Bengtson BE2C User manual

BE2c367/8”

Copyright©2007‐11M.K.BengtsonAllRightsReservedRev07/11

BE2C 36 7/8” 1/12th Scale

R/CScaleModelInstructions

CONTACTINFORMATION

DesignedbyM.K.Bengtson

PrototypebyJohnO’Duffy

ManufacturedandDistributedby:

BengtsonCompany

www.aerodromerc.com

BE2c367/8”Page1

Copyright©2007‐11M.K.BengtsonAllRightsReservedRev07/11

BE2C367/8”1/12thScale

Thankyouforpurchasingthe1/12thScaleBE2Cfor

electricflight.

FinishedModel

ModelSpecifications

Morethan255lasercutparts

Scale: 1/12

Channels: R/E/A/T

Wheels:balsaandplywoodwithNeoprenefoamtires

Wingspan: 367/8ʺ

WingArea: 374.5sqin

Weight: ~25oz

PowerSystem:GWS300c

Prop: 10x7

AirfoilType: Flatbottomed;optionalundercamber

Cowl: N/A

Spinner: N/A

Decals: Availableonwebsite

Designer: M.K.Bengtson

Prototype: JohnO’Duffy

Preparation

Layoutthe2plansheetsandlasercutkitparts.

Studytheplansandidentifyallsuppliedparts,you

mayliketomarkthepartnumbersbesidethepartfor

lateridentification.Asyougo,prepareyour‘stick

shoppinglist’ofstocknotincluded.Thislistwillinclude

butisnotlimitedto,suchaswingspars,leadingedges,

1/8”squareforrearfusesection,andsome1/16”and1/32”

balsasheeting.

Plansandpartslaidout.

Duringconstruction,plansshouldbecoveredwith

somesortof‘planprotector’suchascommercially

availabletypes,or‘greaseproofpaper’orclingwrapor

eventheplasticbagthekitcamein.

Glueisuptoyou,somebuilderslikeCAglueswhich

certainlyspeedsconstructioningeneral,butensureyour

workareaiswellventilatedasmanypeoplehaveadverse

reactionstothepoisonousfumes.Epoxyglueshouldbe

usedforthefusefrontmainstructureforstrengthand

durability.‘White’woodglueisagoodalternativetoCA,

ittakeslongerwaitingforittosetbutgivesmoretimeto

preciselylocateparts,avoids‘stuckfingers’andis

generallyamorestressfreeexperience.

Tools.Notmuchmorethanasharpknifewithagood

supplyofreplacementbladesandsomesandpaperis

required.Veryhelpful,especiallywiththismodelis

havinganumberofset‐squares,straightedgesandrules

availablefortruinguppartsasconstructionproceeds.

Whenremovingpartsfromthesuppliedsheetsuse

careandaverysharpbladetocutthesmallbridges

holdingthepartintothesheetbeforeremovingit.Simply

pressingthepartoutofthesheetriskstearingorbreaking

it,especiallywithsomeofthefinerparts.

Thefuse,wings,tailsurfacesandundercarriage

sectionsareallconstructedseparatelyandbrought

togetherattheassemblystage.Itdoesnotmatterinwhich

orderthesesectionsareconstructedbutnormaladvise

wouldbetostartwiththetailplanesasthattendstobe

easiestandleadsintowingthenfuseconstruction.This

wouldbegoodadviseifyouarenotfamiliarwith

AerodromeRCkits.

BE2c367/8”Page2

Copyright©2007‐11M.K.BengtsonAllRightsReservedRev07/11

TailPlanes

VerticalFinandRudder

RemovepartsS1–S9fromthe1/8”sheet.Youwillalso

needsome1/16”x1/8”balsafromyourstickstock.After

coveringtheplanswithyourchosenprotectorlaythe

partsovertheplans.Whenyouarehappywithhowthe

finandrudderaretobeconstructed,startbypinningthe

twoverticalpieces(S3andS4)totheboard,thenwork

aroundtheruddergluingandpinningeachpieceto

completetheoutsideoftheframe.Fillinthethree

1/16”x1/8”piecesandS11tocompletetherudder.Finish

offtheverticalfinbygluingS1andS2toS3andaddthe

two1/16”x1/8”ribs.Makesureeverythingstaysflat.

Allowwhateverglueyouareusingtocompletelycure

andhardenbeforeremovingthecompletedpartsfromthe

plans.Don’tattachtheplycontrolhornuntilafter

covering.

HorizontalStab.andElevator

H5&H2arelongandsomewhatfragile,usecarewhen

removingthemfromtheirsheetsandwiththelightestof

sandingremoveanyremnantsofthelasercut‘tags’.

Usingastraightedgetokeepitdeadstraight,pinH5

totheplansinposition.GlueandpinH1,thenwith

anotherstraightedge,similarlyglueandlocateH2toH1.

AddthetwoH4sidepiecesandH3’stothecorners.Cut

andfitthe1/8”x1/16”ribs.

Tip:Cutthefirstrib,sandandfitneatlytothe

horizontalstabiliser.Cutalltherestfromthispattern

makingthemeversoslightlyoversize.Acoupleofstrokes

onsandpaperwillbesufficienttotunethesetolengthas

youfitthem.Donotdistortthestructurebytryingto

squeezeinaribthatisjusttoolong,acouplemorestrokes

onthesandpaperandit’llbeperfect.Ifyouover‐sandany

andit’stoolooseafit,putitasideandcutanother.The

shortonecanbeusedforanelevatorrib.

Horizontalstab.startandcomplete.

Whenalltheribsaregluedintothehorizontal

stabiliserremovethestraightedgeagainstH5.

Elevators.

PinthetwoE1totheplans,somethinspacermaterial

betweenH5andthetwoE1willmakethiseasy.Work

aroundtheoutsideontheelevatorstocompletethe

outline.Addtheribsandthetwocontrolhornanchorsto

completethissection.Donotaddthecontrolhorns

themselvesuntilaftercovering.

Wings

Thewingscanbebuiltwithorwithouttheoptional

undercamberwhichislasercutintotheribs.Itisnomore

difficulttohavethisoptionreally,theribsstillsitnicely

flatonthebuildingsurfaceevenafterremovingtheextra

material.Undercamberdoesrequirealittlemore

attentiontotheaileronservohatchareaandyou’llneedto

checkyourservo’sarethinenoughinthenarrowedwing.

Ifyoudowantundercamber,thelasercutlinesareeasy

tofinishwithasharp#11knifebladeandatouchof

sandpapertoremovethe‘bumps’.Don’toversand.Finish

eachrib’slowersurfaceasyouremoveitfromit’ssheet

andyouwon’tevenhavetosandtheundercamberonthe

completedwing.Otherthanalittlemorepreparationof

eachrib,andservorailfitting,wingassemblyisthesame

withorwithoutundercamber.Alsonotewithunder

camber,theply‘P’piecesthatmakethecarbanestrut

socketswillneedsomemoreattentionontheunder

surfaceoftheupperwingbeforecovering.

BE2c367/8”Page3

Copyright©2007‐11M.K.BengtsonAllRightsReservedRev07/11

UpperWings

Selectfourstraight¼”x1/8”bassorsprucesparsfrom

yourstock.Shapetheoutboardendsofthesparsasper

thedetailontheplans.

Foreachwing;

PinW1andW1ainposition.Cutsparstolengthand

fixtoplans.Glueandplacetheinboardoneofthetwo

R3’s,R5andthewingtipR6,checkallisflattothe

buildingsurface,straight,andtheribssquare.

Alsonotethatwiththeinboardribsoftheupperwings

thesparcutoutsarelargerthanthespartoallowlater

insertionoftheplydihedralbracesinfrontofthespar.

Whengluingtheseribstothespars,ensurethesparis

againsttherearofthecutoutintheribs,leavingroom

(1/16”)fortheplybrace.

‘X’pinningthesparswillholdthemdownanduprightwhile

fittingtheribs.

Positionthelowerinboardplytrailingedge.

LeavingribR2tilllast,glueintheremainingribsand

halfribstothewing.GlueinribR2usingtheRFGguide

supplied,thiswillhelpachievethecorrectdihedralangle

whenthetopwingsarejoined.ThetopofribR2leans

awaytowardsthewingtip.

Addtheuppersurfaceplytrailingedges,andapplya

littleweightsothetrailingedgestaysflatandstraight.

Theplytailingedgepiecesrequirenoextratapering,the

narrowedribsaredesignedtolettheedgesoftheplyto

justmeetalongtheirbackedges.

Cuttolengththe¼”x¼”leadingedgefromyourstick

stock.Carefullyremoving/sandingoffonepointofthe

squaresectionforitslength,asindicatedbytheplans,test

andthenfittheleadingedgetothemouthsoftheribs,

glueinplace.Installtheply‘P’pieceseithersideofthe

1/8”ribstoformtheIPstrutsockets.FittheTEpiecesto

finishthewingattheaileronmount.(NottheLEpieces,

theybelongtotheaileron!)

Ailerons

Preparethe6aribpiecesandtheone1/8”6bpiece.Pin

W2andLEinpositionleavingasmallgapattherootend

foraileronclearance.Usingapinwillhelpkeepthegap.

Layaplytrailingedge(upperwing,lower=plywith

horncutout)ontheplanandfit6battherootendanda

6aatthetipend.

Gluetherestofthe6aribsinpositionandaplytrailing

edgeontop.Ensuretheplypiecesaresittingflatinthe

ribsandapplysomeweighttokeepitallflatastheglue

hardens.(Ontheupperwingsthistopsurfaceplypiece

hasnocutout)

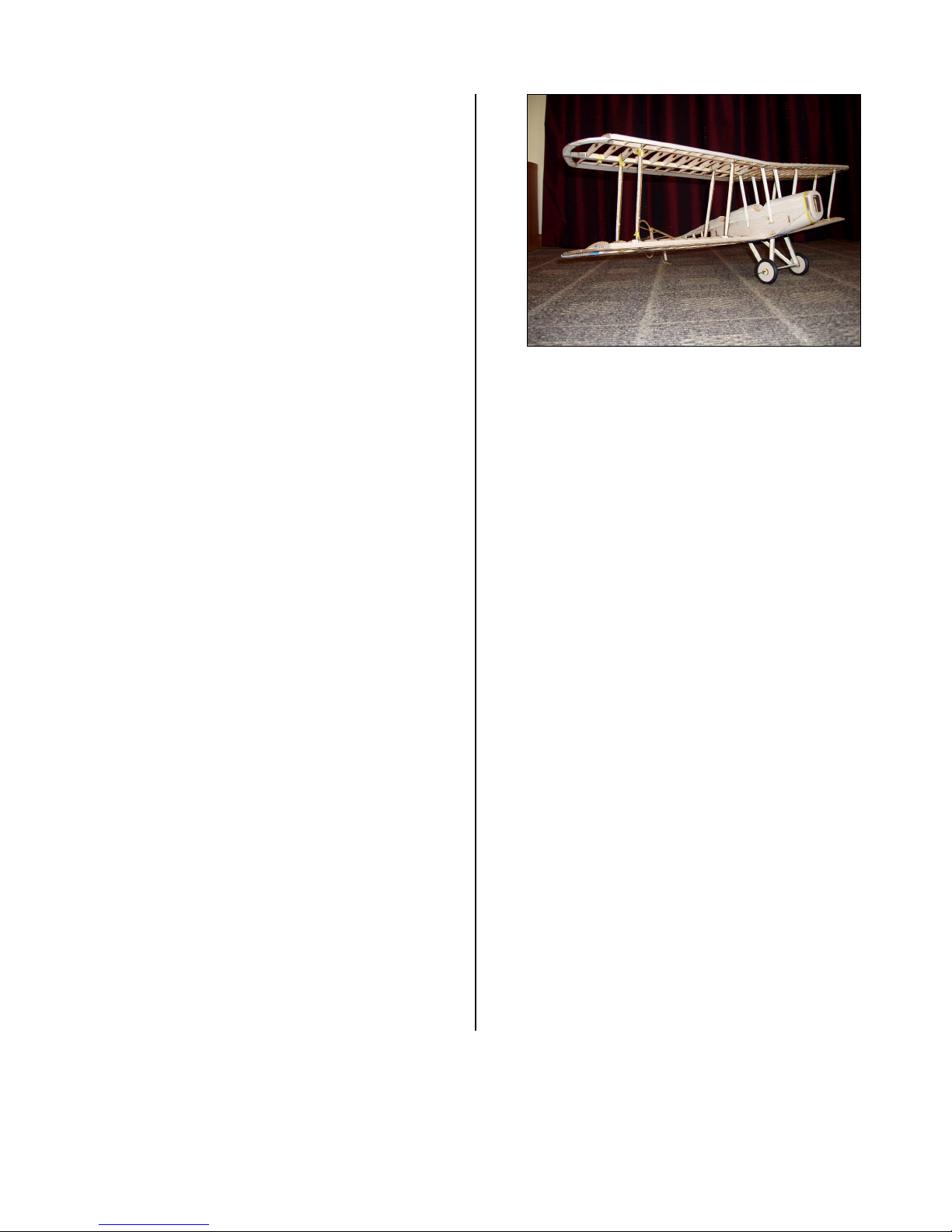

TheWingWorks.Wingsatvariousstages.

LowerWings

Proceedasforupperwingsforthebulkofthe

construction.Lowerwingsparscanbeleft1/8”overlong

attherootends;therearecutoutsinthefusesidesto

receivethesesparends.

Withtheaileronsensurethecontrolhorncutoutsinthe

plytrailingedgesareontheuppersurfacethistime.The

BeWarned!Controlhorncutoutsinthe

plyailerontrailingedgesneedparticular

attention.Ontheupperwingthecutouts

areonthelowersurface,onthelowerwing

theyareontheuppersurface.Alsomake

surethecutoutisoveritspositiononthe

plans.

BE2c367/8”Page4

Copyright©2007‐11M.K.BengtsonAllRightsReservedRev07/11

lowerwingaileronsalsohavethebalsacontrolhorn

mountlabelled‘3’;thisisflushwiththelowersurfaceof

theaileron.

PartsW3andW4needshapingtosuit,W3being

taperedtosuitandW4trimmedtothewingcord

(thickness)beforebeingfitted.Sheettherootwingpanel

(uppersurfaceonly)with1/32”balsaasindicatedonthe

plan.Epoxyinthe1/8”dowelsleaving1/8”protruding

whichwilllocateintheholesprovidedinthefusesides.

Fourstrongwings

AileronServohatch/mounting

Ifyouarenotusingtheundercamberoption,gluethe

¼”x¼”servorailsinpositionbetweentheribsoverthe

plans.Ifyouwanttheplycoverrecessed,putsome1/32”

packingbetweentheplanandtherailasyoupositionit.

(Don’tglueinthepacking!)Alsoifyouarerecessingthe

cover,addanotherpieceof1/8”balsatothefrontservo

railflushwiththewingribs,to‘finishthebox’andattach

thecoveringmaterialto.

Servohatch,undercamberandrecessed.

Ifyouareusingundercamber,waittillthelower

wingsarecompletelydry.Markthepositionsoftheservo

railsonthewingribsfromtheplansthenliftthewings.

Testtherailsinthemarkedpositionsflushwiththe

sandedlowersurfaceofthewingribsbyusingtheply

hatchtocheck.Torecess,pushinthehatchsoit’sflush

withtheribs.Tacktherailsinplace,checkwiththeply

hatchallisniceandflush,removehatchandsecurethe

rails.Alsoifyouarerecessingthecover,addanother

pieceof1/8”balsatothefrontservorailflushwiththe

wingribs,to‘finishthebox’andattachthecovering

materialto.

Theservoisattachedtothehatchbygluingitdirectly

orscrewingittoblocksgluedtothehatch.Hereblocksare

gluedtothehatchtopositiontheservoandsiliconwillbe

usedtoglueintheservosothatitcouldberecycled.Some

builderswraptheservointapethengluethetapedservo

inplace.Latercuttingthetapewillreleasetheservo.

Joiningtheupperwings

Assemblethecentresectionoftheupperwing,joining

the3ribstotheplytrailingedgepiecesandasectionof

preparedleadingedge.Installapieceof1/8”x¼”spar

materialtothebackofthespacesintheribs.Prepare1”x

6”blockswhichwillgounderthewingtipsastheyare

assembled,toestablishthedihedralangleofthewings.

Trailfitthefourplydihedralbracestotheupper

wings.Asmallfilewillhelprelievingtheslotsinthewing

ribsiftheyaretootight.Thebracesmayneedtrimmingso

theymeetatthecentrelinewithoutinterference,check

thisovertheplan.Whenthefitisgood,epoxythemin

place.Locatethewingsovertheirpositionontheplan

withthe1”blocksunderthetips,applyepoxytothe

assembledcentresectionribsand‘spar’andslideitdown

betweenthewingribsslottingtheplydihedralbracesinto

position.Checkthatthecentresectionissittingflatonthe

worksurface,thewingtipdihedralblocksareincorrect

positionandthatthewingsatthatpointaresittingflaton

theblocks.Checkyouhaveanicestraightlinealongthe

leadingedge.

Upperwingcentresection.

BE2c367/8”Page5

Copyright©2007‐11M.K.BengtsonAllRightsReservedRev07/11

FuselageConstruction

Thefuselageisbuiltintwosections,afronthalfanda

rearhalfwhicharethenjoinedovertheplan.This

simplifiesconstructionandhelpsensureastraight

fuselage.

Cowl

GluepartsC1andC2together.The‘top’(flatter)

surfacesandsidesareflush,thelower(morerounded)

surfacesaresteppedforlatersandingtotheprofileonthe

plans.

FrontSection

Startbypinningone1/8”balsafusesidetotheside

viewplanandepoxyFCBandRCBcarbanestrutsinto

theirslotsinthefuseside.NoteFCBandRCBare

different.Ensureeverythingispreciselyovertheplanand

thestructurestaysflatwhilethegluesets.Wing

alignmentwilllaterdependontheaccuracyofthis

assembly.

EpoxyFCBandRCBintofuseside.

Whenthegluehascompletelyhardenedonthefirst

side,eitherremoveitandrepeatforthesecondside,or

buildthesecondsideoverthefirstwithapieceofcling

wrapinbetweensothetwodon’tgluetogether.Either

waytheintentistoachieve2identicalsideswiththe

carbanestrutsalignedandvertical.Thereisnoleftorright

sidetoworryaboutheretheyarethesame.

WhilethesecondsidesetslocatepartsF2,F6,F1Dand

cutthe1/8”x1/4”crossbracesinpreparationforjoining

thefusesides.CleaningouttheU/ClacingholesinF1D

(andF1C)witha1/16”drillwillbeeasiernowthanlater.

Formingthebasisofthefrontfusesectionbeginswith

pinningF1Dtotheplanviewoverit’slocation(note

orientation–lacingholestotherear).Usingepoxy,attach

thetwofusesideswithF2andF6between,toF1Dand

thenthecrossbracestothetop.Taketimeatthisstage,

andusestraightedgesandsquarestoensureeverythingis

deadstraightandsquareandthatthecarbanestrutsand

fusesidesareverticaltothebuildingsurface.

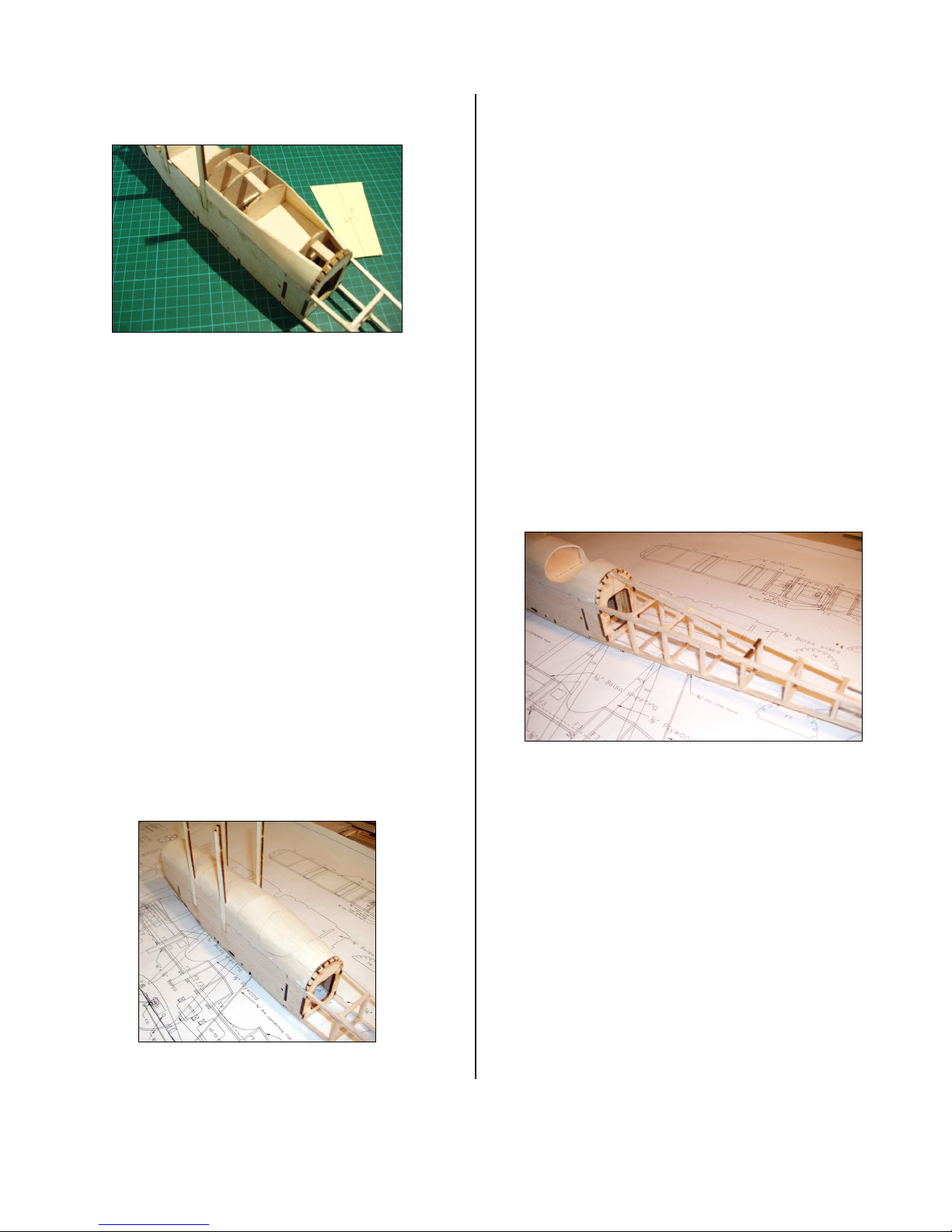

Mainfusepartssetting.(Smallbagofshotweighingthings

down)

Therestofthefuseformersetccanbegluedinafter

thetruenessofthebasicstructurehasbeenachieved.

Nowtheplansideviewhasbeenvacatedconstruction

ofthetaillatticecouldbeginwhiletheepoxysetsinthe

fronthalf.SeeTailSectionbelow.

Whenthebasicfrontstructurehascompletelyset,

continueaddingtheremainingformersF1,F3,F4andF1C

(lacingholestothefront).CheckF1isvertical,withthe

fuseonits‘flat’(ieF1Disflattothebuildingsurface).

Checkcarbanestrutsremaintruewhenattachingthefour

F3formerseithersideofthesestruts.NotetheformersF3

&F4arenarrowerthantheoverallwidthofthefusesides

toallowforthelater1/16”sheetingoftheupperhalf,

ensuretheyareevenlyspacedeitherside.

Installthemotormount3/8”squarestock,usethe

planstohelpestablishthe2‐3degreerightanddown

thrustangles.Completethisstagebygluinginthefour

servomountingrailsasindicatedontheplans.Allowglue

tosetcompletely.

Nextthefusesidesneedtobescoredandcracked

behindF6totaperthesidestothenarrowerF7.

AfterscoringtheinsidesofthesidesjustbehindF6,

locatethefuseovertheplansandbend/crackthesides

behindF6inwardsevenlytoconformtothewidthofF7

keepingitallalignedandpositionedwiththeplans.Glue

andtemporarilytapeF7tothesides.Gluereinforcesyour

BE2c367/8”Page6

Copyright©2007‐11M.K.BengtsonAllRightsReservedRev07/11

score/cracklines,ensureeverythingconformstotheplan

andallowtoset.

FusecrackedforF7

Tohelpavoidhangerrashlateronafewothertasks

canbecompletedatthisstage.Epoxythetwo1/8”brass

bearings(cutfrom1/8”brasstube)intotheirholesinthe

fusesidesjustforwardofF6.Usealengthon3/32”rodor

tubethroughbothbearingstokeepthemalignedasthe

epoxysets.Thebearingsshouldbeflushtotheoutside

andcaneachbe3/8”longsoastogive¼”ontheinside

forglueattachment.Ensureyour‘alignmentrod’through

thebearingsdoesnotgetgluedinplace!

Sheettheundersidefrontofthefuselagewith1/32”

balsa.Usecardtomakeapatternoftheshaperequired,

trimminguntilit’saperfectfitapartfromthefront,which

canbeleftover‐lengthandtrimmedlater.Cutapieceof

1/32”balsasheettothispatternandsoakunderawater

soakedpapertowelfor20‐30min.Thatshouldmakeit

flexibleenoughtotakethecurvedshape.Glueandtape

thesheetinposition.

(Tip:Ifyouarenotexperiencedinsheetingcurveswithbalsa,

thisisafairlysimplecurvetostartwith.Usecardtocreatea

pattern,you’llfind,balsabendsawayfromthewetside,balsa

expandsasitsoaksandshrinksbackasitdries.Bepreparedto

havemorethanone‘go’atyourfirstsheetingattempts,ifit’s

wrong,orthebalsacracksthrowitaway,startagain,it’lltake

onlyaslongasittakestogetright.)

Lastlythemotorcanbefittedtothemountstickwitha

screwortwo,screwsskewedtothefrontsothatthey

couldberemovedthroughthefrontforservicing.The

motorcannowbetakenoutagainsoitdoesnotgetfilled

withbalsadustlater.

Frontandrearsectionsreadytojoin.The‘bar’throughthefuse

iskeepingthebearingsaligned.

Thefrontsectionisnowreadytojointotherear

sectionwhenthatiscomplete.

TailSectionofFuselage

LocatepartsFS1andFS2.Pinthe1/8”square

longeronstotheplanandglueinthecrosspieces,andFS1

andFS2atthetail.Apieceof1/8”squarestockhasbeen

usedinthephotobetweenFS1andFS2tomaintainthe

spacingrequiredforthelaterinsertionofthehorizontal

stabiliser.Makesureitdoesnotgetgluedin!

Fusetailconstructionstarts.

Whenthefirstsidehashardenedremoveitfromthe

plan,turnitover,coverwithalayerofclingwrapand

buildthesecondsideoverthefirstsothetwoare

identical.

BE2c367/8”Page7

Copyright©2007‐11M.K.BengtsonAllRightsReservedRev07/11

Thenthereweretwo

Jointhetwosidesovertheplans.

Notethesideshaveatopandbottomnow,established

byFS1&FS2.

Dothebottomsurfacefirst,pinSF7inpositiononthe

plan,buttthetwosidesuptoSF7keepingthemvertical

andlocateSF5andthesmall1/8”sq.crossbrace(between

SF7andSF5),betweenthetwosides,addthe1/8”sq.to

thefrontofSF5.Addtheremainingfivecrosspieces.Keep

everythingflatandthesidesvertical,allowtodry.

Gluingthecrossbracesbottomsurfaceofthetail

Thetailpiececannowbeturnedoverontheplanand

thetopsurfacedonesimilarlyusingFS6thistime.Note

‘leaveout’twoofthecrossbraces,theonesatlocations

F10andF11arekitsuppliedpartsandwillbeattached

later.

FinishoffaroundthetailareawithpartsSF3andSF4

oneachside.(Apieceof1/8”scrapsheetwrappedincling

wrapstandinginforthehorizontalstabiliserwillhelp

keepeverythingalignedandinposition.)TheendsofSF3

andSF4willneedlightsandingtoneatlymeetatthepoint

andsides.MakingSF3andSF4slightlyproudwillallow

sandingofthisareatotheprofileformedbythetwoSF7

Tailsectionreadytojointofront.

Joiningfrontandtailfusesections.

Thisimportantstepisrelativelyeasy,inthattheunder,

rearsection/planeofthefrontfuseandthebottomsurface

ofthetailsectionareaflatplaneallowingbothtobeflatto

thebuildingsurfaceduringconstruction.

Usestraightedgesorblocksfixedtotheplanseither

sideoftheforwardfusesectiontokeepitaligned.Rock

thefusebackbetweenit’sguidessothatitsitsflatonthe

backfacetoftheunderfuseshape.Usesomeweightto

holdthefuseinthis‘noseup’attitude.Nowslidethetail

section(dry,noglueyet)intopositionlocatingthe4

longeronendsintotheirsocketsinthefrontfuse.The

bottomsurfaceofthetailsectionisflattothebuilding

surfacejustliketherearoftheforwardsection.Check

everythingovertheplansforlengthandalignmentand

thatthe‘point’ofthefusetailisexactlyoverit’sposition

ontheplans.Trimlongeronsiftheyaretoolong.When

youarehappyallisasitshouldbe,slidethetailoutagain,

applygluetothesocketsinthefusefrontandslidethetail

backintoposition,checkthepointofthetailagain,and

allowtoset.Standbackandadmireyourperfectlystraight

fuselage.

Finishoffanyremainingformersandthecockpitfloors

inpreparationforsheetingthetopofthefuse.

Uppersheetingstarts

Cutsomelengthsof1/16”balsafortheuppersidesof

thefuse,wideenoughtofillbetweenthe1/8”lowerfuse

sideandthe‘chine’lineoftheupperformers.Sandor

planeanangleonthetopedgeofthesetocontinuethe

lineoftheformertops,thiswillhelpwithfittingthetop

sheet.Cutthesidestocorrectlengthandfitthe3pieces

eithersidetothefuse.Theaftsideswillrequiresome

BE2c367/8”Page8

Copyright©2007‐11M.K.BengtsonAllRightsReservedRev07/11

bendingtoconformtotheroundingshapeoftheformers,

soakingwithwetpapertowelfor20‐30minswillhelp.

Rear‘sides’curvedtofollowformers,cardtemplatefortopsheet

readytogo.

Thetopsheetingforthismodelwasdoneintwo

pieces,forwardandaftofthelastF4former.Usecardto

maketemplatesforcuttingthe1/16”balsasheeting.Start

withapieceabout1“wideandlongerthanyouneed.

Benditintopositionbetweenthecarbanestruts,markthe

positionofthestruts,removeandcutstrutnotches.Test

fitthenotchesandmarkthelengthrequired,leavingsome

overatthefront.Makethereartemplatebytaperingto

thewidthrequiredatF7.Whenthetemplatesare

complete,layover1/16”balsasheetandcarefullycutto

shape.Onceagainsoakingthebalsashapesunderawet

papertowelwillmakeitsufficientlyflexible.Layingthe

balsaoverasuitableroundshape(e.g.aspraypaintcan)

asit’ssoakingwiththepapertowelontopwillhelpeven

more.Preparetheformertopsandfusesideswithglue

andinstallthetopsheetsholdingitalldownwithplenty

ofmaskingtape.Thetopsheetshouldbeoverhangingthe

sidesbya1/16”orsooneithersideandmorearoundthe

aftcockpit.Sandsmoothwhenthegluehascompletely

dried.

Topsheetingdoneandcockpitsmarked

Nextmarkthepositionandshapeforthecockpitcut

outs.Atechniqueforgettingsymmetricalshapesisto

startwithcard,cutarectanglebiggerthanyouneed.Lay

overthefuseandmarkthelengthyouneedtohave

crosswaystogetthelowestpointsofthecutoutsinthe

correctpositiononthefuseside.Thewidthofthe

rectangleisthefore/aftdimensionofthecut‐outmeasured

fromtheplans.Foldthecardrectangleinhalfsuchthat

thefoldisthecentrelineofthefuse.Transferthecockpit

shapeshownonthesideviewplantoonesideofyour

template.Cutthetemplate,bothsidesatonce,tothis

shape.Openoutthetemplateandalignthefoldlinewith

thecentrelineofthefuse,positioningforeandaftasper

plan.Markaroundtheoutsideofthetemplatewithpencil.

Putanewbladeinyourknifeandwithlightpressure

followthepencilledline.Twoorthreepasseswiththe

bladeshouldseeaneatcutout.Toomuchpressurewill

‘break’thebalsa,toolittleandit’lljusttakeanotherpass,

butyou’llgetaneatcut.

1st stringer and F11

Stringerreardecking

FitandgluepieceF11inpositionbetweentheupper

longerons.Cutthe1/8”x1/16”centrestringertolength,

glueeitherendtoF11andF7.Usingthisasyourguide

assembletheotherupperdeckformersbetweenF11and

F7ensuringtheformersarevertical.Installtherestof1/8”

x1/16”stringers,apairoftweezerswillhelppositioning

theoutboardstringswhichrequiremoretwistbetween

formsF10andF11.Thecutoutsintheformertopsthat

separatethestringersareextremelyfragile,especiallyin

partsF10andF11,useasmuchcareasyoucan,whenyou

breakoffapiece(oh!youwill☺),reattachwithCAas

youassemblethestringertomaintainthespacingbetween

thestringers.

BE2c367/8”Page9

Copyright©2007‐11M.K.BengtsonAllRightsReservedRev07/11

Upperdeckstringers.

Undercarriage

Usingtheplansasaguidecutandshape1/16”music

wiretoformthetwoUCsupports.Gluetogethertheply

UCsidesandsetaside,thesecanbesmoothed/sanded

afterbondingtothewirelegs.Makeyourselfa‘jig’toaid

assembly,asshowninthephoto.

Bindtheendsofthe1/16”musicwirewiththincopper

wireorKevlarthread,usingtheplysidestoguidethe

shape.The‘front’legsshouldbeverticaltothejig,usea

squaretocheck.Somere‐bendingandtuningwill

probablyberequiredtogettheshapeevenand

symmetricaloverall.Whenallisasitshouldbe,bindand

CA/Epoxytheplysidesinplacesecuringthemtothe

1/16”musicwire.

Assemblewheelsbysandwichingthe¼”balsamiddle

piecebetweenthe1/32”plysides.Useapieceof3/32”

tubetoalign/centretheparts,thenremovethetubeand

‘squash’thewheelundersomeweighttomakesureit’s

flatasthegluesets.Whenthisisdrycuttwowheel

bearingsabout5/8”longfrom3/32”brasstube.Usingthe

1/8”plyhubsandawheelbearing,completeeachwheel

usingepoxy,makingsurenoepoxygetsintothebearing.

Beforegluesets,spinthewheelon1/16”musicwireaxel

andrealignbearing/hubsasrequiredtoensurethewheel

spinsstraight.

Toformthetyresmassageonesideoftheneopreneso

itstartstocurl,continueanditwillformacircle,near

enoughanyway.UseCAtogluetheendstogether,butbe

carefulasCAandneopreneisaVERYstickycombination

andiffingersgetinvolveditcangetverymessy.Placethe

neopreneflatonaprotectedpartofyourworksurface.

UseonesmalldropofCAononeend,bringtheotherend

aroundtomatewiththegluedendtryingtoachievea

smoothjoin,you’llonlygetonechance.Whenthetyreis

formedrollitontothewheelandwithatinydroporthree

ofCAsecuretotherim.Onceagainbecarefulwiththe

CA,ifyoustickafingerorthumbtothetyrematerial

you’lllikelytearachunkoutoftheneoprenetryingto

releaseit.

UCandwheels

Thecardconesrequiredtodressthewheelsshouldbe

cutfromcardtothesizeshowontheplans.Scorelines

deeplyintothecutcirclewithapenandcutoutonepie

shapedsection.Foldtheshapesateachscorelinetomake

these‘spokes’moreobvious.Drawtheendstogether

formingaconeandtapeinsidetomaintaintheshape.

GluetheinsideconetoeachwheelandinstalltotheUC

structure.Ensureitspinsfreely,someshortlengthsof

3/32”tubemayberequiredtospacethewheelawayfrom

theUCstructure.Thewheelcanberetainedontheaxelby

asmallwasherandCA/binding.Trimaxeltolengthand

glueoutercardconetowheeltocomplete.

BE2c367/8”Page10

Copyright©2007‐11M.K.BengtsonAllRightsReservedRev07/11

Tailskid

Bendapieceof1/16”musicwiretotheshapeshown

ontheplans.Cuttwopiecesof1/16”balsa3/16”x1‐5/8”

andtwopieces1/16”x1/16”x1‐5/8”.The1/16”kitsheet

thatheldtheaileronribsisagooddonorforthesebalsa

parts.Asshownontheplansforma‘box’aroundthe

1/16”musicwirewiththebalsastrips.Fittheskidtothe

wirewithasmallwashereitherside.Ensuretheskidis

goingtositcorrectly,youmayhaveto‘fix’theinside

washertothemounttogeteverythingtositstraight.

Whenyouarehappyinstalltheoutsidewasherandbind

theendoftheaxel.Trimaxeltosuit.Makesuretheskid

stillmovesontheaxel.Arrangeamountnearthetopof

thestructurefortheelastic‘shockabsorber’shownonthe

plans.Thisshockabsorbercouldbethindressmakers

elasticorevenasuitablysizedrubberband.

TrailAssembly

Usingnoglue!Thisisadrytestassemblyrunto

ensureallmajorcomponentsfitwell.

Placethetopwingupsidedownonyourworksurface,

supportunderthemidsectionwiththe1”dihedralblocks

weusedtosetthetipssothatthewinghassomesupport.

Fitthefusetothetopwingbyinsertingthecarbane

strutsintotheirsocketsinthetopwing,makesurethey

seatallthewaydown.Usesomelighttapetoholdin

place.Placesomesupportunderthefusetailtolevel

thingsup.Checkthedistancebetweensomefixedpoint

oneachwing,saytherootendoftheaileronspace(or

wherethelastwingtipribmeetsTE)andthepointofthe

aftendofthefuse.Thisshouldbethesameonbothsides

andtellshowwellyouputthecarbanestrutsandfuse

sidestogether.Ifthere’sanydiscrepancyitwillneed

adjustmentduringfinalassembly.Withtheassemblystill

upsidedown,installfourIPstruts(notethereareForward

andAftIPstrutsFIPandRIP)inonesideoftheupper

wing.Positionlowerwing,locatingIPstrutsbetweenthe

wings,andwingdowelsandsparendsintothefusecut

outs.Repeatfortheotherlowerwing.Usetapetohold

everythinginplace.Tapetheundercarriageinplace.Turn

theassemblyoverandslidethehorizontalstabiliserinto

place.LocatetheverticalfinintoitsslotinFS6.Installthe

tailskidassembly.There…looksgreat!

FLYING

• ThemodelshouldROGongrass,pavementor

hardsurfaces.

• Letthemodelgainaltitudeslowlyofftherunway.

• Applyingtoomuchupelevatoratslowspeeds

risksastall.

• Makeyourturnsgentlyastightturnsrisktip

stallinginanymodel.

• Don’texpecttheelevatortomakethemodel

climb.

• Thinkoftheelevatorasadevicetochangethe

attitudeofthemodel.

• Thewingandairspeedultimatelymakethe

modelclimb.

• Oftendownelevatorappliedatstallingcanavoid

amajorcrash.

Themostimportantdetailsforproperflight

operations:

• Correct CG location.

• Straightnon‐warpedwings.

CONTACTINFORMATION

Distributedby:

BengtsonCompany

WebSite:www.aerodromerc.com

Table of contents

Popular Aircraft manuals by other brands

Piper

Piper SARATOGA II HP PA-32R-301 Pilot operating handbook

Textron

Textron Cessna 172R Information manual

czech sport aircraft

czech sport aircraft SportCruiser Operating handbook

AIR TRACTOR

AIR TRACTOR AT-402A quick start guide

Zlin Aircraft

Zlin Aircraft Z 242 L Airplane Flight Manual

UP

UP K2 Owners manual and service manual