The following instructions apply to equipment

covered by certicate number Sira 14ATEX 5343:

1. The equipment may be used with ammable

gases and vapors with apparatus groups II and

with temperature class T6.

2. The equipment is only certied for use in am-

bient temperatures in the range +0°C to +40°C

and should not be used outside this range.

3. Installation shall be carried out by suitably trained

personnel in accordance with the applicable code

of practice e.g. EN 60079-14:1997.

4. Inspection and maintenance of this equipment

shall be carried out by suitably trained personnel

in accordance with the applicable code of practice

e.g. EN 60079-17.

5. Repair of this equipment shall be carried out by

suitable trained personnel in accordance with the

applicable code of practice e.g. EN 60079-19.

6. Putting into service, use, assembling, and

adjustment of the equipment shall be tted by

suitably trained personnel in accordance with the

manufacturer's documentation.

Refer to the "Table of Contents" of this service

manual:

a. Installation

b. Operation

c. Maintenance

d. Parts Identication

7. Components to be incorporated into or used as

replacement parts of the equipment shall be tted

by suitably trained personnel in accordance with

the manufacturer's documentation.

8. The certication of this equipment relies upon

the following materials used in its construction:

If the equipment is likely to come into contact with

aggressive substances, then it is the responsibility

of the user to take suitable precautions that prevent

it from being adversely affected, thus ensuring that

the type of protection provided by the equipment

is not compromised.

Aggressive substances: e.g. acidic liquids or

gases that may attack metals, or solvents that

may affect polymeric materials.

Suitable precautions: e.g. regular checks as

part of routine inspections or establishing from

the material's data sheets that it is resistant to

specic chemicals.

Refer to "Specications" in the "Introduction"

section:

a. All uid passages contain stainless steel or

nylon ttings.

b. High voltage cascade is encapsulated with

a solvent resistant epoxy.

9. A recapitulation of the certication marking is

detailed in the "ATEX" section, on the next page,

drawing number: 80528-00 and 80528-01.

10. The characteristics of the equipment shall

be detailed e.g. electrical, pressure, and voltage

parameters.

The manufacturer should note that, on being

put into service, the equipment must be ac-

companied by a translation of the instructions

in the language or languages of the country in

which the equipment is to be used and by the

instructions in the original language.

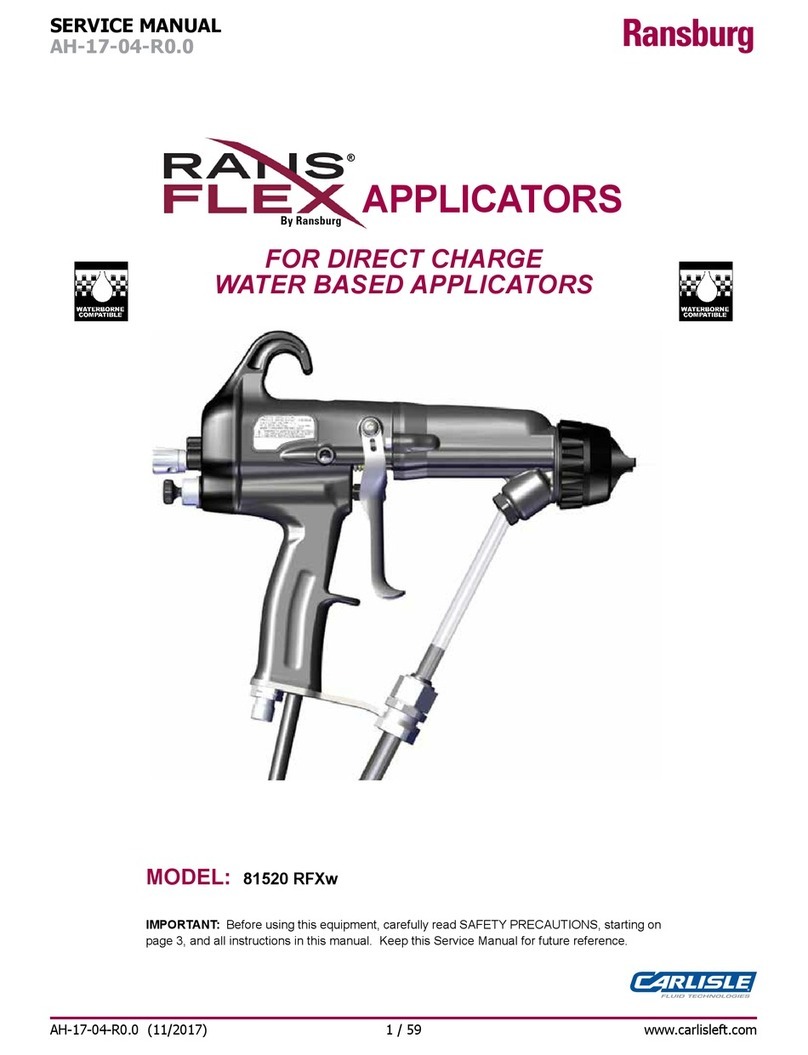

EUROPEAN ATEX DIRECTIVE 2014/34/EU

AH-16-02.1 6

RansFlex Applicators - ATEX/FM