BERKEM GALVALINK 302B User manual

USER MANUAL

OPERATING INSTRUCTION

GALVALINK®302B

2 liters modular plating plants

TRANSLATION OF THE ORIGINAL INSRUCTIONS

Manuale Uso GALVALINK_302B_v3_14

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

2

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

3

CONTENT

1. Warnings.............................................................................................................................................5

2. General Data.......................................................................................................................................5

2.1 Manufacturer's date .......................................................................................................................5

2.2 Machine data ..................................................................................................................................5

2.3 Technical Data Sheet.......................................................................................................................6

2.4 Equipment characteristics...............................................................................................................6

2.5 Machine architecture......................................................................................................................7

2.6 Standard equipment .......................................................................................................................9

3. Work and command stations ...........................................................................................................10

3.1 General information......................................................................................................................10

3.2 Work/command station set up.....................................................................................................10

4. Safety devices and caution for operator and maintenance staff safety ..........................................10

5. Declaration of conformity.................................................................................................................10

6. Use, maintenance and repair; check correct functioning ................................................................11

6.1 Intended use of the machine........................................................................................................11

6.2 Correct use of the machine (GALVALINK 302B)............................................................................11

6.3 Unplanned use of the machine.....................................................................................................12

6.4 Improper use of the machine. ......................................................................................................12

7. Machine movement and transport ..................................................................................................12

8. Installation ........................................................................................................................................12

8.1 General information......................................................................................................................12

8.2 Mechanical installation .................................................................................................................13

8.3 Electrical connection.....................................................................................................................13

9. Assembling and dismantling the machine........................................................................................13

9.1 Initial assembly..............................................................................................................................13

10. Preparing the machine to work........................................................................................................13

10.1 General information......................................................................................................................13

10.2 Checking any damage on the machine .........................................................................................13

10.3 Removal of the blocks...................................................................................................................13

10.4 Cleaning the machine....................................................................................................................13

10.5 Connecting the machine to the electrical mains ..........................................................................14

10.6 Machine adjustment .....................................................................................................................14

11. Operating and using the machine ....................................................................................................14

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

4

11.1 Operation ......................................................................................................................................14

11.2 Using the machine ........................................................................................................................14

12. Maintenance and repair ...................................................................................................................14

12.1 Maintenance .................................................................................................................................14

12.2 Repairs...........................................................................................................................................15

13. SPARE PARTS.....................................................................................................................................15

14. Safety symbols ..................................................................................................................................16

15. Safety risks ........................................................................................................................................17

16. Information on aerial noise on the machine....................................................................................19

17. Information on any emission of non-ionising radiation...................................................................19

18. Documentation attached..................................................................................................................20

ANNEX 1 – CONFORMITY DECLARATION.....................................................................................................21

ANNEX 2 - WARRANTY.................................................................................................................................22

Warranty ..................................................................................................................................................22

Competent court of jurisdiction...............................................................................................................22

ANNEX 3 – Measurements drawing ............................................................................................................23

ANNEX 4 – Installation layout......................................................................................................................24

ANNEX 5 – Electrical circuit diagram ...........................................................................................................25

ANNEX 6 – Programming manual (SOFTWARE ver. M20001.4)..................................................................26

1. Accessing the menu ..........................................................................................................................26

2. VOLT/AMPERE ..................................................................................................................................26

3. TIMER/COUNTER ..............................................................................................................................27

4. MODE................................................................................................................................................28

5. TEMPERATURE/MIXER......................................................................................................................29

6. MODE PRG T .....................................................................................................................................29

7. FREE MODE.......................................................................................................................................30

8. TIME MODE.......................................................................................................................................30

9. CLICK MODE......................................................................................................................................31

10. Quick settings................................................................................................................................31

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

5

1. WARNINGS

ATTENTION: You must read this manual carefully b

efore carrying out any installation,

operation, adjustment and maintenance on the machine.

ATTENTION: The equipment is not intended for installation in a potentially explosive

atmosphere and, therefore, does not meet the requirements

of Directive

94/9/EC “Equipment and protection systems intended for use in potentially

explosive atmospheres”.

ATTENTION: All and only the operations described in this manual are correct: the

manufacturer cannot be held in any way liable for any operations carried out

which do not comply with the specifications and operations not planned in

this manual.

ATTENTION: In the event of a fault or malfunction of the machine, you need to contact a

qualified technical support centre or the manufacturer.

ATTENTION

: The manufacturer cannot be held in any way liable for any accidents or harm

to people or damage to property due to non-

compliance with the

specifications on safety or determined by improper use or tampering with

the machine. The safety standards described in this manual integrate and do

not replace local standards in force,

which must however be complied with

by the user.

2. GENERAL DATA

2.1 Manufacturer's date

Company:

BERKEM S.r.l.

Address:

Via Galileo Galilei, 1/A

Locality

35030 Caselle di Selvazzano Dentro (PD)

Country:

Italy

2.2 Machine data

Type:

GALVALINK 302B PLATING BASE UNIT

Serial number of

machine and

year of

manufacture

See the label applied on the last page of this manual

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

6

2.3 Technical Data Sheet

GALVALINK 302B external dimensions

mm

300x340x300 (width depth height)

Weight

Kg

11 Kg ( 302B )

Voltage

V

220 Vca mono phase 50-60 HZ

Absorbed current (phase)

A

5

Adjustment of plating voltage and

current supplied

V

0-12 V – 10 A

Timer

h/m/s

Maximum 9 hours

Heating elements power

Kw

0.35

Maximum capacity of tanks in Pyrex.

ml

2 litres each tank

2.4 Equipment characteristics

Berkem plating machines are built to plate gold jewellery, costume jewellery, watch-making and

precision mechanics. The objects to plate are processed in the machines, firstly to be degreased and

then to carry out other plating applications.

→Degreasing treatments are generally performed by placing objects in the tank on the left of the

machine, where a degreasing/stripper solution is poured in. The solution is activated by passing

current.

→Instead, the galvanic treatments can be carried out in the tank on the right, by placing the

objects inside electrolytic solutions and activating the appropriate working voltages.

Technical characteristics

Easy to use digital interface

Multi-parameter working settings (voltage, current, time, ampere/minutes)

5 independent working programs

5 independents ampere-minute counters ( consumption calculation )

Variable speed magnetic stirrer

Safety self stop thermal probe

Reduced weight and dimensions

Assembly components in stainless steel

100% made in Italy

Complies with EU directives

ATTENTION: The machines, by operating, develop vapours due to electrolytic plating,

therefore they must be placed in a working place equipped

with an

adequate suction hood.

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

7

2.5 Machine architecture

Fig. 1 Fig. 2

Fig.3 Fig. 4

Fig. 5 Fig. 6

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

8

GALVALINK 302B is composed of:

A. A main casing that contains all the machine parts (Fig.1). The machine casing is equipped

with a cover (Fig.3-1) to protect the glass Pyrex Tanks, where the plating phases are

operated, and a temperature probe.

B. Two glass Pyrex Tanks, with a 2 litre capacity (Fig.2-1)

C. An anode electrode for degreasing, in stainless steel (Fig.2-2)

D. An anode electrode in platinised titanium (Fig.2-3)

E. A black cathode cable with crocodile clip (Fig.2-5 and 2-6)

F. A mains power cable

A1) Machine casing

The machine casing is made of painted metal and contains all the parts of the machine: the walls are

closed and you need tools to enter. The access area of the two Tanks is closed using a sturdy cover,

hinged to the casing. The machine must be placed on a flat, horizontal surface and is stabilised by four 1

cm feet. The machine casing has no sharp parts or protruding corners dangerous for the operator.

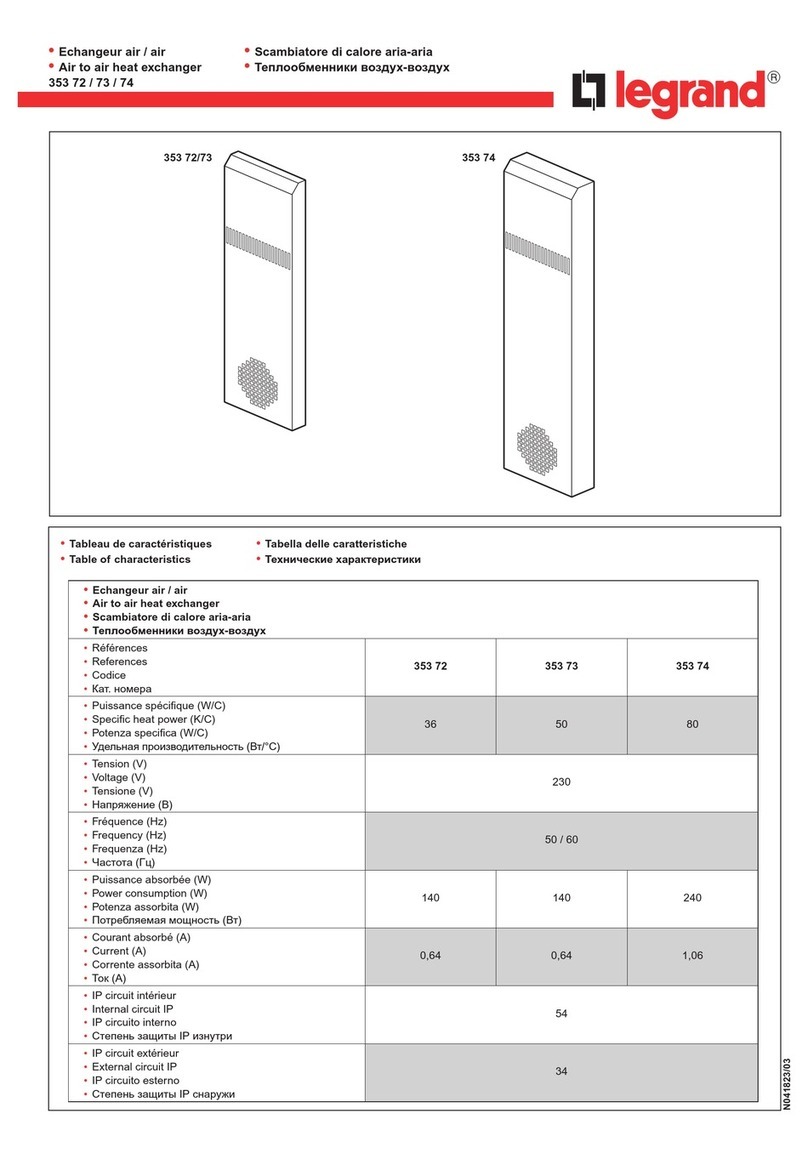

The compartments for the glass Pyrex Tanks are sub-divided into (Fig. 6):

•TANK 1 (left): generally used for degreasing, it does not have a thermostat and comes with an

anode output for the electrode in stainless steel (Fig.2-2)

•TANK 2 (right): Tank for plating use, with a digital thermostat, a magnetic stirrer in the solution

and an electrode in platinised titanium (Fig.2-3)

•The machine is equipped with a current and voltage rectifier, variable from 0 to 12 Volts, 0 – 10

Ampere

The left side of the machine casing has a connection socket to the power supply on the machine - with

an incorporated fuse box for a 5A 220 Vca fuse (Fig.3-2) - and the POWER start-up Key (Fig.3).

Behind the Tanks (Fig.4) there are the contacts to which the cathode cables are connected:

•RED positive anode contacts (Fig.4-1): clamps to connect the anodes

•BLACK negative cathode contact (Fig.4-2): clamp to connect the objects to treat.

ATTENTION: The machines, by operating, develop vapours due to electrolytic

plating, therefore they should be placed in a working place equipped

with an adequate suction hood.

A2) Command and adjustment panel

The command and adjustment panel is on the front of the machine casing (Fig.1 and 5 ).

Description of the command and adjustment functions:

REFERENCE

DESCRIPTION

FUNCTION

KEY 1

KEY 2

Menu

navigation cursors. They are

used to move in the menus and to

change the parameters and settings

KEY 3 START/ STOP/ BACK

Activates the selected program

(START), stops a program in progress

(STOP) or allows you to go back

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

9

through the menus (BACK)

KEY 4 MENU/ENTER

Allows you to enter the various

programming menus (MENU) and to

confirm the changes, entries (ENTER)

KEY 5 ON/OFF temperature

Activated (ON) or deactivated (OFF)

of the heating resistor.

KEY 6 ON/OFF stirrer

Activated (ON) or deactivated (OFF)

of the stirrer

LED

Lighting led that indicates current

supply during work

For machine programming, see the Attached Programming Manual.

A3) Left hand panel (Fig.3 )

The left hand panel contains:

•power cable input, with fuse box, and main POWER Key (Fig.3-22)

•galvalink input/output positive pole red (Fig.3-3)

•galvalink input/output negative pole black (Fig.3-4)

REFERENCE

DESCRIPTION

FUNCTION

Fig.3-1

Cover

Fig.3-2 Power cable input,

with fuse

box, and main POWER Key

Connection point of the power cable and

the main power switch, to switch on (I) or

switch off () the equipment.

Fig.3-3

Galvalink input/output positive

pole red

To use to connect to the corresponding red

clamp on the GALVALINK unit 302S

Fig.3-4

Galvalink input/output negative

pole black

To use to connect to the corresponding

black clamp on the GALVALINK unit 302S

2.6 Standard equipment

On purchase, the GALVALINK 302B is provided complete with:

2 Pyrex glasses, 2 litres (Fig.2-1)

1 stainless steel anode for degreasing (Fig.2-2)

1 anode in platinised titanium (Fig.2-3)

1 magnetic fastener for the stirrer (Fig.2-4)

1 black cathode cable (Fig.2-5)

1 stainless steel support (Fig.2-6)

1 power cable

1 User Manual

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

10

Pyrex glass tanks. The machine includes a compartment (inside the machine casing) for 2 Pyrex glass

Tanks measuring 135 mm in diameter, with a 2 litre capacity and a graduated scale

from 500 to 1500 ml.

The Tanks are normally used for the following operations:

•degreasing (Fig. 6 TANK 1)

•galvanic treatment (Fig.6 TANK 2)

Anode electrodes. The machine is equipped with a set of anode electrodes in Titanium/platinised

(Fig.2-3) and stainless steel (Fig.2-2).

Power cable The machine is equipped with the power cable with the plugs for connection to

the socket on the side of the machine casing and for connection to the voltage

socket which must be present in the installation place.

3. WORK AND COMMAND STATIONS

3.1 General information

The machine is used for an individual workstation. All the commands to start and adjust the machine are

placed on the front, in the command position for the operator.

3.2 Work/command station set up

The machine must be placed on a flat horizontal surface to avoid any risk of overturning; on request, a

metal support can be supplied, suitable to support the machine. Installation must be carried out in a dry,

well-aired and correctly illuminated environment. Furthermore, the machine should have a nearby

water line suitable for cleaning the Tanks.

ATTENTION: The machines, by operating, develop vapours due to electrolytic plating,

therefore they should be placed in a working place equipped with an

adequate suction hood.

ATTENTION: An appropriate disposal system for the galvanic solutions must be used to

drain the solutions used during the operations

, in compliance with the

instructions and with the SDS Safety Date Sheets supplied with the liquids.

4. SAFETY DEVICES AND CAUTION FOR OPERATOR AND MAINTENANCE STAFF SAFETY

In the work area the machine does not produce a weighted average acoustic noise over 80 dB.

The machine does not have rotating parts which can come in contact with the operator.

The liquids used for galvanic baths, for plating operations, can be harmful, toxic, corrosive and

dangerous for the environment.

The operator must carefully read the instructions supplied with the plating products used and wear

appropriate IPD (apron, gloves, goggles).

The machine, during operating, produces vapours that can be toxic, therefore the workstation must be

equipped with an adequate suction hood. It is good practice that the operator avoids smoking, eating or

drinking near the machine.

5. DECLARATION OF CONFORMITY

The declaration of conformity of the equipment is attached to this manual.

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

11

6. USE, MAINTENANCE AND REPAIR; CHECK CORRECT FUNCTIONING

6.1 Intended use of the machine.

The machine was built exclusively for professional use, to plate objects in gold, custom jewellery, watch-

maker and precision mechanics.

ATTENTION:

The machines, by operating, develop vapours due to electrolytic plating,

therefore they should be placed in a working place equipped with an

adequate suction hood.

ATTENTION:

The machine cannot be used in environments where explosive

atmospheres can form.

ATTENTION:

Dispose of used galvanic liquids following the instructions in the reference

SDS Safety Data Sheet of the solutions used.

ATTENTION: Use only galvanic solutions provided by the manufacturer.

ATTENTION: During use, the cover

of the machine must stay open to enable the

operator to correctly position the material.

ATTENTION:

Connect the machine to an electric system compliant with standards in

force.

ATTENTION: The operator must wear protective clothing, goggles and gloves and

anything specific in the SDS Safety Data Sheet for the parts used for

galvanic baths.

ATTENTION:

To clean the surfaces dirtied by galvanic liquids, the operator must use

suitable IPD (gloves, apron, goggles, mask to protect the airways).

ATTENTION: It is forbidden to tamper with the machine.

ATTENTION: It is forbidden to smoke in the area where the machine is working.

ATTENTION: Do not insert objects and/or liquids in excess in the Tanks, as they could

cause corrosive and toxic liquid to leak. If this should occur, carefully follow

the instructions outlined in the SDS Safety Data Sheets supplied with the

products used. Carefully and immediately clean the relevant surfaces.

6.2 Correct use of the machine (GALVALINK 302B)

The machine is used by moving the commands and in an emergency situation you can stop the machine

at any time using the main switch (Fig.3-2) in position .

a) Prepare the electrolytic solutions and fill the tanks on the machine.

The machine contains 2 Pyrex glass tanks as highlighted in Fig.6.

The Tank on the right (Fig.6 TANK 2) is equipped with a thermostatic heater and with an adjustable

stirrer. This Tank is indicated as the galvanic bath (Rhodium, Gold, Silver, Palladium... etc.)

The Tank on the left, instead, (Fig.6 TANK 1) is indicated for degreasing operations.

NOTE The Berkem galvanic systems have anode contacts in both tanks. Therefore, the use sequence of the

galvanic tanks can be modified by the operator, according to the specific needs.

The solutions used (for galvanic baths, degreasing and neutralising baths) must be purchased ready to

use, in order to ensure safe and valid processing. Alternatively, they can be prepared by the operator: in

this case the operator must follow the instructions in the TDS Technical Data Sheets and in the SDS

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

12

Safety Data Sheets referred to the products used. The solution must be mixed before putting them in

the respective Tanks.

Place a sufficient amount of solution in the tanks, until the electrodes are covered. The solutions must

be placed in the tank on preparing the machine or when they are under the coverage level of the

electrodes or, lastly, when they are used up and must be replaced.

Before starting the working processes, check that the temperature probe is correctly immersed in the

solutions (Fig.6).

OPERATIONAL PASSAGES TO OBTAIN A PERFECT END RESULT

1. degreasing in ultrasounds

2. rinsing in running water

3. electrolytic degreasing (Fig.6 - TANK 1)

4. rinsing in running water

5. rinsing in purified water

6. neutralisation/activation

7. rinsing in running water

8. rinsing in purified water

9. galvanic treatment (see Fig.6 TANK 2)

10. rinsing in running water

11. rinsing in purified water

12. drying

6.3 Unplanned use of the machine.

There is no reasonably conceivable use of the machine other than for galvanic treatments.

6.4 Improper use of the machine.

Improper use is any use other than that specified in point 6.2 above.

7. MACHINE MOVEMENT AND TRANSPORT

The machine dimensions and weight enable simple movements, using appropriate mechanical aids.

Transport the machine by placing it in its original packaging or in other suitable packaging, with

parts inside in expanded polystyrene, taking care to transport the upper part of the machine

positioned upwards.

To transport the machine, move it using a suitable trolley to transport objects.

Load only the machine on the trolley in its packaging without placing any other objects on it,

since this could damage the machine or fall. Do not load the machine over other objects because

it could cause unstable transport.

Before transport, check that all the parts of the machine are well fastened and cannot move

during transport.

8. INSTALLATION

8.1 General information

The machine works in safe conditions and with the best results if it is correctly installed in the working

place.

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

13

8.2 Mechanical installation

The machine can be rested on a perfectly flat and horizontal surface, that is dry and clean. The machine

can have the rear resting against a wall; we recommend that you leave at least 1 m around the machine

to conveniently carry out all cleaning operations without having to move the machine. Furthermore, you

are advised to have an open space on the front of the machine as wide as possible, to facilitate the

operator's work.

The installation layout of the machine is outlined in the Attachment.

8.3 Electrical connection

The machine, to be powered, must be connected to an electrical system installed according to the safety

standards in force and meeting non-flammability requirements. Before carrying out any connection, you

need:

to make sure that the data relating to the power line correspond both to those indicated on the

identification plate on the machine and the electric box and to those outlined in the Technical

Data in this manual;

to make sure that the power cables have a minimum section of 2.5 mm2.

Ensure that, upstream of the electrical circuit socket, an automatic circuit breaker switch is connected

and that the circuit has a grounding connection correctly connected to the power socket, which must be

suitable for connection with the plug on the machine cable. Ensure the machine is not powered.

To power the machine, insert the plug of the power cable on the system socket.

In the event of a fault or malfunctioning, contact qualified staff.

9. ASSEMBLING AND DISMANTLING THE MACHINE

9.1 Initial assembly

The machine is supplied ready to work.

The only operation to carry out is to prepare and fill the tanks with the electrolytic liquids as outlined in

point 6.2.

10.PREPARING THE MACHINE TO WORK

10.1 General information

The machine is supplied ready to work.

10.2 Checking any damage on the machine

When you remove the packaging from the machine, carefully check each part and ensure that there was

no damage during transport. If damage is found, firstly contact the carrier company, then the retailer or

the manufacturer. Also ensure you have received the machine with all its parts.

10.3 Removal of the blocks

The machine is delivered without blocked parts, therefore no block removal is required.

10.4 Cleaning the machine

Clean the machine carefully before operating it, removing the dust and any foreign or dirty substances.

To clean the machine, the operator must wear gloves, goggles and an apron. The machine should be

cleaned using a soft cloth and, if necessary, brushes and tools in hard plastic, to avoid scratching the

tanks and any other parts.

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

14

10.5 Connecting the machine to the electrical mains

Ensure that the data relating to the power line correspond both to those indicated on the identification

plate on the machine and the electric box and to those outlined in the Technical Data in this manual.

Before connecting, ensure that the electrical parts to work on are not powered. Insert the plug of the

power cable in the socket on the side of the machine and in the socket provided in the workplace.

10.6 Machine adjustment

The machine does not require any preliminary adjustment for operation.

11.OPERATING AND USING THE MACHINE

11.1 Operation

To operate the machine, correctly installed and prepared for use, you need to heed the following

warnings:

Position the differential switch upstream of the machine in the closed position “”.

The operator must wear individual protection devices planned for the work carried out. Then

you must stand in such a way to have perfect and comfortable visibility of all the signs and

commands.

11.2 Using the machine

To correctly use the machine, refer to paragraph 6.2.

12.MAINTENANCE AND REPAIR

12.1 Maintenance

The machine does not require any particular maintenance operations, except for cleaning the tanks and

the machine. The machine works well only if the Tanks and its parts are clean.

Cleaning the tanks.

Switch off the machine by placing the main sectioning switch in position “”, then section the

machine by separating the plug from the power socket.

Ensure the machine and the tanks are cold and wait for them to cool down.

Wear IDP, remove the tanks from the machine casing, empty and correctly dispose of the

galvanic solutions, then rinse with plenty of running water. For more stubborn residue, clean

with soft sponges and, if necessary, with plastic tools that won't scratch the tanks.

Correctly place the tanks in their compartment inside the machine casing.

ATTENTION: Dispose of used galvanic liquids following the instructions in the reference SDS Safety

Data Sheet of the solutions used.

Electrical connection maintenance.

The electrical power cable must be periodically checked and it must be replaced if not in good working

condition.

Replacing the fuse:

The machine is protected with a 5 A 220Vca fuse. The fuse is hosted in a drawer in the mains socket in

the side of the machine casing.

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

15

To replace the fuse, you need:

To switch off the machine (main POWER switch on “”);

Section the machine from the mains socket by disconnecting the power cable both from the

mains socket and from the socket on the side of the machine.

Open the door, remove the faulty fuse, insert a new fuse and close the door.

Connect the power cable to the machine and the mains socket.

Power the machine bringing the POWER switch to position “I” and check that the green light

switches on.

If the machine does not work, contact the retailer or manufacturer.

12.2 Repairs

The operator must not carry out any repairs: in case of a fault, you must contact qualified staff, your

retailer or the manufacturer.

13. SPARE PARTS

The complete updated list of spare parts is available in the Products area, link to:

http://www.berkem.it/catalogo.aspx

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

16

14. SAFETY SYMBOLS

Fig.7

SYMBOL

DESCRIPTION

SYMBOL

DESCRIPTION

ATTENTION DANGER

ONLY USE UNDER FUME

SUCTION HOOD

READ THE USER MANUAL

CAREFULLY BEFORE

STARTING TO WORK

SAFETY GOGGLES MUST BE

WORN

SAFETY GLOVES MUST BE

WORN

DANGER HOT SURFACES

WEAR THE SAFETY MASK TO

PROTECT THE AIRWAYS

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

17

SYMBOL

DESCRIPTION

SYMBOL

DESCRIPTION

DANGER CORROSIVE

SUBSTANCES

SAFETY APRON MUST BE

WORN

DANGER VOLTAGE

SMOKING FORBIDDEN

15.SAFETY RISKS

The only safety device on the machine is the main switch which can be used as an emergency stop. Its

intervention creates a category 0 emergency: power is instantaneously cut to all the devices on the

machine.

The machine has no mobile parts accessible to the operator requiring use of the interlocking fixed or

mobile guards. The only motor on the machine is the magnetic stirrer which is inside the machine

casing: the motor cannot even be reached by the planned openings to insert the tanks in Pyrex glass.

The stirrer does not have any blades or rotors, but just a magnetic fastener which rotates via two

permanent magnets, moved by the motor.

The machine has danger zones due to the presence of high temperature units, due to the presence of

dangerous substances or fumes and due to the presence of 220Vac powered parts.

The potentially dangerous zones detected on the machine are as follows:

ZONE A = Degreasing tank- Plating tank.

ZONE B = Main switch.

ZONE C = Electric box.

ZONE D = Heater plate.

These potentially dangerous zones were signalled to the operator using adhesive warning, obligation

and instruction plates.

The machine, in the indicated zones, presents residual risks due to reasonably predictable improper

behaviour by the operator: even if adequately signalled on the instructions manual and using

pictograms, the dangers can be ignored by the operator.

The danger zones of the machine are highlighted as follows:

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

18

Fig.8

ZONE A

The degreasing zone and the plating zone are dangerous because they have corrosive substances for

hands, which during the plating process release toxic vapours in the air.

→It is compulsory to use the fume suction hood with the machine on.

→Smoking is forbidden.

→It is compulsory to use the individual protection devices listed below: goggles, gloves,

apron, safety mask to protect the airways.

A residual risk persists, despite all the affixed signs, as the operator may decide not to

comply with them.

ZONE B

The equipment is powered with 220Vac voltage and therefore the danger of electrocution persists if the

powered parts are touched or damaged.

ZONE C

The electric box can present dangers in the event of a short circuit or overloading of the electric devices.

→The cables section and their colouring meet the requirements of standard EN 60204-

1:2006.

→The heater plate is directly connected to the equipotent circuit to avoid dispersion

currents in case of loss of insulation on the heating element.

→The heating element underwent dielectric strength testing at 1250Volt.

→The power socket incorporates the protection fuses on the 220Vac line.

→The power transformer underwent dielectric strength testing at 3750Volt: it is

dimensioned to resist a short circuit on the secondary, staying within the temperature for

insulation class F.

ZONE D

ZONE A

ZONE B

ZONE C

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

19

→The magnetic mixer motor has an insulation class F.

The presence of an electric control board or an electric motor can generate electromagnetic disturbance

for adjacent equipment or disturbance can be felt from the mains.

→The casing of the machine containing the electrical and electronic equipment is

manufactured in sheet metal: the casing connected to the equipotent circuit protects the

equipment and limits any radiated emissions.

→The power socket incorporates a single mains filter.

ZONE C-D

The powered parts can be dangerous if they come in contact with degreasing and plating liquids.

→The electric part controlling the machine is separated from the tank zone using sheet

metal.

→All the electro-mechanical parts assembled on the machine have an IP2X degree of

protection against direct contacts.

→All the electro-mechanical parts are installed on a metal base plate connected to the

equipotent circuit.

→The cables powering the heater resister at 220Vac are protected by a sheath.

→The pre-insulated terminals powering the mixer motor are protected by a sheath.

ZONE D

In the event of breakage of the control circuit, the heating plate can reach dangerous temperatures for

the operator and for the machine.

→In the event of malfunctioning or breakage of the PTC thermal probe, a bi-metal thermal

pellet calibrated to 180°C intervenes, assembled directly on the heater plate. The pellet

directly shuts off power to the heating element.

The heater plate can reach dangerous temperatures for the operator (170°C) and can maintain, due to

thermal inertia, this temperature for many minutes even after the machine is switched off.

→The structure of the machine in painted metal protects the operator from accidental

contact with the heater plate.

→It is compulsory to use safety gloves.

A residual risk persists, despite all the affixed signs, as the operator may decide not to

comply with them.

16.INFORMATION ON AERIAL NOISE ON THE MACHINE

The type of motor, use of a mixer with magnetic fastener, and the mechanical structure that

incorporates all the mobile elements of the machine ensure that during operation it is generated a

weighted average aerial noise level less than 70 dB.

17.INFORMATION ON ANY EMISSION OF NON-IONISING RADIATION

The machine does not emit non-ionising radiation.

01/12/14

Manuale Uso GALVALINK_302B_v3_14 EN Completo

20

18.DOCUMENTATION ATTACHED

This publication has the following listed documents attached, forming an integral part of it:

Annex 1

Conformity Declaration

Annex 2

Warranty

Annex 3

Measurements drawing

Annex 4

Installation layout

Annex 5

Electrical circuit diagram

Annex 6

Programming manual

Table of contents

Popular Industrial Equipment manuals by other brands

HEIDENHAIN

HEIDENHAIN TTR ECI 4090S operating instructions

schmersal

schmersal AZM201Z-I2-ST2-T-1P2PW-DU Instructions for operation

ABB

ABB HT609934 Operation manual

Milwaukee

Milwaukee MSL2000 Original instructions

GREER Company

GREER Company MicroGuard RCI 514 Operator's manual

Moteurs Baudouin

Moteurs Baudouin WEIFU ECU56 Use & maintenance manual