Beta industries BetaColor S2 XPress User manual

Instruction Manual

78910 11

Y/M Y/C M/C

1

2

3

5

99

98

97

95

RES 50%50%

50%

Ver 01.03b

BetaColor S2 XPressBetaColor S2 XPress

S2XPRESS

S2XPRESS

UPGRADEABLE

DENSITY

DENSITY DOT AREA

DOT AREA

DOT GAIN

DOT GAIN

3

Table of Contents ...............Version01.03b

ComponentsandControls..........................4

Getting Started, Touchmatic Memory . . . . . . . . . . . . . . . . . 5

Red, Green Traffic Lights. Zero to Paper. . . . . . . . . . . . . . . 6

MeasureDensity..................................7

MeasureaDotGainTarget..........................7

Factory Settings. Customizing the Settings . . . . . . . . . . . . . 8

EditDensityandTolerances.........................9

Edit Dot % Dot Gain Targets and Tolerances . . . . . . . . . . . 10

Automatically Enter Dot Gains . . . . . . . . . . . . . . . . . . . . . . 11

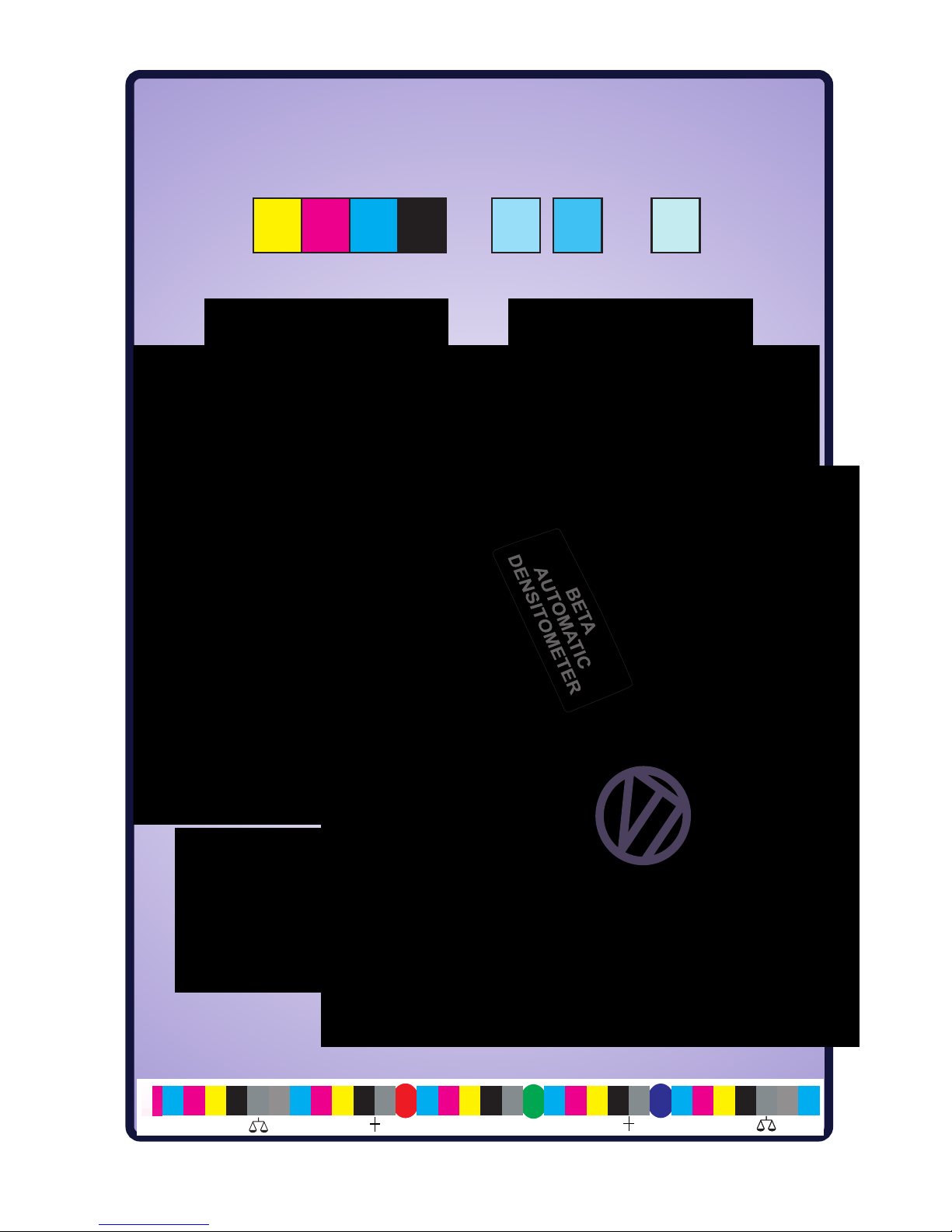

Beta Color Viewer for Subjective Evaluation . . . . . . . . . . 12

Automatic Mode Settings, Auto Paper Zero Modes . . . . . 13

Absolute Density, Dot Gain, Color Select. . . . . . . . . . . . . . 14

MeasureDotArea1%to99%......................15

ManualColorSelect..............................16

Special Functions, Slope Control . . . . . . . . . . . . . . . . . . . . 17

SlopeControlCalibrations.........................18

SettingAbsoluteZero.............................19

ChangingBatteries...............................20

TechnicalSpecifications...........................20

Warranty.......................................21

PressKits......................................22

EyeScanXPress................................23

Print Characterization Chart . . . . . . . . . . . . . . . . . . . . . . . . 24

Components and Controls

Traffic

Lights

Target

Sight

Release

Latch

Battery

Compartment

Display

Reset Button

Underneath

Up Key

Enter Key

Down Key

USB Port

4

S2XPRESS

S2XPRESS

UPGRADEABLE TO S4 XPRESS

Getting Started With “Touchmatic Memory”

RED

Getting Started With “Touchmatic Memory”

The S2 XPress is always ready to use. There is no need to

charge it, plug it in, or connect cables. It will produce more

than 500,000 measurements with 2-AA alkaline batteries,

and turn itself off after the last measurement.

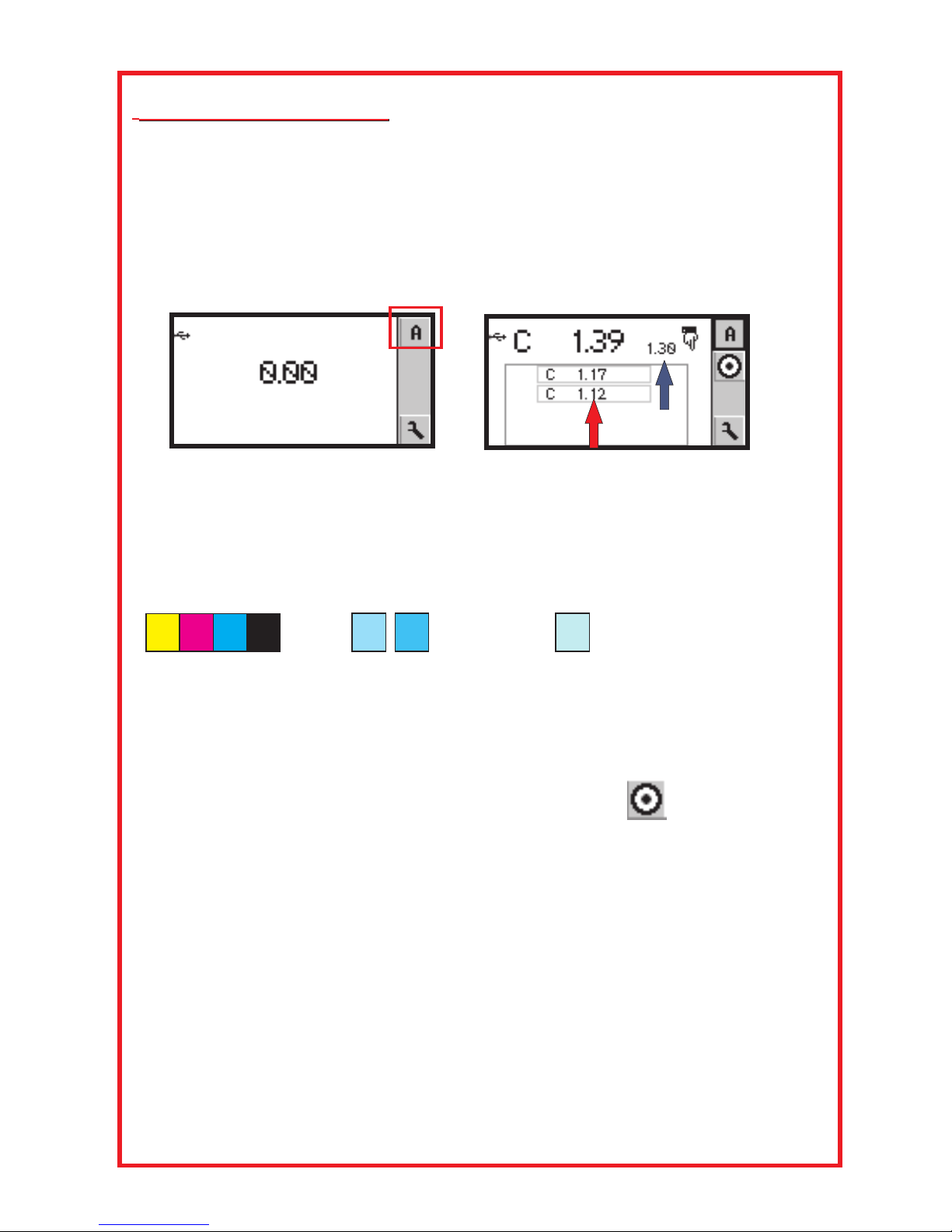

The top Icon in the Vertical Tool Bar indicates you can

automatically perform the following functions.

1.Zero to the paper.

2.Measure Density of the primary colors, yellow, magenta,

cyan, and black.

3.Measure 2 Dot Gain values in each primary color.

2.Density 3. Dot Gain 4. Dot Area

Density, and Dot Gain targets can be readily memorized

for each new print run from the opening screen by

measuring a target, then framing the Bulls Eye with

the up or down keys and storing it in the “Touchmatic

Memory” by pressing ENTER with the middle key. For

example, the first CYAN [C] ink 1.30 Density was measured

and memorized. The next CYAN measurement 1.39 Density

is indicated by the large numbers. The pointer

indicates that the first Cyan 1.30 Density will serve as a

reminder for all subsequent CYAN measurements until it is

changed if necessary. Up to 4 previous measurement

appear in the history stack as indicated by the pointer.

The down pointing icon indicates the 1.39 Density is high.

5

BLUE

Flashing or Traffic Lights indicate when the

Density, and Dot Gains, are in or out of tolerance. This

feature allows the fastest and most accurate measurements

possible without the need to constantly look at the numerical

display.

Note: A color bar with targets of Density, Dot Gain,

Gray Balance, and Trap Colors is essential.

We highly recommend the Beta Custom Gray Balance

Color Bar for accuracy, speed and features.

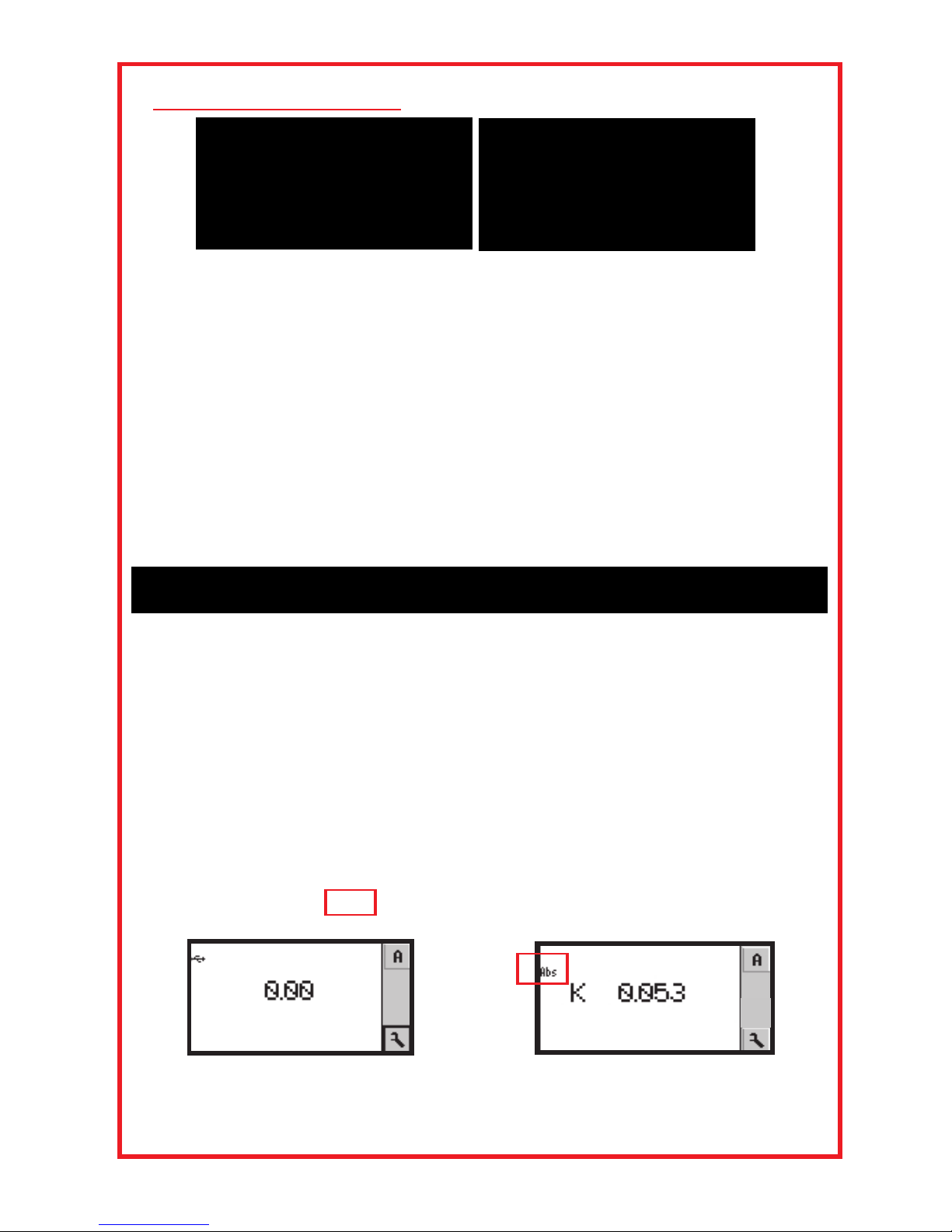

Zero to Paper in RELATIVE or ABSOLUTE Density

Place the aperture on white paper and press the head down.

Rezero on paper any time if in doubt of the zero value or

when changing paper.

Measurements can be done in RELATIVE DENSITY that

produces a 0.000D with paper for any density up to 0.14D,

or in ABSOLUTE DENSITY that will show an average white

paper range between 0.04 to 0.09D. For example, the

display shows a Black Density of 0.053. On the left side of

the display is the Abs symbol as a reminder.

RELATIVE ABSOLUTE

Getting Started

Red Green

6

Getting Started

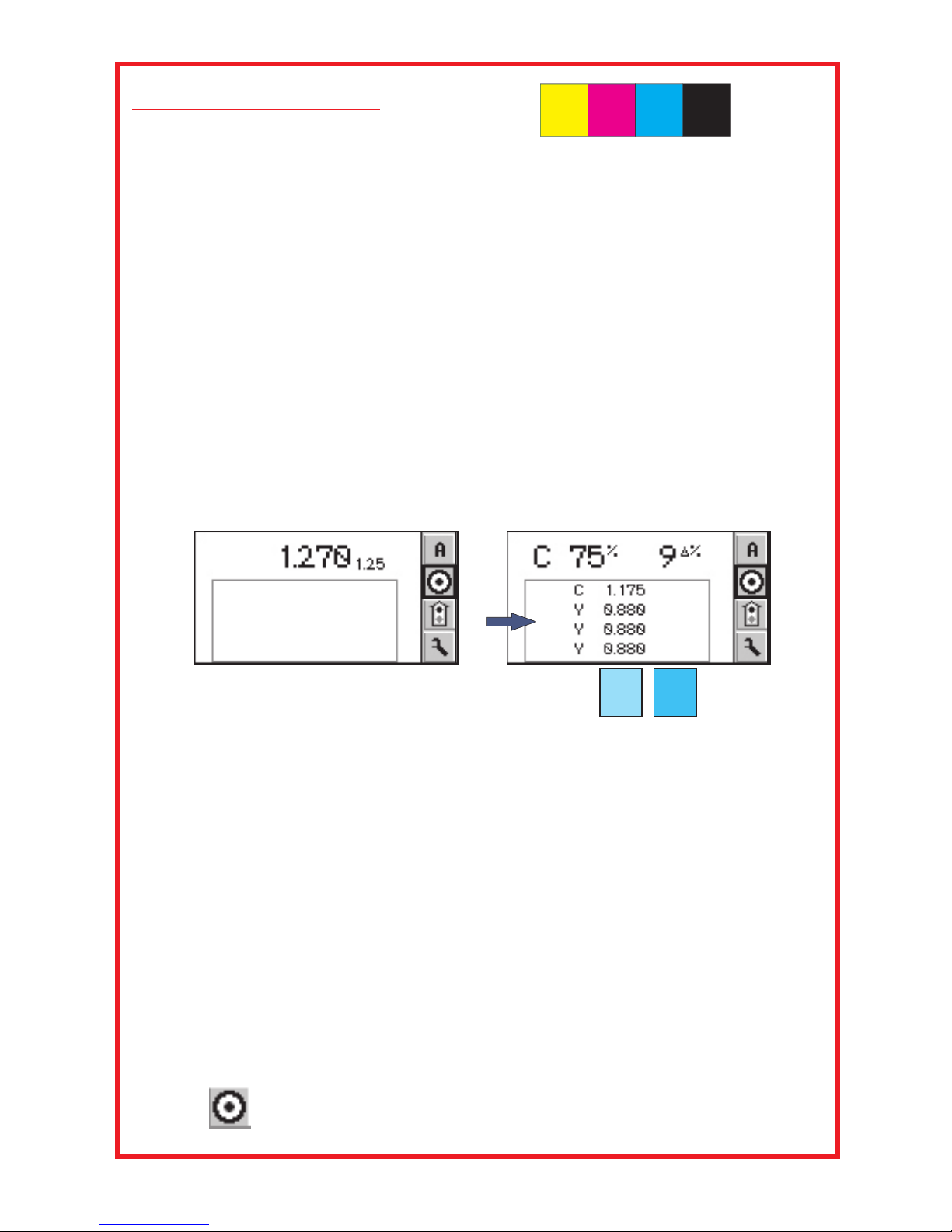

Measure Density

Place the aperture on a solid color of cyan, magenta, yellow,

or black and press the head down. The large Cin this

example shows you’ve measured a Cyan target. Continue

with the other colors in any order.

Up to 4 previous measurements are saved in a history

stack beneath the current measurement. ( )

The last measurement as illustrated was the Cyan target.

After measuring any solid color patch the DOT GAIN targets

of the same color can be automatically measured. The S2

XPress is pre loaded with Dot Gain Targets of 75%, and

50%, to correlate with the Beta Custom Color Bar. The Dot

Gain targets can be changed to other values if needed.

If the last solid color measurement is Cyan, we can now

measure Cyan Dot Gain Targets. Place the aperture on the

Dot Gain Target and press the head down. In this example

the C indicates you’ve measured the Cyan Dot Gain Target.

The 75% indicates which of the three Dot Gain Targets

you’ve measured. The 9?% is the result of the Dot Gain

Calculation. [Murray/Davies equation, which calculates the

actual dot size plus optical dot gain]

?% means CHANGE IN PERCENT. The 75% Target is

actually 84% total Dot Area. In this example the Cyan Dot

Gain Target has 9 points of dot gain. Continue measuring the

2 other Cyan Dot Gain Targets.

The Dot Gain values can be memorized by framing the

Target icon and pressing Enter.

7

Blue Arrow

Measure Dot Gain Targets

C

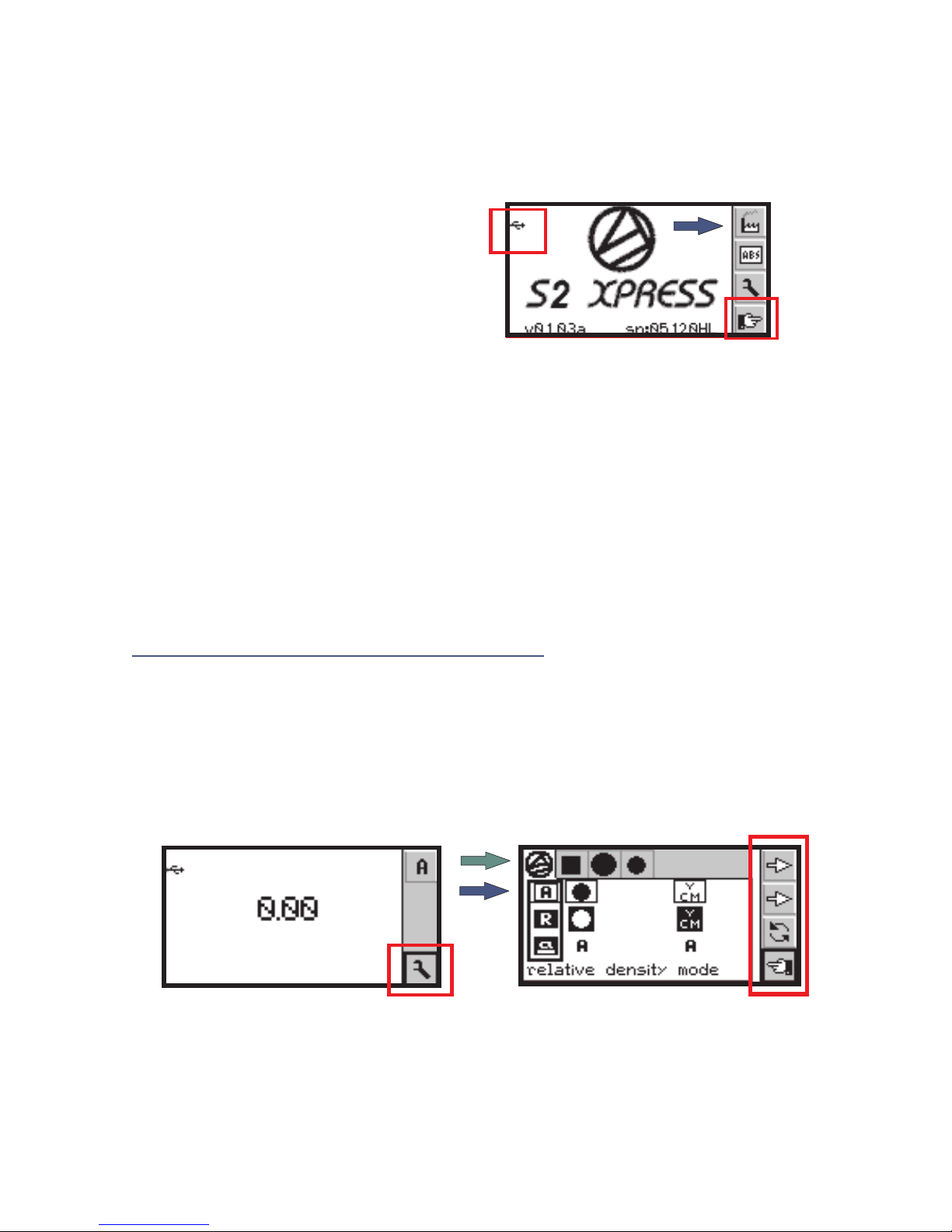

Note: To restore Factory Settings, press the button

on the bottom of the S2 XPress. Select the Factory Tool

[ ] on the top of the Vertical Tool Bar and press

ENTER to restore the original Factory Settings.

Caution: Restoring Factory

Settings will remove your

custom settings.

To return to programs without

making any changes, frame the

symbol and press Enter or Zero to paper.

The USB symbol appears when the densitometer is

connected to your computer.

References are accessed by framing any Reference icon

and then Framing the Change Tool and pressing ENTER.

Each Reference can memorize its own set of DENSITY,

DOT GAINS, and TOLERANCES values.

The BetaColor S2 XPress is extremely flexible and easily

adapted to your shop standards.

Icons are used to navigate through the groups of setting and

adjustments.

Frame the Tool Icon on the VERTICAL TOOL BAR to open

the References and Tolerances.

8

RED

Go Back

1.Vertical Tool Bar Settings. [In red rectangle]

blue pointer

3.Automatic Mode Settings. [Blue arrow]

Customizing the Settings

2.References and Tolerances Settings. [Green arrow]

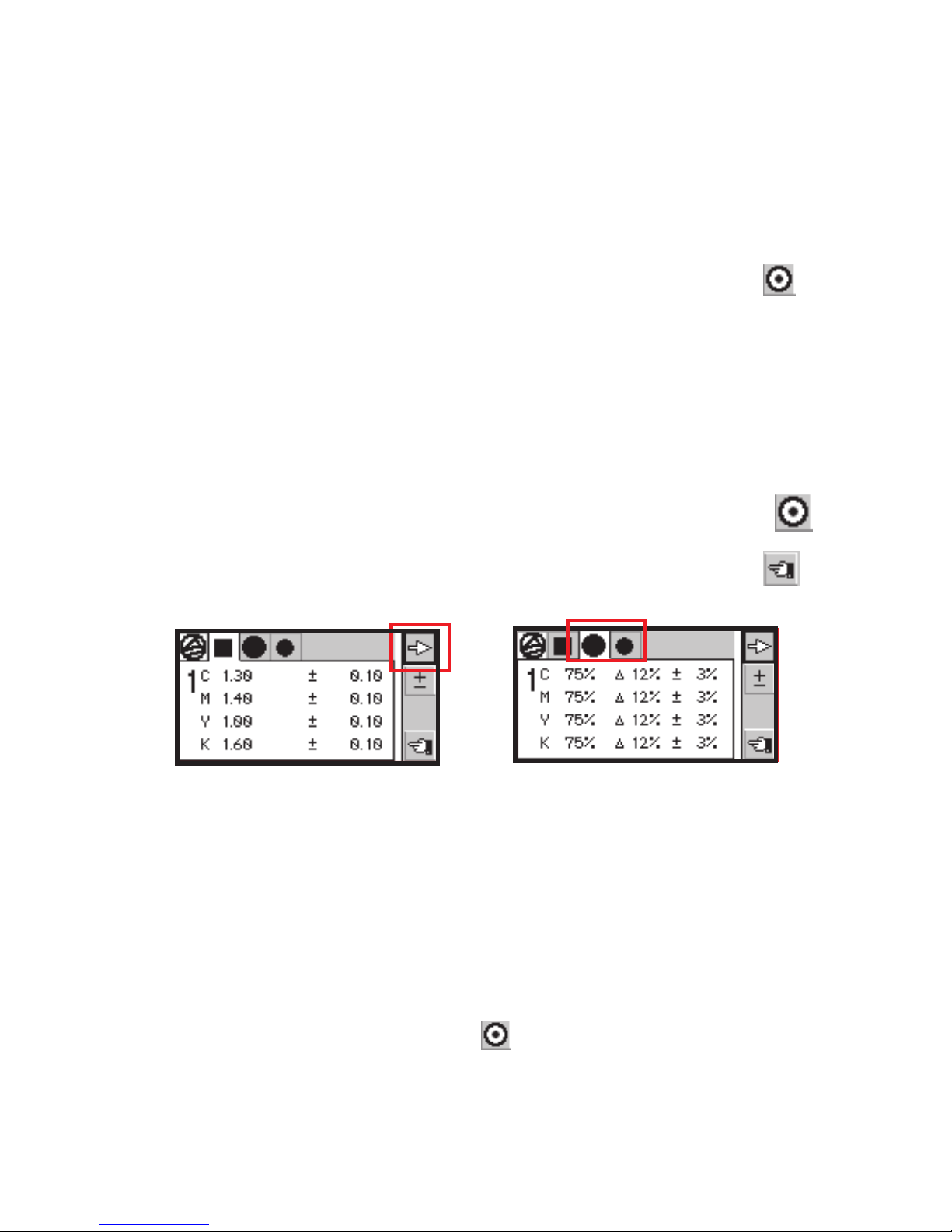

Edit Density and Tolerances

Edit the Dot Gain and Tolerances

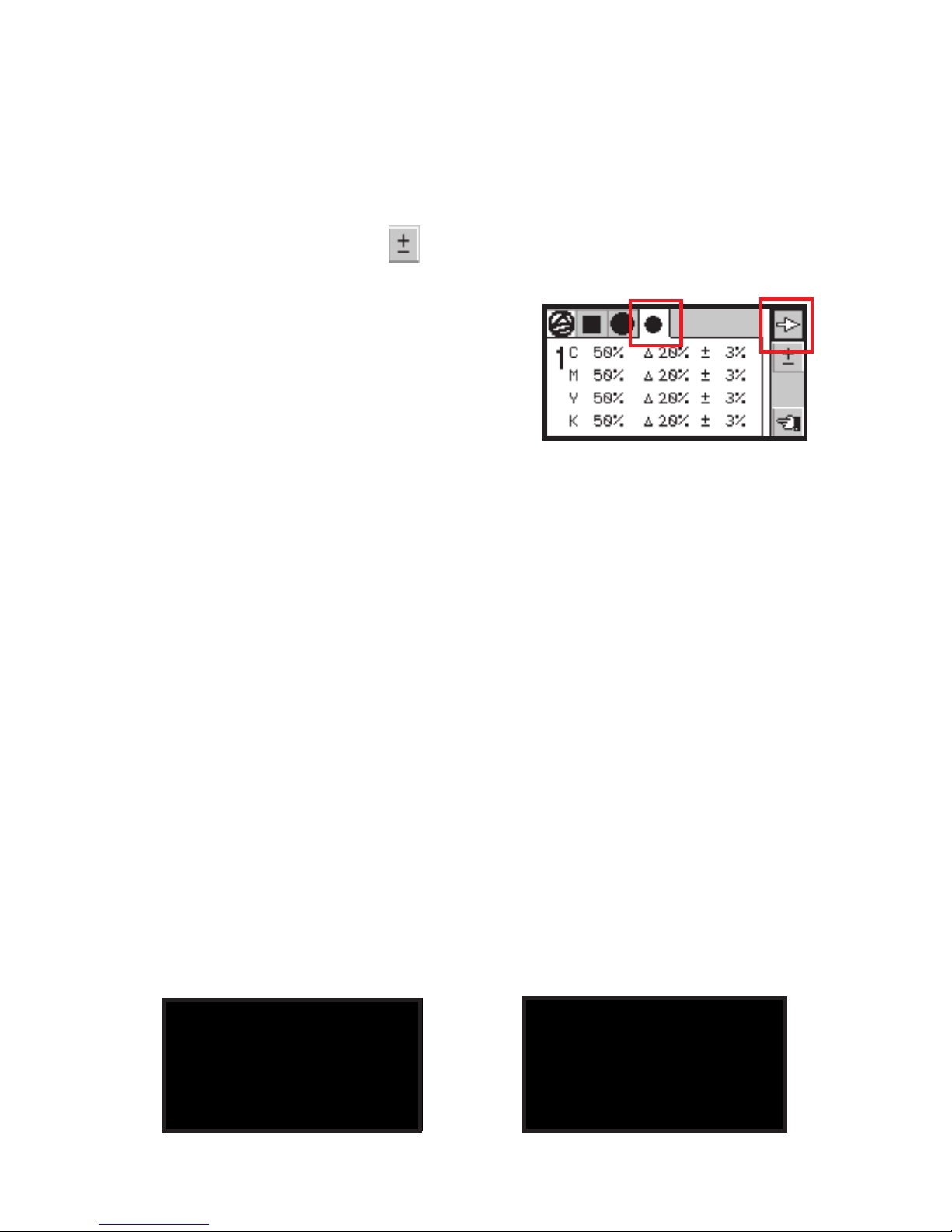

Press the up or down Keys to frame the top arrow .

Press ENTER to open the Solid Density Reference and

Tolerance field. The DENSITY values displayed will be

either the installed pre loaded values, or new values that

were measured and memorized using the BULLS EYE

function. Framing the top arrow and pressing ENTER will

open the edit program for DENSITY values and the +/-

tolerances. To change any other Density values and

Tolerances, frame the top arrow and press ENTER to

proceed to each value and repeat as necessary.

Note: The DENSITY values will change each time you enter

new values in any of the 4 References using the BULLS

EYE function. To proceed to the next editable values it is

necessary to exit the program by framing the RETURN

KEY and press ENTER.

Press the up or down Keys to frame the top arrow and press

ENTER. The DOT GAIN EDIT screen will appear. There are

2 DOT GAIN values that can be programmed.

The S2 XPress is generally set at 75%, and 50%, to agree

with the Beta Custom Color Bar.

In the example above, the first Dot percent is 75%. The Dot

Gain increase is set at 12% or can be actually measured and

memorized with the Bulls Eye. The +/- Tolerance is set at

3%. Measurements within Tolerance will flash .GREEN

9

Edit Dot %, Dot Gain Targets & Tolerances

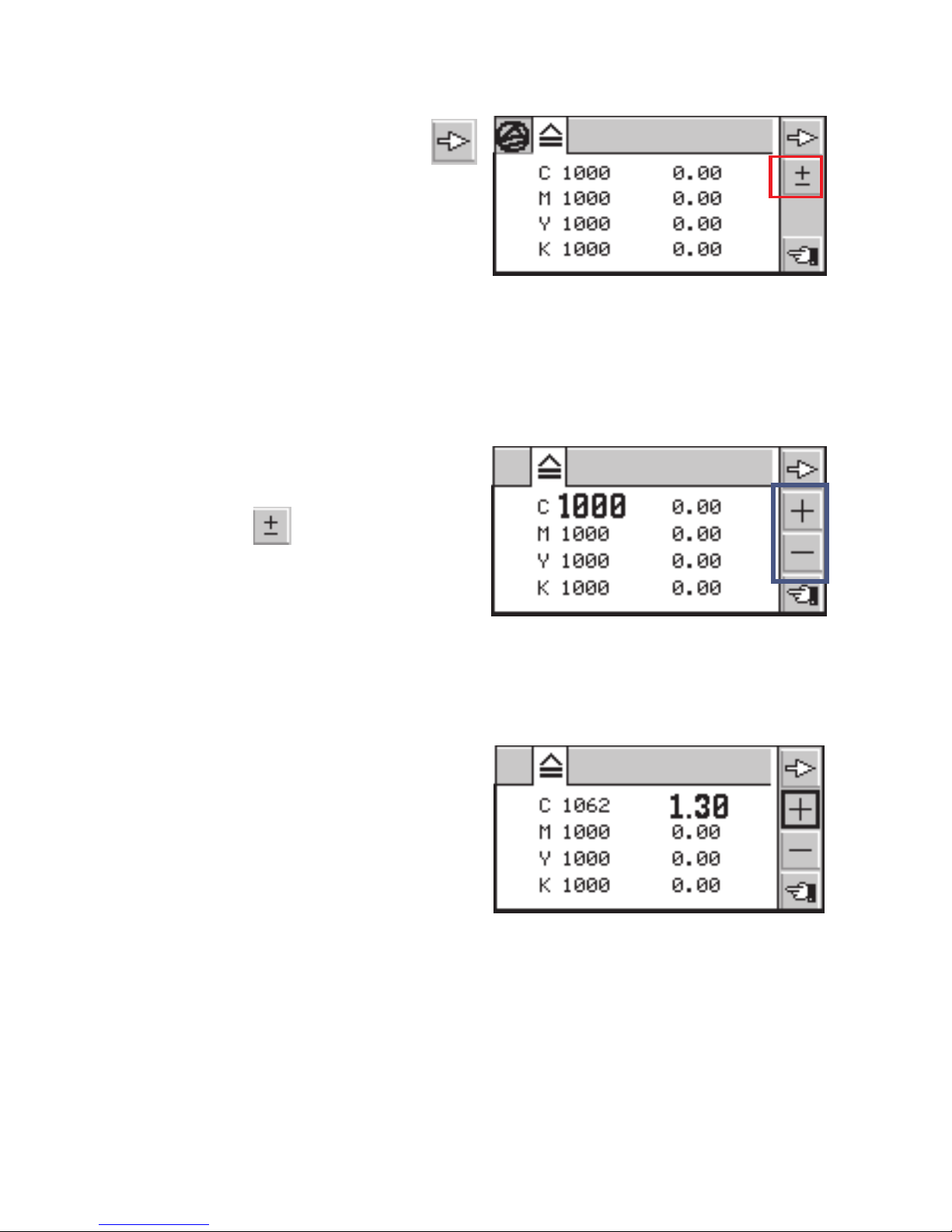

DOT PERCENTAGES from 80% to 25%, plus DOT GAINS

and TOLERANCES can be changed by framing the top

arrow on the vertical tool bar and pressing ENTER. Press

ENTER again to frame the appropriate DOT icon for

adjusting. Frame the and press ENTER. The DOT % for

CYAN will enlarge and a separate + and - symbol will show.

10

The magenta, yellow and black values can be similarly

adjusted. To proceed to the next set of editable values it is

necessary to frame the RETURN KEY and press ENTER.

The automatic DOT GAIN function relies on the

principle that measuring a solid ink patch results in a density

measurement which then can compare it to a 3/4, ½ or 1/4

tone tint value. Under ordinary press conditions a logical

DOT GAIN value is displayed. If an illogical result is

displayed, it is the result of the solid or tint values beyond

normal tolerance values. This may happen when the first

measured solid density patch is significantly higher in density

than subsequent measurements causing a false 3/4 tone

DOT GAIN result in error. In this event, re-zero to paper

and measure the solid again. All DOT GAIN measurements

should be made as close as possible to a solid of the same

color tint to minimize errors. To change the 3/4 tone value to

OFF press the icon beyond 85% to show Density only.

NOTE:

Frame the + or - symbol to change

the DOT % value if necessary.

To continue editing, frame the top

arrow and adjust the DOT GAIN if

necessary. Repeat the procedure

for the TOLERANCE +/- values.

+

GRAY BALANCE

Dot Gains for 3/4tone, midtone, and

1/4 tone can be entered automatically

by measuring a solid and then a tint

value of the same color. The Dot Gain

can be memorized by framing the

BULLS EYE then press ENTER.

The new Dot Gain values will replace the previous ones.

An accurately printed three-color Gray Balance target has

the same visual appearance as a black tint of the same

value.

Because Density, Dot Gain, Trapping, and Pearl Factor

affect Gray Balance targets, they are a good early warning

sign for detecting changes in print conditions. When Gray

Balance targets are located adjacent to a black tint, very

accurate visual judgments can be made with just a glance.

Beta Eye Scan Custom Gray Balance Color Bars have

Gray Balance targets in every ink key zone, and black tints

adjacent to them in every fourth zone, allowing both visual

and densitometer press control. The Balance Symbol

below the Beta Color Bar quickly identifies the 50% black tint

and adjacent 3-color Gray Balance target.

11

Automatically Enter Dot Gains

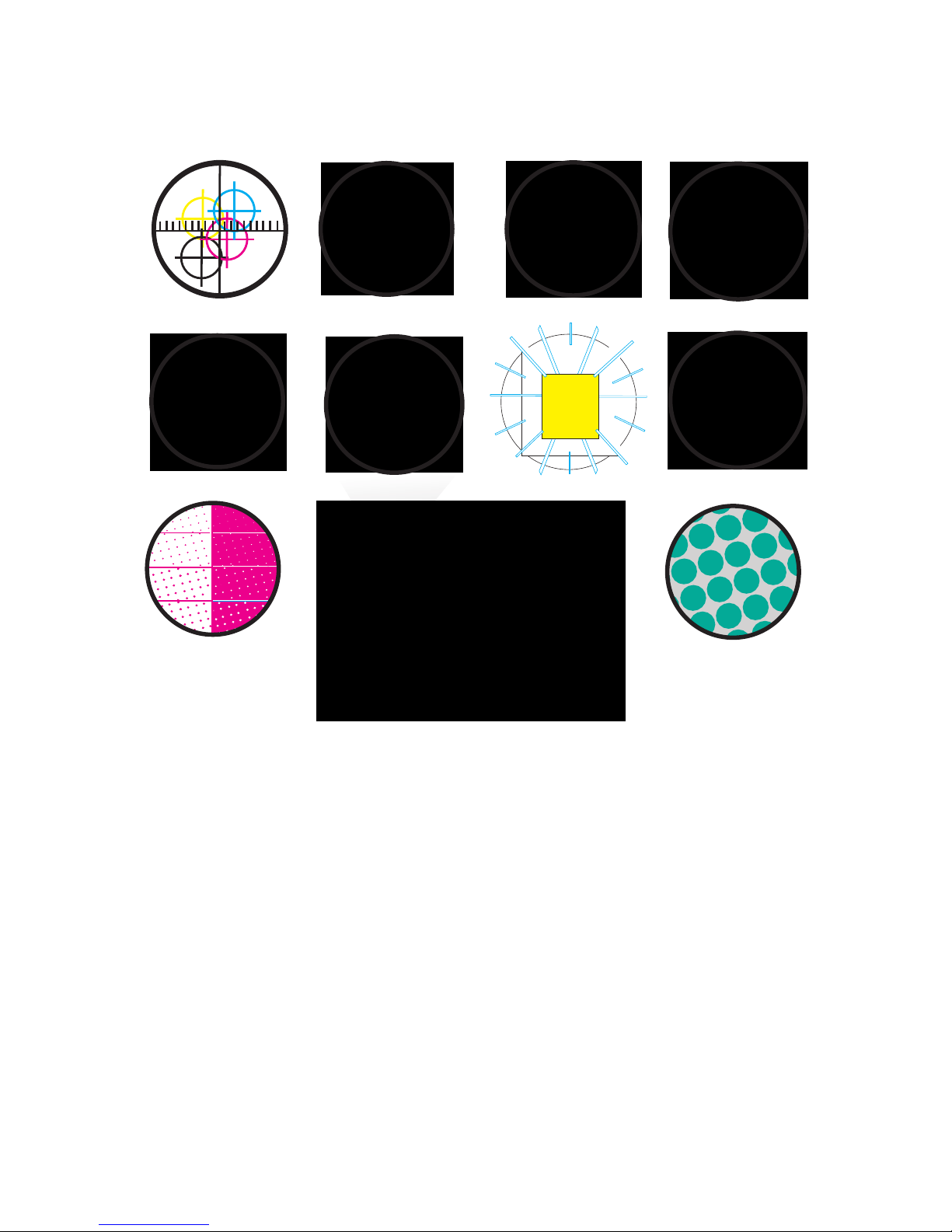

The Beta Color Viewer lll is the ideal companion to the

S2 XPress and Beta Custom Color Bar

See the nearly invisible yellow and defects on plates,

proofs, and print.

Slur and Doubling will affect Dot Gains and Gray Balance

without having any change in Density measurements.

Similarly, when viewing a printed sheet under a different

lighting condition the Gray Balance will also change. Inks

and paper have varying amounts of U.V. brighteners that will

also change Gray Balance and the appearance of a printed

sheet. The Beta Color Viewer lll is a useful tool that features

a U.V. light source that will visually detect the fluorescence

and metameric influence.

See UV

Influence I On

Ink and Paper

FLUORESCENCE

Y

SEE IT MEASURE IT CONTROL IT

INK/WATER BAL.

REGISTRATION

0 18

02 04 06 08 10 12 14 16

FILM

SEE YELLOW

STOCHASTIC

RESOLUTION

DOUBLING

SLUR

99%

2%

1%

3%

5%

95%

98%

97%

PLATES

12

Automatic Mode Settings

To access, go to

settings display

and press Enter.

The screen shows icons in row 2 framed in ,

( ) Each individual icon that is framed in black

indicates that it is active and has an Aunderneath.

The other icons are reversed on a black field and are not

active. A black frame outlines the column that is active

( ) and moves by framing the arrow then Enter

Auto Paper Zero Mode

Automatically zeros [0.00] to any paper density up to 0.14

Density. This is the preferred setting for most measurements

Relative Density Mode

Allows zeroing [0.00] on tinted paper or to any

density for null comparison measurements.

Frame the Relative Density Mode and activate

the Go Back icon. to return to the Starting

Screen. On top of the Vertical Tool Bat there

will be a Density icon and then a Relative Paper icon

Frame the Paper icon and measure any Density to (0.00).

Then measure another density for +/- deviations.

The mode will automatically change to Density.

Subsequent measurements will show +/- differences to the

Zeroed or NULLED value. This is useful for measuring

densities across the width of a sheet without having to

remember the original density.

All Automatic

Function Details

Are Displayed:

RED

red arrow

1

blue arrow

1 2 3

A

R

13

Automatic Mode Settings

Blue Arrow

Absolute Density Mode

Allows measurements in the

Status T mode. Measuring

white paper generally

produces a value between

0.04 and 0.09 Density. Measurements in Relative Density

( ) allow the S2 XPress to NULL (0.00) on any

Density for +/- measurements in any color.

Dot Gain. The S2 XPress is programmed to

automatically measure 2 dot gain percentages, generally

75% and 50%. Measure a solid 100% of a K,C,M,Y and

then measure a tint percentage on the color bar of the same

color. Adding the dot gain to the starting percent is the

equivalent of dot area.

The Dot Gain range can be set from 25% to 85%

Color Select in Aallows the S2 XPress to

automatically recognize a process color. Changing A to M

(Manual) will show the Density values of C,M,or Y in any

color.

The S2 XPress can be upgraded at any time to provide

additional features of 3 Dot Gain Levels, Auto Gray Balance,

Trapping, Pearl Factor, and Color Match

1

2

3

Optional Upgrade to S4 XPress

1 2 3

Y

C M

a

14

K

K

C

C

M

M

Y

Y

DOT GAIN

DOT GAIN

C/M

C/M

Y/M

Y/M Y/C

Y/C Color Match

Color Match

Gray Balance

Gray Balance

Manual Mode Settings

1

2

3

4

5

Measure Dot Area 1% to 99%

. Move the black frame to

column 2.

Frame the Change

Tool and press Enter to

change to Manual Dot Area.

The Relative Density Mode

will automatically frame.

. Frame the go back icon and press Enter.

. Frame the paper icon and zero to paper.

. Frame the Density icon and measure a solid primary.

. Frame the Dot icon and measure dot areas of that

primary color.

15

3

4

5

Manual Mode Settings

2

3

4

5

6

Manual Color Select

. Move the black frame to

column 3.

. Frame the Change icon

and press Enter for Manual

Color Select.

. Frame the Go Back icon

and press Enter.

. Frame a C,M,Y, or K icon

on the vertical Tool Bar.

. Zero to paper by framing

the Bulls Eye and press Enter.

. Measure any color and the display will show the density of

that specific color in the sample being measured. For

example, if Magenta is selected, then the Magenta

component in any CMYK or special color can be measured

without the influence of other colors.

1

16

Optional EyeScan XPress Software

Measure and record vital data for total control and recall.

Ace Printing 101 Gray Balance

GRAY BALANCE

Automatic Data Entry

Statistical Library

COLOR MATCHCOLOR MATCH

DENSITYDENSITY

Ace Printing 101 Gray Balance

GRAY BALANCE

GRACoL G7TM

GRACoL G7TM

Match PantoneTM Colors

17

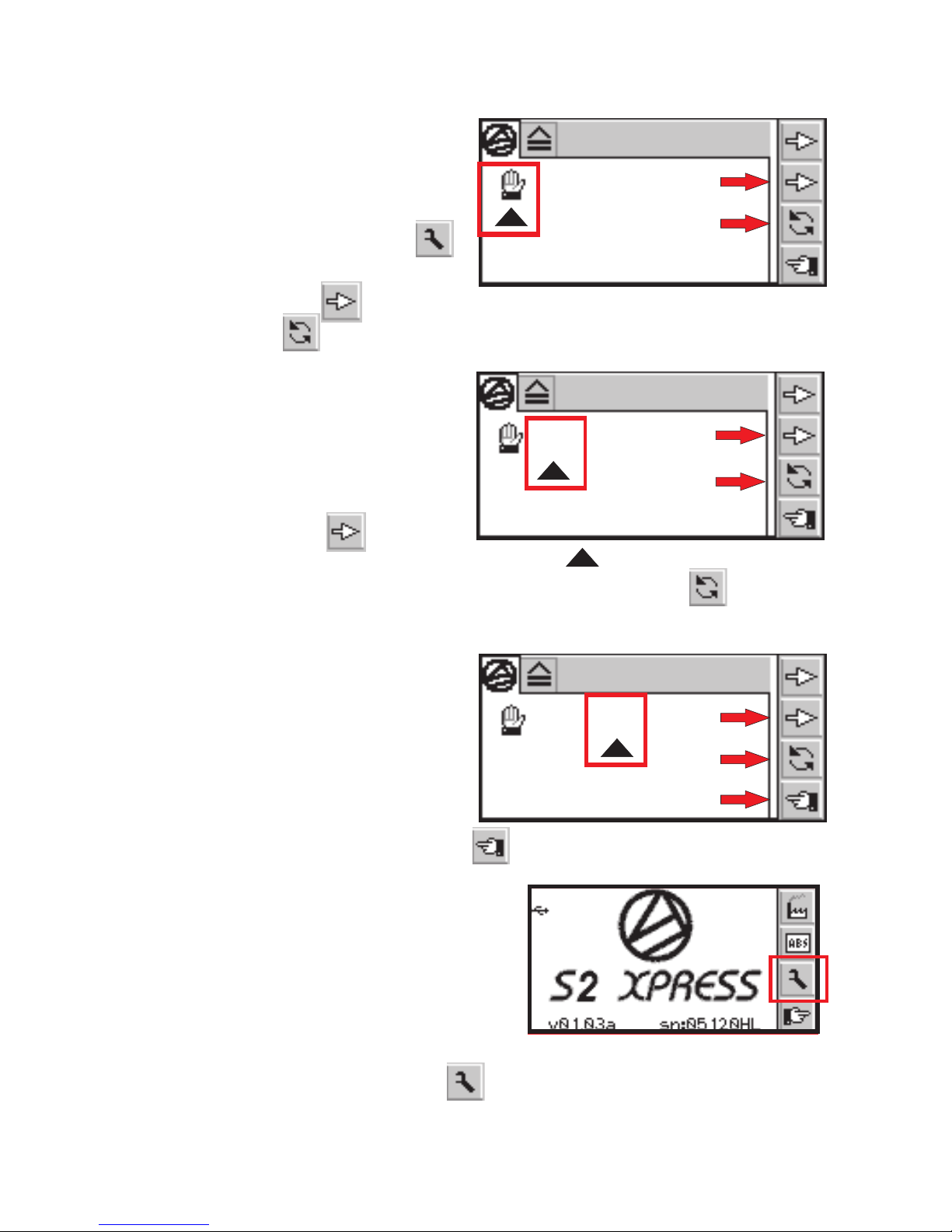

Special Functions

Right Hand / Left Hand

functions can be activated by

pressing the

on the underside.

Frame the Change Tool

and press ENTER. Frame the

pointer on row 2 and press Enter. Then frame the

Change Tool and press ENTER. The display will invert

for left handed users.

Numerical Resolution

To change the numerical

display to either two 0.00 or

three 0.000 places after the

decimal point, Frame the

pointer on row 2 and

press Enter to move the triangle icon to below the

numerical display. Then Frame the Change Tool and

press Enter.

Fluorescence

The presence of fluorescence

in inks can be detected by

changing the normally OFF to

ON. The influence of Fluor-

essence is generally greater

in yellow ink and Hexachrome

Return to the opening screen

Changing the SLOPE value

allows the S2 XPress to agree

with densitometers using other

standards for density values.

Press the on the underside.

Frame the Settings Display and press ENTER to open

SLOPE CONTROL.

RED BUTTON

RED BUTTON

.000

Slope Control

.000

.000 Fluor

OFF

Then frame the Top Arrow

and press ENTER for C M Y K

adjustments. The S2 XPress

is pre set with C M Y K SLOPE

values of 1000 for each color

and the Densities in the right column are set at 0.00 for

Paper Relative Density.

In Absolute Density, other minimum Density values are

shown. These values generally range from 0.05 to 0.10.

The SLOPE adjustment range is 750 to 1250.

In the left column are Density

Slope values for C, M, Y, K.

Frame the icon on the

opening screen and press

ENTER. For example, the

Cyan slope value can be

raised or lowered.

Use the PLUS + or MINUS - icons framed in to raise

or lower the slope values for each channel as needed.

NOTE: The slope values can

also be adjusted interactively

by measuring a sample with

a known density for each color.

The samples can be measured

in any order and the corresponding values will be updated

automatically.

Pressing the on the underside will reset to

original 0.00 values and the change Slope will remain.

BLUE

RED BUTTON

Slope Control Calibrations

18

Setting Absolute Zero

Special Features

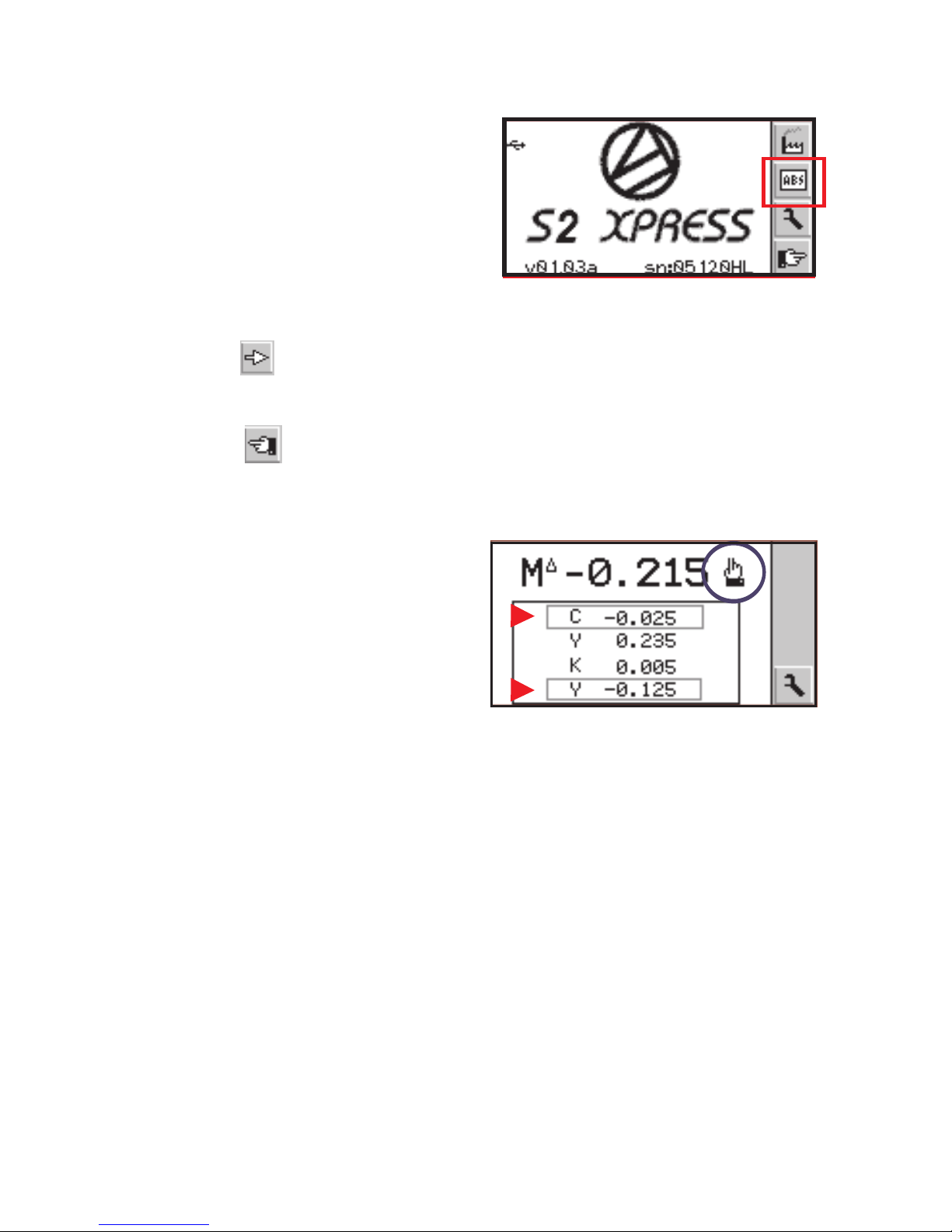

Press the on

the underside. Frame the ABS

Icon and press ENTER to

open the screen.

Measure white paper to display

CMYK and corresponding minimum density values.

Measure the supplied White Calibration Cap. Frame the

top arrow and press ENTER to enlarge any minimum

density number to be changed to agree with the values as

marked. Press the + or – Icon accordingly. Press the

RETURN icon and continue to the next function.

The Guide Pointer marked by

a blue circle indicates that the

density of the last measure-

ment must be increased.

The operator must increase the ink feed to that zone.

Subsequent density measurements are placed in the history

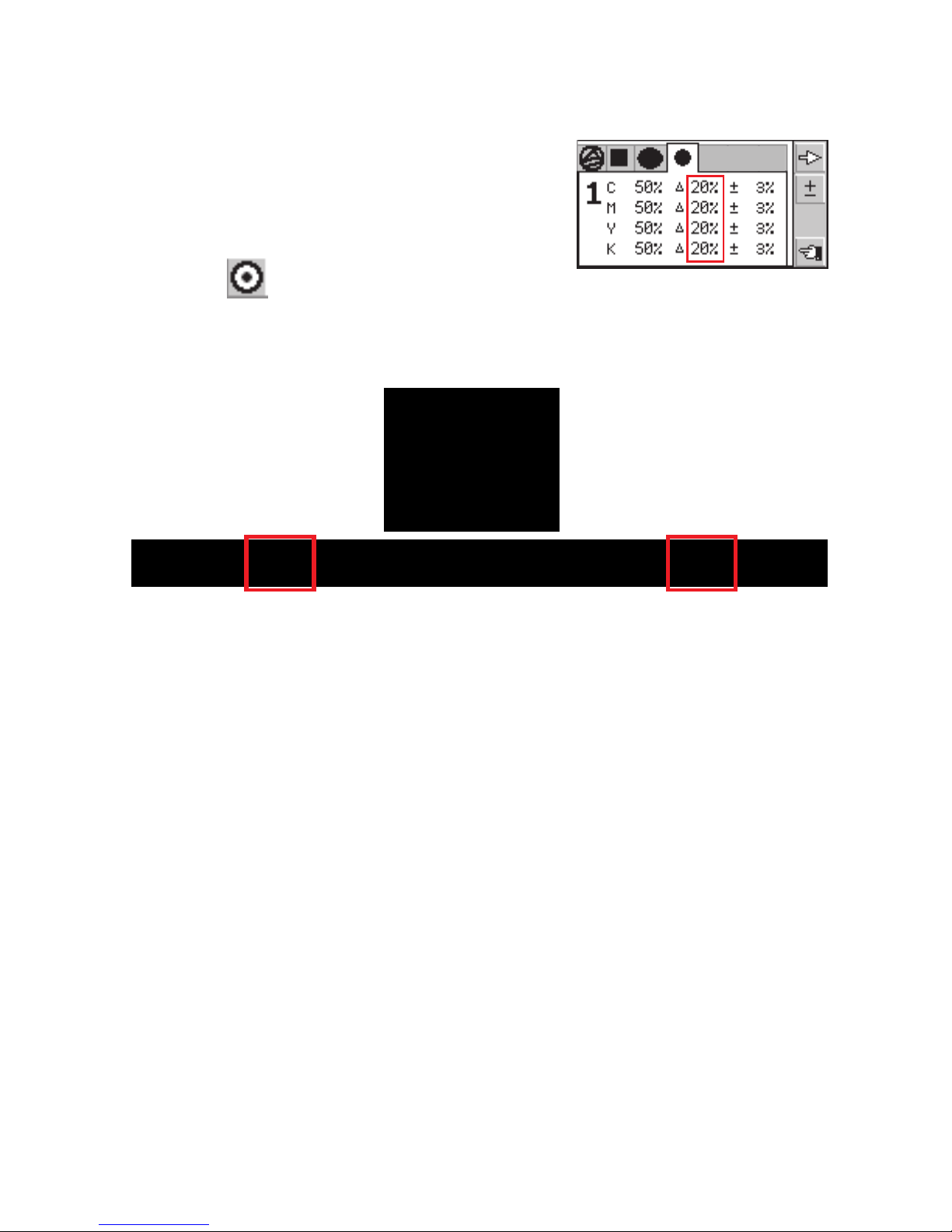

stack as shown below.

Out of tolerance density values in the stack are surrounded

by a gray rectangle as marked by red pointers.

Dot gain measurements are marked in the same manner

during measurement and when they are placed in the history

stack.

RED BUTTON

19

Changing Batteries

The S2 XPress is powered by 2- alkaline AA batteries.

There are no cables or chargers or Ni-Cad batteries. As the

batteries approach the end of their usable life span a low

battery warning will appear.

The S2 XPress will continue to produce many accurate

measurements, but the batteries should be replaced when

convenient. Remove the bottom plate to access the battery

compartment.

Note: Notice the polarity and replace as indicated. The

customized settings will be unchanged.

Technical Specifications

Illumination LightEmittingDiodes,45°/0°geometry

Aperture 3mm(Optional 2mmor1mm)

DensityRange D0.00–2.50

Percent %0–100

Measuringtime 0.5seconds

GraphicalDisplay 160x80Pixel,4grayscales

RepeatabilityD +/-0.01D,0.2DE

Linearity% +/-1%

SerialInterface USB

Measurementsperbatteryset Over500,000

Batteries 2AAAlkaline1.5V

Filters StatusT [StatusI/E/TSpecialOrder]

Polarizationfilter Optional

Dimensions 6.75x3x1.75in. 175x75x47mm

Operatingcondition 10°Cto40°C

10%to80%relativehumiditynon-

condensing

Storageconditions -20°Cto60°C

10%to90%relativehumiditynon-

condensing

20

Warranty and Contact Information

Warranty

The complete instrument is covered for THREE YEARS

against manufacturing defects for Parts and Labor.

The light source and filters are covered for SEVEN YEARS

against failure and fading.

Warranty repairs or replacement will be performed on

instruments shipped freight prepaid to our office.

Unlimited technical support is provided for the life of the

instrument. Support calls are toll-free in the US and parts of

Canada.

Contact Information

Beta Industries

707 Commercial Ave.,

Carlstadt, NJ 07072 USA

Toll Free 800-272-7336

Tel 201-939-2400

Fax 201-939-7656

Email [email protected]

www.betascreen.com

21

Table of contents

Other Beta industries Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Brooks Instrument

Brooks Instrument Sho-Rate Series Installation & operation manual

GOK

GOK ODR Assembly and operating manual

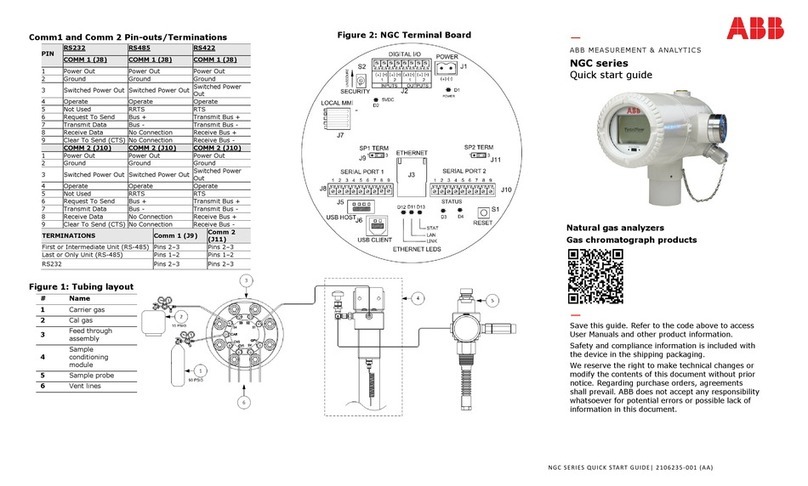

ABB

ABB NGC Series quick start guide

Niagara

Niagara 6600 Series Installation, operation & maintenance manual

Mecmesin

Mecmesin 172100 operating manual

BRIGHT

BRIGHT BlueEye Ex-D operating manual