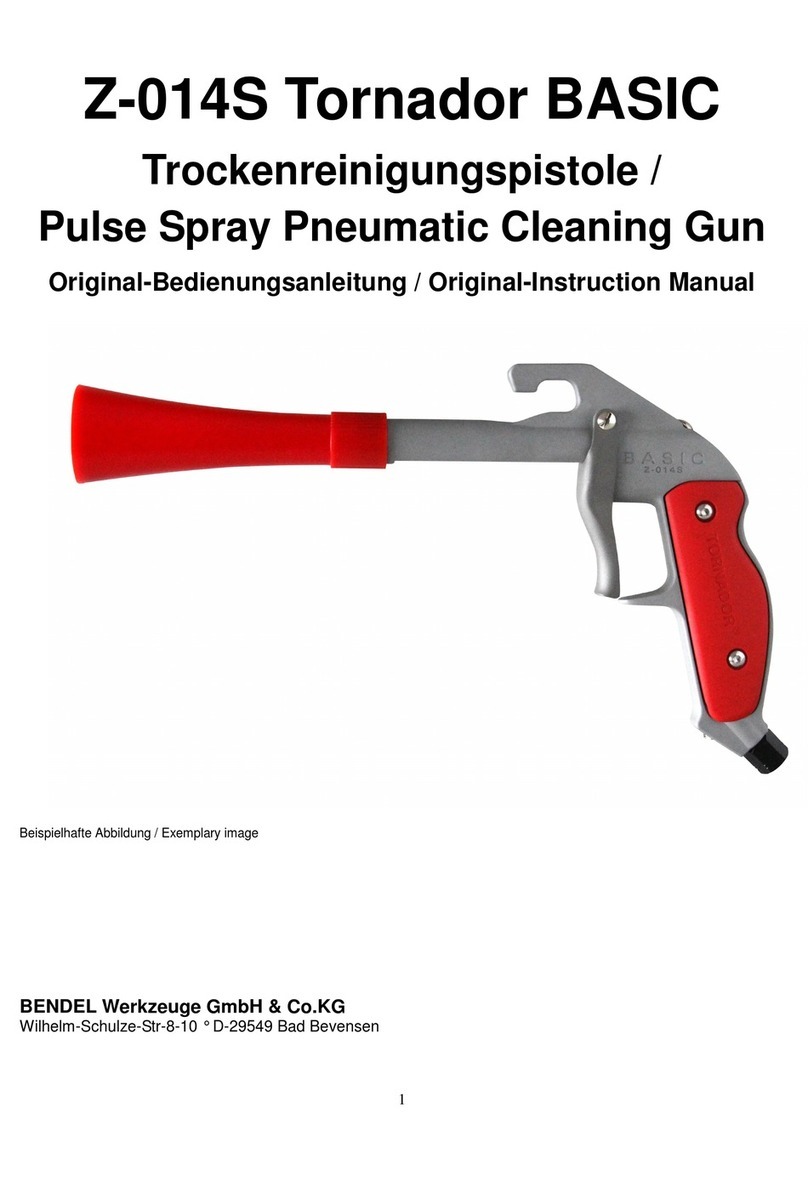

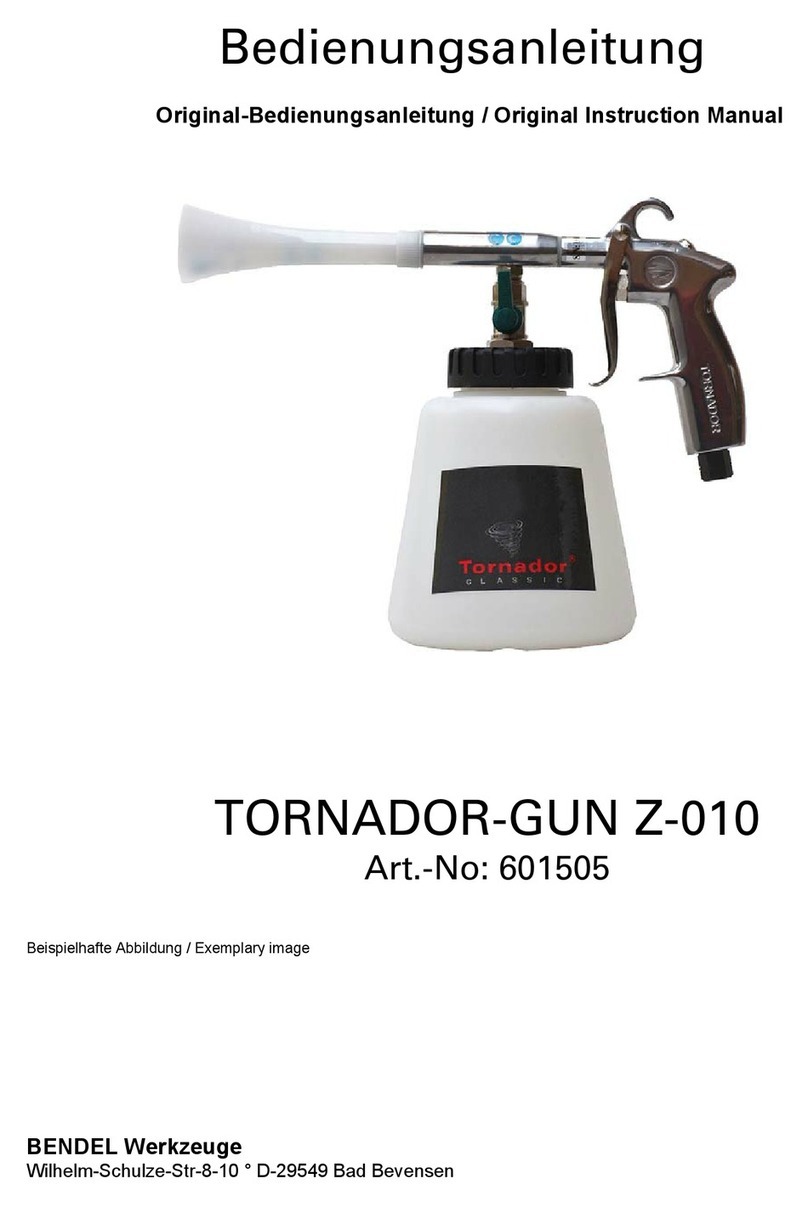

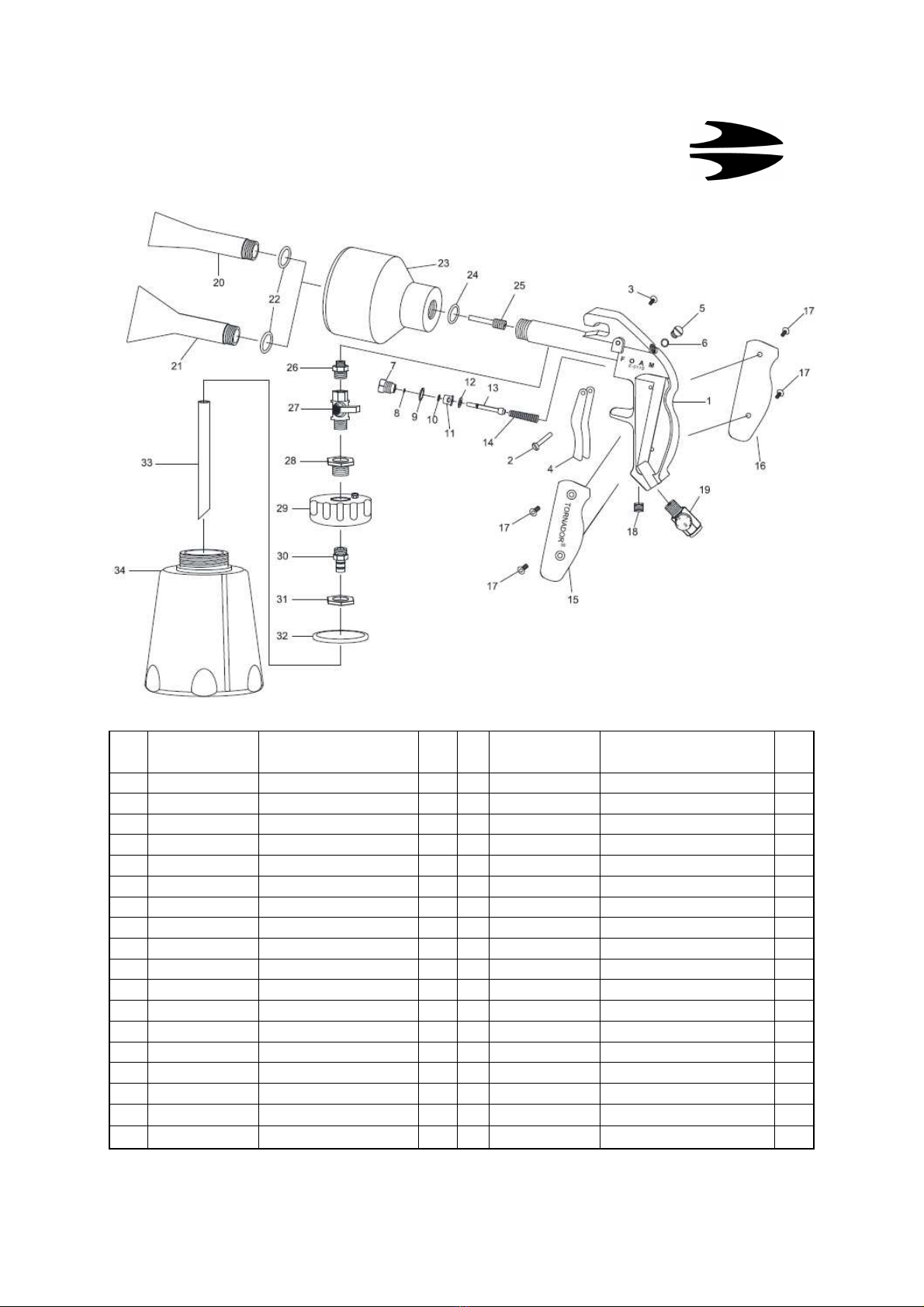

Beispielhafte Abbildung / Exemplary image

BENDEL Werkzeuge GmbH & Co.KG

Wilhelm-Schulze-Str-8-10 ° D-29549 Bad Bevensen

TORNADOR-FOAM-GUN

Z-011S

Bedienungsanleitung

Orignal-Bedienungsanleitung / Original Instruction Manual

Ref.

Part No. Description Q'ty

Ref.

Part No. Description Q'ty

No. Tool

No.

Tool

1 SPZ011S001 Housing 1 19

SPZ011022A Air Inlet (1/4"PF) 1

2 SPZ020S007 Pin 1 20

SPZ011030 Small Nozzle 1

3 SPZ010008A Screw 1 21

SPZ011031 Big Nozzle 1

4 SPZ010009B Trigger (Stainless) 1 22

SPZ011032 O-Ring AS-018 2

5 SPZ010010 Screw 1 23

SPZ011002 Snow Cup Ass'y 1

6 SPZ010026 O-Ring (4.47x1.78) 1 24

SPZ011035 O-Ring (14x2) 1

7 SPZ010011 Screw 1 25

SPZ011S002 Screw 1

8 SPZ010031 O-Ring (2x1) 1 26

SPZ011014 Screw 1

9 SPZ010028 O-Ring (9x2) 1 27

SPZ011015 Air Reverse Switch Ass'y 1

10 SPZ010027 O-Ring (3.5x1.5) 1 28

SPZ010018 Screw 1

11 SPZ010012 Bushing 1 29

SPZ010019C Cap (with hole) and Valve 1

12 SPZ010013 Gasket 1 30

SPZ011028 Screw 1

13 SPZ010014 Valve Stem 1 31

SPZ010021 Nut 1

14 SPZ010015A Spring 1 32

SPZ020014A Gasket 1

15 SPZ020S002 Left Side Cap (Black) 1 33

SPZ011020 Tube 1

16 SPZ020S003 Right Side Cap (Black) 1 34

SPZ010023A Cup With Window 1

17 SPZ020S004 Screw 4

18 SPZ020S005 Screw 1

Ver.2016.02

Read and understand these instructions before operating the tool.

General safety instructions and individual

safeness

Attention

•You need to read, understand and follow the complete instruction

manual and the safety briefing BEFORE USE. Afterwards the

instruction needs to be kept at a adequate place, accessible for

any user.

•The unit may only be used, cleaned and maintained by persons

who understand and follow this instruction. The operator must be in

physically condition to utilize the tool.

•Improper use or unauthorized modification will cause serious

health damage by yourself, somebody else or animals and other

property.

•Individual safety instructions from the related countries needs to be

observed additional.

•

Make sure that the tool is out of range for children or other persons

who are not familiar with the handling of the unit. Switching on the

device by such persons is dangerous.

Workplace hazards:

• Slipping, stumbling or collapsing are the main reasons for serious or deadly

accidents. Take care for hoses which maybe are in the near operating area.

• Maintain a balanced body position and secure footing.

• Cyclic courses of movements, inappropriate posture and constant vibrations will

cause fatigue to arms, hands and body.

• High sound levels can lead to permanent hearing loss. Use hearing protection as

recommended.

• Avoid breathing in dust or handling debris from work process which can be

harmful to your health.

• This tool may only be used and maintained by qualified people who are in the

constitutional position to handle the dimension, weight and force of the device.

• This tool is not intended for use in explosive atmospheres and is not insulated for

contact with electrical power sources.

• Please consider that the material your tool is made of always can have material

tiredness.

Projectile hazards:

• Even small projectiles, for example swirled by the outlet air of your tool, can

injure eyes and lead to blindness.

• Always wear impact-resistant eye and face protection when involved with or near

the operation, repair or maintenance of the tool or changing accessories on the

tool.

• Also take care that people surrounding you will follow the instruction to wear

impact-resistant eye goggles and face masks.

• In case of a male function switch off the device immediately and provide the tool

to a authorized service station to check.

• If you recognize high unusual vibration switch of the unit and look for the

reasons. Do not switch on again until before the problem is solved.

Individual safeness

• Only use the tool in well-rested conditions.

• Always take care what you are doing and use your commonsense.

• Do not use the tool when you are tired or under the influence of medicine, alcohol

or drugs. Any carelessness will cause serious hurts.

• Always wear adequate protective clothing and eye protection. Further protection

like dust masks, helmets, ear protection, work gloves or nonskid safety shoes

may be required. Pls. refer to the pictograms in this manual. Even if these

clothing’s are not especially required we highly recommend to use them as the

risk of injury will decrease formidable.

• Always disconnect the device from air supply when not in use, before changing

accessories or maintenance to avoid starting the tool by mistake.

• Always check the unit, hoses and fittings for damages or loose before use.

• Make sure that any spanners or other parts you have used with the tool will be

removed before operating.

• Do not super extend and take care on a balanced position and secure footing to

control the tool also in unexpected situations.

• Long hairs and loose clothing could tangled up in rotating parts of the device and

cause serious hurts.

Exemplary drawing.

Air supply requirements

• Supply tool with a maximum pressure according to the technical data of this unit

of clean, dry air. Higher pressure drastically reduces tool life and/or can cause

several injury.

• Connect tool to air line using pipe, hose and fitting sizes shown in the diagram

above.

• Do not install a quick coupler directly into the air tool handle.

• In order to have the tool working to full satisfaction the minimum air delivery must

be at least 10% higher than the indicated air consumption of the air tool.

• Please consult the technical data in this instruction manual.

Pneumatic tool and safety instructions

• The goal of Bendel Werkzeuge is to offer tools that help your work safely and

efficiently.

• The most important safety device for this or any tool is YOURSELF.

• Your care and good judgment are the best protection against injury. All possible

hazards cannot be considered here, but we have tried to highlight some of the

most important ones.

• This tool may only used by qualified people.

• This tool and its accessories must not be modified.

•

Do not lay down the device before all the rotary parts stopped.

•

Do not keep the air tool running while carrying it.

•

Maintain a firm grip on the power tool and position your body and arm to allow

you to resist kickback forces. Always use auxiliary handle, if provided, for

maximum control over kickback or torque reaction during start-up. The operator

can control torque reactions or kickback forces, if proper precautions are taken.

•

Never place your hand near the rotating accessory. Accessory may kickback

over your hand.

•

Switch off the unit immediately in case of blocking or twist. Disconnect the air

supply and do not switch on again until the problem is solved. Understand the

reason why the tool has been blocked and make sure that this situation will not

occur once more by counteract accordingly.

Air supply and connection hazards:

• Air under pressure can cause several injury !

• Always shut off air supply, drain hose of air pressure and disconnect tool from air

supply, when not in use, before changing accessories or maintenance.

• Never put direct air at yourself or anyone else.

• Whipping hoses can cause serious injury. Always check for damaged or loose

hoses and fittings.

• Do not exceed maximum air pressure according on the name plate respectively

6.3 bar.

• Do not use quick disconnect couplings directly at the tool. See instructions for

correct set-up !

For additional safety information consult:

• Your employer, union and/or trade association.

• Council of the European communities and/or local codes

• ,,Safety requirements for hand-held non-electric Power Tools", available from:

European committee for standardization, Rue de Stassart 36. 1050 BRÜSSEL,

BELGIEN.

http://www.cen.eu/cenorm/homepage.htm

Maintenance:

• Damaged or worn out parts should be replaced only by licensed original parts.

Get in contact with your dealer or a authorized service station for support. Using

unlicensed parts male functions could occur followed by possible hurts of health.

• Check the tool regularly to recognize cracks, unusual clearance, mismatch and to

check the rotary parts for proper operation..

• Recognizing a abnormality the unit needs to be provided to a authorized service

station before using it again. Please consider that many accidents are cause by

insufficient maintenance.

Tool applications:

• Pulse spray pneumatic cleaning gun: To clean automobiles

You must observe the following points in the interest of your own safety!!!

Safety instructions:

•When working with the FOAM-GUN, please wear protective goggles to prevent eye injuries.

•Only use the FOAM-GUN in ventilated spaces.

•Never operate the FOAM-GUN with more than 6.3bar.

•Do not use cleaning agents which are acidic, alkali and/or inflammable.

We recommend the use of neutral cleaning agents.

•When using cleaning fluids which need to be diluted, always strictly observe the

manufacturer's instructions to make sure the mixture is correct.

•To prevent health hazards from inhalation, wear appropriate respiratory protection.

•Never point the FOAM-GUN towards the face or body.

•Keep the FOAM-GUN out of the reach of children.

We recommend you never clean any safety-related components, e.g. safety belts, electrical or

electronic modules, with the Z-011S.

Special instructions:

The written and spoken information and recommendations which we provide to support the

purchase/user, are the result of previous experience and the latest findings. Because of the manifold

possibilities for use and processing conditions, this information is without obligation and do not

constitute a contractual legal relationship or any supplementary obligations of the sales contract.

In any event, the purchaser holds responsibility for checking suitability for the intended use himself.

Always read the safety warnings for cleaning liquids and contact the manufacturer in case of doubt.

Our liability and repsonsibility is based exclusively on our general terms and conditions of business

and are not expanded on by either this information or the technical advice of our technical field staff.

Operating instructions:

1. Remove loose soiling from the surface you wish to clean (brush or vacuum clean)

2. Turn the green rocker lever into the vertical position to activate the (cleaning) liquid in the

bottle

3. Depending on the required application pls. screw in one of the nozzles in the head of the

device.

4. Press the "trigger" all the way to foam in the surface accordingly.

5. Give the cleaner a little bit residence time but take care it will not become touch dry.

6. Afterward clean the surface with opluant water. For a optimal result we recommend to use our

TORNADOR-GUN.

Care and Maintenance

Pls. flush the head filling regular water in the cup and pressing the trigger for a while. With this

procedure you will avoid that the gaskets and filters dry out by the used cleaner when the item is not in

use.

Afterwards turn the green control switch into the horizontal "air only" position and press the trigger to

remove any remaining moisture out of the head.

Required Air Rate

To perform to its full potential, the Foam Gun requires a constant air pressure of 6 bar.

CAUTION: Constant air rates vary depending on the size and power of the compressor. Always make

sure that the tank and the air hoses are free of impurities of any kind.

Explanation of the pictograms:

Always use face and eye-protection, breath-mask if necessary, protective gloves and read /

understand the instruction manual.

Technical Data

Air inlet 1/4"

Air pressure 90 psi / 6,3bar

Air consumption 188 l/min

Weight 0.67 Kg.

Serial number

EG declaration of conformity for machines

(EG-RL 2006/42/EG)

Herewith

BENDEL Werkzeuge GmbH & Co.KG

Wilhelm-Schulze-Str.8-10

D-29549 Bad Bevensen

declares that the machine Z-011, Z-011a, Z-011aN, Z-011WR, Z-011S Tornador-Foam-Gun is

conform with the legal regulation of the above mentioned directive.

Name and address of the person who is authorized to assort the technical documentation:

Frank Bendel

Wilhelm-Schulze-Str.8-10

D-29549 Bad Bevensen

Bad Bevensen, 01.11.2015

___________________

Frank Bendel, Managing Director

Table of contents

Other BENDEL Paint Sprayer manuals