Beton Trowel BTS-35H User manual

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

1/14

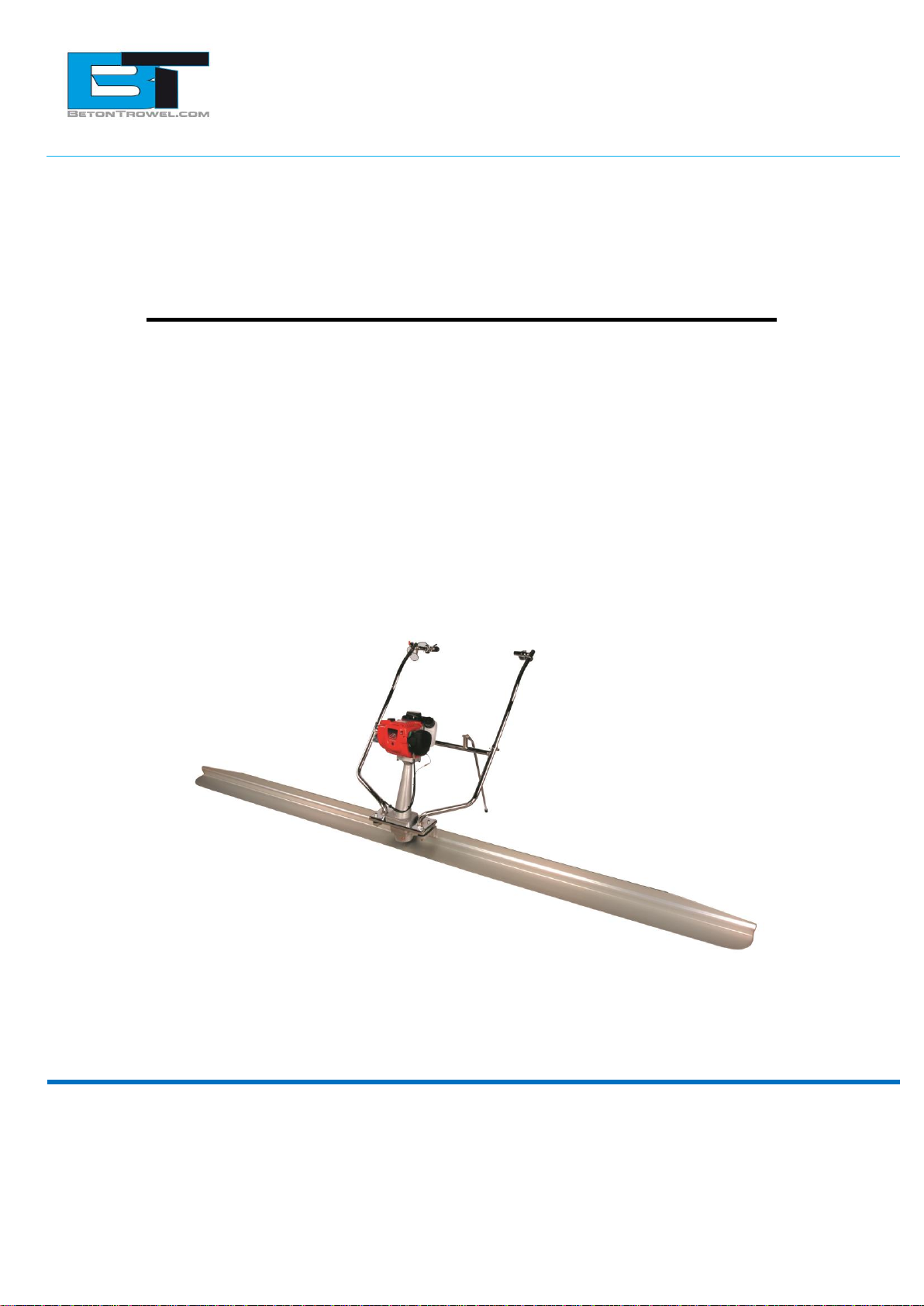

INSTRUCTION MANUEL

BETON SCREED

BTS-35H

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

2/14

Use this guide along with the parts lists attached to locate and identify components of

your screed. When ordering replacement parts, be sure to provide the model number

and serial number.

Copyright

© Copyright 2011 by Beton Trowel.

Contact

BETON TROWEL

Nijverheidsstraat 11

1840 Londerzeel

BELGIUM

www.betontrowel.com

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

3/14

Foreword

Quality assurance / machine break in

The machine is the product of extensive engineering development designed to give long life

and unmatched performance. The screeds are shipped fully assembled, and only require

filling with fuel and a brief check of lubricant levels in preparation for operation.

You can help ensure that your screed will perform at top levels by observing a simple routing

on first use. Consider that your new screed is like a new car. Just as you would break in a

new car to the road or any new machine to the job, you should start gradually and build up to

full use. Learn what your machine can do and how it will respond. Refer to the engine

manufacturer’s manual for run-in times. Full throttle and control may be used after this time

period, as allowed by material. This will serve to further break in the machine on your specific

application, as well as provide you with additional practice using the machine.

We thank you for the confidence you have placed in us by purchasing a Beton Trowel

machine and wish you many years of satisfied use.

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

4/14

Table of contents

Foreword 3

1 Safety precautions 5

2 Setup of the screed 6

3 Operation 7

1 Operation principal 7

2 Starting procedure: warm climate 7

3 Starting procedure: cold climate 7

4 Stopping procedure 7

5 Operation 8

6 Lubrication 8

4 Maintenance 9

1 Maintenance plan 9

2 Service 10

5 Labels 11

6 Specifications 12

1 Technical data sheet 12

2 Parts 13

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

5/14

1 Safety precautions

Do not use the screed, fitted with a gasoline engine, indoors or in poorly

ventilated areas. Ensure there is sufficient ventilation to avoid inhaling exhaust

gasses, as they may be harmful.

Avoid touching the electrical cables or spark plug cap while the engine is running to

avoid electric shock.

Check the fuel tank and lines for leaks before starting engine.

Wear appropriate personal protective equipment while operating the screed.

Protective footwear, safety glasses, hearing protection, padded gloves, and a dust

mask are highly recommended.

Wear work gloves and safety glasses while refueling the screed.

Ensure sufficient ventilation during refueling to avoid a build-up of dangerous fumes.

Refuel the screed only after the engine has cooled after use.

Avoid smoking or open ignition sources such as furnaces, welders or torches during

refueling.

Avoid contact of limbs with the vibrating blade or base unit during operation. Use only

the handles to control the screed.

Some vibration in the control handles during operation is normal. Take appropriate

measures dictated by your workplace regulations to minimize health effects of

vibration exposure.

Regular maintenance and inspection of the screed can prevent injuries caused by

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

6/14

2 Initial setup

Upon removing the screed from its box for the first time, you will find the base unit

with the handles removed for shipping. The left handle is sitting freely in the box,

while the right handle is attached to the base unit by its electrical cable and throttle

control cable. The throttle control cable is not connected to the engine during

shipping to avoid damage to the cable and engine.

To connect the throttle cable, first set up the handles using the clamps and hex key

provided. Set the length and rotation to suit the operator. Then:

Open the Honda engine air filter cover by gently squeezing the clip on the

inside front of the black filter housing, and rotate the housing cover back out of

the way.

Pull the throttle cable over to the engine throttle wheel.

Rotate the silver throttle wheel so that the larger hole is pointing toward the

top of the engine.

-Slide the stainless steel throttle cable through the slotin the throttle wheel.

Pull the stainless steel throttle cable downward to insert the slug fitting into the

large hole in the throttle wheel.

Place the threaded fitting of the throttle cable conduit into the clamp below the

throttle wheel.

Tighten the nuts of the threaded fitting onto the clamp to lock the conduit in

place. Adjust the tension and length of the throttle cable by moving these nuts.

With the throttle grip at the end of the right operator handle released, the

throttle wheel on the Honda engine should be at the zero position.

-After verifying the operation of the throttle cable by squeezing the throttle

grip a few times, replace the air filter cover on the Honda engine. Your

screed is now ready to use!

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

7/14

3 Operation

1 Operating principal

An eccentric weight mounted on the exciter shaft contained within the vibration housing is

driven at high speed by a clutch drive system. This high speed shaft revolution causes the

rapid vibratory motion of the blade as well as imparting a forward motion.

The screed is designed to run at an engine speed (engine take off shaft) of 3600 rpm.

(normally considered full throttle). Running the engine at lower rpm’s will result in a decrease

of consolidation force and lower travel speed. It will create excessive “out-of-synch”

vibrations resulting in poor consolidation, maneuverability, excessive wear to the machine,

and discomfort to the operator.

2 Starting procedure: warm climate

Open fuel valve on gas tank. Set throttle lever to “Fast” idle position, set choke to closed

position, start engine. Open choke slightly to prevent flooding. Move to “Open” or “Run”

position when engine is warm, increase throttle to maximum operation position (3600 rpm).

3 Starting procedure: cold climate

Follow same procedure as above but allow longer warm-up period –3 to 5 minutes. In cold

weather, oil is much heavier to move and requires more time to work its way into the moving

parts. If maximum power is not attained, allow further warm-up time. Fill fuel tank with clean

gasoline, use safety approved gas containers. DO NOT MIX OIL WITH GASOLINE –USE

UNLEADED GAS ONLY.

4 Stopping procedure

Throttle engine down.

Depress or turn off stop switch

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

8/14

5 Operation

On level surfaces the screed moves forward or backward rapidly, depending on the

tilt of the handle. On uneven surfaces or inclines, light forward pressure on handle

may be required to assist the screed in moving. Lean the handle up or away from you

to make the screed travel toward you (i.e. forward). Lean the handle down or toward

you to make the screed travel away from you (i.e. backward).

ALWAYS OPERATE THE MACHINE AT FULL THROTTLE. If excessive vibration is

felt through the handle, do not operate until the engine is checked and set at its

maximum running speed of 3600 rpm.

The handle has four (4) adjustment clamps to allow the operator to use the screed

more comfortably. Ensure that the screws of all of these clamps are tightened to

securely hold the handle sections rigidly. A loose clamp will cause that section to

rotate and/or slide away from the desired position.

6 Lubrication

ENGINE OIL: Always check engine oil before starting and at regular intervals

thereafter. Use proper engine oil as recommended –see chart below. Keep engine oil

clean, change accordingly. Fill crankcase to levels as recommended in

manufacturer’s engine manual.

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

9/14

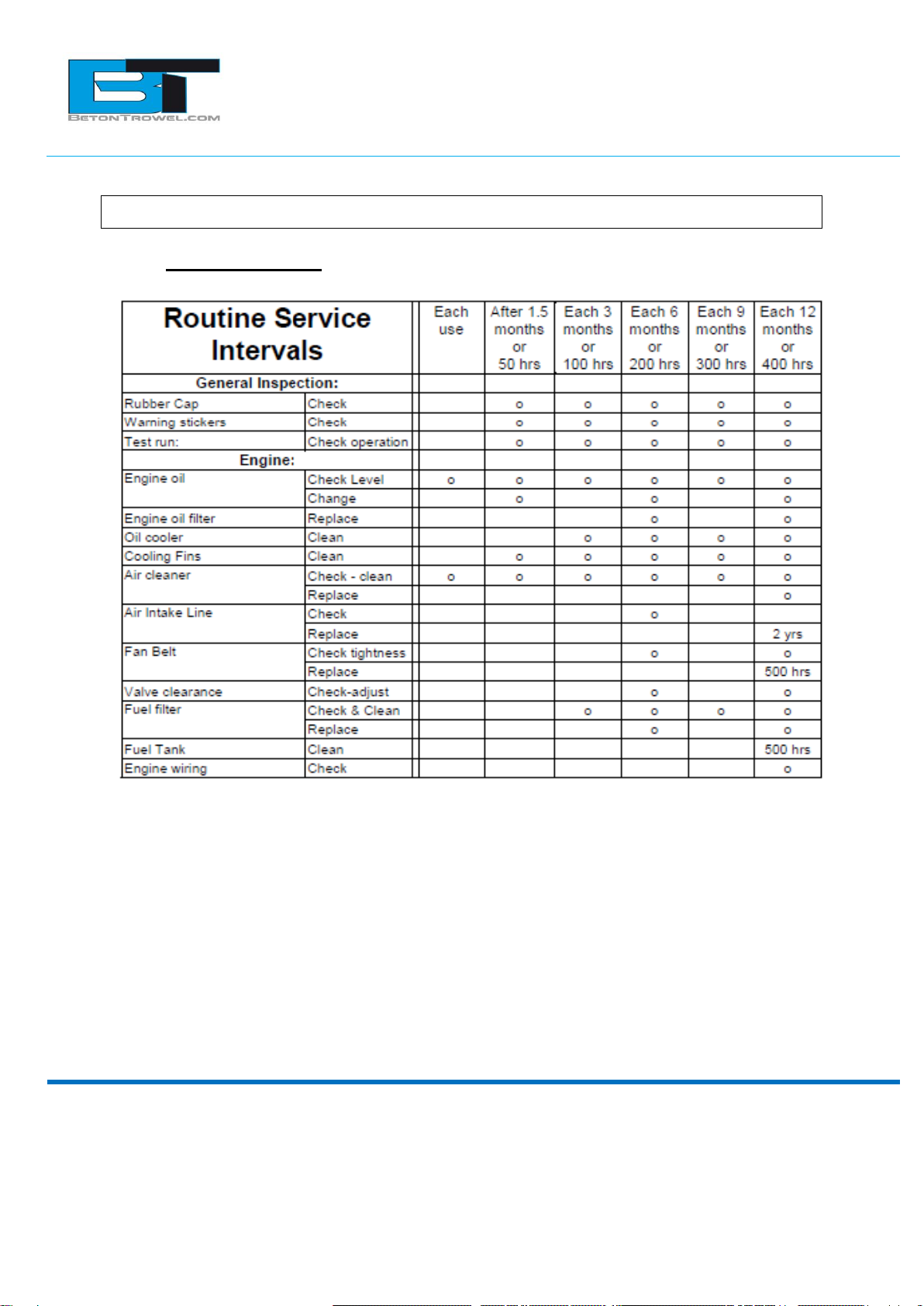

4 Maintenance

1 Maintenance plan

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

10/14

2 Service

Due to the nature and environment of use, the machines could be exposed to severe

operating conditions. Some general maintenance guidelines will extend the useful life of your

Screed.

It is highly recommended that all maintenance and repairs are carried out by

approved dealers.

Always use genuine replacement parts; use of foreign parts may void your warranty

and result in injury or damage to property.

Refer to your engine manual for details of engine cleaning, maintenance, and your

engine’s warranty coverage.

Clean concrete, dust, and residue from the blade and base unit daily. Failure to do so

will result in decreased performance and premature failure.

The blade and lower base unit (i.e. below the engine) can be cleaned with a water

sprayer. Avoid getting water inside the engine housing or into the on/off switch on the

handle.

Clean the engine ventilation openings using a brush or damp cloth. Dirt, grease, or

concrete entering the ventilation openings will reduce engine cooling, leading to

premature engine wear and failure. Refer to your engine manual for more information.

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

11/14

5 Labels

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

12/14

Specifications

1 Technical data sheet

MODEL

BTS35H

ENGINE

HONDA GX35 1.3 HP 4-STROKE

WEIGHT (WITHOUT BLADE)

12.7 KG

SOUND POWER

50 dBA

VIBRATION (HANDLE)

< 9 M/S SQ

BLADE

SIZE

WEIGHT

1.2 M

2.9 KG

1.8 M

4.4 KG

2.4 M

5.8 KG

3.0 M

7.3 KG

3.7 M

8.7 KG

4.5 M

10.2 KG

4.9 M

11.6 KG

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

13/14

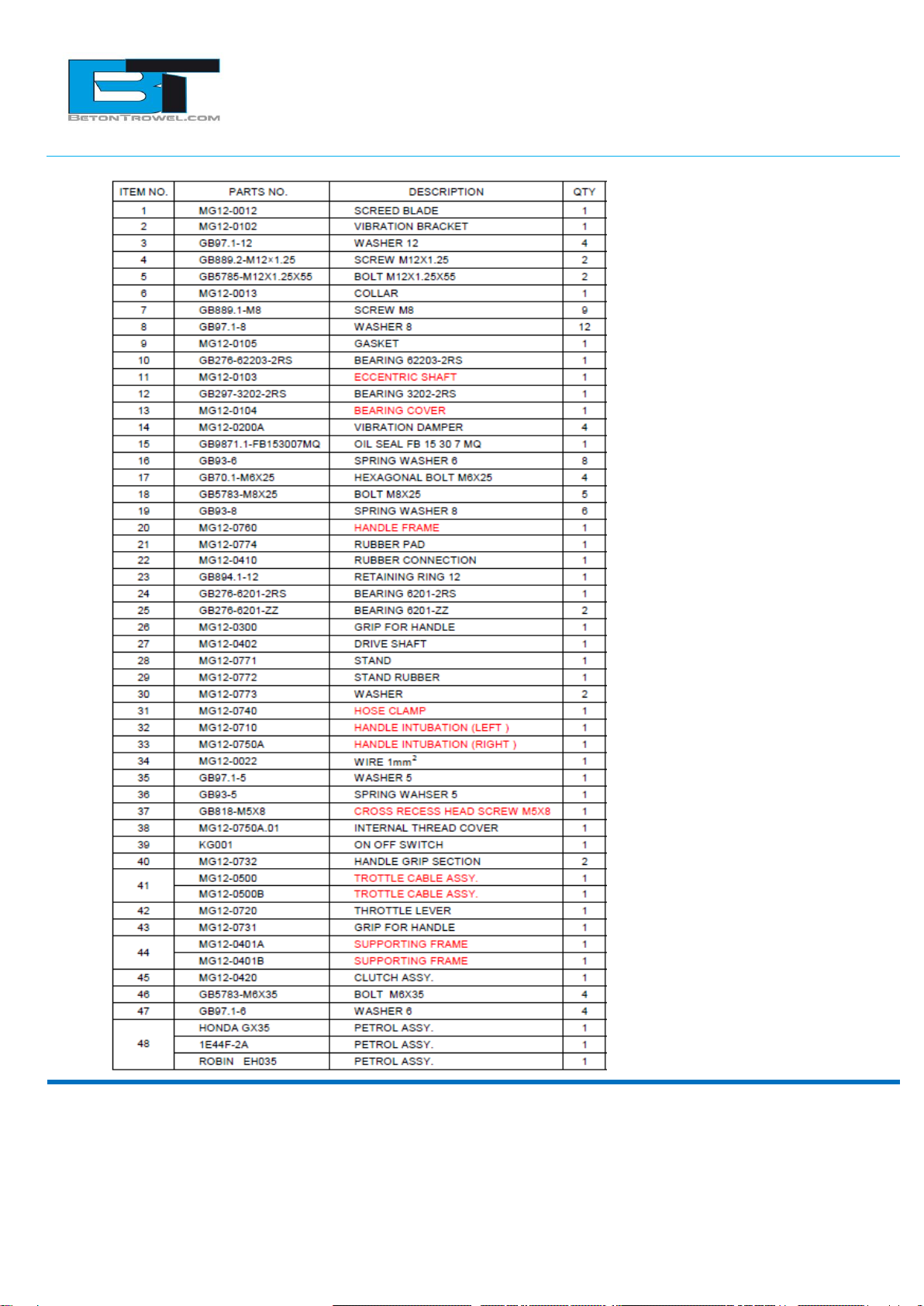

2 Parts

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

14/14

Table of contents

Other Beton Trowel Trowel manuals

Popular Trowel manuals by other brands

MULTIQUIP

MULTIQUIP Whiteman series Operation manual

MULTIQUIP

MULTIQUIP Whiteman STXD6i Operation manual

MQ Multiquip

MQ Multiquip JS36/30H55DE Series Operation and parts manual

MULTIQUIP

MULTIQUIP hhn34tvdtcsl4 Operation manual

Husqvarna

Husqvarna BG Combi Operator's manual

WACKER Group

WACKER Group CT 30 Series Repair manual