Bender EDS3065 User manual

EDS3065

Portable Insulation Fault

Location Device

Operating Manual TGH1266E

BENDER

© 2004 BENDER, Germany

Alle Rechte vorbehalten

Nachdruck nur mit Genehmigung des Herausgebers

Änderungen vorbehalten

Dipl.Ing. W. Bender GmbH & Co KG

Londorfer Str. 65 • 35305 Grünberg

Postfach 1161 • 35301 Grünberg

Tel.: +49 - 6401 - 807 - 0

Fax: +49 - 6401 - 807259

E-Mail: [email protected]

Internet: http://www.bender-de.com

3

TGH1266E - 05/04

Contents

1 General ............................................................................................................ 4

Critical Use ............................................................................................................. 4

What is EDS3065 ................................................................................................... 4

The Insulation Resistance ..................................................................................... 5

Basic Standards ....................................................................................................... 6

Terms and Definitions .......................................................................................... 6

2 Safety Instructions ........................................................................................ 7

Proper Use ............................................................................................................... 7

Warranty and Liability ........................................................................................... 7

Copyright ................................................................................................................ 7

Explanation of Symbols and Notes .................................................................... 8

Risks when Operating the System....................................................................... 8

Special Notes .......................................................................................................... 8

Warranty Obligations ............................................................................................ 9

Inspection, Transport and Storage ...................................................................... 9

3 Operating Principle of the EDS3065 ...................................................... 10

Operating Principle of Insulation Fault Location ......................................... 10

Response Values .....................................................................................................10

Operation in the RCM-Mode ............................................................................11

4 Product Description ...................................................................................12

The System Components at a Glance .............................................................. 12

Parts List .................................................................................................................13

Supply Voltage .......................................................................................................13

Options ...................................................................................................................13

Aluminium Case ................................................................................................... 14

EDS165 Insulation Fault Evaluator ................................................................... 14

Test Device PGH185 ........................................................................................... 15

PSA3020 Clamp-on Probe ...................................................................................16

PSA3052 Clamp-on Probe ...................................................................................16

Technical Data EDS3065 ..................................................................................... 17

Technical Data EDS165 .......................................................................................18

Technical Data Clamp-on Probes ......................................................................18

5 Operation and Setting................................................................................ 19

Factory Settings ..................................................................................................... 19

Settings on the EDS165 Evaluator..................................................................... 19

Switching On the EDS165 ..................................................................................19

The EDS165 Display ........................................................................................... 20

The EDS165 in the EDS-Mode ......................................................................... 20

The EDS165 in the RCM-Mode ....................................................................... 22

Error Messages ...................................................................................................... 23

Serial Interface ...................................................................................................... 24

Interface Protocol ................................................................................................ 24

Replacing the Accumulators .............................................................................. 25

6 Points to be Considered before Use........................................................26

Reduced Measurement Current ........................................................................ 26

A Sensible Approach to Fault Location .......................................................... 27

Characteristic Curves .......................................................................................... 28

Limits of Insulation Fault Location ................................................................. 32

7 Practical Use ................................................................................................34

Use as a Portable Insulation Fault Location Device ..................................... 34

Using the EDS165 within an EDS470 system ................................................ 36

Using the EDS165 as a Residual Current Monitor ....................................... 38

EDS3065 in diode decoupled systems ............................................................. 39

Coupling unit AGE185 for higher voltages .................................................... 42

8 Ordering Information ............................................................................... 44

4

TGH1266E - 05/04

1 General

What is EDS3065

Critical Use Before making use of the EDS3065 portable insulation fault location device, the user must have a

very accurate knowledge of its possibilities, the special circumstances relating to its systems, and of

certain hazards which are possible. Among the relevant points to be considered, particular attention

must be paid to the maximum test current. Depending on the switch position of the PGH185, this

is a maximum of 25 mA or 10 mA respectively.

The test current flows between the system and earth, not as a load current. Under unfavourable

combinations of circumstances (low impedance insulation fault in connection with the test cycle

of the test current), control errors cannot be ruled out in the case of sensitive system components

(SPC, relays). Account must be taken of this possibility prior to use. If appropriate, a lower test

current should be set, or the fault location device in this system should not be used.

Attention: the test current of the PGH185 may cause triggering of RCDs. Although the test

current is limited to a maximum of 25 mA (or 10 mA respectively), 30 mA RCD (for example) may

already respond between 15 and 30 mA.

The EDS3065 is a portable insulation fault location device for IT systems (unearthed systems). It

enables insulation faults to be located during operation and without system shutdowns.

The EDS3065 consists of:

• PGH185 Insulation Fault Test Device

• EDS165 Insulation Fault Evaluator

• PSA3020 and PSA3052 Clamp-on Probes

In the past, classical insulation fault location consisted of disconnecting system sections one after

another and then carrying out often laborious and protracted work to search for the faults. Modern

fault location devices such as the EDS3065, PKA3001 or EDS470 (installed as a fixed system) make

the fault location a good deal easier and shorter, and contribute in this way to a better power supply.

While insulation fault location is being undertaken with the EDS3065, any insulation monitoring

device which may be present must be disconnected from the system for the duration of the fault

location, if its internal resistance R is < 120 kΩ. This must be done by effecting an all-pole

interruption of the system coupling - it is not sufficient to switch off the supply voltage to the

insulation monitoring device.

Insulation monitoring devices with an Riof 28 kΩbring about a current conduction against earth

of approximately 14 mA. When a device is used with an Riof 120 kΩthe influence is negligible,

and in this case there is no need to disconnect.

The EDS3065 can be used to accomplish the following measurement tasks:

• insulation fault location in IT systems, AC 19.2 ... 575 V / DC 19.2 ... 504 V

• insulation fault location in IT systems, AC 19.2 ... 575 V / DC 19.2 ... 504 V in

combination with an EDS470 insulation fault location device as a fixed installation

• residual current measurement in TT and TN systems (earthed systems)

Danger !

5

TGH1266E - 05/04

The Insulation

Resistance

General

One determining factor for the availability of an electrical system is the insulation resistance. It

appears at the head of the list of protection goals for electrical safety. This applies as a fundamental

principle, regardless of the form of the system.

A planning decision to construct a safe and reliable power supply with the goal of achieving

maximum availability means:

• constructing the power supply as an IT system. By doing so, greater operational safety

and reliability, greater fire safety, greater safety from accidents and a higher reliable

resistance to earth are achieved than in the case of a system form where the active

conductors are connected to earth.

• use of the correctly selected insulation monitoring device. The advantages cited in the

foregoing paragraph stand or fall with the selection of the A-ISOMETER which is

appropriate to the respective application. Unless there is functional monitoring, it is

impossible to utilise the advantages of the IT system. The desired high level of

insulation resistance cannot be maintained in the long term without continuous

monitoring.

• reduction of maintenance costs and outage times thanks to the use of an insulation fault

location device. Rapid location of an insulation fault immediately after it has occurred

is a long-cherished wish on the part of the maintenance staff. The fault is reported and

located without interruption of operations, and without the need for possible night and

weekend work. The actual repair can then be carried out at a suitable point in time.

The system operator makes the decision as to whether the insulation fault location

device to be used should be a fixed installation or a portable device.

• An alternative to power supply in the form of an IT system may be offered by a TT or

TN system which is equipped with residual current monitors and residual current

detection devices. While this does not make it possible to avoid switching off when a

first low-impedance fault occurs, it nevertheless guarantees a time advantage as far as

information is concerned. As a result, deteriorations in the insulation and creeping

insulation faults are detected at an early stage and a considerable number of shutdowns

are prevented in this way.

Ensuring that the insulation is well-maintained is a decisive factor as far as the reliability of the

power supply is concerned. This is only possible with the use of suitable monitoring devices. These

devices cannot prevent the insulation fault or the deterioration of the insulation. However, early

and rapid detection with information about the location of the fault will simplify maintenance to

an extraordinary degree.

Without suitable tools, fault location was (and continues to be) time-consuming and troublesome.

Week-end work was frequently necessary in order to locate the fault or faults while the system was

switched off.

Modern monitoring devices such as the EDS3065, EDS470 or RCMS470 solve these problems.

Thanks to the automatic location of the insulation fault, the necessary fault elimination is made

very simple and the required high level of insulation is maintained. Localising takes place during

continuous operation and it is not necessary to shut the system down.

6

TGH1266E - 05/04

General

Basic Standards

Terms and

Definitions

If a power supply is constructed as an IT system, the relevant standards require that the first

insulation fault to occur must be eliminated as quickly as possible.

IEC 364-4-41, Point 413.1.5.4 (Note)

It is recommended that the first fault should be eliminated with the shortest practical delay.

DIN VDE 0100 Part 410:1983-11, Point 6.1.5.7

It is recommended that the first insulation fault should be eliminated as quickly as possible.

Rapid insulation fault location is made possible thanks to insulation fault location devices such as

the EDS3065, EDS470 or RCMS470. In this way, the risk of the power supply being switched off

because of a possible second fault is considerably reduced.

At the present time, work is in progress on IEC1557-9. This document deals with devices for

insulation fault location in operational IT AC systems, IT AC systems with electrically connected

DC circuits and IT DC systems. This international draft standard lays down some special

requirements for insulation fault location devices in IT systems of up to AC 1000 V and DC 1500

V.

BENDER’s insulation fault location devices are based on this draft of IEC1557-9. As far as possible,

this operating manual attempts to use the terminology of the draft Standard, including the term

‘insulation fault location device’. This indicates not only that insulation faults with 0 Ω(faults to

earth) are found, but also insulation faults which involve resistance.

In addition, IEC 1010-1 is applicable. The title of this international Standard is ”Safety

requirements for electrical equipment for measurement, control, and laboratory use”.

I∆= fault current. The current which comes to flow through an insulation

fault.

I∆n= nominal fault current. The fault current at which the evaluator unit

responds under specified conditions.

I∆s= measured value of the discriminating fault current of the evaluator

unit.

7

TGH1266E - 05/04

2 Safety Instructions

Copyright

Warranty and

Liability

The intended use of the EDS3065 is to:

• locate insulation faults in IT systems, AC 50, 60 and 400 Hz, 19.2 ... 575 V and

DC 19.2 ... 504 V.

In addition to this, the EDS165 insulation fault evaluator - which is a component of the EDS3065

- can be used to:

• evaluate insulation faults in combination with an EDS470 insulation fault-finding device

as a fixed installation (EDS mode);

• measure residual currents in TN and TT systems (RCM mode)

Any other use, or any use which goes beyond the foregoing, is deemed to be improper. The

BENDER companies shall not be liable for any loss and damages arising therefrom.

As a basic principle, our ”General Conditions of Sale and Delivery” shall apply. These shall be

available to the operator no earlier than the time when the contract is concluded.

Warranty and liability claims in the event of injury to persons or damage to property are excluded

if they can be attributed to one or more of the following causes:

• improper use of the EDS3065

• improper assembly/fitting, commissioning, operation and maintenance of the EDS3065.

• failure to take note of the information in the operating instructions concerning transport,

storage, assembly/fitting, commissioning, operation and maintenance of the EDS3065.

• unauthorised structural modifications to the EDS3065

• failure to take note of the technical data

• improperly performed repairs and the use of spare parts or accessories which are not

recommended by the manufacturer

• cases of disaster brought about by the effect of foreign bodies and force majeure

• the assembly and installation of non-recommended combinations of devices.

In order to handle the EDS3065 in accordance with safety requirements and to ensure its trouble-

free operation, the fundamental prerequisite is a knowledge of the basic safety information and the

safety regulations.

Everyone who works with the EDS3065 must take note of this operating manual, and in particular

of the safety information.

In addition to this, the rules and regulations concerning accident prevention which are valid for the

operating location must be obeyed.

Only suitably qualified staff may work with the EDS3065. The term ‘qualified’ means that such

staff are familiar with the assembly, commissioning and operation of the product and that they have

undergone training which is appropriate to their activities.

The staff must have read and understood the safety chapter and the warnings in these operating

instructions.

Proper Use

8

TGH1266E - 05/04

Safety Instructions

Explanation of

Symbols and

Notes

Risks when

Operating the

System

Danger !

Warning

Caution

The following designations and symbols for hazards and warnings are used in BENDER

documentation:

This symbol means an immediate threat of danger to human life and health.

Failure to observe these warnings means that death, severe bodily injuries or substantial damage to

property will occur if the corresponding precautions are not taken.

This symbol means a possible threat of danger to human life and health.

Failure to observe these warnings means that death, severe bodily injury or substantial damage to

property may occur if the corresponding precautions are not taken.

This symbol means a possibly hazardous situation.

Failure to observe these warnings means that slight bodily injuries or damage to property may occur

if the corresponding precautions are not taken.

This symbol gives important information about the correct way to handle the EDS3065.

Failure to comply with this information may result in faults on the EDS3065 or in its environment.

This symbol guides you to application tips and particularly useful items of information.

These will help you to make optimal use of all the functions on the EDS3065.

The EDS3065 is built according to the state-of-the-art and the recognised safety engineering rules.

During use, it is nevertheless possible that dangers will arise to the life and limb of the user or of third

parties, or that the EDS3065 system or other items of property may be impaired. The EDS3065

must only be used:

• for the purposes for which it is intended

• when it is in perfect condition as regards safety engineering aspects

Any faults which might impair safety must be eliminated immediately. Inadmissible modifications,

and the use of spare parts and additional devices which are not sold or recommended by the

manufacturer of the devices may cause fires, electric shocks and injuries.

Note the maximum nominal insulation voltage!

No unauthorised persons may have access to the EDS3065.

Warning signs must always be easy to read. Damaged or illegible signs must be replaced

immediately.

Special Notes

9

TGH1266E - 05/04

Safety Instructions

Inspection,

Transport and

Storage

Warranty Obligat-

ions

Inspect the despatch and equipment packaging for damage, and compare the contents of the

package with the delivery documents. In the event of transport damage, please notify the BENDER

company immediately.

The components of the EDS3065 must only be stored in rooms where they will be protected against

dust, moisture, and sprayed or dripping water, and where the indicated storage temperatures are

maintained.

BENDER provides a warranty of fault-free execution and faultless material quality on the

EDS3065 with all its components for a period of 12 months as from the date of delivery, under

normal operating conditions.

This warranty does not extend to any maintenance work, regardless of its nature.

The warranty is only valid for the initial purchaser, and does not extend to products or individual

parts thereof which have not been correctly used or to which modifications have been made. Any

warranty whatsoever shall lapse if the EDS3065 system is operated under abnormal conditions.

The warranty obligation is limited to the repair or exchange of a product which has been sent in

to BENDER within the warranty period. It is also a qualifying condition of warranty that

BENDER shall acknowledge that the product is faulty, and that the fault cannot be attributed to

improper handling or modification of the device, or to abnormal operating conditions.

Any warranty obligation whatsoever shall lapse if repairs to the EDS3065 are undertaken by persons

who are not authorised by BENDER.

The foregoing warranty conditions shall apply exclusively, and in the place of all other contractual

or legal warranty obligations, including (but not limited to) the legal warranty of marketability,

suitability for use and expediency for a specified purpose of use.

BENDER shall not assume any liability for direct and indirect concomitant or consequent damages

or losses, regardless of whether these may be attributable to legal, illegal or other actions.

10

TGH1266E - 05/04

3

Operating Principle of the EDS3065

Operating Principle

of Insulation Fault

Location

IT-System

AC/DC Consumer

Evaluator

Test device

PGH185

PE R

F

EDS165

measuring clamp, measuring current transformer

Response Values

Caution

When a first insulation fault occurs in IT systems, a fault current flows which is essentially

determined by the leakage capacitances of the system. The basic concept in fault location is therefore

to close the fault current circuit for a short period over a defined resistance. As a result of this

principle, the system voltage itself drives a test current which receives a signal that can be evaluated.

The test current is generated periodically by the PGH185 test device (which is a component of the

EDS3065 system). The test current is limited in amplitude and time. As this happens, the system

conductors are connected alternately to earth over a defined resistance. The fault current which is

generated in this manner depends on the size of the insulation fault present, and on the system

voltage. It is limited to a maximum of 25 mA, and when I

max

= 10mA is set, it is limited to 10 mA.

For planning purposes, it should be noted that no system components are present in which this test

current can bring about a damaging reaction, even in unfavourable cases.

The test current pulse flows from the test device via the ‘live’ leads, taking the shortest path to the

location of the insulation fault. From there, it flows via the insulation fault and the earth lead (PE

conductor) back to the test device. This current pulse is then detected by the clamp-on probes or

measuring current transformers located in the insulation fault path, and is reported by the connected

EDS165 evaluator.

Theclamp-onprobes and/ormeasuringcurrent transformers areused as residualcurrenttransformers

- that is to say, the PE conductor is not passed through the transformer.

Important: normal commercial clamp-on probes or measuring current transformers must not be

used.

The response value is determined by the sensitivity of the EDS165 evaluator. In DC as well as AC

and 3 AC systems, this is 5 mA as an arithmetic average value.

The accuracy is +/- 2 mA of the displayed measurement value. System faults and excessively high

system leakage capacitances may have a negative influence on the accuracy.

11

TGH1266E - 05/04

Operating Principle of the EDS3065

I∆=0

PE

Iab

Izu

I∆=0

PE

Iab

Izu

RF

Operation in the

RCM-Mode

In the RCM mode, the EDS3065 operates according to the principle of residual current

measurement. In this case, only the EDS165 evaluator unit with the clamp-on probe is used, and

the PGH185 test device is not required.

In accordance with Kirchhoff’s Law, the sum of the inflowing currents at every intersection in a

network is equal to the sum of the outflowing currents.

The two currents Ito and Ifrom are equal in

quantity but have different directions, so

that the resultant sum is zero. The EDS165

recognises this and no message is generated.

A portion of the current is flowing away

via an insulation fault RF. The sum of the

currents is no longer zero. If the residual

current is equal to or greater than the

response value, the EDS165 will generate

a message.

In the RCM mode, residual currents can be measured in one- and three-phrase TT or TN systems.

If the system leakage capacitance upstream of the clamp-on probe is sufficiently high, the EDS165

can also be used for measurements in one- and three-phase IT systems. Its suitability for this

purpose must be checked in each individual case.

12

TGH1266E - 05/04

4 Product Description

The System

Components at a

Glance

PGH185

100mA

10mA

25mA

Imax

ON

ON

Us

L1(+)

L2(-)

L3

AC/DC

aluminium case with

carrying strap

PSA3020

clamp-on probe

PSA3052

clamp-on probe

EDS165 Evaluator

PGH185 Test device

The primary function of the EDS3065 is that of an insulation fault location device in IT systems.

The individual components of the EDS3065 are used in combination for this purpose.

Not illustrated:

Power supply lead (europlug with connector for cold conditions) for PGH185 Insulation Fault Test

Device.

Safety measuring leads, 3 x black and 1 x green/yellow.

Safety claw grip to connect the PGH185 with the system conductors and PE.

BNC adapter unit/banana plug to connect measuring current transformers.

Banana plug.

Accumulator charging set for EDS165.

Accessory: clamp-on probe PSA3165 (internal diameter 100 mm)

PSA3320

13

TGH1266E - 05/04

Product Description

Parts List

Supply Voltage

Options

Caution

Caution

The EDS3065 Insulation Fault Location Device comprises the following components:

1 pc. Aluminium Case with Carrying Strap

1 pc. PGH185 Test Device

1 pc. EDS165 Insulation Fault Evaluator Unit, inclusive of accumulators

1 pc. PSA3020 Clamp-on Probe (diameter 12 mm)

1 pc. PSA3052 Clamp-on Probe (diameter 52 mm)

1 pc. Mains Cable

3 pcs. Safety Measuring Lead, black

1 pc. Safety Measuring Lead, green/yellow

4 pcs. Safety Claw Grip (3 x black, 1 x green/yellow)

1 pc. BNC Adapter / Banana Plug -> Transformer

2 pcs. Banana Plug

1 pc. Accumulator Charging Set

1 pc. TGH1266 Operating Manual

Before commissioning, please check that all the components listed above are included. Do not

undertake any work with an incomplete system. If any components are missing, please contact a

Technical Adviser at BENDER.

Two different EDS3065 Insulation Fault Location Devices are available. The difference between

them is the supply voltage for the PGH185 Insulation Fault Test Device:

• PGH185 - supply voltage: AC 230 V

• PGH185-13 - supply voltage AC 90 ... 132 V

Prior to commissioning, it is absolutely essential to check whether the supply voltage of the

EDS3065 system matches the voltage of the mains supply. Operation of the EDS3065 with the

wrong supply voltage can result in the destruction of the PGH185 Test Device.

When working with the EDS3065, only use those components which are supplied with the system.

In particular, do not use any other clamp-on probes, measuring leads or measuring terminals.

The EDS3065 represents a complete system. In addition to the PSA3020 and PSA3052 clamp-

on probes which are supplied with the system, measuring current transformers can be connected

to the EDS165 insulation fault evaluator. These may be BENDER Measuring Current Trans-

formers which are already installed in the system.

The following types of transformers are suitable:

Measuring Current Transformers, Model Series W1-S35 ... W5-S210

Rectangular Measuring Current Transformers, Model Series WR ...

Split-Core Type Measuring Current Transformers, Model Series WS ...

Important: normal commercial measuring transformers must not be used!

This also applies to additional clamp-on probes or measuring current transformers from the

BENDER range.

Attention: if transformers are not being used, they must not be left open in the system. In this case,

the transformer terminals k u. l should be shorted.

14

TGH1266E - 05/04

Product Description

Aluminium Case

430

310

340

145

155

EDS165

Insulation Fault

Evaluator

BNC-socket for clamps or

measuring current transformers

RS232-interface

Alarm-LED

socket for power pack

keys

LC-display

selection switch

Theoperating mode switch onthe EDS165

has three positions:

Middle Position: OFF - the device is

switched off.

Position I∆s: Function as evaluator

within an EDS3065 or

EDS470 system (EDS

mode)

Position I∆n: Function as residual

current measuring

device (RCM mode)

All dimensions in mm

All the components of the EDS3065 are accommodated in a stable aluminium case with foam inlays.

15

TGH1266E - 05/04

Product Description

Test Device PGH185

PGH185

100mA

10mA

25mA

Imax

ON

ON

Us

L1(+)

L2(-)

L3

AC/DC

solid casing with grip

ON/OFF switch

eurosocketfor cold

conditions

Fuse 100 mA socket for PE-

connection

3 sockets for coupling to the

electrical system

Display-LEDs:

ON Operating-LED

indicates positive test cycle

indicates negative test cycle

selection switch

for max. test

current

(25 / 10 mA)

Not visible:

magnetic adhesive strip on

the rear side of the housing

to fasten onto metal parts

(switch cabinet).

The PG185 is activated by using its ON/OFF switch, and it generates a defined test current signal.

The voltage present in the system is used to drive the test current. The value of the test current which

is generated therefore depends on the value of the insulation fault that is present, and on the system

voltage. The test current is limited to a maximum of 25 mA, or to 10 mA when the switch is in

the 10 mA position. The test current flows from the system via the PGH185 and then through the

protective conductor (PE) and the insulation fault (or faults) back into the system. The test current

signal is registered by the clamp-on probes or measuring current transformers located in the fault

current circuit, and the sections affected by faults are displayed by the EDS165 insulation fault

evaluators whenever the operating threshold of 5 mA is exceeded.

If the PGH185 is active, the cycle LEDs light up alternately in time with the test cycle.

If the device is connected by terminals L1, L2, L3 (or L1, L2) to a system that is ‘live’ for operational

reasons the terminal must not be disconnected from the protective conductor (PE).

The test current flows between the system and earth. If unfavourable combinations of

circumstances arise (low-impedance insulation fault in combination with the test cycle),

control errors cannot be ruled out on very sensitive system components (SPC, miniature relays).

This possibility should be taken into account prior to use. If this possibility exists, then setting Imax

= 10 mA should be selected.

16

TGH1266E - 05/04

Product Description

PSA3020

Clamp-on Probe

PSA3052

Clamp-on Probe

The PSA3020 clamp-on probe can be

used to encircle leads of up to 20 mm in

diameter. TheconnectiontotheEDS165

insulation fault evaluator is made via a

BNCconnectorand measuring leadwith

a length of approximately 2 m.

The PSA3052 clamp-on probe can be used to encircle leads of up to 52 mm in diameter. The

connection to the EDS165 insulation fault evaluator is made via a BNC connector and measuring

lead with a length of approximately 2 m.

PSA3320

PSA3052

MESSZANGE / CLAMP ON PROBE

Datenblatt / Datasheet : TGH 1266

Durchmesser / Diameter : 52 mm

Art.-Nr. /Art.-no. : B 980 694

max. 1 A

600 V CATIII

1000 mA / 0,1 mA ~

17

TGH1266E - 05/04

Product Description

Technical Data

EDS3065

EDS3065 Insulation Fault Location Device

Insulation co-ordination acc. to IEC 664-1: dependent on the

current sensor used

Type of operation: continuous operation

PGH185 Insulation Fault Test Device

Rated insulation voltage: AC 500 V

Rated impulse withstand voltage/contamination level: 4 kV / 3

Monitored System

Operating range of Rated mains voltage, AC: 19.2 ... 575 V

Operating range of Rated mains voltage, DC: 19.2 ... 504 V

Supply Voltage

Supply voltage, US: AC 230 V for PGH185

Operating range at AC 230V : 0.8 ... 1.15 x UN

AC 90 ... 132 V for PGH185-13

Fuse protection for supply voltage: Fine-wire fuse, 100 mA, slow-acting

Measuring Cycle

Maximum test current: 25 / 10 mA

Test cycle: 2 s

Pause time 4 s

Type Tests

Test of electromagnetic compatibility (EMC):

Immunity against electromagentic interference acc. to EN 50 082

Emissions acc. to EN 50 081:

Emissions acc. to EN 55 011/CISPR11: Class B *)

Mechanical Tests

Shock resistance, to IEC 68-2-27: 15 g / 11 ms

Bumping acc. to IEC 68-2-29: 40 g / 6 ms

Vibration strength acc. to IEC 68-2-6: 10 .... 150 Hz / 0.15 mm - 2 g

Environmental Conditions

Ambient temperature during operation: -10 ... +55 °C

Ambient temperature during storage: -40 ... +70 °C

Climate class acc. to IEC 721: 3K5, but without dew and ice formation

General Data

Operating position: as desired

Type of connection: flexible safety leads with safety terminals

Set-up mode: upright, horizontal, or on metal parts with the use of magnetic strips

Protection class acc. to EN 50529: IP20

Weight: approximately 700 g

Dimensions, WxHxD: 160x148x81 mm

*) Class B devices are suitable for the use in industrial application as well as in house holds.

18

TGH1266E - 05/04

Product Description

Technical Data

EDS165

+-

Technical Data

Clamp-on Probes

Insulation co-ordination acc. to IEC 664-1: depends on the clamp-on probe used

Type of operation: continuous operation

Monitored System:

Rated insulation voltage: see PGH185 and/or clamp-on probes

System frequency in EDS mode: 50, 60, 400 Hz (adjustable)

System frequency in RCM mode: 45 ... 65 Hz

Supply Voltage

Supply voltage US: DC 6 V

Operating range: 4.2 ... 6.2 V

Supply: via 4 round cells, type LR6 AA - 1.5 V or 4 NC cells, 1.2 V, or via accumulators or power

unit

For supply via external power unit: DC 7.5 V

Imax: 100 mA

Polarity:

Operating lifetime of the batteries: minimum 8h

Power consumption: 0.6 W

Measurement Input for I∆sFunction

(EDS Mode, in combination with EDS470 Systems)

Operating value: 5 mA

Accuracy: +/- 2 mA

Measurement Input for I∆nFunction

(RCM Mode, Residual Current Measurement)

Measuring range with clamp-on probes: 10 mA ... 16 A

Measuring range with measuring current transformers: 10 mA ... 10 A

Operating range for alarm: 10 mA ... 10 A

Accuracy: +/- 10 %

RS232 Interface with 9-Channel Sub-D Plug Connector

Weight: approximately 370 g

Clamp-on probes:

Insulation co-ordination acc. to IEC 664-1

Nominal insulation voltage, PSA3020 AC 250 V

Nominal insulation voltage, PSA3052 a. PSA3165 AC 630 V

Voltage test acc. to IEC 348:

PSA3020 AC 3 kV

PSA3052 a. PSA3165 AC 2 kV

Type of protection acc. to DIN 40 050 IP40

Protection class acc. to VDE 0411 Class III

Measurement output BNC plug

Dimensions, PSA3052 216x111x45

Dimensions, PSA3020 135x65x30

Dimensions, PSA3165 308x150x43

Permissible cable diameter, PSA3052 52 mm

Permissible cable diameter, PSA3020 20 mm

Permissible cable diameter, PSA3165 100 mm

Weight, PSA3052: approximately 550 g

Weight, PSA3020: approximately 200 g

Weight, PSA3165: approximately 1700 g

19

TGH1266E - 05/04

5 Operation and Setting

Factory Settings

Settings on the

EDS165 Evaluator

Switching On the

EDS165

Three buttons are used to operate the EDS165:

The components of the EDS3065 are delivered with factory settings, which are suitable for many

standard applications. The following list shows the factory settings for the individual devices:

PGH185 Test Device

Imax = 25 mA

EDS165 Insulation Fault Evaluator (with the switch in position I∆s)

Alarm storage: off

Buzzer: on

Frequency: 50 Hz

Sensor: Clamp-on Probe PSA3052

Except for the changeover of the maximum test current, all the settings to the EDS3065 system are

performed on the EDS165 Insulation Fault Evaluator.

The operating mode selector switch on the left-hand side of the EDS165 has three positions:

middle position : OFF - the device is switched off

right-hand position : I∆s- function as an insulation fault evaluator within the EDS3065

or one within the EDS470 system (EDS mode)

left-hand position: I∆n- function as a residual current measuring device

(RCM mode)

operating mode selector switch

I∆nI∆s

UP DOWN ENTER

20

TGH1266E - 05/04

Operation and Setting

The EDS165 is operated and set using three control buttons and the LCD display. When making

any of the settings, you must press the relevant control buttons for about 1 second. The different

settings which are possible in the EDS mode (position I∆s) are described below.

If you move the operating mode selector switch to position I∆, the EDS165 will be in the EDS mode.

As soon you have done this, you will see the display menu (see above).

The EDS165 in

the EDS-Mode

The EDS165

Display

From the display menu, press the <ENTER> key to reach the setting menus. The <ENTER> key

activates whichever sub-menu you have called up; use the <UP> key to move to the next menu.

Here is an example of a display on the EDS165 in the EDS mode:

test current (measuring

value) response value exceeded

go on with <ENTER>

adjusted frequency of the

electrical system

buzzer is activated

clamp-on probe is

correctly connected

indication of battery

charging

Ι∆s=8 mA ALARM

50Hz

Menu 1 (m1) allows you to set the sensor

which is connected. The possible settings are:

clamp-on probes

split-core measuring current transformers

closed measurng current transformers.

Press <ENTER> to reach the menu for modification; press <UP> to move on to the next menu,

m2.

The sensor which is set at present is the PSA3052

clamp-on probe. Press <ENTER> to accept this

setting and then return to the display; or use the

<DOWN> key to set the PSA3020 clamp-on

probe and/or split-core measuring current transformers or closed measuring current transformers.

The following settings are possible:

PSA3052 Clamp-on Probe Standard Measuring Current Trans-

formers: W1-S35 ...

W5-S210; W1-P ... W4-P, WR ...

PSA3020 Clamp-on Probe Split-Core Measuring Current Trans-

formers in the

WS ... series

PSA3165 Clamp-on Probe

sensor:

sensor:

m2:

m1: set sensor

Table of contents

Popular GPS manuals by other brands

US Fleet Tracking

US Fleet Tracking PT-X5 user guide

TitanGPS

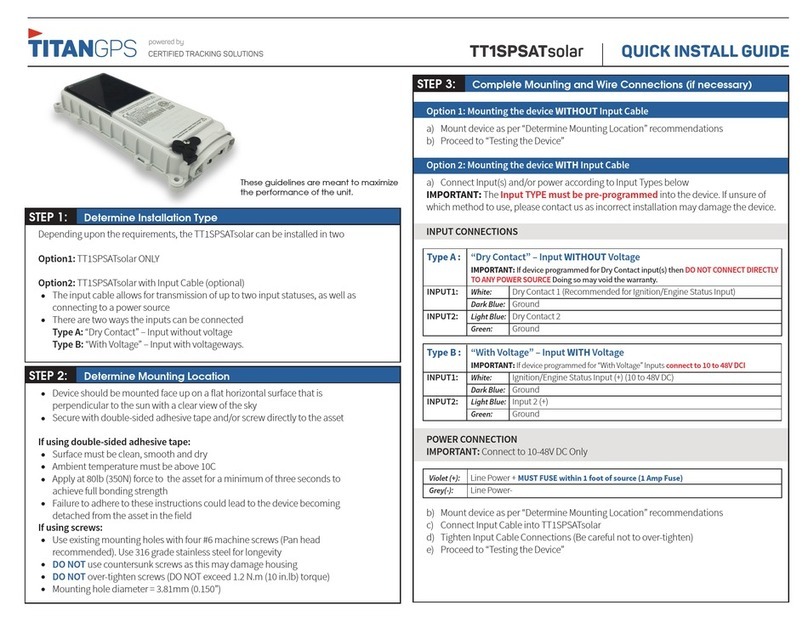

TitanGPS TT1SPSATsolar Quick install guide

CalAmp

CalAmp LMU-3 Series Hardware installation guide

CalAmp

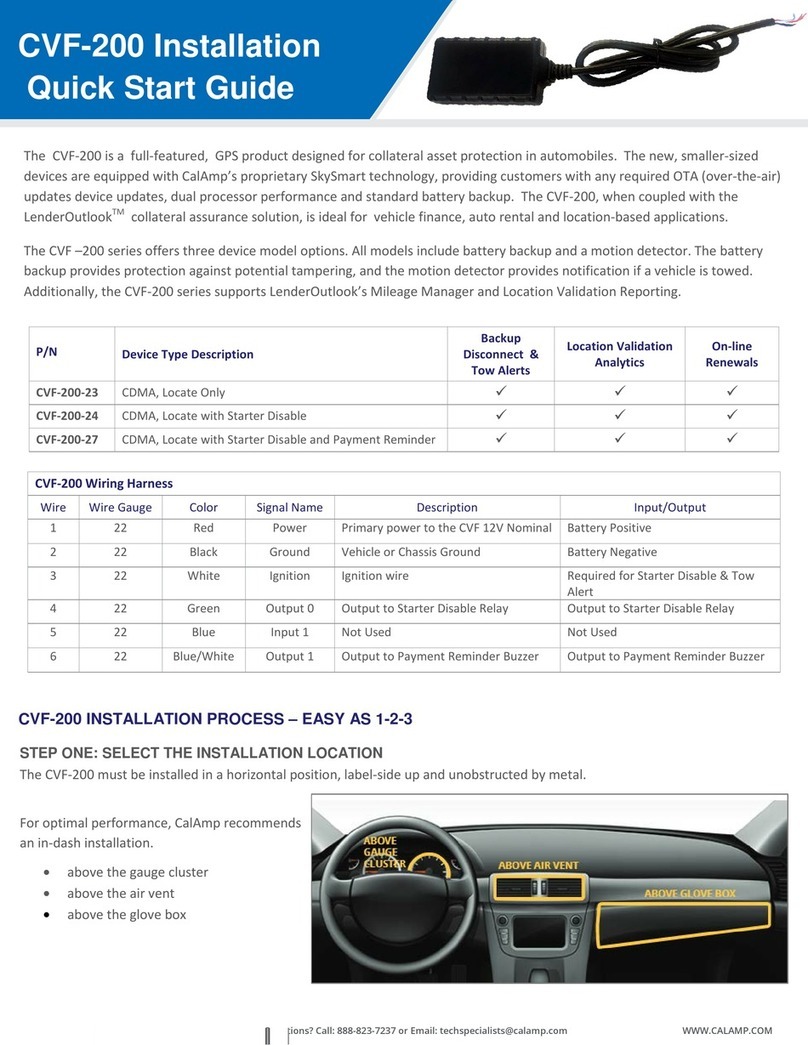

CalAmp CVF-200-23 Installation & quick start guide

mySmartObject

mySmartObject IOT-200 user manual

Tracking The World

Tracking The World Enduro Plus CDMA user manual