-

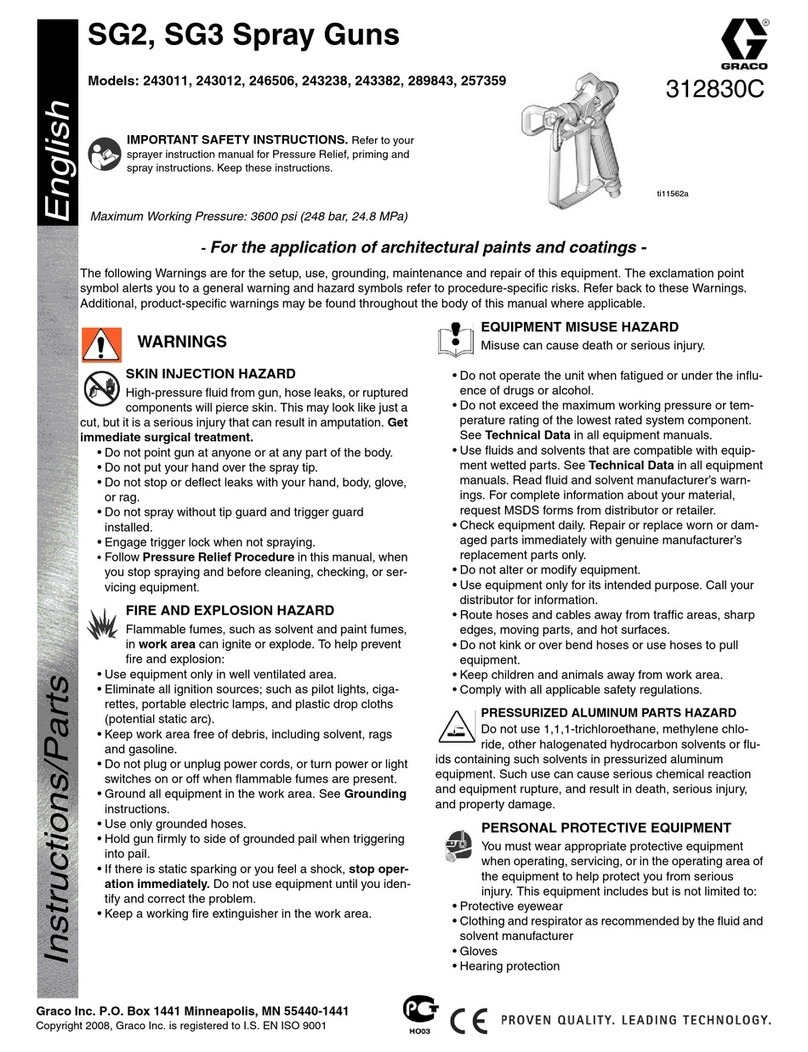

FIRE, EXPLOSION OR ELECTROSTATIC

SHOCK

HAZARD

-

which may result from electrical discharge,

it

is essential that:

To

reduce the risk of fire, explosion, or electrostatic shock, 7.

All

electrically conductive objects or devices

in

the spray

area, including paint containers and wash cans, must be

All

patis of the electrostatic system are properly grounded. properly grounded.

9

All

personnel in

or

close lo the spray area are properly

grounded.

8.

All

persons entering the spray area: shoes must have con-

ductive soles, such as leather, or personal grounding

All electrically conductive objects

or

devices in the spray straps must be worn. Rubber or plastic soles are

not

con-

area, including paint containers, wash cans and tools, are ductive. The operator must not wear gloves that insulate

properly grounded. tive or modified as shown

in

Fig

2,

page

9.

the hand from the spray

gun.

The gloves must be wnduc-

When operating the electrostatic device, any ungrounded 9. The floor of the spray area must be electrically conductive

objects

in

the spray area.(such as people, containers, tools,

etc.) can become electrically charged. Arcing may occur

if

and grounded.

Do

not cover the floor with cardboard or

these objects then come in contact or close lo ground. Arcing any non-conductive material which would interrupt

grounding continuity.

of sufficient energy levels can ignite the fluid being sprayed,

fumes irom solvents, dust particles, and other flammable sub-

10.

Flammable

liquids

in the spray area must be kept in

stances. This can cause a fire, explosion, or electrostatic

shock and result in serious injury and propetty damage.

approved, grounded containers.

Do

not store more than

the quantity needed for one shift.

Static electricity can also be generated by the flow

of

fluid 11.Allsolventpails: use only grounded metal pails, which are

through the pump, hose, gun,

and

nozzle, but

it

is

dissipated conductive.

Do

not place the pail

on

any non-conductive

through proper grounding as described in Groundlng below. surface, such as cardboard or paper, which would inter-

rupt grounding continuity.

If

you experience any arcing or feel even a slight shock,

stop

spraying Immedlately. Check for proper grounding

of

the

entire system. Be sure you have corrected the problem before

starting to spray again.

Grounding

The following are minimum requirements for grounding a

basic electrostatic system. Your system may include other

equipment or objects which must also be grounded. Always

tions. Be sure your system is connected to a true earth

check your local electrical code

for

detailed grounding instruc-

ground.

1.

Pump: ground by using a ground wire and clamp

as

described in your separate pump instruction manual.

2.

Air

compressors and hydraulic power supplies: ground

according to the manufacturer's recommendations.

3.

Electrostatic

Air

Spray

Gun: obtain grounding through

connection to a properly grounded air supply hose. Use

only the Graco Electrically Conductive Air Supply Hose;

see ACCESSORIES section to order. Connect the air

hose ground wire

lo

a true earth ground.

4.

Ailair andfluidlines must be properly grounded. Use only

grounded hoses

with

a maximum

of

500

feet

(150

m)

combined hose length to ensure grounding continuity:

Refer

also

to

Hose

Groundlng Continuity

on

page

4.

5.

All

electric cables must be properly grounded.

6.

Object being sprayed: keep the workpiece hangers clean

and grounded at all times. Contact points must be sharp

points or knife edges.

Rushing

and

Cleaning Safety

To reduce the risk of fluid injection injury, static sparking or

splashing, always follow the Pressure Relief Procedure on

page

2

and remove the spray

tip

before flushing. Use the

lowest possible pressure to flush. Trigger the gun into a

grounded metal waste container.

Be sure

the

ES

ON-OFF

lever

Is

OFF

before flushlng or

cleanlng any part

of

the

spray system.

point equal to

or

greater

than

that of the fluid being sprayed.

To

flush

orpurge equipment, always use solvents with a flash

with a flash point of higher than

100'

F

(38"

C).

To clean the exferior of the equipment, always use solvents

Always remove all solvent from the system before reactivating

the spray gun.

and hangers.

Use only non-sparking tools to clean residue from the booth

Ventilate

the

Spray

Booth

To

prevent hazardous concentrations of toxic and/or

flam-

mable vapors, spray only in a properly ventilated spray booth.

Check and follow all National, State and Local codes regard-

local safety and fire codes and OSHA standard 1910.107.

ing air exhaust velocity requirements. Check and follow all

Never operate the spray gun unless the ventilating fans are

operating.

308-294

3