nekos MR28-B User manual

INSTRUCTION MANUAL

TUBULAR GEARMOTOR FOR BLINDS

Elec

trical feeding

NEKOS S.r.l. -

Via Capitoni, 7/5

+39 0424 411011

EN

4420003 – Rev. 2003

MR28-B

INSTRUCTION MANUAL

TUBULAR GEARMOTOR FOR BLINDS

trical feeding

24V

Via Capitoni, 7/5

- 36064 Colceresa (VI)

–

+39 0424 411011

– +39 0424 411013 - www.nekos.it -

TUBULAR GEARMOTOR FOR BLINDS

– Ø28MM

–

ITALY

2

USER INSTRUCTIONS

CAUTION. Carefully observe all the following installation

instructions to ensure personal safety.

The device is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lacking

experience and knowledge. Do not allow children to play with the

fixed controls and keep any remote-control units out of their

reach.

Have installation checks performed periodically by qualified

personnel from a service centre authorised by the manufacturer.

Do not use if repair or adjustment is required.

CAUTION: if the power cable is damaged, it must be replaced by

qualified personnel from a service centre authorised by the

manufacturer.

CAUTION. Disconnect the power supply during cleaning or

maintenance operations. Do not use solvents or jets of water to

wash the appliance; the appliance should not be submerged in

water.

In the event of fault or malfunction, switch off the device at the

main switch. All repairs and adjustments (e.g. setting the stroke)

must only be performed by qualified personnel from a service

centre authorised by the manufacturer.

Always request exclusive use of original spare parts. Failure to

respect this condition could compromise safety and invalidate

the benefits contained in the warranty for the appliance. In the

event of any problems or queries, consult your agent or contact

the manufacturer directly.

The A-weighted sound pressure level is less than 70dB(A).

Carefully preserve these instructions after installation.

INSTALLER

nekos

products have been manufactured in accordance with safety standards and

conforms to the stipulations of current standards in force.

When correctly assembled, installed and used according to the present instructions,

they will not generate any danger for persons, animals or items.

Symbols used in the manual

DANGER

Contents

1. Security rules

................................

2.

Construction and standards

3. Technical data

................................

4. ID plate and marking data

................................

5. Electricity supply

................................

5.1.

Section choice of supply cables

6. Assembly

................................

6.1.

Blind support tube and end cap

6.2. Gear motor

................................

6.3.

Assembly of the supports

6.4.

Assembly of motorization

7. Electrical connections

................................

8.

Luminous indications on led

9.

Adjustment of the two stroke

10. Troubleshooting

................................

11.

Indications for correct assembly

12. Environmental protection

................................

13. Warranty

................................

14. Declaration of

incorporation (for a partly completed machine) and EC Declaration of

Conformity

................................

3

INSTALLER

INSTRU

CTIONS

products have been manufactured in accordance with safety standards and

conforms to the stipulations of current standards in force.

When correctly assembled, installed and used according to the present instructions,

they will not generate any danger for persons, animals or items.

Symbols used in the manual

This indication draw the attention about potential dangers for

safety and health of peoples and animals.

................................

................................

................................

Construction and standards

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

Section choice of supply cables

................................

................................

................................

................................

................................

Blind support tube and end cap

................................

................................

................................

................................

................................

Assembly of the supports

................................

................................

Assembly of motorization

................................

................................

................................

................................

................................

Luminous indications on led

................................

................................

Adjustment of the two stroke

-ends ................................

................................

................................

................................

................................

Indications for correct assembly

................................

................................

................................

................................

................................

................................

................................

................................

incorporation (for a partly completed machine) and EC Declaration of

................................

................................

................................

CTIONS

products have been manufactured in accordance with safety standards and

When correctly assembled, installed and used according to the present instructions,

This indication draw the attention about potential dangers for

safety and health of peoples and animals.

................................

....................... 4

................................

................................. 5

................................

...................... 5

................................

.... 6

................................

.................. 6

................................

.................. 6

................................

.............................. 7

................................

.................. 7

................................

................. 7

................................

........................... 8

................................

............................ 8

................................

.......... 8

................................

................................. 9

................................

....................... 9

................................

..................10

................................

..........................10

................................

....10

................................

.............................11

incorporation (for a partly completed machine) and EC Declaration of

................................

...........................12

1. Security rules

PLEASE

NOTE:

IMPORTANT

ALL THE FOLLOWING IN

I

MPROPER INSTALLATION

INSTRUCTIONS AFTER I

MANDATORY RISK ANALY

The Nekos electrical actuators comply with the Machinery Directive (2006/42/EC), Standard

IEC 60335-2-

103 (Particular requirements for drives for gates, doors and windows) and

other directives and regulations indicated in the attached Declarations of Incor

CE Conformity (at the end of the manual). According to the Machinery Directive, actuators

are “partly completed machinery” intended for incorporation into doors and windows. The

manufacturer/supplier of the window is required, with exclusive r

compliance of the entire system with the applicable standards and to issue CE certification.

We strongly discourage any use of the actuators other than that specified and therefore, in

any case, the supplier of the complete sys

For systems installed at a height of less than 2.5 m above floor level or other levels

accessible to users, the manufacturer/supplier of the window must conduct

regarding potential harm (violent blows, crushing, w

use or possible malfunction or accidental breakage of the automated windows, and to

implement suitable

protective measures

recommended by the specified standard:

-

controlling the actuators via a “deadman’s button” placed near the system and within

the operator’s field of view, to ensure that people are out of the way during operation.

The button should be placed at a height of 1.5 m and operated by key if accessible

the public; or:

-

use of contact safety systems (also included in the actuators) that ensure a maximum

closing force of 400/150/25 N, measured in accordance with paragraph BB.20.107.2 of

IEC 60335-2-103; or:

- use of non-

contact safety systems (lasers, li

-

use of fixed safety barriers that prevent access to moving parts.

Automated windows are deemed adequately protected if they:

-

are installed at a height of >2.5 m; or:

- have a leading-

edge opening of <200 mm and a closing speed of <15 mm

-

are part of a smoke and heat evacuation system for emergency use only.

In any case, moving parts of windows that could fall below 2.5 m following breakage of a

system component need to be fixed or

falling or collapsing

: e.g. the use of safety arms on bottom

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge. Do

not allow childre

n to play with the fixed controls and keep any remote

out of their reach.

The actuator is destined exclusively for installation indoors. For any special

application we recommend you consult the manufacturer beforehand.

After removing

packaging, check for any damage on the appliance.

MAINTENANCE and REPAIRS

Periodically check the installation by inspecting the cables, springs, rods and

mechanical parts for wear or damage. Do not use if repair or adjustment is

required.

Disconnect the p

ower supply during cleaning or maintenance operations.

4

IMPORTANT

SAFETY

INSTRUCTIONS.

ALL THE FOLLOWING IN

STALLATION INSTRUCTI

ONS TO ENSURE PERSON

MPROPER INSTALLATION

CAN SERIOUSLY ENDANG

ER SAFETY

INSTRUCTIONS AFTER I

NSTALLATION

.

MANDATORY RISK ANALY

SIS AND PROTECTION MEASURES

.

The Nekos electrical actuators comply with the Machinery Directive (2006/42/EC), Standard

103 (Particular requirements for drives for gates, doors and windows) and

other directives and regulations indicated in the attached Declarations of Incor

CE Conformity (at the end of the manual). According to the Machinery Directive, actuators

are “partly completed machinery” intended for incorporation into doors and windows. The

manufacturer/supplier of the window is required, with exclusive r

esponsibility, to ensure the

compliance of the entire system with the applicable standards and to issue CE certification.

We strongly discourage any use of the actuators other than that specified and therefore, in

any case, the supplier of the complete sys

tem retains full liability.

For systems installed at a height of less than 2.5 m above floor level or other levels

accessible to users, the manufacturer/supplier of the window must conduct

regarding potential harm (violent blows, crushing, w

ounds) caused to people by normal

use or possible malfunction or accidental breakage of the automated windows, and to

protective measures

in view of these.

Such measures include those

recommended by the specified standard:

controlling the actuators via a “deadman’s button” placed near the system and within

the operator’s field of view, to ensure that people are out of the way during operation.

The button should be placed at a height of 1.5 m and operated by key if accessible

use of contact safety systems (also included in the actuators) that ensure a maximum

closing force of 400/150/25 N, measured in accordance with paragraph BB.20.107.2 of

contact safety systems (lasers, li

ght grids); or:

use of fixed safety barriers that prevent access to moving parts.

Automated windows are deemed adequately protected if they:

are installed at a height of >2.5 m; or:

edge opening of <200 mm and a closing speed of <15 mm

are part of a smoke and heat evacuation system for emergency use only.

In any case, moving parts of windows that could fall below 2.5 m following breakage of a

system component need to be fixed or

secured in order to prevent them from suddenly

: e.g. the use of safety arms on bottom

-

hung windows.

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge. Do

n to play with the fixed controls and keep any remote

The actuator is destined exclusively for installation indoors. For any special

application we recommend you consult the manufacturer beforehand.

packaging, check for any damage on the appliance.

MAINTENANCE and REPAIRS

Periodically check the installation by inspecting the cables, springs, rods and

mechanical parts for wear or damage. Do not use if repair or adjustment is

ower supply during cleaning or maintenance operations.

INSTRUCTIONS.

C

AREFULLY OBSERVE

ONS TO ENSURE PERSON

AL SAFETY

.

ER SAFETY

.

K

EEP THESE

The Nekos electrical actuators comply with the Machinery Directive (2006/42/EC), Standard

103 (Particular requirements for drives for gates, doors and windows) and

other directives and regulations indicated in the attached Declarations of Incor

poration and

CE Conformity (at the end of the manual). According to the Machinery Directive, actuators

are “partly completed machinery” intended for incorporation into doors and windows. The

esponsibility, to ensure the

compliance of the entire system with the applicable standards and to issue CE certification.

We strongly discourage any use of the actuators other than that specified and therefore, in

For systems installed at a height of less than 2.5 m above floor level or other levels

accessible to users, the manufacturer/supplier of the window must conduct

risk analysis

ounds) caused to people by normal

use or possible malfunction or accidental breakage of the automated windows, and to

Such measures include those

controlling the actuators via a “deadman’s button” placed near the system and within

the operator’s field of view, to ensure that people are out of the way during operation.

The button should be placed at a height of 1.5 m and operated by key if accessible

to

use of contact safety systems (also included in the actuators) that ensure a maximum

closing force of 400/150/25 N, measured in accordance with paragraph BB.20.107.2 of

edge opening of <200 mm and a closing speed of <15 mm

/s; or:

are part of a smoke and heat evacuation system for emergency use only.

In any case, moving parts of windows that could fall below 2.5 m following breakage of a

secured in order to prevent them from suddenly

hung windows.

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge. Do

n to play with the fixed controls and keep any remote

-control units

The actuator is destined exclusively for installation indoors. For any special

application we recommend you consult the manufacturer beforehand.

packaging, check for any damage on the appliance.

Periodically check the installation by inspecting the cables, springs, rods and

mechanical parts for wear or damage. Do not use if repair or adjustment is

ower supply during cleaning or maintenance operations.

Do not use solvents or jets of water to wash the appliance. The appliance should

not be submerged in water.

In the event of breakage or malfunction, switch the appliance off at the general

switch and

call for the services of a qualified technician.

Repairs should only be performed by qualified personnel at assistance centres

authorised by the manufacturer.

Always request exclusive use of original spare parts. Failure to respect this

condition could com

promise safety and invalidate the benefits contained in the

warranty for the appliance.

In the event of any problems or queries, consult your agent or contact the

manufacturer directly.

2.

Construction and standards

INTENDED USE

.

The MR28

moving curtains and small blinds

the supplier of the entire system in any case retaining sole liability.

The actuator is manufactured in accordance with the EC Directives and

Re

gulations listed in the attached Declaration of Incorporation and Conformity

Electrical connections must conform to regulations in force for the design and

set up of electrical equipment.

To ensure efficient separation from the grid, an approved type of bipolar “dead

man” switch should be used. An omnipolar general power switch with minimum

distance of 3 mm between contacts should be installed upstream of the control line.

3. Technical data

Model

Voltage supply (U

n

)

Traction force (C

n

)

Theoretical capacity load on tube Ø28

Limit switches maximum programming height

Power absorbance (I

n

)

Power absorbance on charge

Feeding cable

Speed at nominal charge (v

n

No load speed (v0)

Electrical insulation

Service (D

r

)

Working temperature

Electrical device protection rating

End stroke

Connection

of two or more devices in parallel

Dimensions

Device weight

Any data reported in this table is not binding and may be susceptible to variations without notice.

5

Do not use solvents or jets of water to wash the appliance. The appliance should

not be submerged in water.

In the event of breakage or malfunction, switch the appliance off at the general

call for the services of a qualified technician.

Repairs should only be performed by qualified personnel at assistance centres

authorised by the manufacturer.

Always request exclusive use of original spare parts. Failure to respect this

promise safety and invalidate the benefits contained in the

warranty for the appliance.

In the event of any problems or queries, consult your agent or contact the

manufacturer directly.

Construction and standards

The MR28

-B tubular gear

motor is destined exclusively for

moving curtains and small blinds

;

any other use is strongly discouraged, with

the supplier of the entire system in any case retaining sole liability.

The actuator is manufactured in accordance with the EC Directives and

gulations listed in the attached Declaration of Incorporation and Conformity

Electrical connections must conform to regulations in force for the design and

set up of electrical equipment.

To ensure efficient separation from the grid, an approved type of bipolar “dead

man” switch should be used. An omnipolar general power switch with minimum

distance of 3 mm between contacts should be installed upstream of the control line.

MR28

24V

0,70 Nm

Theoretical capacity load on tube Ø28

5,5 Kg

Limit switches maximum programming height

0,340A

Power absorbance on charge

(P

n

)

8,8

2x0,50

n

)

24 rpm

32 rpm

Class III

5 cycles

-

5 + 65 ºC

Electrical device protection rating

IP44

By encoder, p

of two or more devices in parallel

Ø24,5 x 210

0,282 Kg

Any data reported in this table is not binding and may be susceptible to variations without notice.

Do not use solvents or jets of water to wash the appliance. The appliance should

In the event of breakage or malfunction, switch the appliance off at the general

Repairs should only be performed by qualified personnel at assistance centres

Always request exclusive use of original spare parts. Failure to respect this

promise safety and invalidate the benefits contained in the

In the event of any problems or queries, consult your agent or contact the

motor is destined exclusively for

any other use is strongly discouraged, with

the supplier of the entire system in any case retaining sole liability.

The actuator is manufactured in accordance with the EC Directives and

gulations listed in the attached Declaration of Incorporation and Conformity

.

Electrical connections must conform to regulations in force for the design and

To ensure efficient separation from the grid, an approved type of bipolar “dead

-

man” switch should be used. An omnipolar general power switch with minimum

distance of 3 mm between contacts should be installed upstream of the control line.

MR28

-

B

/ 24V

24V

0,70 Nm

5,5 Kg

5 m

0,340A

8,8

W

2x0,50

mm

2

– 3m

24 rpm

32 rpm

Class III

5 cycles

5 + 65 ºC

IP44

By encoder, p

rogrammable

Yes

Ø24,5 x 210

mm

0,282 Kg

Any data reported in this table is not binding and may be susceptible to variations without notice.

4.

ID plate and marking data

The MR28-B gear motors

have CE marking and comply with the Standards listed in the

Declaration of Conformity. They also come with a Declaration of Incorporation, due to

their classification by the Machinery Directive as “partly completed machines”. Both

declarations are include

d in the final pages of this manual.

on an adhesive label placed on the outside of the casing, which m

visible. T

he main information it displays includes: manufacturer's address, product

name - model number,

technical characteristics, production date and serial number.

the event of a complaint, please indicate the serial number (SN) displayed on the label.

An explanation of the symbols used on the label to abbreviate the technical

characteristics is given

in the table in the chapter on “TECHNICAL DATA”.

5. Electricity supply

MR28-

B gear motors can use 24V

For this reason, a feeder with an

outcoming tension correspondent to the

one indicated on the technical data label

attached to device and which transforms

supply mains voltage (230V~50Hz or

other) in 24V

should be used. Correct

functioning is guaranteed

if a feeder type

approved or suggested by the

manufacturer is used.

The manufacturer

also provides the ALì-SW

power supply

device, built specifically for this type of application, which can directly power and

control the gear motor of the blind.

in the Italian 3-

module recessed power and switching box, and the gear motor control

uses the innovative touch

-

touching the “deadman's switch” key or in automa

be applied on any commercial hole

control integrated in the design of the home environment.

5.1.

Section choice of supply cables

In low tension supply systems, tension falls due to current passage in conductors is a

basic aspect for safety and good appliance function. It is therefore extremely important

that the conductor section in function of cable length is calculated correctly.

The following table indicates cable lengths for a gear motor connected to a 24V

feeder, with power suitable for moving a motor on its nominal charge. In the event that

only a feeder is used to furnish energy to various gear motors, divide the cable lengt

for the number of gear motors connected.

CABLE SECTION

0.50 mmq

0.75 mmq

1.00 mmq

1.50 mmq

2.50 mmq

4.00 mmq

6.00 mmq

6

ID plate and marking data

have CE marking and comply with the Standards listed in the

Declaration of Conformity. They also come with a Declaration of Incorporation, due to

their classification by the Machinery Directive as “partly completed machines”. Both

d in the final pages of this manual.

The plate data is displayed

on an adhesive label placed on the outside of the casing, which m

he main information it displays includes: manufacturer's address, product

technical characteristics, production date and serial number.

the event of a complaint, please indicate the serial number (SN) displayed on the label.

An explanation of the symbols used on the label to abbreviate the technical

in the table in the chapter on “TECHNICAL DATA”.

B gear motors can use 24V

.

For this reason, a feeder with an

outcoming tension correspondent to the

one indicated on the technical data label

attached to device and which transforms

supply mains voltage (230V~50Hz or

should be used. Correct

if a feeder type

approved or suggested by the

The manufacturer

power supply

device, built specifically for this type of application, which can directly power and

control the gear motor of the blind.

The power

supply device is designed to be inserted

module recessed power and switching box, and the gear motor control

-

switch technology that activates the control by simply

touching the “deadman's switch” key or in automa

tic steps. The touch

be applied on any commercial hole

-

cover element maintaining an elegant electric

control integrated in the design of the home environment.

Section choice of supply cables

In low tension supply systems, tension falls due to current passage in conductors is a

basic aspect for safety and good appliance function. It is therefore extremely important

that the conductor section in function of cable length is calculated correctly.

The following table indicates cable lengths for a gear motor connected to a 24V

feeder, with power suitable for moving a motor on its nominal charge. In the event that

only a feeder is used to furnish energy to various gear motors, divide the cable lengt

for the number of gear motors connected.

CABLE SECTION

Actuator fed at

24V

0.50 mmq

~40 m

0.75 mmq

~60 m

1.00 mmq

~80 m

1.50 mmq

~120 m

2.50 mmq

~200 m

4.00 mmq

~320 m

6.00 mmq

~480m

have CE marking and comply with the Standards listed in the

Declaration of Conformity. They also come with a Declaration of Incorporation, due to

their classification by the Machinery Directive as “partly completed machines”. Both

The plate data is displayed

on an adhesive label placed on the outside of the casing, which m

ust remain intact and

he main information it displays includes: manufacturer's address, product

technical characteristics, production date and serial number.

In

the event of a complaint, please indicate the serial number (SN) displayed on the label.

An explanation of the symbols used on the label to abbreviate the technical

in the table in the chapter on “TECHNICAL DATA”.

device, built specifically for this type of application, which can directly power and

supply device is designed to be inserted

module recessed power and switching box, and the gear motor control

switch technology that activates the control by simply

tic steps. The touch

-switch board can

cover element maintaining an elegant electric

In low tension supply systems, tension falls due to current passage in conductors is a

basic aspect for safety and good appliance function. It is therefore extremely important

that the conductor section in function of cable length is calculated correctly.

The following table indicates cable lengths for a gear motor connected to a 24V

feeder, with power suitable for moving a motor on its nominal charge. In the event that

only a feeder is used to furnish energy to various gear motors, divide the cable lengt

h

24V

Never connect two feeders to the same gear motor

6. Assembly

T

HESE INDICATIONS ARE

INTENDED FOR THE ATT

PERSONNEL

.

BASIC JOB AND SAFETY

All preparatory operations, assembly and electrical connections must be carried out by

technical and spe

cialized personnel to guarantee best performances and good function

of the MR28-

B tubular gear motor. First of all, please check that the following

fundamental assumptions have been satisfied:

Check that the electrical supply used corresponds to the

“TECHNICAL DATA” label attached to the machine and that the given

temperature range is compatible with the place of installation.

Gear motor performances must be sufficient to move the curtain; any limits

indicated in the technical data

(page 5).

Ensure the gear motor has not been damaged during transport, first visually

and then by working it in both directions.

Check that the inner section of the window length is over 270 mm in length.

Anything

shorter than this will not allow for assembly of the gear motor.

Before mounting gear motor into position, ensure supports have been adequately

prepared. These operations must be carried out “at the bench” with the help of

minimum equipment.

6.1. Blind support

tube and end cap

CAUTION: the blind support tube must have an internal diameter of 26 mm.

After cutting the blind support tube to the desired length, which depends on the width of

the window, the tube must be cleaned of all burr caused by the cutting; it

recommended that a deburring knife be used to round the internal edges in order to

facilitate insertion of the support end caps.

6.2. Gear motor

Insert the gear motor into the tube until it reaches the stop of the sliding bush.

At a distance of 206

mm from

holes at 180° to one another with Ø2.5 mm and 10 mm deep.

Figure 1

7

Never connect two feeders to the same gear motor

.

INTENDED FOR THE ATT

ENTION OF TECHNICIAN

BASIC JOB AND SAFETY

TECHNIQUES ARE THERE

FORE NOT INCLUDED

All preparatory operations, assembly and electrical connections must be carried out by

cialized personnel to guarantee best performances and good function

B tubular gear motor. First of all, please check that the following

fundamental assumptions have been satisfied:

Check that the electrical supply used corresponds to the

“TECHNICAL DATA” label attached to the machine and that the given

temperature range is compatible with the place of installation.

Gear motor performances must be sufficient to move the curtain; any limits

indicated in the technical data

table on the product cannot be exceeded

Ensure the gear motor has not been damaged during transport, first visually

and then by working it in both directions.

Check that the inner section of the window length is over 270 mm in length.

shorter than this will not allow for assembly of the gear motor.

Before mounting gear motor into position, ensure supports have been adequately

prepared. These operations must be carried out “at the bench” with the help of

tube and end cap

CAUTION: the blind support tube must have an internal diameter of 26 mm.

After cutting the blind support tube to the desired length, which depends on the width of

the window, the tube must be cleaned of all burr caused by the cutting; it

recommended that a deburring knife be used to round the internal edges in order to

facilitate insertion of the support end caps.

Insert the gear motor into the tube until it reaches the stop of the sliding bush.

mm from

the head unit of the gear motor (see figure 1), drill 2

holes at 180° to one another with Ø2.5 mm and 10 mm deep.

206 mm

.

ENTION OF TECHNICIAN

S AND SPECIALIZED

FORE NOT INCLUDED

.

All preparatory operations, assembly and electrical connections must be carried out by

cialized personnel to guarantee best performances and good function

B tubular gear motor. First of all, please check that the following

Check that the electrical supply used corresponds to the

indications on the

“TECHNICAL DATA” label attached to the machine and that the given

temperature range is compatible with the place of installation.

Gear motor performances must be sufficient to move the curtain; any limits

table on the product cannot be exceeded

Ensure the gear motor has not been damaged during transport, first visually

Check that the inner section of the window length is over 270 mm in length.

shorter than this will not allow for assembly of the gear motor.

Before mounting gear motor into position, ensure supports have been adequately

prepared. These operations must be carried out “at the bench” with the help of

CAUTION: the blind support tube must have an internal diameter of 26 mm.

After cutting the blind support tube to the desired length, which depends on the width of

the window, the tube must be cleaned of all burr caused by the cutting; it

is

recommended that a deburring knife be used to round the internal edges in order to

Insert the gear motor into the tube until it reaches the stop of the sliding bush.

the head unit of the gear motor (see figure 1), drill 2

8

Use a conical tool to make a small flare at 90° which will contain the head of the

screw.

Take the M3x8 countersunk head screws provided and screw them into the two

holes. The holes do not require tapping since these are self-tapping screws.

Fix each screw until the head disappears completely.

Caution. If the head of the screw protrudes from the windup tube, the depth of

the flare must be increased accordingly. Any protrusion of the screw from the

tube may damage the fabric being wound up around the roller.

6.3. Assembly of the supports

Follow the steps below.

Carefully select the position at which to fix the supports. Horizontal fixing uses the

holes in line with the tube, whereas orthogonal fixing uses the holes located at 90°

on the bracket.

The support bracket with the cross slots should be positioned near the motor, i.e.,

where the power supply cable comes out.

Take the plastic bush with Ø4 hole that can be found in the bag of small metal parts

and assemble it in the hole of the other bracket; this requires a certain amount of

pressure so an appropriate tool should be used.

Mark the positions of the holes with a pencil.

Depending on the type of support (wall, frame or other), use a drill bit to drill a hole

with the selected diameter in the points marked previously with the pencil.

Screw in the screws without tightening them and check the linearity and orientation

of the brackets.

6.4. Assembly of motorization

Insert opposite motor cover pin in opening provided on bracket.

Insert protruding tongue of motor head into cross threading slot and position in

alignment with curtain.

Check that wrapping tube is horizontal. Should this not be the case, loosen fixing

screws and reset properly. Remember that even a slight inclination of the mounting

means that the curtain is not aligned and will produce waves in the fabric.

Fix bracket screws permanently into position.

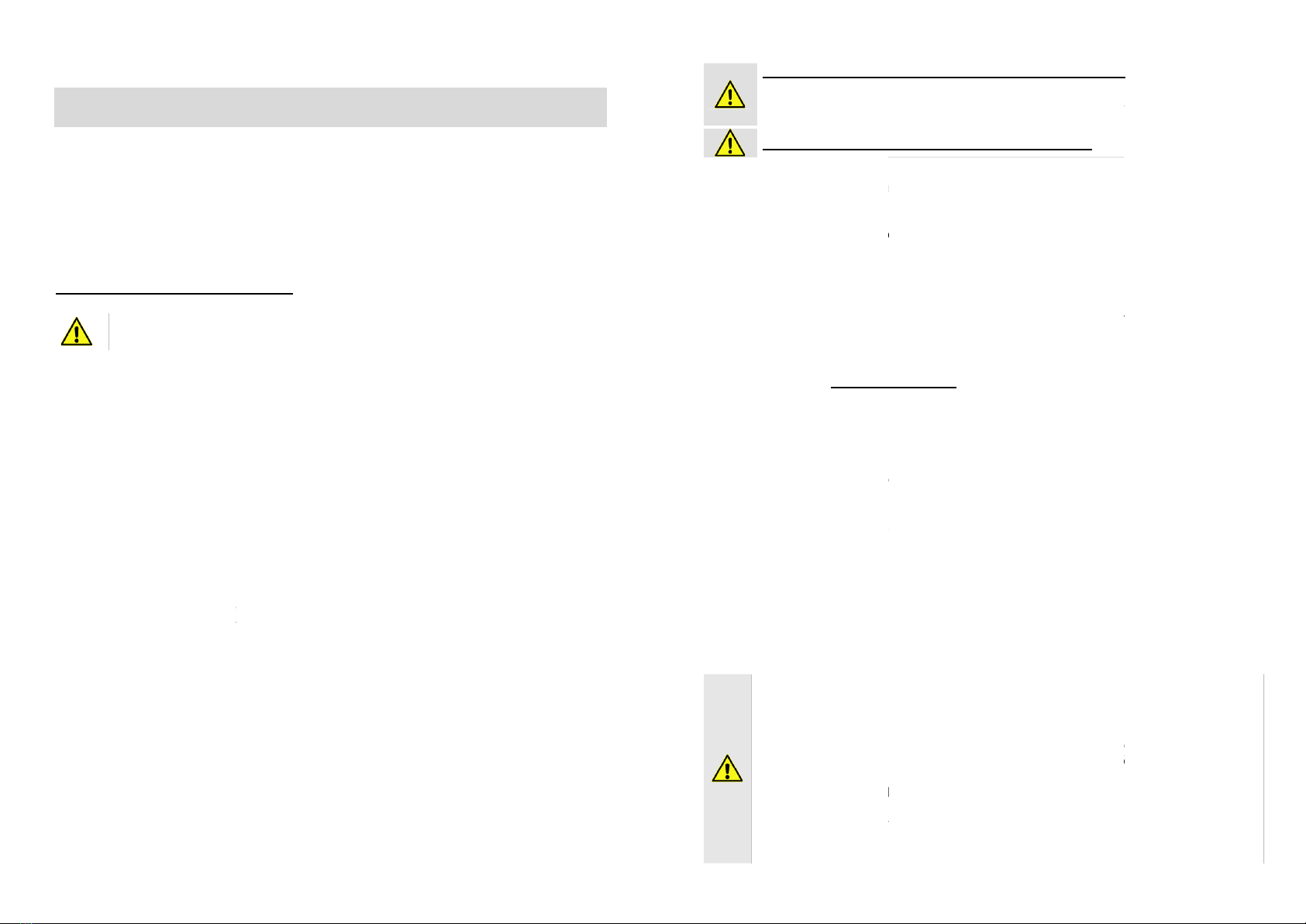

7. Electrical connections

The cable furnished with the MR28-B tubular gear motor is 2 m long and has been

calculated in accordance with safety rules. In the event that the distance between the

gear motor and feeder should exceed this length, the cable should be extended.

See table on page 6 for conductor section indications.

After connecting electricity supply to feeder, check that up key function opens the

curtain and down key function closes it. In the event that keys function to the contrary,

invert cable positions.

For harness, please follow the diagram indicated on this page.

9

8. Luminous indications on led

Before activating the gear motor, familiarise yourself with messages indicated by the

red led on the head of the gear motor. This will allow you to check machine is

functioning properly or allow you to recognize possible anomalies.

LED function

Meaning

Constantly on Motor in use. Limit switch programming active.

300ms on – 300ms off Motor not programmed; limit switch programming

phase.

100ms on – 1sec off Motor in electronical protection due to excessive

charge.

1sec on – 1sec off Motor has regularly reached a limit stop but is still

connected to electricity supply.

100ms on – 100ms off Encoder error

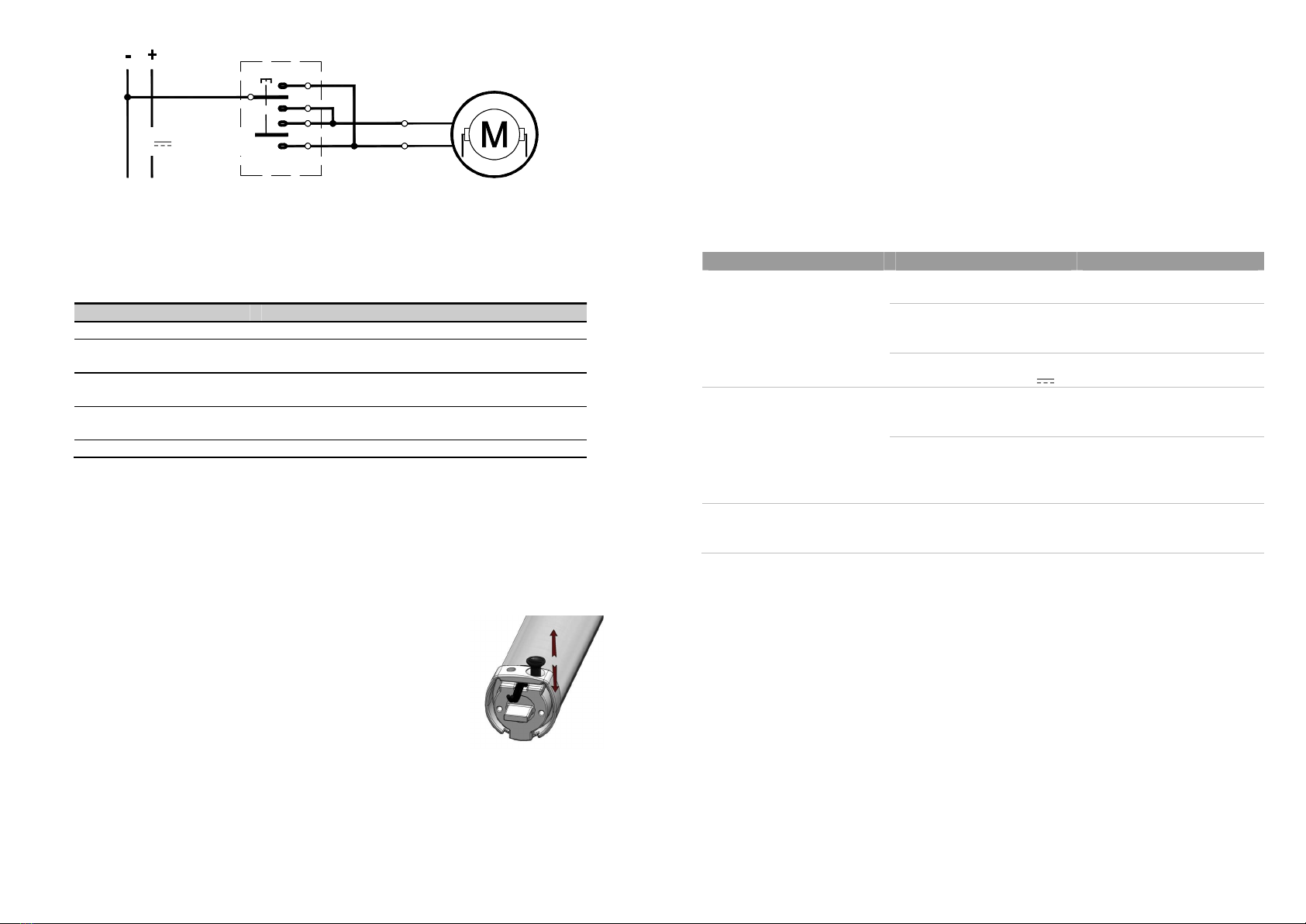

9. Adjustment of the two stroke-ends

The gear motor allows you to adjust the stopping position of the blind at the desired

upper or lower points. Both stroke-ends are programmed in the same step, by using

the up and down control button and removing the plug located on the head unit of the

gear motor. The motor is factory set with a random stroke-end, i.e., not following any

particular logic. The programming procedure is simple and immediate; just strictly

follow the steps below:

1. Remove the plug (which looks like a screw) housed on the

head unit of the gear motor (see figure to the side). The plug

has a small magnet used to block the programming of the

two stroke-ends.

2. Operate the control button in one direction (either up or

down, it doesn't matter) and move the blind into the desired

position without ever reversing the direction of travel; there

can be intermediate stops as long as the next command is in

the same direction.

3. During the control action, the LED must be flashing. This means that the stroke-

ends are being programmed.

4. Operate the control button to reverse the direction of travel and move the blind to

the opposite desired position, again without ever reversing the direction of travel.

5. The LED must be flashing during the entire control phase.

24V

10

6. Insert the plug into its position (see figure to the side). Now the programming is

finished.

7. Perform a complete stroke up and down of the blind and check that it stops in the

desired position. In this case the LED should remain steady-on during the entire

control phase.

8. Otherwise, repeat steps 1 to 6. The programming of the stroke-ends can be

repeated as often as necessary.

9. Perform a few maneuvers to check the blind's operation.

10. Troubleshooting

Please consult the following table for any eventual problems with function during

installation or normal use:

Problem Possible cause Solution

Gear motor doesn’t work.

No electricity supply for

feeder.

Check state of safety

switch.

Connecting cable not

connected or wire not

connected.

Check all electrical

connections of gear motor.

Feeder doesn’t deliver

foreseen tension (24V ).

Possible transformer

winding break down.

Led is lit but gear motor

doesn’t work.

Limit switch programming

is too close.

Loosen screw on head and

reset limit switch

programming.

Gear motor is damaged

due to a shock. Motor

connection has

unsoldered.

Send gear motor to a

Service Centre.

In spite of programming,

gear motor doesn’t get one

or both limit switches.

Programming hasn’t been

carried out correctly. Repeat programming.

11. Indications for correct assembly

Check that curtain is perfectly spread without any folds or looseness.

Check that both up and down limit switches have reached the desired positions

Check that the gear motor support brackets are aligned and the four fixing screws

are firmly screwed into position

12. Environmental protection

All materials used in the manufacture of this appliance are recyclable.

We recommend that the device itself, and any accessories, packaging, etc. be sent to

a centre for ecological recycling as established from laws in force on recycling.

The device is mainly made from the following materials: aluminium, zinc, iron, plastic of

various type, cuprum. Dispose materials in conformity with local regulations about

removal.

11

13. Certificate of guarantee

The manufacturer will guarantee good function of the appliance. The manufacturer shall

undertake to replace defective parts due to poor quality materials or manufacturing

defects in accordance with article 1490 of the Civil Code.

The guarantee covers products and individual parts for 2 years from the date of

purchase. The latter is valid as long as the purchaser possesses proof of purchase and

completion of all agreed conditions of payment.

Guarantee of good function of appliances agreed by the manufacturer implies that the

latter undertakes to repair or replace free of charge and in the shortest period possible

any parts that break while under warranty.

The purchaser is not entitled to any reimbursement for eventual direct or indirect

damage or other expenses incurred. Attempt to repair by personnel unauthorised by

the manufacture shall render the warranty null and invalid.

The warranty does not cover fragile parts or parts subject to natural wear and tear or

corrosion, overload, however temporary etc. The manufacturer will accept no

responsibility for eventual damage incurred by erroneous assembly, manoeuvre or

insertion, excessive stress or inexpert use.

Repairs performed under guarantee are always "ex factory of the manufacturer".

Respective transport expenses (out/back) are the responsibility of the purchaser.

12

14. Dichiarazione di Incorporazione (per una quasi macchina) e Dichiarazione

CE di Conformità / Declaration of incorporation (for a partly completed

machine) and EC Declaration of Conformity.

Con la presente il / Hereby the

Costruttore:

Manufacturer:

NEKOS S.r.l.

Via Capitoni 7/5- 36064 Colceresa (Vicenza) - Italy

Tel +39 0424 411011 – Email [email protected]

dichiara sotto la propria responsabilità che i seguenti prodotti

declare under its own responsibility that the following products

Descrizione prodotto:

Product Designation:

Attuatore a cremagliera, lineare a stelo, elettroserratura, tubolare per tende

Rack and pinion drive, linear drive, electromechanical lock, tubular drive

Modello:

Type:

230 V: SKY450

–

SKY 650

NKL 450

24 V: SKY 650

K-LOCK – BK-LOCK

MR28-B

Anno di costruzione dal / Year of manufacturing from: 2017

Soddisfano gli applicabili requisiti essenziali della Direttiva Macchine 2006/42/EC, Allegato I

Fulfil the essential requirements of the Machinery Directive 2006/42/EC, Annex I, Art. 1.1.2, 1.1.3, 1.1.5, 1.2.1,1.2.3,

1.2.6; 1.3.2, 1.3.4, 1.3.9, 1.5.1, 1.5.2, 1.5.6, 1.5.7, 1.5.8, 1.5.9, 1.5.10, 1.5.11, 1.7.1, 1.7.1.1, 1.7.3, 1.7.4.2, 1.7.4.3

La documentazione tecnica pertinente è compilata secondo l’Allegato VII, sezione B

The relevant technical documentation is compiled in accordance with Annex VII, Part B

La persona autorizzata a costituire la documentazione tecnica pertinente è:

The person authorised to compile the relevant technical documentation is: ing. Matteo Stefani – Nekos S.r.l.

Su richiesta adeguatamente motivata delle autorità nazionali, la documentazione tecnica dei citati prodotti sarà resa

disponibile, via e-mail, entro un tempo compatibile con la sua importanza.

In response to a reasoned request by the national authorities, we will provide, via e-mail, the relevant information on

the product listed above within an adequate period proportional to its importance.

Inoltre i succitati prodotti sono conformi alle disposizioni pertinenti delle seguenti Direttive:

Furthermore the products listed above complies with the provisions of followings Directives :

2014/30/EU Direttiva Compatibilità Elettromagnetica / ElectroMagnetic Compatibility Directive (EMCD)

2014/35/EU Direttiva Bassa Tensione / Low Voltage Directive (LVD)

2011/65/EU Direttiva sulla restrizione dell’uso di determinate sostanze pericolose nelle apparecchiature

elettriche ed elettroniche (Direttiva RoHS) / Restriction of the use of certain hazardous substances Directive (RoHS

Directive)

2015/863/EU Direttiva Delegata recante modifica dell’allegato II della Direttiva 2011/65/EU del Parlamento

Europeo e del Consiglio per quanto riguarda l’elenco delle sostanze con restrizioni d’uso/ Delegated

Directive amending Annex II of Directive 2011/65/EU of the European Parliament and of the Council regarding the

list of substances with usage restrictions

e delle seguenti norme armonizzate e/o specifiche tecniche:

and of the following harmonised standards and/or technical specifications:

EN 60335

-

2

-

10

3;

EN 61000

-

6

-

3:2007 + A1:2011 + AC:2012; EN IEC 61000

-

6

-

2:2019;

EN 60335-1:2012 + AC:2014+A11:2014; EN 50581:2012;

La messa in moto di una macchina completa che includa la quasi macchina sopra menzionata, da noi fornita, non è

permessa finché non sia accertato che l’installazione sia stata fatta secondo le specifiche e le indicazioni di

installazione contenute nel “Manuale d’istruzioni” fornito con la quasi-macchina, e che sia stata espletata e

documentata, in apposito protocollo, una procedura di accettazione da parte di un tecnico abilitato.

Commissioning of the complete machinery including the above mentioned drives delivered by us is not allowed until it

is ascertained that the installation of the complete machinery was performed in accordance with the specifications and

the operating and installation advice given in our Mounting Instructions, and that the acceptance procedure was duly

carried out and documented in an acceptance protocol by a specialist.

Questa dichiarazione è fatta dal costruttore / This is declared by the manufacturer:

NEKOS S.r.l. - Via Capitoni 7/5- 36064 Colceresa (Vicenza) - Italy

Rappresentato da / Represented by: Giuliano Galliazzo – A.D. Presidente / President CEO

Luogo e data / Place and date: Colceresa 04/03/2020 Firma / Valid signature

NEKOS S.r.l. - Via Capitoni, 7/5

36064 Colceresa (VI) – ITALY

+39 0424 411011 – +39 0424 411013

Table of contents

Other nekos Engine manuals

Popular Engine manuals by other brands

O.S. engine

O.S. engine O.S. Motor OMH-5825-520 Owner's instruction manual

FNM

FNM HPE 300 owner's manual

Newport

Newport mks IDL165-200LM user manual

Selva

Selva T25/30 owner's manual

O.S. engine

O.S. engine FSA-72 Owner's instruction manual

Predator Engines

Predator Engines 173cc Owner's manual & safety instructions