EDRO DynaWash DW Series Guide

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

1

INSTALLATION — OPERATION

PARTS MANUAL

THREE POCKET END-LOADING WASHER-EXTRACTORS

RIGID – SOFT MOUNT – PASSTHRU

Technical specications are based on the latest information available

at the time of printing and are subject to change without notice.

Manufactured in accordance to Canadian Standards Association general requirements.

The EDRO Corporation

37 Commerce Street - P.O. Box 308 • East Berlin, CT 06023-0308 USA

Tel. (860) 828-0311 • Fax (860) 828-5984 • Web www.edrocorp.com

Models: DW100, DW150, DW200, DW300 & DW400

Series: DW; DW_SM; DW_PT; DW_PTSM

DW Range:

End-Loading; Rigid Mount

DW_SM Range:

End-Loading; Soft Mount

DW_PTSM Range:

Barrier Type; Soft Mount

DW_PT Range:

Barrier Type; Rigid Mount

Date: Feb, 2016

Part No: MANC-1002 - Revision 6

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

2

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

3

The EDRO Corporation, from here on known as the Seller, warrants all EDRO DynaWash® washer extractors

shipped by it to be free from defects in material and workmanship for a period of eighteen (18) months from the date

of shipment from the Seller’s factory or two-thousand two-hundred operating hours whichever occurs rst, provided:

(a) the machine is used by the original Buyer, (b) it is given normal and proper usage, (c) all electrical and mechani-

cal connections are made in accordance with Seller’s specications, (d) proper installation and start up procedures

are employed by qualied personnel, (e) machine is not altered in any way, shape, or form from it’s original factory

specications, and (f) warranty card is completed and returned to Seller prior to warranty expiration.

Consumable and normal wear items, such as control switches, regulators, solenoids, gaskets, glass, and plastic are

not covered under this warranty. All labor charges incurred during any warranty activity are the sole responsibility

of the Buyer.

Notice of any warranty claim must be presented to the Seller immediately upon Buyer’s discovery of the defect. The

right of inspection must be given to the Seller while the product is in the claimed defective condition, and operation

of the product must be suspended until written clearance is issued for continued operation.

Upon receipt of a warranty claim notice, the Seller will proceed without unreasonable delay to remedy any defect

found to exist under the terms of warranty. During the warranty period, parts found to be defective after the Seller’s

inspection, will, at the Seller’s option, be repaired or replaced with new or factory rebuilt parts free of charge, except

that of freight charges, custom charges, or other associated fees involved with the returning of the defective compo-

nent to the Seller, and shipment of the replacement component will be the responsibility of the Buyer.

Vendor Supplied Items : Vendor supplied items shall be warranted in accordance with the available warranty, if any,

provided to the EDRO Corporation, by the vendor. Claims relating to vendor supplied items will be dealt with on a

case-by-case basis.

Five (5) year pro-rated warranty on shell, cylinder and frame. For a period of ve years, from the date of shipment,

EDRO DynaWash® shells, cylinders and frames are guaranteed not to develop any structural fractures to the

material due to workmanship.

There are no warranties which extend beyond the description and the warranties contained herein. The warranties

expressed herein are in lieu of any other warranties, expressed or implied. Any implied warranty of merchantability

and implied warranty of tness for a particular purpose are hereby excluded. The Buyer’s remedy is limited to, and

the Seller’s liability shall not exceed either, (1) repair or replacement of the defective part of the product or, at the

Seller’s option (2) return of the product and refund of the purchase price. Such remedy shall be the Buyer’s entire

and only remedy.

FAILURE TO COMPLETE AND RETURN WARRANTY REGISTRATION FORM WILL NULLIFY WARRANTY

Battleship Quality

NEW MACHINE LIMITED WARRANTY

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

4

TABLE OF CONTENTS

SECTION 1 Page

Safety 8

Key to Symbols 10

Operator Safety 11

Machine Location 12

Input and Output Services and Requirements 12

Water Pressure 12

Steam Heating (Optional) 12

Electric Heating (Optional) 12

Compressed Air 12

Drainage System 12

Grounding 12

Electrical Overload 12

Misuse 13

Safe Operating Environment 13

End-User Responsibility for Environment Conditions 13

Ambient Temperature 13

Humidity 13

Ventilation 13

Elevation 14

Detergent Chemicals 14

Water Damage 14

SECTION 2

Installation 15

Rigid Mount Models (DW & DW_PT) 15

DynaMount Soft Mount Models (DW_SM & DW_PTSM) 15

PassThru Models (DW_PT & DW_PTSM 16

Foundation 16

Foundation Diagram (Plan View) 17

Grouting 19

Standard Plumbing Connections 19

Pneumatic Connections 19

Standard Electrical Connections 20

Service Connections 21

Plumbing 21

Electrical 21

DynaMount Soft Mount Models (DW_SM & DW_PTSM) 21

Hold Down Bolts 21

Air Pressure Safety Switch 21

Vibration Switch 21

Warranty Registration 21

Installation, On-Site Testing and Operational Checkout Form 22

SECTION 3

Theory of Operation 23

Design and Construction 24

DynOzone - DynaWash®Ozone System 25

Programming - DynOzone 25

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

5

SECTION 3 (con’t)

Theory of Operation - DynOzone 25

System Monitoring During Operation 26

DynOzone - DynaWash®Ozone System Maintenance 27

PowerCell 27

Pump 27

Tubing 27

Fittings 27

Ballast 27

Options 27

Heating: Steam / Electric 27

Extra Drain & Extra Water Inlet (Water Reuse System) 28

Automatic Positioning 28

Safety Features 28

Automatic Braking on Power Failure 28

Positioning Interlock - Cylinder Jog 28

Door Lock 28

Emergency Stop 28

Vibration Switch 29

Customer Service 29

SECTION 4

Machine Operation 30

Before Operation 30

Loading 31

Automatic Operation 31

SECTION 5

Machine Conguration 33

Motor Setup 34

Water Level Setup 34

Ozone/Signal Setup 34

Timers Setup 35

Miscellaneous Congurable Parameters 35

Language Setup 36

Programming 36

Wash/Rinse Step 38

Drain Step 39

Extract Step 40

Operation 42

AutoStart 43

Wash Screen 44

Drain Screen 45

Extract Screen 45

Program Complete 45

Alarms and Warnings 46

Reports 47

Alarms 48

Counters 48

Program History 49

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

6

SECTION 5 (con’t)

Technical Information 50

Onscreen Control Manual 50

Debug Screens 51

Settings 52

Control Information 52

Time & Date Settings 52

Screen Calibration & Brightness/Contrast 52

Password Management 53

Copy Program 54

Clear Program Names 54

Transfer Programs 54

USB Utilities 55

Reset Factory Programs 55

Default Factory Programs 55

Reset Machine Defaults 55

SECTION 6

General Maintenance 56

Periodic Maintenance 56

2 Motor Drive Models Only 57

Inverter with Single Motor Drive Models Only 57

Periodic Maintenance Requirements 57

Lubrication Diagram 58

Maintaining the Clutch 59

Installation 59

To replace discs or repair clutch 59

Maintaining the Brake 60

Installation 60

Lubrication 60

Maintenance 60

Inverter with Single Motor Drive Models Only 60

Maintaining the Bearings 61

Lubrication 61

Removal 61

Installation 61

Solid Seals 62

Bearing Mounting Bolts 62

Torque Requirement 62

SECTION 7

Troubleshooting Guide 63

Introduction 63

DynaTrol 63

Preliminary Troubleshooting 63

General PLC Troubleshooting 64

Troubleshooting Procedures 65

PLC Input and Output Function Description 65

Troubleshooting Guide 66

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

7

SECTION 8

PassThru Models Only 69

Operation 69

PassThru Control System - PushButton and Indicator Functions 69

Operating Instructions 70

Loading (Soiled or Loading) Operations 70

Unloading (Clean or Unload Side) Operations 71

SECTION 9

Parts Reference and Drawings 72

Control Dashboard Operation Lights and Switches 72

Soiled Room Control 72

Clean Room Control Operation Light and Switches PassThru Only 73

Drain Assembly 74

Bearing Assembly 76

Main Water and Automatic Supply Valves 78

Direct Steam Injection 79

Indirect Steam Injection 80

Main Door Assembly 82

Door Latch Assembly 83

Inner Door Assembly 84

Cylinder Assembly 85

Motor Assembly - PassThru Models Only (DW100PT) 86

Motor Assembly - PassThru Models Only (DW150 - DW200PT) 87

Motor Assembly - PassThru Models Only (DW300PT) 88

Motor Assembly - PassThru Models Only (DW400PT) 89

Transfer Shaft Assembly - PassThru Models Only 90

Drive Assembly 92

Brake Assemblies 93

Vibration Sensor 94

Vibration Switch 95

Pneumatic Assembly (Standard) 96

Pneumatic Assembly (Water Reuse System) 98

Automatic Positioning 100

DynaMount Suspension System 101

Variable Speed Motor Wiring 102

Extract Motor Connection 103

2-Motor, Three Speed Wiring 104

Electrical Panel Assembly - Non-PassThru Models Only 105

Electrical Panel Assembly - PassThru Models Only 108

Electrical Schematic Non-PassThru Models Only 110

Electrical Schematic PassThru Models Only 111

Installation, On-Site Testing and Operational Checkout Form 112

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

8

Section 1

SAFETY

Anyone operating or servicing this machine must follow the safety rules in this manual.

Particular attention must be paid to the DANGER, WARNING, and CAUTION blocks, which

appear throughout the manual. The following warnings are general examples that apply to

these machines. Warnings specic to a particular installation or maintenance procedure will

appear in the manual with the discussion of that procedure.

DANGER

Identies a condition, which is not strictly

observed could result in injury to or death

to personnel.

WARNING

Identies an operating or maintenance

procedure, practice, statement, etc.,

which if not strictly observed could result

in injury to or death to personnel.

CAUTION

Identies an operating or maintenance

procedure, practice, condition, statement,

etc., which if not strictly observed could

result in damage to or destruction of

equipment or loss of effectiveness.

NOTE

Identies an essential operating or

maintenance procedure, precondition or

statement which are essential but not of

a known hazardous nature as indicated

by warnings and cautions.

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

9

The following are general CAUTION, DANGER and WARNING notices to be familiar with when working

or servicing the machine.

CAUTION

Be careful around the open door, particularly when loading

from a level below the door. Impact with door edges can

cause personal injury.

WARNING

Dangerous voltages are present in the electrical control

box(s) and at the motor terminals. Only qualied personnel

familiar with electrical test procedures, test equipment, and

safety precautions should attempt adjustments and trou-

bleshooting. Disconnect power from the machine before

removing the control box cover, and before attempting any

service procedures.

DANGER

Death or serious injury can result if children become

trapped in the machine. Do not allow children to play on

or around this machine. Do not leave children unattended

while the machine door is open.

WARNING

This machine must be installed, adjusted, and serviced by

qualied electrical maintenance personnel familiar with the

construction and operation of this type of machinery. They

must also be familiar with the hazards involved. Failure to

observe this warning may result in personnel injury and/or

equipment damage, and may void the warranty.

CAUTION

Ensure that the machine is installed on a level oor of

sufcient strength and that the recommended clearance for

inspection and maintenance are provided. Never allow the

inspection and maintenance space to be blocked.

WARNING

Never touch internal or external steam pipes, connections,

or components. These surfaces can be extremely hot and

will cause severe burns. The steam must be turned off and

the pipe, connections, and components allowed to cool to

a safe temperature before the pipe can be touched.

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

10

KEY TO SYMBOLS

The Lightning bolt within the triangle is a warning sign indicating the presence of dangerous

voltage.

The exclamation point within the triangle is a warning sign indicating important instructions

concerning the machine and possibly dangerous conditions.

This warning symbol indicates the presence of potentially dangerous drive mechanisms and

possibly dangerous pinch points within the machine. Moving mechanical parts can crush

and/or sever body parts. Guards should always be in place when the machine is in operation.

This warning symbol indicates the presence of possibly dangerous chemicals. Proper

precautions should be taken when handling corrosive or caustic materials.

This warning symbol indicates the presence of hot surfaces that could cause serious burns.

Steel and steam lines can become extremely hot and should not be touched.

Safety decals appear at crucial locations on the machine. Failure to maintain legible safety

decals could result in injury to the operator or service technician. To provide personal safety

and keep the machine in proper working order, follow all maintenance and safety procedures

presented in this manual. If questions regarding safety arise, contact the factory immediately.

Use factory-authorized spare parts to avoid safety hazards.

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

11

OPERATOR SAFETY

To ensure the safety of the machine operators, the following maintenance checks must be

performed daily:

Prior to operating the machine, verify that all warning signs are present and legible. Missing or

illegible signs must be replaced immediately. Make certain that spares are available.

Check door interlock before starting operation of the machine. Attempt to start the machine

with the door open. The machine should not start with the door openand an alarm should sound.

If the door lock and interlock are not functioning properly, call a service technician.

Do not attempt to operate the machine if any of the following conditions are present:

a. The door does not remain securely locked during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly grounded circuit.

DO NOT BYPASS ANY SAFETY DEVICES IN OR ON THE MACHINE.

WARNING

NEVER insert hands or objects into cylinder until it has

completely stopped. Doing so could result in serious injury.

WARNING

NEVER operate the machine with a bypassed or discon-

nected vibration switch or sensor. Operating the machine

with severe unbalanced loads could result in personal

injury and serious equipment damage.

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

12

MACHINE LOCATION

Foundation: The concrete oor must be of sufcient strength and thickness to handle the oor

loads generated by the high extract speeds of the machine.

Service/Maintenance Space: Provide sufcient space to allow comfortable performance of

service procedures and routine preventative maintenance.

CAUTION

Replace all panels that are removed to perform service and

maintenance procedures. Do not operate the machine with

missing guards or with broken or missing parts. Do not

bypass any safety devices.

INPUT AND OUTPUT SERVICES AND REQUIREMENTS

Water Pressure: Best performance will be realized if water is provided at a pressure of 30-85

PSI (2.0-5.7 bar). Although the machine will function at a lower pressure, increased ll times

will occur. Water pressure higher than 100 PSI (6.7 bar) may result in damage to machine

plumbing. Component failure(s) and personal injury could result.

Steam Heating (Optional): Best performance will be realized if steam is provided at a pressure

of 30-80 PSI (2.0-5.4 bar). Steam pressure higher than 125 PSI (8.5 bar) may result in

damage to the machine and may cause personal injury. For machines equipped with optional

steam heating, (either direct or indirect), install piping in accordance with approved commercial

steam practices. Failure to install the supplied steam lter may void the warranty.

Electric Heating (Optional): For best performance, size the power source to the power rating of

the heating element and in accordance with local codes. A qualied electrician must determine

the amount of power supplied.

Compressed Air: Air source should provide pressure between 80-100 PSI (5.4-6.7 bar).

Drainage System: Provide drain troughs large enough to accommodate the total number of

gallons that could be dumped if all machines on the site drained at the same time from the

highest attainable level. Troughs should be covered to support light foot trafc.

Grounding: For personal safety and for proper operation, the machine must be grounded in

accordance with State and Local Codes. The ground connection must be to a proven earth

ground, not to conduit or water pipes.

Electrical Overload: Do not use fuses in place of a circuit breaker. Each machine should be

connected to a separate circuit breaker, with proper suppression devices for the machine. The

circuit breaker must be an inverse time type. An easy-access disconnect switch should also

be provided. These components must conform to the latest National Electric Code (NEC) and

State and Local Codes.

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

13

WARNING

Ensure that a ground wire from a proven earth ground is

connected to the ground lug near the input power block

on this machine. Without proper grounding, personal injury

from electric shock could occur and machine malfunctions

may be evident.

MISUSE

Never wash petroleum-soaked rags in machine. This could result in an explosion.

Never wash mechanical parts or automotive parts in machine. This could result in serious

damage to the cylinder.

Never allow children to play on or around machine. Death or serious injury can result if

children become trapped in machine. Do not leave children unattended while machine door is

open. These cautions apply to animals as well.

Always disconnect power and water supplies before a service technician performs any service

procedure. Where applicable, steam supply should also be disconnected before service is

performed.

SAFE OPERATING ENVIRONMENT

Safe operation requires an appropriate operating environment for both the operator and the

machine. If questions regarding safety arise, contact EDRO immediately.

END-USER RESPONSIBILITY FOR ENVIRONMENT CONDITIONS

Ambient Temperature: Temperatures above 120º F (50º C) will result in more frequent motor

overheating and in some cases, malfunction or premature damage to solid state components.

Special cooling devices may be necessary. Increases and decreases in temperature affect

water pressure switches. Every 25º F (10º C) change in temperature will have a 1% effect on

the water level. Water in the machine will freeze at temperatures of 32º F (0º C) or below.

Humidity: Relative humidity above 90% may cause the machine’s electronics or motors to

malfunction or may trip the ground fault interrupter. A corrosion problem may occur on some

metal components in the machine. If the relative humidity is below 30%, belts and rubber

hoses may eventually develop dry rot. This condition can result in hose leaks, which may

cause safety hazards external to the machine in conjunction with adjacent electrical equipment.

Ventilation: The need for make-up air openings for the washer-extractor and other laundry

room accessories such as dryers, ironers, water heaters, etc. must be evaluated periodically.

Louvers, screens, or other separating devices may reduce the available air opening signicantly.

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

14

Elevation: If the machine is to be operated at elevations of over 3,280 feet (1,000 meters)

above sea level, pay special attention to water levels and electronic settings (particularly

temperature) or desired results may not be achieved.

Detergent Chemicals: Keep all steel surfaces free of chemical residues. Damage to any

part of the machine caused by corrosion resulting from the use of concentrated chemicals

will impede machine performance and is specically excluded from warranty.

DANGER

Do not place volatile or ammable uids in any machine.

Do not clean the machine with volatile or ammable

uids such as acetone, lacquer, thinners, enamel reducers,

carbon tetrachloride, gasoline, benzene, etc. Doing so

could result in serious personal injury and/or damage to

the machine.

Water Damage: Do not spray the machine with water. Short circuiting and serious damage

may result. Immediately repair all seepage due to worn or damaged gaskets, etc.

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

15

Section 2

It is the responsibility of the Installer to check and complete the

following items upon installation of the machine.

The installation procedure of your DynaWash® washer-extractor should not take more than one

day to complete. Except for re-connecting certain parts disconnected in shipping, no internal

assembly or wiring is necessary. By reading these instructions carefully and following the

recommended procedures, you will not only save time, but should avoid many unnecessary

complications and possible future problems.

INSTALLATION

For installing DynaWash® Rigid Mount Models (DW100, DW150, DW200, DW300, DW400, and

DW100PT, DW150PT, DW200PT) the ground oor thickness must be at least 12” (ref. page 17),

and must be constructed of the equivalent of 5,000 PSI re-enforced concrete. For upper oor

installations, check with a structural engineer to verify the capability of the oor to support the

machine’s static operating weight. Static operating weight is equal to the machine weight, a full

load of laundry and 100% full water. Before positioning the machine, be sure to have adequate

oor area to achieve a level foundation. Existing oors should be lled in if necessary to obtain

the area needed for a proper installation. DynaWash® rigid mount models with down drain are

designed to straddle a drain trough. Models with drain to rear option are designed to be piped

to a sewer drain. It is required that all factory supplied mounting holes in the base footings of

the machine be used to anchor the machine to the oor.

RIGID MOUNT MODELS (DW & DW_PT)

For installing DynaWash® with DynaMount Soft Mount option (DW100SM, DW150SM,

DW200SM, DW300SM, DW400SM, and DW100PTSM, DW200PTSM, DW300PTSM DW-

400PTSM), the oor thickness must be constructed of the equivalent of 5,000 PSI re-enforced

concrete and able to support the machine’s static operating weight. For upper oor installations,

check with structural engineer to verify the capability of the oor to support the machine’s static

operating weight. Static operating weight is equal to the machine weight, a full load of laundry

and 100% full water. Even though the deection of vibration is less than 5%, before position-

ing the machine, be sure to have adequate oor area to achieve a level foundation. This is

important so that the washer can maintain a stable and level operating environment and not

put undue stress on any components of the suspension system. To achieve this condition, the

existing oor should be lled in if necessary to obtain the area needed for a proper installation.

We require the existing four (4) holes in the machine’s base be used for anchoring the base of

the machine to the oor.

The shock absorbers and reverse loaded coil springs on DynaMount units are pre-adjusted at

the factory, however, nal adjustments maybe necessary and should be made as follows:

DYNAMOUNT SOFT MOUNT MODELS (DW_SM & DW_PTSM)

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

16

Tighten shock nuts snug at upper and lower locations. DO NOT CRUSH THE RUBBER

BUSHINGS!

Main spring shafts should have two (2) full threads extending beyond lower locks nuts to

ensure proper locking action.

To achieve the required operating clearance or if leveling is required, rst determine which

spring assembly is out of level, then loosen the locking nut and either tighten or loosen the

adjusting nut located on the threaded rod at the top of the main spring shaft assembly.

Perform this operation in intervals of two (2) full turns at a time to compress or release the

reverse loaded coil spring. Repeat as necessary. Once level, tighten the lock nut. For

optimum performance, DynaWash® washer-extractors should be level left to right, as well as

front to back. Minimum distance from the bottom of the front and rear plate to the top of the

base plate is 1-1⁄4 ” (3.175 cm).

•

•

•

The PassThru option of DynaWash® machines, DW_PT and DW_PTSM, differs from the other

models by its construction allowing the machine to be loaded from one side and unloaded from

the other. The operation and the performance of these machines are identical with the standard

end loading DynaWash® units. PassThru units require the installation of the clean side seal.

The superstructure of the clean side seal goes between clean side of unit and barrier wall. The

clean side plate of the machine has bolts studded to it to assist in assembly of the barrier

material from the machine to the barrier wall.

PASSTHRU MODELS (DW_PT & DW_PTSM)

It is vitally necessary to provide a proper foundation for DynaWash® machines. Anchor the

machine to the oor by either pouring a new foundation in accordance with factory specications

or install on existing oor. In either case, the foundation should be constructed of 5,000 PSI

re-enforced concrete. For installations on upper oors, check with a structural engineer to verify

the capability of the oor to support the machine’s static weight and forces once in operation.

For best machine performance, it is recommended that DynaWash® straddle a drain trough,

unless the drain to rear option is ordered in which case the machine should be piped directly to

a sewer drain. The drain trough should have a capacity to sustain the maximum amount of

water for all machines at the site if all washers were to simultaneously drain from their high

water level.

Minimum foundation requirements can be found on the following charts. For reference, the

minimum foundation requirement for DynaMount Soft Mount models (DW_SM & DW_PTSM)

is ability of oor to support the static weight of a fully loaded machine taking into account a 5%

variance for vibration deection. Variations may be made to suit a specic installation as long

as minimum and/or maximum requirements are met.

FOUNDATION

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

17

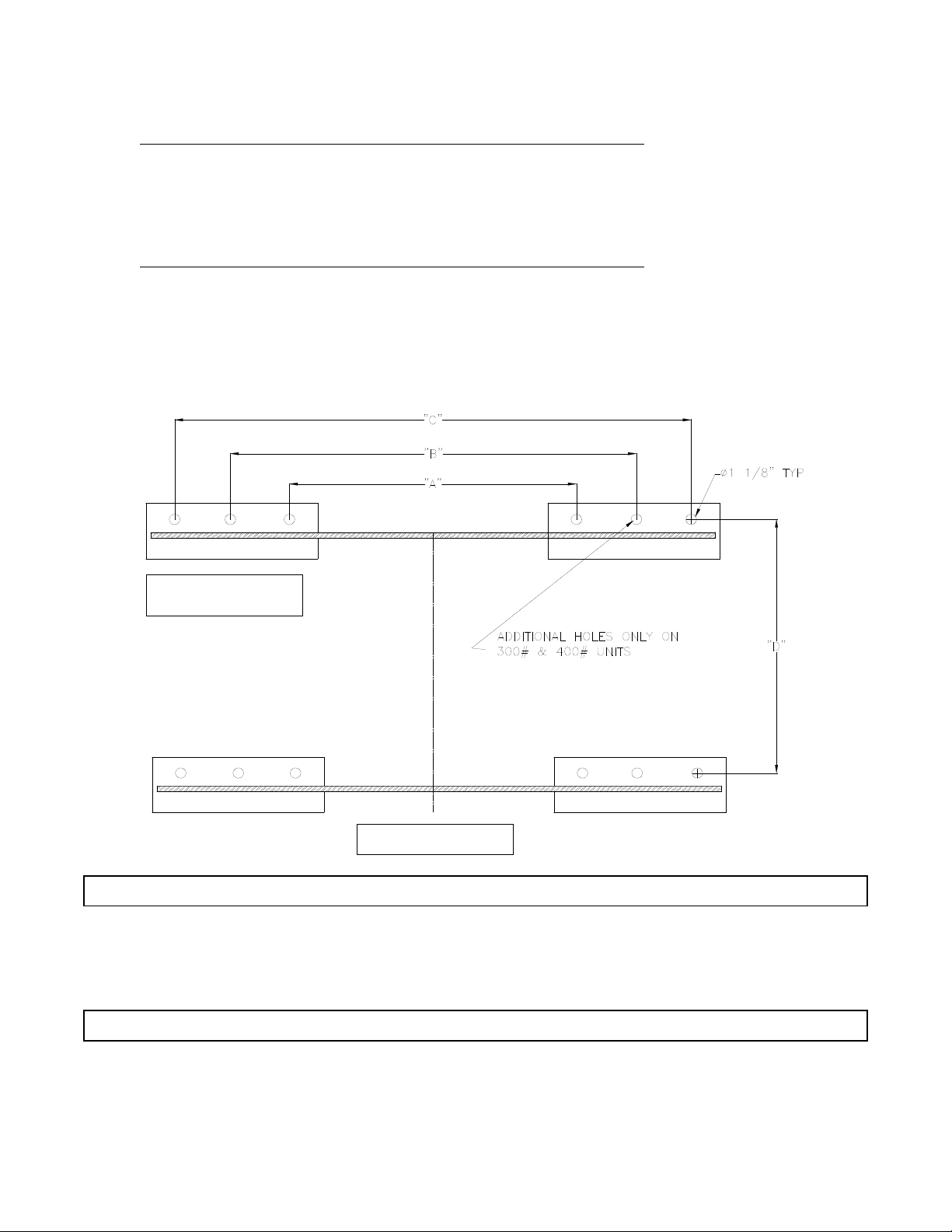

MINIMUM FOUNDATION REQUIREMENT

DW100 DW150 DW200 DW300 DW400

12” 16” 16” 18” 20”

DW100 DW150 DW200 DW300 DW400

18” 18” 20” 24” 24”

MAXIMUM TRENCH WIDTH

MAXIMUM TRENCH WIDTH

DW (End-Loading Rigid Mount) & DW_PT (PassThru Rigid Mount)

Plan View of Machine

Footprint

Machine Front

DW

DW_PT

Dimension 100 150 200 300 400

A23 30 30 35 1⁄243

BN/A N/A N/A 47 1⁄255

C47 54 54 59 1⁄267

D31 32 5⁄839 5⁄849 1⁄449 1⁄4

Dimension 100 150 200 300 400

A35 1⁄249 49 N/A N/A

BN/A N/A N/A N/A N/A

C59 1⁄273 73 N/A N/A

D27 7⁄829 36 1⁄8N/A N/A

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

18

DW_SM (End-Loading Soft Mount) & DW_PTSM (PassThru Soft Mount)

Machine Front

DW_SM

Dimension 100 150 200 300 400

A82 88 90 92 100

B38 41 5⁄848 3⁄857 57

DW_PTSM

Dimension 100 150 200 300 400

A92 99 101 102 3⁄8108

B38 40 5⁄847 3⁄857 55

NOTE

Drawings reect standard production models. Options

such as Electrical Right (ER) will effect foundation layout.

NOTE

All dimensions are in inches.

NOTE

To avoid alignment errors install foundation bolts after

machine placement.

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

19

It is very important to understand that proper grouting of DynaWash® machines will result in

best performance. Correct grouting will assure perfect alignment of the machine with the oor.

GROUTING

View of Bolting and

Grouting Requirement

RIGID MOUNT MODELS (DW & DW_PT):

First, make the foundation level and at. Next, pour grout in area that the base of the machine

will be located. Then lower the machine on the grouted area evenly. Check level front to back

and side to side. Pull down high side(s) using foundation bolts. Allow grout to harden. Install

all at washers and lock washers and tighten all nuts. After service connections are made run a

cycle and recheck that all nuts are tight. Make periodically checks as follows:

1. Daily for one (1) week.

2. Weekly for one (1) month.

3. Set up periodic inspection. (Section 6).

DYNAMOUNT SOFT MOUNT MODELS (DW_SM & DW_PTSM):

Install Soft Mount models as in paragraph above. Before loading and running the rst cycle

adjust the suspension system to the following measurements. Bottom of front plate to base

must be 1 1⁄4” and front plate must be level side to side. Bottom of rear plate to base must be 1

1⁄8” and rear plate must be level side to side. When machine is fully loaded with water it should

be level front to back.

STANDARD PLUMBING CONNECTIONS

PNEUMATIC CONNECTIONS

All DynaWash® machines require a single compressed air source of three-quarter (1⁄4”) NPT at a

minimum of 80 PSI (5.4 bar).

DW100 DW150 DW200 DW300 DW400

Inlet Valve 11⁄4” 2” 2” 2” 2”

Drain Valve 4” 6” 6” 8” 8”

NOTE

Reference installation drawings for proper length of J-bolt

and concrete depth per model.

EDRO Dy n a Wa s h ®T h r e e P o c k e T W a s h e r - e xTracTors

20

STANDARD ELECTRICAL CONNECTIONS

DW100 DW150 DW200 DW300 DW400

Wire Size #6 AWG #6 AWG #6 AWG #2 AWG #2 AWG

Circuit Breaker 30 AMP 50 AMP 50 AMP 100 AMP 100 AMP

208 - 240 volts / 3 phase / 60 cycle:

440 - 480 volts / 3 phase / 60 cycle:

DW100 DW150 DW200 DW300 DW400

Wire Size #12 AWG #10 AWG #10 AWG #6 AWG #6 AWG

Circuit Breaker 20 AMP 25 AMP 25 AMP 50 AMP 50 AMP

380 - 415 volts / 3 phase / 50 cycle:

DW100 DW150 DW200 DW300 DW400

Wire Size #10 AWG #8 AWG #8 AWG #6 AWG #6 AWG

Circuit Breaker 25 AMP 30 AMP 30 AMP 60 AMP 60 AMP

NOTE

Options such as Water Reuse System and Electric Heating

Element will require larger wire sizes and must be

determined at site by a qualied electrician. Contact

Factory for Electrical Connections not listed.

2 MOTOR - 3 SPEED DRIVE

DW100 DW150 DW200 DW300 DW400

Wire Size #6 AWG #6 AWG #6 AWG #2 AWG #2 AWG

Circuit Breaker 30 AMP 30 AMP 50 AMP 80 AMP 100 AMP

230 volt / 3 phase / 60 cycle:

460 volt / 3 phase / 60 cycle:

DW100 DW150 DW200 DW300 DW400

Wire Size #12 AWG #10 AWG #10 AWG #6 AWG #6 AWG

Circuit Breaker 20 AMP 20 AMP 25 AMP 40 AMP 50 AMP

SINGLE MOTOR

This manual suits for next models

20

Table of contents