2 – 5 LB Icarus Operating Manual

(*This temperature is a recommended recovery temperature when dealing with compounds with low boiling terpenes.

Adjust water bath temperature according to the needs of your chosen extract)

3. Bleed off nitrogen by disconnecting the dewaxer dump line on collection base. The now open valve on

the collection is opened to relieve nitrogen pressures

(NOTE: It is important to take temperature of collection chamber. This will help determine the

pressures of our solvent mixture. When valve opens, nitrogen will escape first. Gas pressure leaving

the bleed off valve will drop when nitrogen has been evacuated. Check pressure in collection base

when completed to verify nitrogen is gone. ALWAYS BLEED NITROGEN IN A WELL VENTILATED AREA.

Some flammable solvent may escape.)

4. Place collection base in warm water bath.

5. Open recovery valves on collection base and LP tank

6. Check completion of recovery via LP tank weight and sight windows.

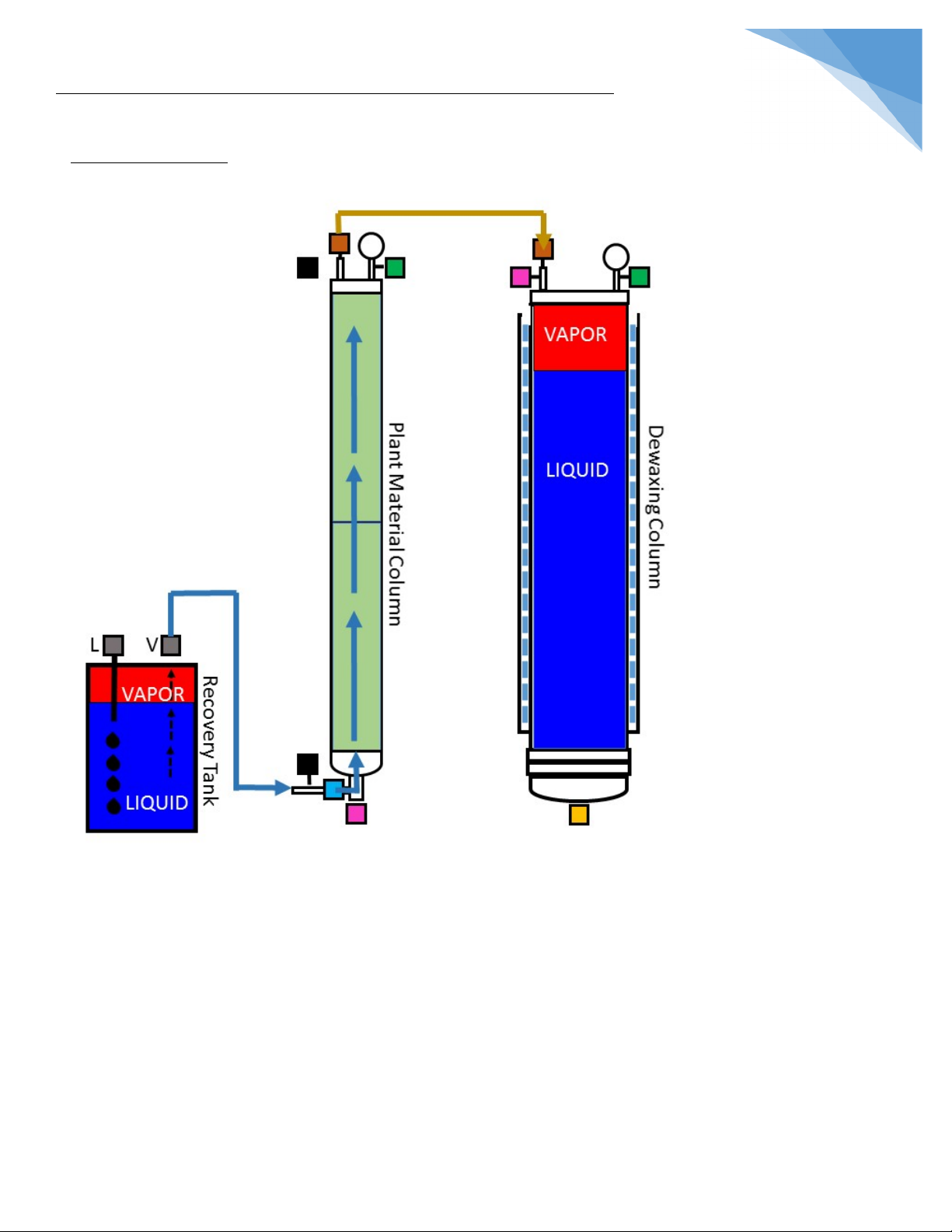

b) Recovery to Vapor Port (blue):

Recovery to the vapor port is the most straight forward method. Solvent vapors from the collection

chamber are emptied into the headspace of the LP tank. As the vapor is chilled within the tank,

pressures drop until the gas is condensed. In order to efficiently recover using the vapor port, it is

essential that the LP tank be completely covered in dry ice. The ultimate goal is to ensure the top

portion of the tank remains as cold as the bottom. Failure to keep the top half of the LP covered can

result in slow recovery, potentially a vapor lock on the end of recovery.

Vapor port recovery requires less attention to pressures as it is difficult for recovered gas to flow in

reverse.

c) Recovery to the Liquid Port (red):

Recovery to the liquid port tends to give increased recovery speeds. The liquid port has a siphon tube

that will push solvent vapors to the bottom of the LP tank. Once liquid levels reach the siphon tube,

solvent vapors will percolate through the condensed liquid, given the pressures entering the LP exceed

the pressure of the LP tank. As vapor percolates in the condensed liquid, vapor pressures are instantly

eliminated. This method of recovery tends to require less dry ice being that it is not as essential to

keep the very top of the LP covered.

Liquid port recovery is typically faster, however attention must be paid to vapor pressures on both the

collection chamber and LP. It is essential that the collection chamber be at a higher pressure than the

LP. Failure to maintain this pressure gradient will result in solvent flow being reversed.

*Note: Liquid will siphon from the LP into the collection until pressures equalize IF the LP pressures drop below that of the

collection.**