6

2.2 PREPARING THE BATTERY

The battery must be prepared before it is mounted on the machine. This simple precaution will prevent

the machine from being damaged by the electrolytic liquid of the battery. Always prepare the battery

in a sufficiently ventilated environment. Do not smoke or use flames during this operation (see the

section on battery maintenance). Once the battery has been charged, make sure the electrolytic liquid

containers are stored in a safe place AWAY FROM CHILDREN.

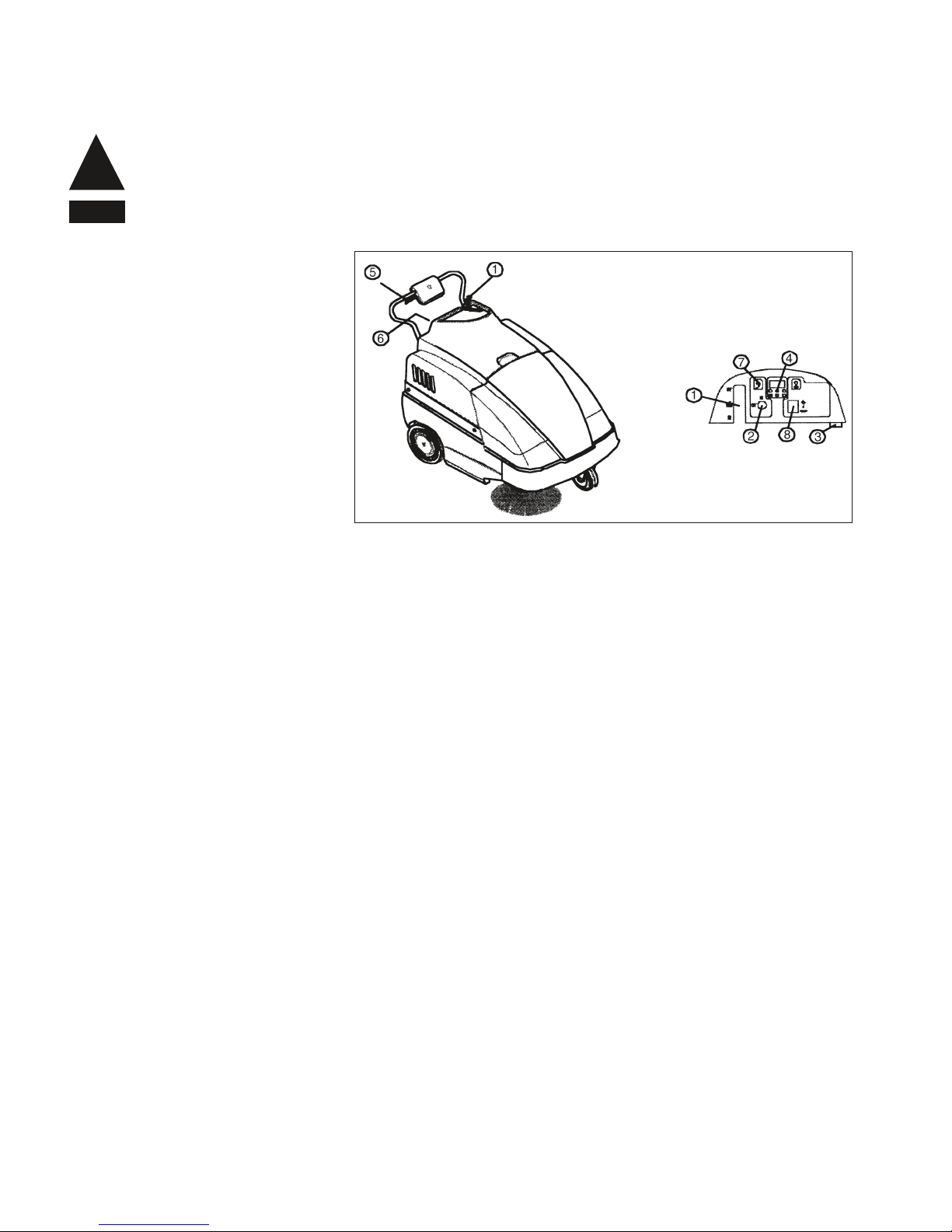

3.1 CONTROLS

1. Side brush control lever: Switch

the lever to ON and the side brush

will move to work position and

start spinning. To stop the brush,

switch the lever to OFF.

2. Key switch: This switch starts

and stops all the machine’s

functions.

3. Battery charger socket:By

plugging a battery charger in this

socket you will recharge the

battery.

4. Charge indicator light: This light indicates the state of the battery during operation.

5. Traction lever: By pressing this lever, the machine will start moving forwards.

6. Filter shaker lever: This lever operates the filter shaker to clean the filter (see the section on filter

maintenance).

7. Mains led

8. Suction switch

4.1 STARTING

ATTENTION! The machine must be used by authorized personnel only. DO NOT leave the machine UNATTENDED

when it is running. Do not use the machine to soak up liquid. Take out the key before leaving the machine. KEEP

THE MACHINE OUT OF THE REACH OF CHILDREN.

To start the machine, carry out the following operations:

- Make sure the side brush (#1, Fig. 3) is OFF.

- Turn the switch (#2, Fig. 3) ON. Wait 10 seconds before the machine sets off.

- Before the machine sets working, check the indicator (#4, Fig. 3) to assess whether the battery is fully charged.

If it is not, proceed to recharge it.

- Pull the traction lever (#5, Fig. 3) to start cleaning.

If necessary, operate lever (#1, Fig. 3) by turning it ON, to start the side brush. If you have been using the side

brush, at the end of your work remember to turn it OFF. Switch off the machine and remove the key from the control

panel. An automatic device will prevent you from using the machine beyond a certain battery charge limit. When

this limit is reached, the machine will stop and the battery must be recharged.

!

NOTE

Fig. 3