Rekluse Adventure-Bike EXP Page 6

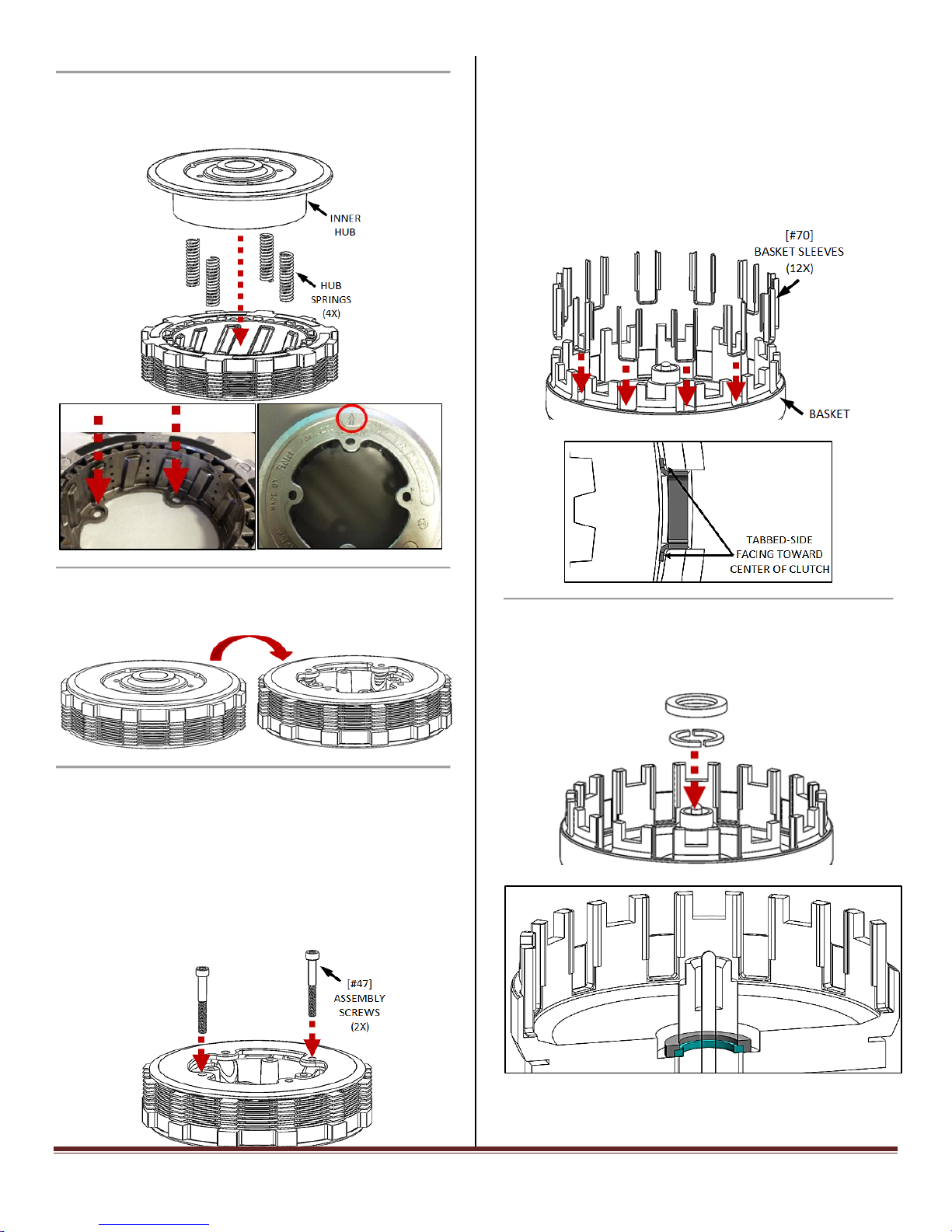

3. Install the hub assembly into the clutch basket,

making sure that all of the friction disk tabs

index into the steel basket sleeves and the

inner hub spline indexes correctly to the

mainshaft.

NOTE: Use only the full tang slots.

Never install any disks into the half-slots.

4. Reinstall the OEM washer and center nut,

applying Loctite© 243 or equivalent thread-

locking compound to the threads.

Use a torque wrench to tighten the center nut to

74 ft-lb (100 N-m), but do not over-torque!

This may require placing the transmission in the

highest gear and having a friend hold the brake

pedal to keep the clutch from spinning.

WARNING: Do not over-torque the center nut!

Over-torqueing will cause drag and can damage

your engine’s bearings or transmission

components.

5. Reinstall the OEM throwout and pressure plate,

followed by the springs [#60.2] and OEM bolts.

NOTE: The Rekluse-provided pressure plate

springs (white) are stiffer than the OEM springs,

and they have been found to significantly help

improve overall clutch performance in the form

of positive engagement and hookup. It is

recommended to install them at this time.

Due to the light nature of the clutch lever with

the stock springs, the stiffer springs should not

adversely affect the clutch lever effort or feel.

Torque the spring bolts to 4.4 ft-lb (6 N-m).

6. With the clutch installed, you can now remove

the screws that were used to hold the assembly

together during installation.

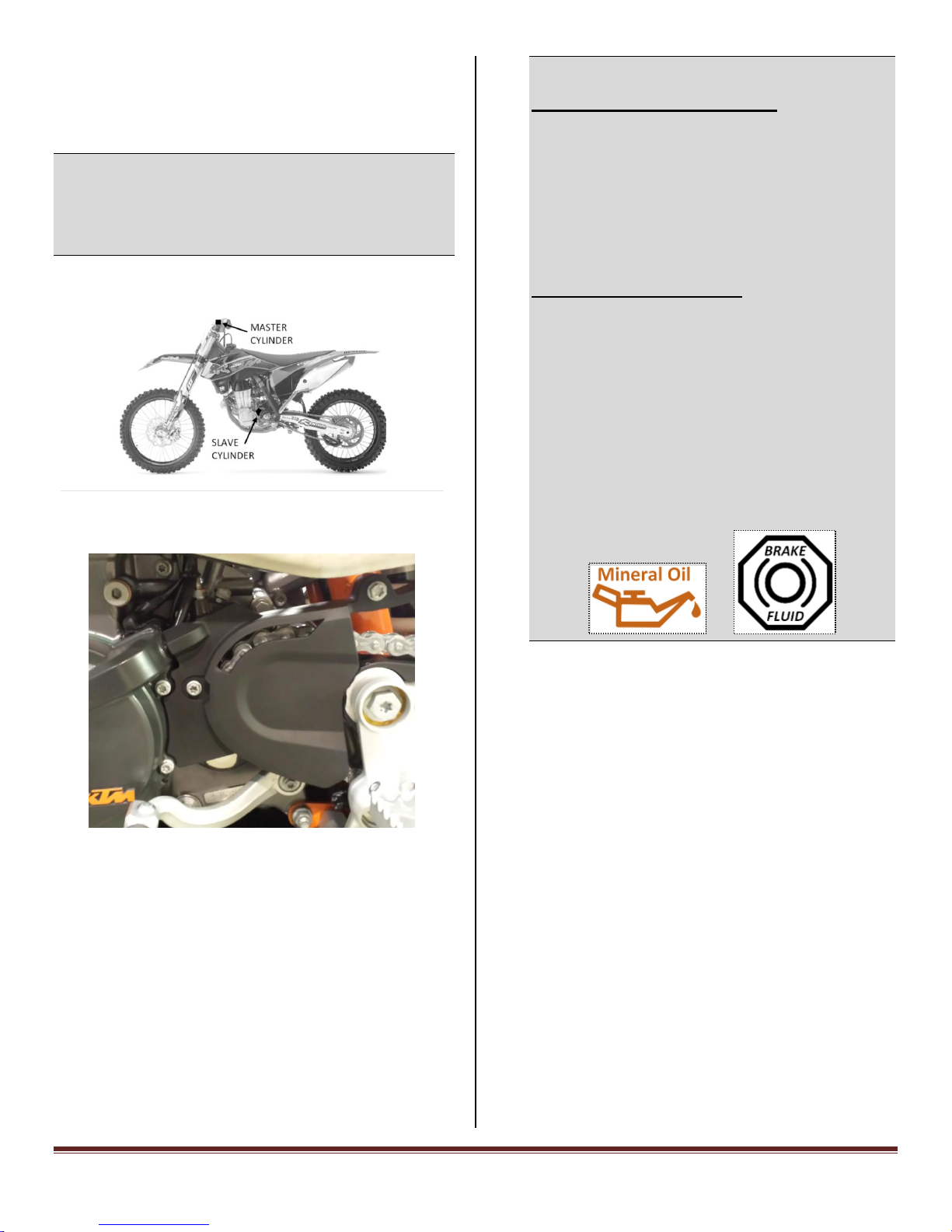

7. Reinstall the clutch cover and oil filter cover,

torqueing the bolts to the OEM spec:

Clutch Cover Bolts: 7.4 ft-lb (10 N-m)

Oil Filter Cover Bolts: 4.4 ft-lb (6 N-m)

8. Reinstall the foot peg assembly and swingarm

bolt, applying thread-locking compound to the

swingarm bolt and torqueing to 59ft-lb (80N-m).