BERLON Lowe XR Series User manual

HYDRAULIC TRENCHING

ATTACHMENTS

FOR SKID LOADERS

XR-SERIES

OPERATOR’S MANUAL

Do Not Use or Operate This Equipment Until the Manual

and Assembly Instructions Have Been Read and Understood!!

Part #RAL 3122

1

18903 High Point Road

Viola, WI 54664

USA

Table of Contents

I

II

III

IV

V

VI

VII

VIII

IX

Warranty and Reservations

Safety Information

Machine Setup

Mounting Instructions for Skid Loaders

Operation

Troubleshooting

Trencher Replacement Parts

Maintenance

Specifications

http://www.loweman.com

For more information, call:

North America, Toll Free 1-800-356-9180 • FAX 608-538-3995

1-888-DIG-LOWE (344-5693)

1-608-538-4000

© Lowe Attachments, LLC

2

I

WARRANTY

Lowe Attachments, LLC (LOWE®) is proud of its reputation for producing products with high standards of quality and

workmanship. When LOWE® products are used and maintained in the prescribed manner, you can be assured they will

provide reliable service.

Period of Warranty: Any new LOWE® product purchased and registered with LOWE® will be warranted against defects in

materials and workmanship for a period of one year from the date of purchase, subject to the exclusions noted herein.

Replacement parts used in warranty repairs will be warranted for the balance of the applicable warranty period.

Warranty Registration: To be eligible for warranty coverage, LOWE® product(s) must first be registered with LOWE®. A

warranty registration form is provided in the Operator’s Manual. This form must be completed, signed, and mailed to

LOWE® by either the authorized selling dealer or the purchaser.

Customer’s Responsibility: Under the terms of this warranty, the customer will be responsible for ensuring the product is

properly operated and maintained as specified in the Operator’s Manual. The owner of the product shall give notice to an

authorized dealer of any and all apparent defects within ten (10) days of discovery and make the product available for

inspection and repairs at the dealer’s place of business.

The customer’s responsibilities include all costs of normal maintenance, replacement wear parts, non-warranty repairs,

accidents, collision damage, and other repairs resulting from abnormal strain, neglect, or abuse. Specific examples

include, but are not limited to, bending or prying with the product, failure to monitor wear, use of contaminated hydraulic

fluid, excessive oil flow or pressure, and operation with a broken or damaged part which causes another part to fail. The

customer is also responsible for incidental costs such as transportation due to a failure. If you have any specific questions

on operation or maintenance, please contact your dealer for advice.

General Exclusions From Warranty: This warranty is not transferable and applies only to the original owner of the

equipment. It does not apply to products sold or used previously, rental fleets, products subject to misuse, service other

than normal, damage in transit or handling, normal wear, or products which in the opinion of LOWE® have had

unauthorized alterations or repair.

LOWE® will replace any warrantable parts with original LOWE® parts. LOWE® will not pay for unauthorized parts, nor will it

pay for the freight, labor, travel time, or mileage connected with the replacement of warranty parts. LOWE® will also not

pay third party repair or replacement charges.

All defective parts against which warranty claims are made must be returned to LOWE®, freight prepaid, in accordance

with the LOWE® Official Return Policy current at the time of the warranty claim. The hydraulic motor(s) used in LOWE®

products are warranted by the motor manufacturer and, in case of possible warranty failure, must be returned to LOWE®

or the nearest authorized hydraulic motor distributor for service. Any attempt by you, your dealer, or another company to

repair the motor will result in denial of warranty credit.

This warranty is in lieu of all other warranties, expressed or implied. Any claims for incidental or consequential

damages are hereby disclaimed by LOWE® and excluded from this warranty. LOWE® neither assumes nor authorizes any

person or company to assume for it any other obligations or liabilities in connection with its products.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Model Number____________________________ Serial Number______________________ Date Purchased ___________

Owner’s Name _________________________________________________________________________________________

Owner’s Address _______________________________________________________________________________________

Dealer’s Name __________________________________________________________________________________________

Dealer’s Address _______________________________________________________________________________________

City____________________________________________________________ State_____________ Zip __________________

Dealer’s Phone Number _________________________________________________________________________________

3

II

SAFETY INFORMATION

The Safety Alert Symbol is used on messages wherever your safety is involved.

When you see it, pay attention!

Safety Alert Symbol

To emphasize special information, the words listed below carry specific meanings and

should be carefully reviewed.

Danger ......... Denotes the most serious specific potential hazard(s).

Warning ....... The personal safety of the operating personnel or other persons may

be involved. Disregarding this information could result in injury or

death.

Caution ........ General reminders of good safety practices or to direct attention to

unsafe practices.

Note ............. This is special information which may make operation or maintenance

easier, or make instructions more clear.

4

Location of Safety Notices:

MODELS XR-7, XR-14, XR-21, XR-25, & XRH-35

Ref. Part

No. No. Description

1 SD-2 No Step Decal

2 SD-4 Before Leaving Loader

3 SD-6a Danger Decal (2)

4 SD-8 Flying Debris

5 SD-12 Side Shift (Hydraulic only)

6 SD-7 Before Using Machine

7 SD-10 Excess Chain Tension

8 L-Large Lowe® Logo

9 SD-9 Cover Caution (2)

Replacement Safety Decals

Worn, damaged, or illegible labels should be replaced. New labels may be obtained from the manufacturer. Labels are

listed under specific part numbers and are included in the safety decal illustration.

Replacement Safety Shields

All worn, damaged, unusable, or missing safety shields should be replaced. New shields may be obtained from the

manufacturer. They are listed with a specific part number and are included in the exploded parts diagram.

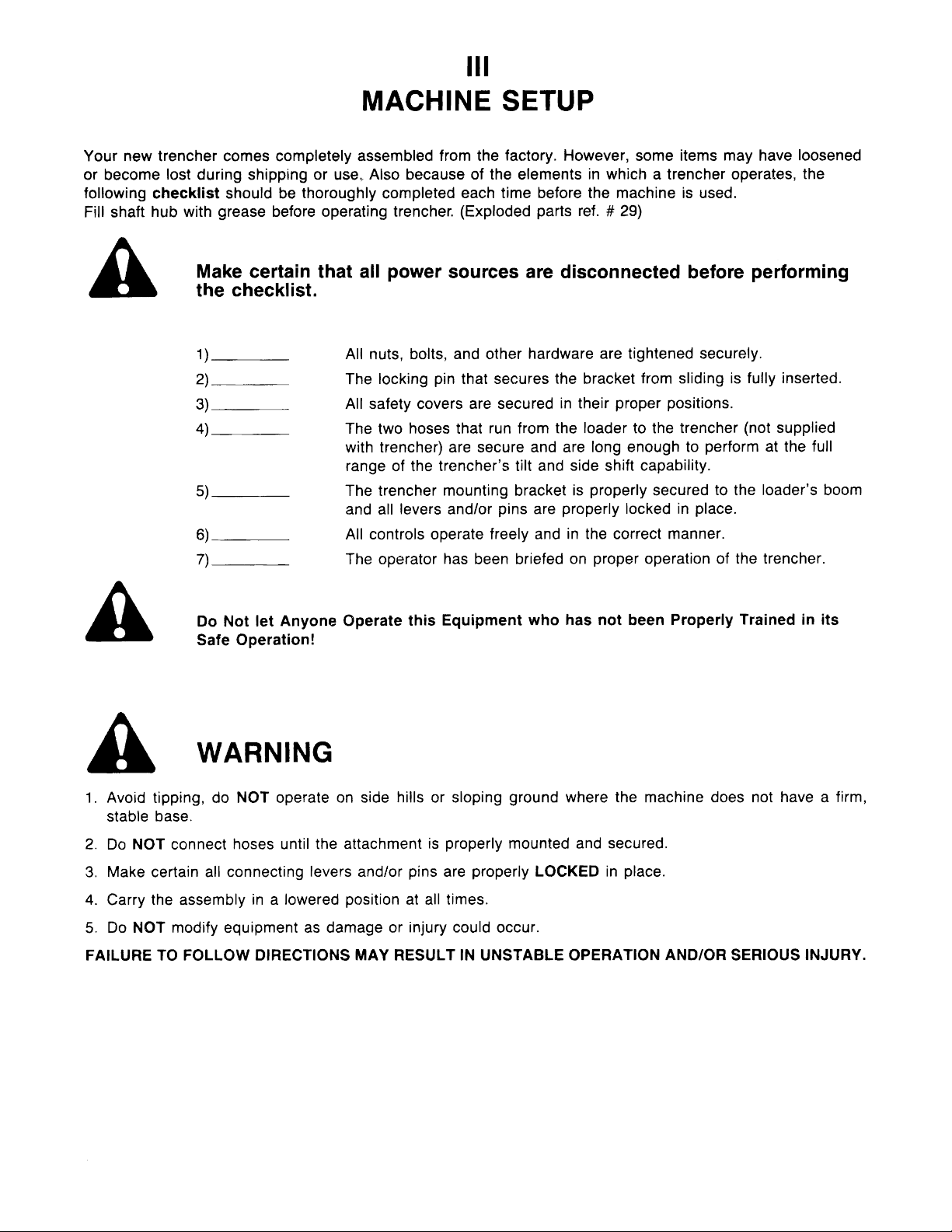

Obligations and Usage:

This product is intended to be used only under the guidelines of this manual and relevant literature published by Lowe

Manufacturing Company, Incorporated. It is the owner and/or operator’s obligation to ensure this product is operated only

for its intended uses. Operation contrary to guidelines set forth may cause premature breakage of the equipment and

create serious safety problems.

5

6

IV

MOUNTING INSTRUCTIONS FOR SKID

LOADERS

Single point hose attachment

for most loaders.

NOTE: All LOWE® skid-steer trenching attachments are equipped with 37 degree JIC adapters. Attachment hoses should

have 5⁄8 inch (-10) female fittings on the attachment end.

1) Insert loader boom plate into Trencher Mounting Bracket.

2) Secure all locking levers or pins in their proper location.

3) Connect two hydraulic hoses to the Trencher and the Loader’s Auxiliary Hydraulic system. Make sure that hoses

are routed through the hose guide provided. Before they are secured, check to ensure adequate length and

clearance through the trencher’s tilt and lift range.

4) You are now ready for operation.

WARNING:

Carry trencher low to the ground at all times. Failure to do so may result in unstable

operation or injury.

Removing the Trenching Attachment

1) Roll the loader’s tilt arms back and lower lift arms to lay attachment level.

2) Stop the engine, release hydraulic pressure in hoses and disconnect auxiliary hoses.

3) Release locking levers or pins.

4) Start the engine and disengage loader mounting plate from trencher mounting bracket.

7

V OPERATION

Max. Depth

TRENCH WIDTHS & DEPTHS

Max. Width

In./Cm. In./Cm.

MODEL XR-7 36/91 6/15

30/76 8/20

MODEL XR-14 48/122 6/15

36/91 8/20

30/76 10/25

24/61 12/30

MODEL XR-21 60/152 6/15

48/122 8/20

36/91 10/25

30/76 12/30

Max. Depth Max. Width

In./Cm. In./Cm.

MODEL XR-25 60/152 6/15

48/122 8/20

36/91 10/25

30/76 12/30

MODEL XRH-35 60/152 6/15

48/122 8/20

36/91 12/30

NOTE: Based on use in moderate soil conditions and on typical skid loaders that match the specific trenching

attachments, your performance may vary depending upon digging conditions and loader used.

Digging with the Trencher:

Operating a skid steer trencher attachment can be fairly complicated, but it can be made much easier if you follow a

few specific guidelines:

1) Making your initial cut should be done with the trencher boom lying flat against the ground. As the chain is

rotating, begin inserting the nose of the boom into the ground while slowly raising the trencher a few inches off

the ground. Point the nose down gradually.

Once the trencher boom is in the ground and your angle or trench is established, lower the trencher until the

skid shoe is just above ground level. Be certain the optional trench cleaner is operating freely.

You are now ready to trench.

2) During the trenching operation:

A) Use the center trench position whenever possible. You will find it much easier to control the machinery

and dig a straighter trench.

B) Trench at a 45 to 60 degree angle for best performance.

C) Gently creep the loader controls backward. Too much back movement will cause the trencher

to stall.

D) Do not use the “float” control on the loader as this increases drag on the system. You will trench faster

by controlling the depth with periodic adjustments of the boom arms of the loader.

Digging Chain Setup:

In setting up your digging chain for use with width spacers, we recommend using a “V” configuration as a start. One

tooth in the center of the chain acts as the point of the “V” with appropriate spacers and teeth taking a progressively

wider cut in the trench.

After one “V” has cut, another begins the process all over. (See illustration below.)

8

VI

TROUBLESHOOTING

Shut off power and disconnect power source before performing service checks.

WARNING: Diesel fuel or hydraulic fluid under pressure can penetrate the skin or damage

eyes. Fluid leaks under pressure may not be visible. Never use a bare hand to find leaks

and always wear safety goggles for eye protection. Such fluid, if injected into the skin,

must be removed within a few hours by a doctor familiar with this type of injury. Make

certain pressure is relieved and power source is disconnected before servicing.

Sympton Possible Cause Action

Jerky Cold oil or air in lines

Loader hydraulic pump or system

Give time to warm up.

See loader's manual.

Slow Restriction in lines, couplers,

or in loader's hydraulic system

Worn, damaged, or insufficient loader hydraulic pump

Loader oil filter

Check with pressure

and flow gauge.

See loader dealer.

Request flow and

pressure check.

Check for dirt and grime. See if

filter is installed correctly.

Insufficient

digging

capacity

Hydraulic pump in loader or motor in trencher

ExcessiveLoad

Relief valve

See your dealer.

Request pressure check.

Reduce digging load because load

exceeds capacity of system.

Check for proper

pressure operation

Wrong Direction Hoses not properly connected Reinstall properly.

Oil leaks Hydraulic motor seals are worn or damaged

Loose fittings on hoses or motor

Hoses are loose or damaged

See dealer for replacement of

seals.

Tighten or replace as required.

Tighten or replace as required.

Notes

9

Exploded Parts Diagram: MODEL XR-7

1) TR7-501AXR Motor Cover

2) MEL-12K

2a) TR-504X

3) TR60-15XR

4) TR7-506XR

5) TR7-501X

6) TR7-500X

7) TR-517

Hydraulic Motor

Motor Fitting (2 required)

Motor Sprocket (includes key) Drive

Chain (includes master link) Drive

Chain Cover

Trencher Housing

Grease Fitting

8) TR7-14512X Drive Sprocket (digging chain)

#HBK-7 - Hub Bearing Kit (# 9-14)

9) TR-518 Seal Protection Plate (Incl cap screw)

10) TR-507 3/4” Shaft Spacer (2 required)

11) 10-368A Bearing Cone (2 required)

12) 10-362A Bearing Cup (2 required)

13) 10-25028 Shaft Seal (2 Required)

15) TR60-18XR

16) W-10

17) N-10

18) CR7-200X

19) TR7-508X

20) TR7-518X

21) TR7-510AX

21a) TR7-510BX

21b) TR7-510CX

IK7 - Idler Kit (# 22-26)

22) TR7-514X

23) TR7-515X

24) TR-516X

Driven Sprocket

Lockwasher

Locknut (1)

Drive Shaft

Spoil Auger

Grease Cylinder Assembly

Boom for 24” Depth

Boom for 30” Depth

Boom for 36” Depth

Shaft/Lockwasher/Bolt

Spacers (2 required) Sealed

Bearing

25) TR7-16000X Idler Roller

TR-514FW

VII

TRENCHER REPLACEMENT PARTS

26)

27

27

27) NLP

Flat Washer

Nylon Locking Plug

10

Exploded Parts Diagram: MODEL XR-14, XR-21, & XR-25

1) TR-501AXR Motor Cover

2) MEL-12K

MEL-18K

MEL-21K

2a) TR-504X

3) TR80-13XR

Hydraulic Motor for XR-14 Trencher

Hydraulic Motor for XR-21 Trencher

Hydraulic Motor for XR-25 Trencher

Motor to hose fitting (2 required)

Motor Sprocket (includes keys)

4) TR21-506SH Drive Chain (includes master link)

5) TR-501X

6) TR-500XR

7) TR-517

8) TR-16016X

Drive Chain Cover

Trencher Housing

Grease Fitting

Drive Sprocket (digging chain)

HBK - Hub Bearing Kit (# 9-15)

9) TR-518 Seal Protection Plate(includes cap screws)

11) TR-507 3/4” Shaft Spacer

12) 10-368A Bearing Cone (2 required)

13) 10-362A Bearing Cup (2 required)

14) TR-507B 1/2” Shaft Spacer

15) 10-25028 Shaft Seal

16) TR80-26X

17) P2-12

18) TR-520C

19) CR200-X

20) TR-508X

21) TR-518X

22) TR-510AX

22a) TR-510BX

22b) TR-510CX

22c)

TR-510DX

TR-514X

TR-515X

TR-516X

TR-16000X

TR-514FW

23)

24)

25)

26)

27)

28

28

28) NLP

Driven Sprocket

Hex Jam Nut

Holding Bolt

Drive Shaft

Spoil Auger

Grease Cylinder Assembly

Boom for 24” Depth

Boom for 36” Depth

Boom for 42” Depth

Boom for 48” Depth

Boom for 60” Depth

Shaft/Lockwasher/Bolt

Spacers (2 required) Sealed

Bearing

Idler Roller

Flat Washer

Nylon Locking Plug

22d) TR-510EX

11

Exploded Parts Diagram: MODEL XRH-35

1) TR35-501AX Motor Cover

2) TKL-30T

2a) TR35-504X

3) TR80-15XR

Hydraulic Motor

Motor to hose fitting (2 required)

Motor Sprocket (includes keys)

4) TR35-506SH Drive Chain (includes master link)

5) TR-501X Drive Chain Cover

6) TR35-500XR Trencher Housing

7) TR-517

8) TR-16016X

Grease Fitting

Drive Sprocket (digging chain)

HBK - Hub Bearing Kit (# 9-15)

9) TR-518 Seal Protection Plate (includes cap screws)

10) 10-24982 Shaft Seal

11) TR-507 3/4” Shaft Spacer

12) 10-368A Bearing Cone (2 required)

13) 10-362A Bearing Cup (2 required)

14) TR-507B 1/2” Shaft Spacer

15) 10-25028 Shaft Seal (2 Required)

16) TR80-27X Driven Sprocket

17) P2-12

18) TR-520C

19) CR200-X

20) TR-508X

21) TR-518X

22) TR-510AX

22a) TR-510BX

22b) TR-510CX

22c) TR-510DX

22d) TR-510EX

IK - Idler Kit (# 23-27)

TR-514X

TR-515X

TR-516X

TR-16000X

TR-514FW

23)

24)

25)

26)

27)

28

28

28) NLP

Hex Jam Nut

Holding Bolt

Drive Shaft

Spoil Auger

Grease Cylinder Assembly

Boom for 24” Depth

Boom for 36” Depth

Boom for 42” Depth

Boom for 48” Depth

Boom for 60” Depth

Shaft/Lockwasher/Bolt

Spacers (2 required) Sealed

Bearing

Idler Roller

Flat Washer

Nylon Locking Plug

12

CRX-7 Trench Cleaner Assembly for Model XR-7

Ref. Part

# # Description

1) 51-ARM-X7 Trench Cleaner Arm

2) TCLA-9 9 Inch (229 mm) Trench Cleaner Linkage Assembly

3) TCLA-11 11 Inch (279 mm) Trench Cleaner Linkage Assembly

4) 51-BAR-X7 Trench Cleaner Bar for 24”, 30”, & 36” Depths

5) L-3015 Pin & Collar

6) TR7-701X 4 Inch (102 mm) Dirt Shoe

7) TR7-702X 6 Inch (152 mm) Dirt Shoe

8) TR7-703X 8 Inch (203 mm) Dirt Shoe

CRX-51 Trench Cleaner Assembly for Models XR-14, XR-21, XR-25, & XRH-35

Ref. Part

# # Description

1) 51-ARM-X Trench Cleaner Arm

2) TCLA-9

3) TCLA-1 1

9” (229 mm) Trench Cleaner Linkage Assembly

11” (279 mm) Trench Cleaner Linkage Assembly

4) 51-BAR-36 Trench Cleaner Bar for 36” & 42” Depths

51-BAR-48 Trench Cleaner Bar for 48” & 60” Depths

5) L-3015

6) TR-702

7) TR-703X

8) TR-704X

9) TR-705X

Pin & Collar

8 Inch (203 mm) Dirt Shoe

10 Inch (254 mm) Dirt Shoe

12 Inch (304mm Dirt Shoe

8 Inch (152 mm) Dirt Shoe

13

VIII

MAINTENANCE

Shut off power and disconnect power source before performing maintenance.

WARNING: Diesel fuel or hydraulic fluid under pressure can penetrate the skin or

damage eyes. Fluid leaks under pressure may not be visible. Never use a bare hand

to find leaks and always wear safety goggles for eye protection. Such fluid, if injected

into the skin, must be removed within a few hours by a doctor familiar with this type

of injury. Make certain pressure is relieved and power source is disconnected

before servicing.

Length of Operation

Daily

Check As Needed for

Looseness

50 Hours * *

20 Hours * *

Maintenance Required

Grease Shaft Bearings

Tension Boom Idler Nut

Motor Drive Chain

Trencher Chain

Trencher Teeth

Spoil Auger

Trench Cleaner

As Needed

Before Each Use

Before Each Use

Assembly Option

Type of Maintenance

With normal grease gun, apply grease to grease

fitting until full. (Ref. #7 on exploded parts

diagram.)

Tighten nut to 150 lbs/ft. (203 N.m)

Adjust and lubricate. Chain should have

1/2 inch (1.25 cm) of free play.

Adjust and lubricate. Digging chain should have at

least 11/2 inches (4 cm) of free play.

Do not use diesel oil.

Excess chain tension may ruin drive components

and impair performance.

Replace if worn excessively.

Check for wear and the tightness of the two

attaching bolts.

Check mounting bolts for tightness and check free

play in the mechanism at the end of the arm.

* * More often under extreme conditions.

Chain lubricant can be any premium grade grease or commercial chain lube. The lubricant will do its best job when

applied to a warm chain. Give lubricant time to soak into the working parts of the chain before resuming operation.

XR Boom/Chain Tightening

1. Find and expose grease zerk under one of two nylon locking plugs (NLP); usually found under the plug on the

drive chain side of the boom.

2. Loosen the two bolts holding the boom.

3. Use small pumps of grease to extend the boom until there is about 3 cm of free play between middle of boom

and chain.

4. Tighten bolts holding boom 82 lb/ft.

5. Replace Nylon Locking Plugs (NLP)

13

14

IX SPECIFICATIONS

Operational Range

Model XR-7

Model XR-14

Model XR-21

Model XR-25

Model XRH-35

GPM (lpm)

8 to 14 (30.3 to 53)

10 to 20 (37.9 to 75.7)

13 to 25 (49.2 to 94.7)

16 to 25 (60.6 to 94.7)

20 to 45 (75.7 to 170.3)

Relief PSI (kPa)

1,700 to 3,300 (11,721 to 22,753)

1,900 to 3,300 (13,100 to 22,753)

2,000 to 3,300 (13,790 to 22,753)

2,000 to 3,300 (13,790 to 22,753)

2,000 to 4,200 (13,790 to 28,958)

SPEED POWER

MODEL XR-7

Gal/min

8

9

10

11

12

13

14

Feet/min

192

216

241

265

289

313

337

Litres/min

30.30

34.09

37.87

41.66

45.45

49.24

53.02

Meters/min

58.65

65.98

73.31

80.64

87.97

95.30

102.63

Shaft RPM

116

131

145

160

175

189

204

PSI

1,700

1,800

1,900

2,000

2,100

2,200

2,300

2,400

2,500

2,600

2,700

2,800

2,900

3,000

Near Actual

Torque

(lbs/ft)

266

282

298

313

329

345

360

376

392

407

423

439

454

470

kPa

11,721

12,411

13,100

13,790

14,479

15,168

15,858

16,547

17,237

17,926

18,616

19,305

19,995

20,684

N.m

361

382

403

425

446

467

488

510

531

552

573

595

616

637

Theoretical

Torque

(lbs/ft)

322

341

360

379

398

417

436

455

474

493

512

531

550

569

SPEED POWER

MODEL XR-14

Gal/min

10

11

12

13

14

15

16

17

18

19

20

Feet/min

233

256

279

302

326

349

372

396

419

442

465

Litres/min

37.87

41.66

45.45

49.24

53.02

56.81

60.60

64.39

68.17

71.96

75.75

Meters/min

70.92

78.01

85.10

92.19

99.28

106.38

113.47

120.56

127.65

134.74

141.83

Shaft RPM

107

118

129

139

150

161

172

182

193

204

215

PSI

2,000

2,100

2,200

2,300

2,400

2,500

2,600

2,700

2,800

2,900

3,000

Near Actual

Torque

(lbs/ft)

522

548

574

600

627

653

679

705

731

757

783

kPa

13,790

14,479

15,168

15,858

16,547

17,237

17,926

18,616

19,305

19,995

20,684

N.m

708

743

779

814

849

885

920

956

991

1,026

1,062

Theoretical

Torque

(lbs/ft)

632

664

695

727

758

790

822

853

885

916

948

15

DEEPS REWOP

12-RXLEDOM

nim/laG

31

41

51

61

71

81

91

02

12

22

32

42

52

nim/teeF

212

922

542

162

872

492

013

723

343

953

673

293

804

nim/sertiL

42.94

20.35

18.65

06.06

93.46

71.86

69.17

57.57

45.97

23.38

11.78

09.09

96.49

nim/sreteM

27.46

07.96

86.47

56.97

36.48

16.98

95.49

75.99

55.401

25.901

05.411

84.911

64.421

MPRtfahS

08

68

29

89

401

011

611

321

921

531

141

741

351

ISP

000,2

001,2

002,2

003,2

004,2

005,2

006,2

007,2

008,2

009,2

000,3

lautcAraeN euqroT

)tf/sbl(

587

428

368

209

149

189

020,1

950,1

890,1

831,1

771,1

aPk

097,31

974,41

861,51

858,51

745,61

732,71

629,71

616,81

503,91

599,91

486,02

m.N

460,1

711,1

071,1

322,1

672,1

033,1

383,1

634,1

984,1

245,1

695,1

laciteroehT euqroT

)tf/sbl(

809

359

999

440,1

090,1

531,1

081,1

622,1

172,1

713,1

263,1

DEEPS REWOP

52-RXLEDOM

nim/laG

61

71

81

91

02

32

52

nim/teeF

012

322

632

052

362

203

823

nim/sertiL

06.06

93.46

71.86

69.17

547.57

11.78

96.49

nim/sreteM

50.46

50.86

50.27

60.67

60.08

70.29

80.001

MPRtfahS

97

48

98

49

99

311

321

ISP

000,2

001,2

002,2

003,2

004,2

005,2

006,2

007,2

008,2

009,2

000,3

lautcAraeN euqroT

)tf/sbl(

729

379

910,1

660,1

211,1

851,1

502,1

152,1

792,1

443,1

093,1

aPk

097,31

974,41

861,51

858,51

745,61

732,71

629,71

616,81

503,91

599,91

486,02

m.N

652,1

913,1

283,1

544,1

705,1

075,1

336,1

696,1

957,1

228,1

488,1

laciteroehT euqroT

)tf/sbl(

390,1

841,1

202,1

752,1

213,1

663,1

124,1

674,1

035,1

585,1

046,1

DEEPS REWOP

53-HRXLEDOM

nim/laG

02

22

42

62

82

03

23

43

63

83

04

nim/teeF

222

442

662

982

113

333

553

773

004

224

444

nim/sertiL

17.57

82.38

58.09

24.89

99.501

65.311

31.121

07.821

72.631

58.341

24.151

nim/sreteM

76.76

34.47

02.18

79.78

37.49

05.101

62.801

30.511

08.121

65.821

33.531

MPRtfahS

38

19

001

801

611

521

331

141

941

851

661

ISP

000,2

005,2

000,3

005,3

000,4

lautcAraeN euqroT

)tf/sbl(

441,1

924,1

517,1

100,2

782,2

aPk

097,31

732,71

486,02

231,42

085,72

m.N

155,1

839,1

623,2

517,2

101,3

laciteroehT euqroT

)tf/sbl(

574,1

448,1

212,2

185,2

059,2

16

This manual suits for next models

5

Table of contents

Popular Saw manuals by other brands

Toolex

Toolex 535819 instruction manual

EINHELL

EINHELL TC-SM 2531 2 U Original operating instructions

MK Diamond Products

MK Diamond Products MK-145 owner's manual

RIDGID

RIDGID MS 1290 owner's manual

GMC

GMC REDEYE DB305SMS instruction manual

TYROLIT Hydrostress

TYROLIT Hydrostress HRH500 Series operating instructions

Scheppach

Scheppach hs 120 o Original instruction manual

Bosch

Bosch GCM Professional 80 SJ Original instructions

Makita

Makita 5017RKB user manual

Chicago Pneumatic

Chicago Pneumatic SCG 350 operating instructions

EINHELL

EINHELL TE-CC 250 UF operating instructions

Milwaukee

Milwaukee M18 FUEL FPS55 Operator's manual