Apr 24/03

30-11-00 Page 2

EFFECTIVITY: All

zSD3-60 AIRCRAFT MAINTENANCE MANUAL

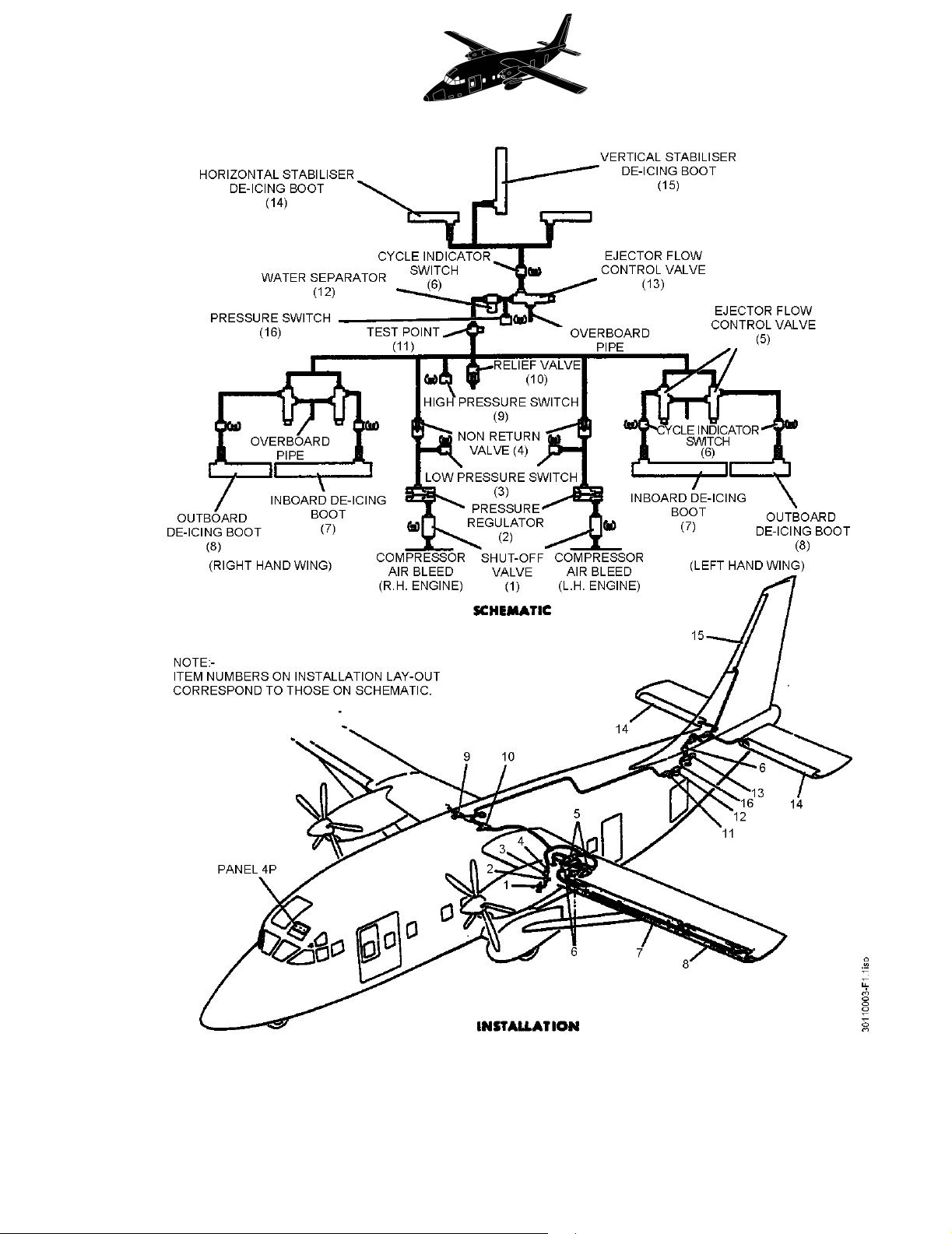

E. System Indication

(1) Shut-Off Valves

The 'open' - 'closed' indication of the Shut-Off Valves is signalled via an integral set of

microswitches which operate in response to the solenoid valve movement.

Position indication is afforded by indicator modules on panel 4P (immediately above

control switches).

(2) Cycling

Cycle indicator switches, sited downstream of each ejector valve connect a supply to the

appropriate indicator light (green) on panel 4P when the related boot/s are on the

inflation phase of a cycle.

(3) High/Low Pressure Warning (System)

(a) High Pressure Warning

A H.P. switch is sited upstream of the relief valve and will make a supply available

(e.g. in the event of a failed pressure regulator) to the bleed air DUCT PRESSure

light on panel 4P should the system pressure exceed 24 p.s.i; attention is drawn by

the simultaneous illumination of the BLEED air module on the centralized warning

panel.

(b) Low Pressure Warning

A L.P. switch is introduced immediately downstream of the pressure regulator in

each engines delivery line. Should either switch 'make' (e.g. as a result of a burst

pipe) a supply will be made available to the bleed air DUCT PRESSure light on

panel 4P; attention is drawn by the simultaneous illumination of the BLEED air

module on the centralized warning panel.

NOTE: Circuits for both warning systems are wired in series with engine oil pressure

relays such that warning is only afforded when engines are running.

(4) Pressure Warning and Time Delay

A pressure switch is located between the ejector flow control valve and the water

separator. The switch is set to illuminate an amber SYS Pressure caution light on panel

4P, on a falling de-icing boot inflation pressure of 11.5 psig. The A/ICE PANEL (BLEED

on early aircraft) module on the centralized warning panel is also illuminated. The

caution light will extinguish on a rising inflation pressure of 13.5 psig.

NOTE: The pressure switch only functions when the aircraft is in the air i.e. it is inhibited

when the weight switches are operational.