Version 1.3 Page 4 of 20 13.01.2016

Put the unit into its place using the adjustable feet. If the unit is added to an existing kitchen line, bring it

to the same height by adjusting the feet and combine it with the suitable connection system.

If you are installing a built-in model carefully check and precisely follow the relative built-in drawing

supplied with the unit itself.

The air circulation openings of the built-in module must be transferred to an eventually existing partition

sheet and by no means be clogged in order to assure the primary air intake. If the kitchen module does

not have air circulation openings, then remove the existing partition sheet and use the one of the built-in

module. In case of doubts, please contact your retailer/wholesaler.

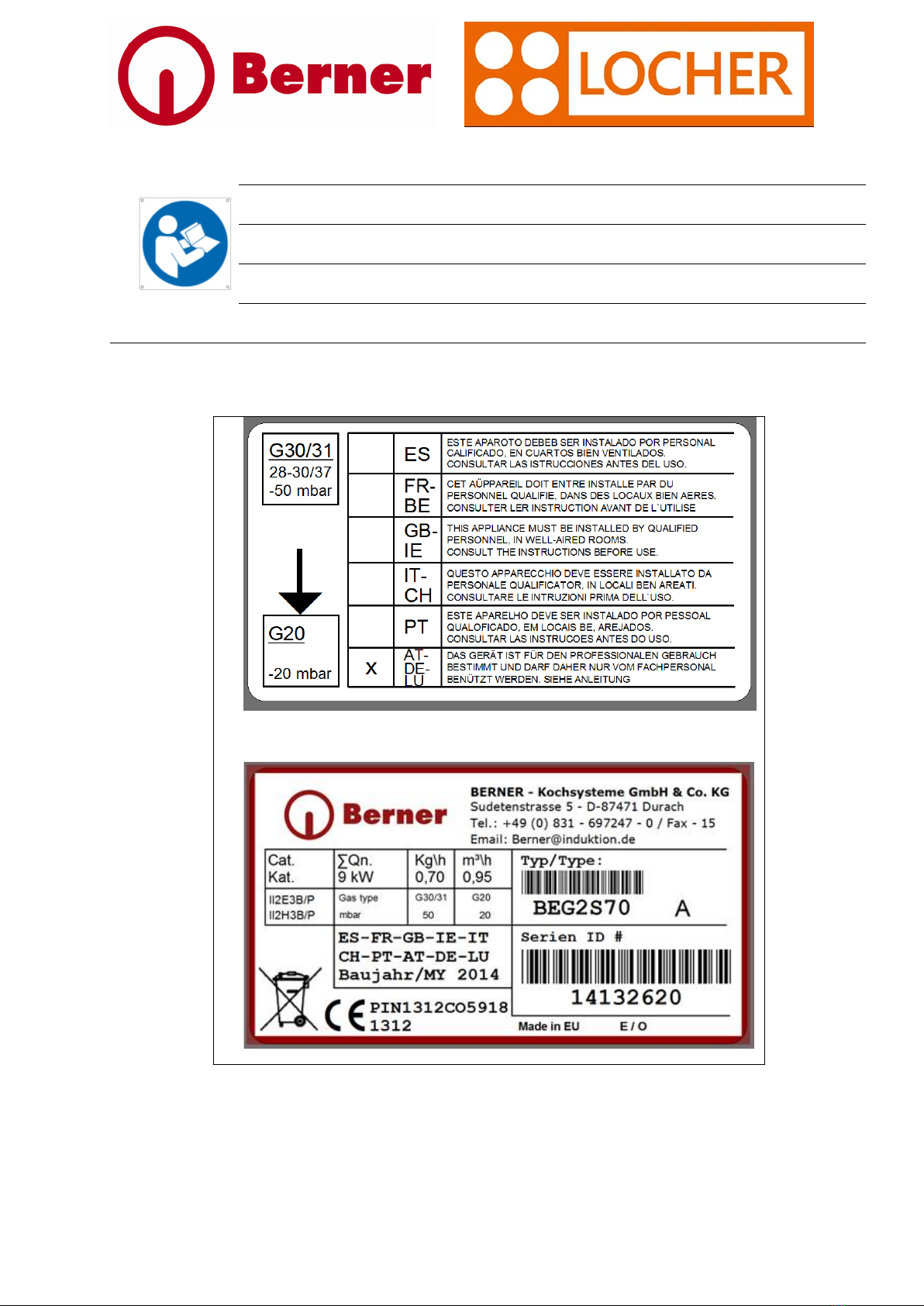

Please determine the exact gas type the unit is set with through the technical data plate placed near the

gas connection and on the packing. The unit must be installed only through authorised, trained and

licensed personnel following the local rules and regulations. Make sure to also follow the rules and

regulations of the local gas supply company. The unit must be operated only by trained personnel.

The gas unit must be installed only in adequately ventilated/aired areas as the contrary could lead to

serious consequences due to combustion residues and/or low oxygen environment air. The installation

room must not be modified after installation of the gas unit. Never ignite the gas unit, if there is a strong

gas smell in the air; open wide windows and doors to change the air inside the room and check the gas

connections for leaks. If you can’t determine the leak position, close the main gas tap and contact your

retailer/wholesaler for a profound analysis of the gas connection system. The unit must be installed only

through authorised, trained and licensed personnel following the local rules and regulations. Make sure to

also follow the rules and regulations of the local gas supply company. Prior to installation, the gas unit

must be checked for dimensions, power and OEM set gas type. If locally there is another gas type

available, only authorised, trained and licensed personnel can substitute the nozzle installed by the OEM.

The exact gas type the unit is set with is indicated on the technical data plate placed near the gas

connection and on the packing. The supply includes also the nozzles for different gas types, enabling the

substitution. Connection to the main gas tap must be carried out exclusively through the OEM gas train.

The gas pressure must be measured and checked. The gas train is equipped with a measuring pipe ( see

image). Loose the screw of the pipe (without removing it) and apply the gas pressure measuring

equipment over it and measure the gas pressure. Tighten the screw after measuring and check if the gas

train is sound by applying soapy water on the joints.

follows