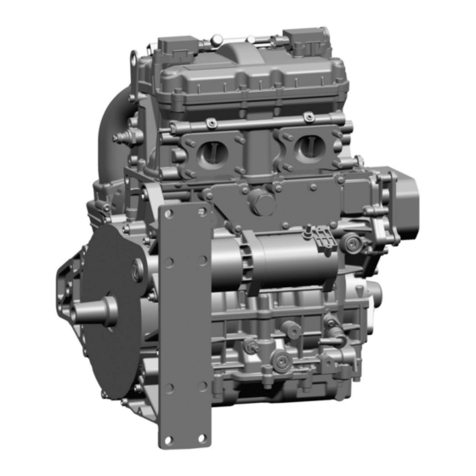

Bergen B35:40 User manual

Marine

Project Guide

Bergen engine type B35:40 Gas

[ BLANK ]

Editon October 2011 (Rev. 05. January 2018) 2

PROJECT GUIDE

BERGEN ENGINE TYPE B

FUEL GAS OPERATION

The information in this manual is PRELIMINARY as this is a new engine type under

development. The data and information given, related to the engines, are subject to

change without notice.

This project guide is intended as a tool to assist in project work for installations that include

Bergen engines.

Binding drawings and technical data will be submitted after receipt of orders.

Components and systems shown in this guide are not necessarily included in the Rolls-Royce

scope of supply. All copies of this document in hard and soft format are uncontrolled. To verify

NOTE

The data and information, related to the engines given in this guide, are subject to change

without notice.

NOTE

The information in this guide is applicable for marine applications only.

© Bergen Engines AS 2018

A Rolls-Royce Power Systems Company

The information in this document is the property of Bergen Engines AS, a Rolls-Royce Power Systems Company, and may not be

copied, or communicated to a third party, or used, for any purpose other than that for which it is supplied without the express written

consent of Bergen Engines AS.

Whilst the information is given in good faith based upon the latest information available to Bergen Engines AS, no warranty or

representation is given concerning such information, which must be taken as establishing any contractual or other commitment binding

upon Bergen Engines AS, its parent company or any of its subsidiaries or associated companies.

Bergen Engines AS

P.O.Box 329 Sentrum

N-5804 BERGEN

NORWAY

Tel. +47 55 53 60 00

Homepage: www.rolls-royce.com

E-mail: salessupport.bergen@rolls-royce.com

Enterprise no. NO 997 016 238

A Rolls-Royce Power Systems Company

[ BLANK ]

B, Gas Project Guide

Page 1 : 1

0315 B Gas

PROJECT GUIDE

Part 1

1.01 Operating principle

1.02 Technical data

1.03 Main dimensions

1.05 Fuel gas specification

1.07 Load limit

1.08 Noise measurement

Part 2

2.01 Starting and control air system

2.02 Combustion air system

2.03 Exhaust gas system

2.04 Ventilation system

2.05 Fuel gas system

2.06 Cooling water system

2.07 Cooling water quality

2.08 Lubricating oil system

2.09 Lubricant guide

Part 3

3.01 Standard and optional generator design

3.02 Safety, control and monitoring

3.03 Ignition system

Part 4

4.01 Routine Maintenance Schema (RMS)

[ BLANK ]

, Gas Operation principle, lean-burn gas engine

Page 1 : 2

1.01

0211 BC

OPERATION PRINCIPLE,

LEAN-BURN GAS ENGINE

Introduction

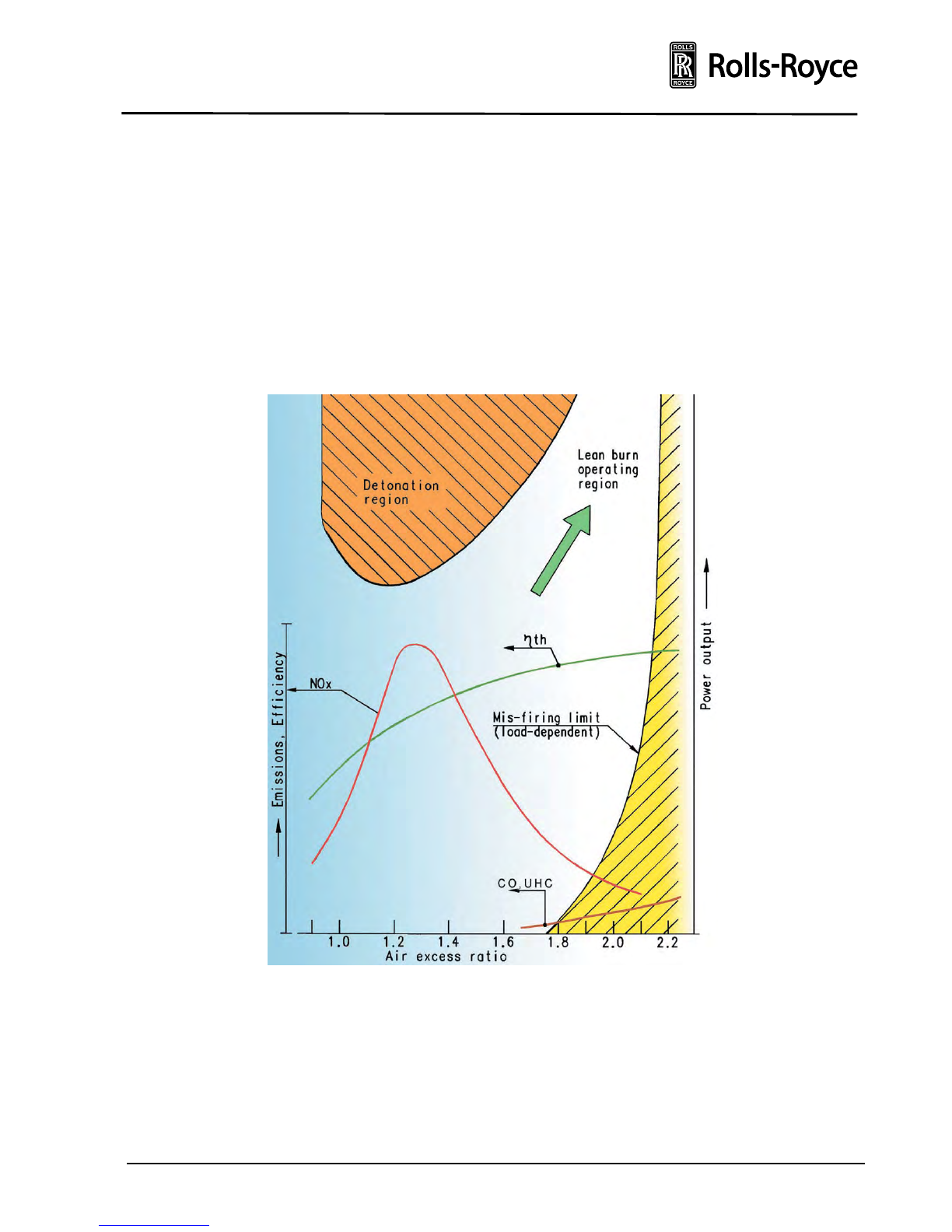

The Bergen engine lean burn spark ignition (s.i. gas

engine operates according to the lean-burn Otto

cycle, i.e. a lean mixture of gas and air is compressed

and ignited by an electric system.

A lean-burn engine operates at a.e.r’s (air excess

ratios , of 1.8 and higher, and as the illustration

shows, this gives increased power, efficiency and

reduced NOx-emissions.

To achieve this, a special combustion system has

been developed that gives a strong increase in

ignition energy capable of firing such lean mixtures

reliably. Also, a highly efficient turbo-charging

system is used to take advantage of the possible

power increase offered by the extended knock limit

of lean mixtures

Principle of operation in brief

Air is drawn in by the turbocharger, through the

charge air cooler and into the cylinder. A timed

mechanical gas valve injects gas under over-pressure

into the inlet air stream to ensure a homogeneous

and lean mixture of air and gas.

Air flow is controlled by the variable turbine geome-

try, VTG, while gas flow is controlled by mechanical

valves before each cylinder.

The gas pressure is set electronically by the pressure

regulating valve on the fuel gas supply module

ahead of engine.

Operation principle, lean-burn gas engine

Page 2 : 2

1.01

, Gas

0211 BC

An air flap for each cylinder restricts the air supply

during start-up and low load operation.

As the pressure in the cylinder is low, gas is

admitted into the small pre-chambers - one in each

cylinder head, electronically controlled by the pre-

chamber pressure unit. During compression, the

lean charge in the cylinder is partially pushed into

the pre-chamber, where it mixes with the pure gas

to form a rich mixture that is easily ignited by the

spark plug. This powerful ignition energy from the

pre-chamber ensures fast and complete combustion

of the main charge in the cylinder.

Advanced electronic engine management ensures

the operating parameters of the engine are

adjusted and optimised in relation to each other.

The system sets the optimum main, and pre-

chamber gas pressures, the AFR (air/fuel ratio , the

fuel rack position, the ignition timing and air throttle

position.

The alarm and monitoring part of the system

features many built-in safety functions. It combines

safe operation with high availability, protecting the

engine and signalling any fault. It includes a mis-

firing detection system based on analysing different

operational parameters and a knock

detection system. The system detects and eliminates

knocking individually for each cylinder.

The complete engine management, control and

monitoring system fits into a cabinet next to the

engine and communicates with the plant control

through one simple cable.

Operating principle, lean- urn gas engine

, Gas Technical data

Page 1 : 8

1.02

0611 B

TECHNICAL DATA

Technical data

Page 2 : 8

1.02

, Gas

0611 B

Technical data: B35:40 L9AG Drawing No.: L1089_23 Rev. 00

Fuel type: NATURAL GAS Project No.:

Application: Marine Auxiliary Engine No.:

Yard/Power plant: Standard

Engine data:

Number of cylinders - 9

Cylinder bore mm 350

Piston stroke mm 400

Rated power (MCR), engine kW 3940

Rated active power, generator kW 3800

Generator efficiency - 0,965

Rated output, electric

with COS(phi) = 0,8 kVA 4750

Mean effective pressure bar 18,2

Rated speed RPM 750

Mean piston speed m/s 10

Displacement l 346

Gas data:

Specific energy consumption kJ/kWh 7550

Gas consumption at MCR m³n/h 825

Gas consumption at MCR kg/h 660

Minimum gas feed at MCR:

-at engine inlet barg 3,2

-to press. control module barg 3,5

Start air data:

Start air pressure, max./min. barg 30/15

Air consumption per. start m³n 3

No of starts, 1000l receiver - 3

Lubrication data:

Lubrication oil - SAE 40

Main pump capacity m³/h 68

Priming pump capacity m³/h 13

Lub. oil pressure

-normal barg 4-5

-alarm, pressure low barg 2,5

-shut-down, pressure low barg 1,7

Lub. oil temp engine inlet

-normal °C 60

-alarm, temp high °C 70

Spec. lub. oil consumption g/kWh 0,4

Lub. oil consumption kg/h 1,6

Crankcase, lub. oil volume

-high level l 4500

-low level l 3850

Jacket water waste heat recovery:

Waste heat, 100% load MJ/h 3420

Waste heat, 80% load MJ/h 2450

Waste heat, 50% load MJ/h 1285

Cooling water data:

Two-stage charge air cooler:

-Low temp. stage:

-temp. at inlet, max °C 37

-water flowrate, normal m³/h 50

-water flowrate, max m³/h 58

-High temp. stage:

-water flowrate, normal m³/h 36

Jacket water system:

-pump capacity m³/h 81

-normal stop/shut-down barg 1.0

-water quantity, engine block l 370

-Temp. at engine outlet

-normal °C 90

-alarm, temp. high °C 95

-shut-down, temp. high °C 95

-temp. rise in engine, max °C 6,2

-incl. high temp. ca-cooler °C 10,1

-Expansion tank:

-volum, single-engined l 300

-volum, multi-engined l 500

-height above engine m 3-10

Air data:

Turbocharger type ABB TPL-65 VTG

Charge air cooler type - RR9L3240B

Air consumption m³n/h 15700

Air consumption kg/h 20400

Charge air pressure barg 2,4

Charge air temperature:

-normal °C 55

-alarm, temp high °C 62

Turbocharger speed alarm rpm 27761

Exhaust data:

Mass flow kg/h 21000

Volume flow, after turbin m³/h 40200

Temp, after cylinder °C 485

Temp, after turbine °C 395

Back pressure, max mmWG 400

Part load data:

-Mass flow, 90% load kg/h 18500

-Temp, after turbine °C 415

-Mass flow, 80% load kg/h 16600

-Temp, after turbine °C 430

-Mass flow 50% load kg/h 10900

-Temp, after turbine °C 465

Heat dissipation:

Lubrication data:

Lub. oil .cooler MJ/h 1695

Cooling water data:

Low temp. stage MJ/h 1590

High temp. stage MJ/h 1325

Jacket water cooler:

-Heat dissipation, engine MJ/h 2095

-incl. high temp. ca-cooler MJ/h 3420

Ventilation data:

Radiation engine MJ/h 930

Radiation generator (IP23) MJ/h 505

Engine power definition is according to ISO 3046-1

However the engine ratings are valid for the following reference conditions:

Air inlet temperature max. + 45 °C

Air inlet temperature min. + 0°C

Heat dissipation. + 25°C

Charge air low temp. cooling water inlet temp. max. +37°C

Relative humidity 60%

Spec. NOx emissions 1,4 g/kWh at full load (MCR).

Specific energy consumption is according to ISO 3046-1 and is given at full load(MCR),

running on NATURAL GAS with a lower heating value of 36.0 MJ/m³n and

no engine-driven pumps. With engine-driven pumps, add 0.5% for each pump.

Methane no. min 70 , according to AVL calculation

Spec. lub. oil consumption is for guidance only

NOTE! Due to continuous development, some data may change

1.02

, Gas Technical data

Page 3 : 8

0611 B

Technical data: B35:40 L9AG Drawing No.: L1089_22 Rev. 00

Fuel type: NATURAL GAS Project No.:

Application: Marine Auxiliary Engine No.:

Yard/Power plant: Standard

Engine data:

Number of cylinders - 9

Cylinder bore mm 350

Piston stroke mm 400

Rated power (MCR), engine kW 3780

Rated active power, generator kW 3650

Generator efficiency - 0,965

Rated output, electric

with COS(phi) = 0,8 kVA 4560

Mean effective pressure bar 18,2

Rated speed RPM 720

Mean piston speed m/s 10

Displacement l 346

Gas data:

Specific energy consumption kJ/kWh 7550

Gas consumption at MCR m³n/h 795

Gas consumption at MCR kg/h 635

Minimum gas feed at MCR:

-at engine inlet barg 3,2

-to press. control module barg 3,5

Start air data:

Start air pressure, max./min. barg 30/15

Air consumption per. start m³n 3

No of starts, 1000l receiver - 3

Lubrication data:

Lubrication oil - SAE 40

Main pump capacity m³/h 65

Priming pump capacity m³/h 13

Lub. oil pressure

-normal barg 4-5

-alarm, pressure low barg 2,5

-shut-down, pressure low barg 1,7

Lub. oil temp engine inlet

-normal °C 60

-alarm, temp high °C 70

Spec. lub. oil consumption g/kWh 0,4

Lub. oil consumption kg/h 1,5

Crankcase, lub. oil volume

-high level l 4500

-low level l 3850

Jacket water waste heat recovery:

Waste heat, 100% load MJ/h 3280

Waste heat, 80% load MJ/h 2350

Waste heat, 50% load MJ/h 1235

Cooling water data:

Two-stage charge air cooler:

-Low temp. stage:

-temp. at inlet, max °C 37

-water flowrate, normal m³/h 50

-water flowrate, max m³/h 58

-High temp. stage:

-water flowrate, normal m³/h 36

Jacket water system:

-pump capacity m³/h 81

-normal stop/shut-down barg 1.0

-water quantity, engine block l 370

-Temp. at engine outlet

-normal °C 90

-alarm, temp. high °C 95

-shut-down, temp. high °C 95

-temp. rise in engine, max °C 5,9

-incl. high temp. ca-cooler °C 9,7

-Expansion tank:

-volum, single-engined l 300

-volum, multi-engined l 500

-height above engine m 3-10

Air data:

Turbocharger type ABB TPL-65 VTG

Charge air cooler type - RR9L3240B

Air consumption m³n/h 15100

Air consumption kg/h 19500

Charge air pressure barg 2,4

Charge air temperature:

-normal °C 55

-alarm, temp high °C 62

Turbocharger speed alarm rpm 27761

Exhaust data:

Mass flow kg/h 20100

Volume flow, after turbin m³/h 38500

Temp, after cylinder °C 485

Temp, after turbine °C 395

Back pressure, max mmWG 400

Part load data:

-Mass flow, 90% load kg/h 17700

-Temp, after turbine °C 415

-Mass flow, 80% load kg/h 15900

-Temp, after turbine °C 430

-Mass flow 50% load kg/h 10400

-Temp, after turbine °C 465

Heat dissipation:

Lubrication data:

Lub. oil .cooler MJ/h 1630

Cooling water data:

Low temp. stage MJ/h 1525

High temp. stage MJ/h 1270

Jacket water cooler:

-Heat dissipation, engine MJ/h 2010

-incl. high temp. ca-cooler MJ/h 3280

Ventilation data:

Radiation engine MJ/h 890

Radiation generator (IP23) MJ/h 470

Engine power definition is according to ISO 3046-1

However the engine ratings are valid for the following reference conditions:

Air inlet temperature max. + 45 °C

Air inlet temperature min. + 0°C

Heat dissipation. + 25°C

Charge air low temp. cooling water inlet temp. max. +37°C

Relative humidity 60%

Spec. NOx emissions 1,4 g/kWh at full load (MCR).

Specific energy consumption is according to ISO 3046-1 and is given at full load(MCR),

running on NATURAL GAS with a lower heating value of 36.0 MJ/m³n and

no engine-driven pumps. With engine-driven pumps, add 0.5% for each pump.

Methane no. min 70 , according to AVL calculation

Spec. lub. oil consumption is for guidance only

NOTE! Due to continuous development, some data may change

Technical data

Page 4 : 8

1.02

, Gas

0611 B

Technical data: B35:40 L9PG Drawing No.: L1089_14 Rev. 00

Fuel type: NATURAL GAS Project No.:

Application: Marine Propulsion Engine No.:

Yard/Power plant: Standard

Engine data:

Number of cylinders - 9

Cylinder bore mm 350

Piston stroke mm 400

Rated power (MCR), engine kW 3940

Mean effective pressure bar 18,2

Rated speed RPM 750

Mean piston speed m/s 10

Displacement l 346

Gas data:

Specific energy consumption kJ/kWh 7550

Gas consumption at MCR m³n/h 825

Gas consumption at MCR kg/h 660

Minimum gas feed at MCR:

-at engine inlet barg 3,2

-to press. control module barg 3,5

Start air data:

Start air pressure, max./min. barg 30/15

Air consumption per. start m³n 1,5

No of starts, 1000l receiver - 7

Lubrication data:

Lubrication oil - SAE 40

Main pump capacity m³/h 68

Priming pump capacity m³/h 13

Lub. oil pressure

-normal barg 4-5

-alarm, pressure low barg 2,5

-start, stand-by pump barg 0

-shut-down, pressure low barg 1,7

Lub. oil temp engine inlet

-normal °C 60

-alarm, temp high °C 70

Spec. lub. oil consumption g/kWh 0,4

Lub. oil consumption kg/h 1,6

Crankcase, lub. oil volume

-high level l 1950

-low level l 1350

-dry sump, system tank l 0

Jacket water waste heat recovery:

Waste heat, 100% load MJ/h 3420

Waste heat, 80% load MJ/h 2450

Waste heat, 50% load MJ/h 1285

Cooling water data:

Two-stage charge air cooler:

-Low temp. stage:

-temp. at inlet, max °C 37

-water flowrate, normal m³/h 50

-water flowrate, max m³/h 58

-High temp. stage:

-water flowrate, normal m³/h 36

Jacket water system:

-pump capacity m³/h 81

-normal stop/shut-down barg 1.0

-water quantity, engine block l 370

-Temp. at engine outlet

-normal °C 90

-alarm, temp. high °C 95

-shut-down, temp. high °C 95

-temp. rise in engine, max °C 6,2

-incl. high temp. ca-cooler °C 10,1

-Expansion tank:

-volum, single-engined l 300

-volum, multi-engined l 500

-height above engine m 3-10

Air data:

Turbocharger type ABB TPL-65 VTG

Charge air cooler type - RR9L3240B

Air consumption m³n/h 15700

Air consumption kg/h 20400

Charge air pressure barg 2,4

Charge air temperature:

-normal °C 55

-alarm, temp high °C 62

Turbocharger speed alarm rpm 27761

Exhaust data:

Mass flow kg/h 21000

Volume flow, after turbin m³/h 40200

Temp, after cylinder °C 485

Temp, after turbine °C 395

Back pressure, max mmWG 400

Part load data:

-Mass flow, 90% load kg/h 18500

-Temp, after turbine °C 415

-Mass flow, 80% load kg/h 16600

-Temp, after turbine °C 430

-Mass flow 50% load kg/h 10900

-Temp, after turbine °C 465

Heat dissipation:

Lubrication data:

Lub. oil .cooler MJ/h 1695

Cooling water data:

Low temp. stage MJ/h 1590

High temp. stage MJ/h 1325

Jacket water cooler:

-Heat dissipation, engine MJ/h 2095

-incl. high temp. ca-cooler MJ/h 3420

Ventilation data:

Radiation engine MJ/h 930

Engine power definition is according to ISO 3046-1

However the engine ratings are valid for the following reference conditions:

Air inlet temperature max. + 45 °C

Air inlet temperature min. + 0°C

Heat dissipation. + 25°C

Charge air low temp. cooling water inlet temp. max. +37°C

Relative humidity 60%

Spec. NOx emissions 1,4 g/kWh at full load (MCR).

Specific energy consumption is according to ISO 3046-1 and is given at full load(MCR),

running on NATURAL GAS with a lower heating value of 36.0 MJ/m³n and

no engine-driven pumps. With engine-driven pumps, add 0.5% for each pump.

Methane no. min 70 , according to AVL calculation

Spec. lub. oil consumption is for guidance only

NOTE! Due to continuous development, some data may change

SHH - 08.04.2011

1.02

, Gas Technical data

Page 5 : 8

0611 B

Technical data: B35:40 V12AG Drawing No.:

Fuel type: NATURAL GAS Project No.:

Application: Marine Auxiliary Engine No.:

Yard/Power plant:

Engine data:

Number of cylinders - 12

Cylinder bore mm 350

Piston stroke mm 400

Rated power (MCR), engine kW 5040

Rated active power, generator kW 4870

Generator efficiency - 0,966

Rated output, electric

with COS(phi) = 0,8 kVA 6085

Mean effective pressure bar 18,2

Rated speed RPM 720

Mean piston speed m/s 10

Displacement l 462

Gas data:

Specific energy consumption kJ/kWh 7475

Gas consumption at MCR m³n/h 1045

Gas consumption at MCR kg/h 835

Minimum gas feed at MCR:

-at engine inlet barg 3,2

-to press. control module barg 3,5

Start air data:

Start air pressure, max./min. barg 30/15

Air consumption per. start m³n 11

No of starts, 1500l receiver - 3

Lubrication data:

Lubrication oil - SAE 40

Main pump capacity m³/h 81

Priming pump capacity m³/h 13

Lub. oil pressure

-normal barg 4-5

-alarm, pressure low barg 2,5

-shut-down, pressure low barg 1,7

Lub. oil temp engine inlet

-normal °C 60

-alarm, temp high °C 70

Spec. lub. oil consumption g/kWh 0,4

Lub. oil consumption kg/h 2

Crankcase, lub. oil volume

-high level l 3430

-low level l 2750

Jacket water waste heat recovery:

Waste heat, 100% load MJ/h 4435

Waste heat, 80% load MJ/h 3020

Waste heat, 50% load MJ/h 1495

Cooling water data:

Two-stage charge air cooler:

-Low temp. stage:

-temp. at inlet, max °C 37

-water flowrate, normal m³/h 108

-water flowrate, max m³/h 140

-High temp. stage:

-water flowrate, normal m³/h 54

Jacket water system:

-pump capacity m³/h 108

-normal stop/shut-down barg 2

-water quantity, engine block l 750

-Temp. at engine outlet

-normal °C 90

-alarm, temp. high °C 95

-shut-down, temp. high °C 97

-temp. rise in engine, max °C 5,5

-incl. high temp. ca-cooler °C 9,8

-Expansion tank:

-volum, single-engined l 300

-volum, multi-engined l 500

-height above engine m 3-10

Air data:

Turbocharger type ABB TPS-61E VTG

Charge air cooler type - RR66-132-V12

Air consumption m³n/h 20400

Air consumption kg/h 26400

Charge air pressure barg 2,4

Charge air temperature:

-normal °C 55

-alarm, temp high °C 62

Turbocharger speed alarm rpm 33640

Exhaust data:

Mass flow kg/h 27200

Volume flow, after turbin m³/h 53700

Temp, after cylinder °C 485

Temp, after turbine °C 415

Back pressure, max mmWG 400

Part load data:

-Mass flow, 90% load kg/h 23800

-Temp, after turbine °C 435

-Mass flow, 80% load kg/h 21400

-Temp, after turbine °C 455

-Mass flow 50% load kg/h 14100

-Temp, after turbine °C 485

Heat dissipation:

Lubrication data:

Lub. oil .cooler MJ/h 2035

Cooling water data:

Low temp. stage MJ/h 1555

High temp. stage MJ/h 1935

Jacket water cooler:

-Heat dissipation, engine MJ/h 2500

-incl. high temp. ca-cooler MJ/h 4435

Ventilation data:

Radiation engine MJ/h 1175

Radiation generator (IP23) MJ/h 610

Engine power definition is according to ISO 3046-1

However the engine ratings are valid for the following reference conditions:

Air inlet temperature max. + 45 °C

Air inlet temperature min. + 0°C

Heat dissipation. + 25°C

Charge air low temp. cooling water inlet temp. max. +37°C

Relative humidity 60%

Spec. NOx emissions 1,4 g/kWh at full load (MCR).

Specific energy consumption is according to ISO 3046-1 and is given at full load(MCR),

running on NATURAL GAS with a lower heating value of 36.0 MJ/m³n and

no engine-driven pumps. With engine-driven pumps, add 0.5% for each pump.

Methane no. min 70 , according to AVL calculation

Spec. lub. oil consumption is for guidance only

NOTE! Due to continuous development, some data may change

Technical data

Page 6 : 8

1.02

, Gas

0611 B

Technical data: B35:40 V12AG Drawing No.:

Fuel type: NATURAL GAS Project No.:

Application: Marine Auxiliary Engine No.:

Yard/Power plant:

Engine data:

Number of cylinders - 12

Cylinder bore mm 350

Piston stroke mm 400

Rated power (MCR), engine kW 5250

Rated active power, generator kW 5070

Generator efficiency - 0,966

Rated output, electric

with COS(phi) = 0,8 kVA 6335

Mean effective pressure bar 18,2

Rated speed RPM 750

Mean piston speed m/s 10

Displacement l 462

Gas data:

Specific energy consumption kJ/kWh 7475

Gas consumption at MCR m³n/h 1090

Gas consumption at MCR kg/h 870

Minimum gas feed at MCR:

-at engine inlet barg 3,2

-to press. control module barg 3,5

Start air data:

Start air pressure, max./min. barg 30/15

Air consumption per. start m³n 11

No of starts, 1500l receiver - 3

Lubrication data:

Lubrication oil - SAE 40

Main pump capacity m³/h 86

Priming pump capacity m³/h 13

Lub. oil pressure

-normal barg 4-5

-alarm, pressure low barg 2,5

-shut-down, pressure low barg 1,7

Lub. oil temp engine inlet

-normal °C 60

-alarm, temp high °C 70

Spec. lub. oil consumption g/kWh 0,4

Lub. oil consumption kg/h 2,1

Crankcase, lub. oil volume

-high level l 3430

-low level l 2750

Jacket water waste heat recovery:

Waste heat, 100% load MJ/h 4620

Waste heat, 80% load MJ/h 3145

Waste heat, 50% load MJ/h 1555

Cooling water data:

Two-stage charge air cooler:

-Low temp. stage:

-temp. at inlet, max °C 37

-water flowrate, normal m³/h 108

-water flowrate, max m³/h 140

-High temp. stage:

-water flowrate, normal m³/h 54

Jacket water system:

-pump capacity m³/h 108

-normal stop/shut-down barg 2

-water quantity, engine block l 750

-Temp. at engine outlet

-normal °C 90

-alarm, temp. high °C 95

-shut-down, temp. high °C 97

-temp. rise in engine, max °C 5,8

-incl. high temp. ca-cooler °C 10,2

-Expansion tank:

-volum, single-engined l 300

-volum, multi-engined l 500

-height above engine m 3-10

Air data:

Turbocharger type ABB TPS-61E VTG

Charge air cooler type - RR66-132-V12

Air consumption m³n/h 21200

Air consumption kg/h 27500

Charge air pressure barg 2,4

Charge air temperature:

-normal °C 55

-alarm, temp high °C 62

Turbocharger speed alarm rpm 33640

Exhaust data:

Mass flow kg/h 28300

Volume flow, after turbin m³/h 55800

Temp, after cylinder °C 485

Temp, after turbine °C 415

Back pressure, max mmWG 400

Part load data:

-Mass flow, 90% load kg/h 24800

-Temp, after turbine °C 435

-Mass flow, 80% load kg/h 22300

-Temp, after turbine °C 455

-Mass flow 50% load kg/h 14600

-Temp, after turbine °C 485

Heat dissipation:

Lubrication data:

Lub. oil .cooler MJ/h 2120

Cooling water data:

Low temp. stage MJ/h 1620

High temp. stage MJ/h 2015

Jacket water cooler:

-Heat dissipation, engine MJ/h 2605

-incl. high temp. ca-cooler MJ/h 4620

Ventilation data:

Radiation engine MJ/h 1225

Radiation generator (IP23) MJ/h 645

Engine power definition is according to ISO 3046-1

However the engine ratings are valid for the following reference conditions:

Air inlet temperature max. + 45 °C

Air inlet temperature min. + 0°C

Heat dissipation. + 25°C

Charge air low temp. cooling water inlet temp. max. +37°C

Relative humidity 60%

Spec. NOx emissions 1,4 g/kWh at full load (MCR).

Specific energy consumption is according to ISO 3046-1 and is given at full load(MCR),

running on NATURAL GAS with a lower heating value of 36.0 MJ/m³n and

no engine-driven pumps. With engine-driven pumps, add 0.5% for each pump.

Methane no. min 70 , according to AVL calculation

Spec. lub. oil consumption is for guidance only

NOTE! Due to continuous development, some data may change

1.02

, Gas Technical data

Page 7 : 8

0611 B

Technical data: B35:40 V12PG Drawing No.:

Fuel type: NATURAL GAS Project No.:

Application: Marine Propulsion Engine No.:

Yard/Power plant:

Engine data:

Number of cylinders - 12

Cylinder bore mm 350

Piston stroke mm 400

Rated power (MCR), engine kW 5250

Mean effective pressure bar 18,2

Rated speed RPM 750

Mean piston speed m/s 10

Displacement l 462

Gas data:

Specific energy consumption kJ/kWh 7475

Gas consumption at MCR m³n/h 1090

Gas consumption at MCR kg/h 870

Minimum gas feed at MCR:

-at engine inlet barg 3,2

-to press. control module barg 3,5

Start air data:

Start air pressure, max./min. barg 30/15

Air consumption per. start m³n 11

No of starts, 1500l receiver - 3

Lubrication data:

Lubrication oil - SAE 40

Main pump capacity m³/h 86

Priming pump capacity m³/h 13

Lub. oil pressure

-normal barg 4-5

-alarm, pressure low barg 2,5

-start, stand-by pump barg 0

-shut-down, pressure low barg 1,7

Lub. oil temp engine inlet

-normal °C 60

-alarm, temp high °C 70

Spec. lub. oil consumption g/kWh 0,4

Lub. oil consumption kg/h 2,1

Crankcase, lub. oil volume

-high level l 3430

-low level l 2750

-dry sump, system tank l 0

Jacket water waste heat recovery:

Waste heat, 100% load MJ/h 4620

Waste heat, 80% load MJ/h 3145

Waste heat, 50% load MJ/h 1555

Cooling water data:

Two-stage charge air cooler:

-Low temp. stage:

-temp. at inlet, max °C 37

-water flowrate, normal m³/h 108

-water flowrate, max m³/h 140

-High temp. stage:

-water flowrate, normal m³/h 54

Jacket water system:

-pump capacity m³/h 108

-normal stop/shut-down barg 2

-water quantity, engine block l 750

-Temp. at engine outlet

-normal °C 90

-alarm, temp. high °C 95

-shut-down, temp. high °C 97

-temp. rise in engine, max °C 5,8

-incl. high temp. ca-cooler °C 10,2

-Expansion tank:

-volum, single-engined l 300

-volum, multi-engined l 500

-height above engine m 3-10

Air data:

Turbocharger type ABB TPS-61E VTG

Charge air cooler type - RR66-132-V12

Air consumption m³n/h 21200

Air consumption kg/h 27500

Charge air pressure barg 2,4

Charge air temperature:

-normal °C 55

-alarm, temp high °C 62

Turbocharger speed alarm rpm 33640

Exhaust data:

Mass flow kg/h 28300

Volume flow, after turbin m³/h 55800

Temp, after cylinder °C 485

Temp, after turbine °C 415

Back pressure, max mmWG 400

Part load data:

-Mass flow, 90% load kg/h 24800

-Temp, after turbine °C 435

-Mass flow, 80% load kg/h 22300

-Temp, after turbine °C 455

-Mass flow 50% load kg/h 14600

-Temp, after turbine °C 485

Heat dissipation:

Lubrication data:

Lub. oil .cooler MJ/h 2120

Cooling water data:

Low temp. stage MJ/h 1620

High temp. stage MJ/h 2015

Jacket water cooler:

-Heat dissipation, engine MJ/h 2605

-incl. high temp. ca-cooler MJ/h 4620

Ventilation data:

Radiation engine MJ/h 1225

Engine power definition is according to ISO 3046-1

However the engine ratings are valid for the following reference conditions:

Air inlet temperature max. + 45 °C

Air inlet temperature min. + 0°C

Heat dissipation. + 25°C

Charge air low temp. cooling water inlet temp. max. +37°C

Relative humidity 60%

Spec. NOx emissions 1,4 g/kWh at full load (MCR).

Specific energy consumption is according to ISO 3046-1 and is given at full load(MCR),

running on NATURAL GAS with a lower heating value of 36.0 MJ/m³n and

no engine-driven pumps. With engine-driven pumps, add 0.5% for each pump.

Methane no. min 70 , according to AVL calculation

Spec. lub. oil consumption is for guidance only

NOTE! Due to continuous development, some data may change

Technical data

Page 8 : 8

1.02

, Gas

0611 B

Technical data: B35:40 V16PG Drawing No.:

Fuel type: NATURAL GAS Project No.:

Application: Marine Propulsion Engine No.:

Yard/Power plant:

Engine data:

Number of cylinders - 16

Cylinder bore mm 350

Piston stroke mm 400

Rated power (MCR), engine kW 7000

Mean effective pressure bar 18,2

Rated speed RPM 750

Mean piston speed m/s 10

Displacement l 616

Gas data:

Specific energy consumption kJ/kWh 7475

Gas consumption at MCR m³n/h 1455

Gas consumption at MCR kg/h 1165

Minimum gas feed at MCR:

-at engine inlet barg 3,2

-to press. control module barg 3,5

Start air data:

Start air pressure, max./min. barg 30/15

Air consumption per. start m³n 15

No of starts, 2000l receiver - 3

Lubrication data:

Lubrication oil - SAE 40

Main pump capacity m³/h 95

Priming pump capacity m³/h 20

Lub. oil pressure

-normal barg 4-5

-alarm, pressure low barg 2,5

-start, stand-by pump barg 0

-shut-down, pressure low barg 1,7

Lub. oil temp engine inlet

-normal °C 60

-alarm, temp high °C 70

Spec. lub. oil consumption g/kWh 0,4

Lub. oil consumption kg/h 2,8

Crankcase, lub. oil volume

-high level l 4320

-low level l 3440

-dry sump, system tank l 0

Jacket water waste heat recovery:

Waste heat, 100% load MJ/h 6160

Waste heat, 80% load MJ/h 4190

Waste heat, 50% load MJ/h 2075

Cooling water data:

Two-stage charge air cooler:

-Low temp. stage:

-temp. at inlet, max °C 37

-water flowrate, normal m³/h 128

-water flowrate, max m³/h 160

-High temp. stage:

-water flowrate, normal m³/h 64

Jacket water system:

-pump capacity m³/h 144

-normal stop/shut-down barg 2

-water quantity, engine block l 970

-Temp. at engine outlet

-normal °C 90

-alarm, temp. high °C 95

-shut-down, temp. high °C 97

-temp. rise in engine, max °C 5,8

-incl. high temp. ca-cooler °C 10,2

-Expansion tank:

-volum, single-engined l 300

-volum, multi-engined l 500

-height above engine m 3-10

Air data:

Turbocharger type ABB TPL-65 VTG

Charge air cooler type - RR88-176-V16

Air consumption m³n/h 28300

Air consumption kg/h 36600

Charge air pressure barg 2,4

Charge air temperature:

-normal °C 55

-alarm, temp high °C 62

Turbocharger speed alarm rpm 27761

Exhaust data:

Mass flow kg/h 37700

Volume flow, after turbin m³/h 74400

Temp, after cylinder °C 485

Temp, after turbine °C 415

Back pressure, max mmWG 400

Part load data:

-Mass flow, 90% load kg/h 33100

-Temp, after turbine °C 435

-Mass flow, 80% load kg/h 29800

-Temp, after turbine °C 455

-Mass flow 50% load kg/h 19500

-Temp, after turbine °C 485

Heat dissipation:

Lubrication data:

Lub. oil .cooler MJ/h 2830

Cooling water data:

Low temp. stage MJ/h 2160

High temp. stage MJ/h 2685

Jacket water cooler:

-Heat dissipation, engine MJ/h 3475

-incl. high temp. ca-cooler MJ/h 6160

Ventilation data:

Radiation engine MJ/h 1635

Engine power definition is according to ISO 3046-1

However the engine ratings are valid for the following reference conditions:

Air inlet temperature max. + 45 °C

Air inlet temperature min. + 0°C

Heat dissipation. + 25°C

Charge air low temp. cooling water inlet temp. max. +37°C

Relative humidity 60%

Spec. NOx emissions 1,4 g/kWh at full load (MCR).

Specific energy consumption is according to ISO 3046-1 and is given at full load(MCR),

running on NATURAL GAS with a lower heating value of 36.0 MJ/m³n and

no engine-driven pumps. With engine-driven pumps, add 0.5% for each pump.

Methane no. min 70 , according to AVL calculation

Spec. lub. oil consumption is for guidance only

NOTE! Due to continuous development, some data may change

, Gas Main dimensions

Page 1 : 8

1.03

0611 B

MAIN DIMENSIONS

Main dimensions

Page 2 : 8

1.03

, Gas

0611 B

1.03

, Gas Main dimensions

Page 3 : 8

0611 B

Main dimensions

Page 4 : 8

1.03

, Gas

0611 B

Table of contents

Popular Engine manuals by other brands

Textron

Textron MPE 850 OFF-ROAD Diagnostic manual

Danfoss

Danfoss VLT Brook Crompton Motor FCM 300 Design guide

Volvo Penta

Volvo Penta MD2010 Operator's manual

Rompa

Rompa 18524 manual

Rekluse Motor Sports

Rekluse Motor Sports EXP Installation & user guide

Beckhoff

Beckhoff AM8000 Series Operation instructions

Kohler

Kohler PCH680 owner's manual

MTHTrains

MTHTrains HO 2-6-6-6 Allegheny Engineer's guide

Kohler

Kohler Courage SV470 Service manual

Briggs & Stratton

Briggs & Stratton 90000 series Operating & maintenance instructions

Siemens

Siemens SIMOTICS DP 1PC134 operating instructions

LONCIN

LONCIN LC1P85FA owner's manual