Beton Trowel BT90HF160 User manual

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

1/32

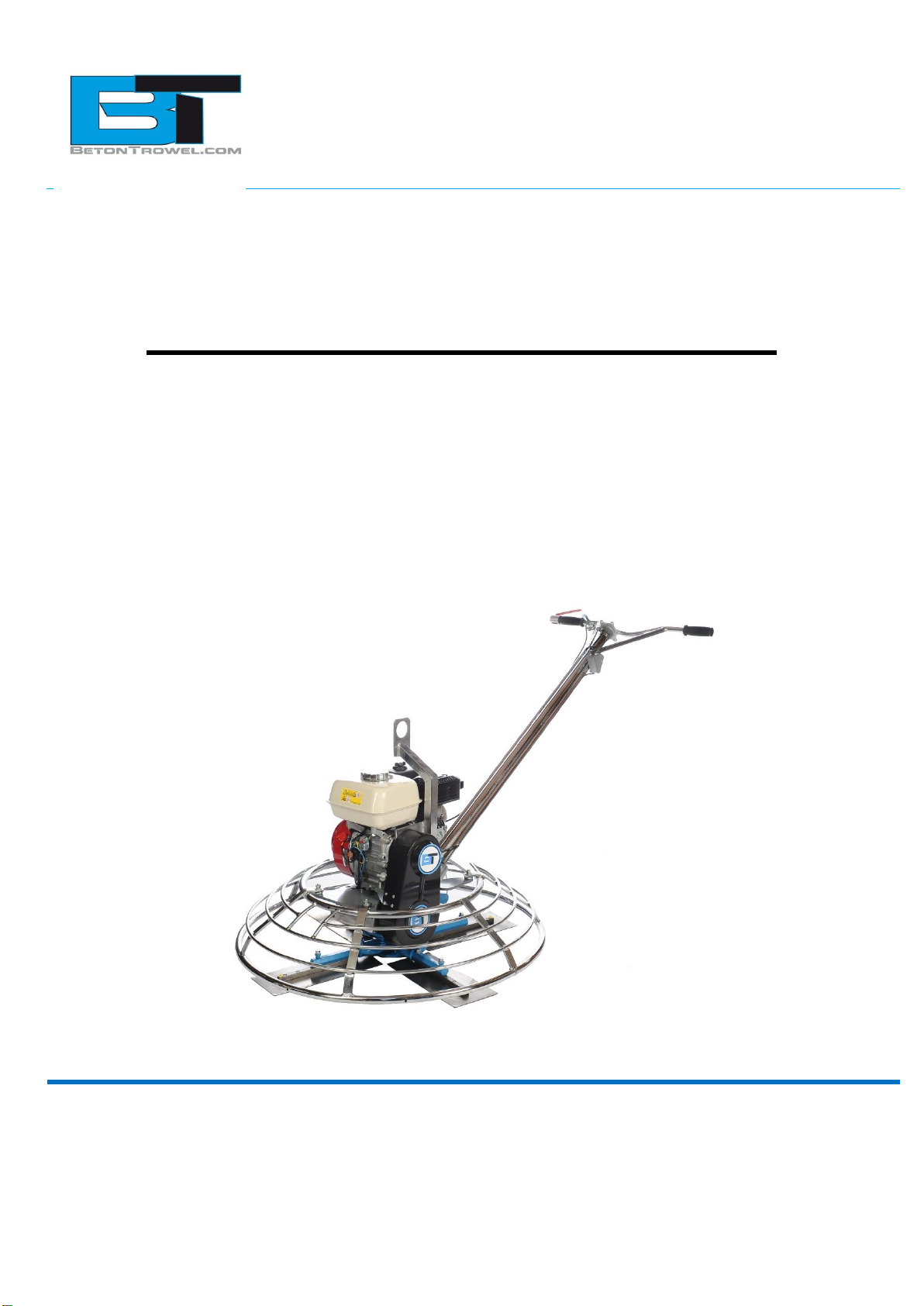

INSTRUCTION MANUAL

POWER TROWEL

BT90H160 –BT90H270 –BT90E

BT90HF160 –BT90HF270 –BT90YDK

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

2/32

Use this guide along with the parts lists attached to locate and identify components of

your trowel. When ordering replacement parts, be sure to provide the model number

and serial number from the trowel.

Copyright

© Copyright 2011 by Beton Trowel.

Contact

BETON TROWEL

Nijverheidsstraat 11

1840 Londerzeel

BELGIUM

www.betontrowel.com

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

3/32

Foreword

Quality assurance / machine break in

The machine is the product of extensive engineering development designed to give long life

and unmatched performance. The trowels are shipped fully assembled, and only require

filling with fuel and a brief check of lubricant levels in preparation for operation.

You can help ensure that your trowel will perform at top levels by observing a simple routing

on first use. Consider that your new trowel is like a new car. Just as you would break in a

new car to the road or any new machine to the job, you should start gradually and build up to

full use. Learn what your machine can do and how it will respond. Refer to the engine

manufacturer’s manual for run-in times. Full throttle and control may be used after this time

period, as allowed by material. This will serve to further break in the machine on your specific

application, as well as provide you with additional practice using the machine.

We thank you for the confidence you have placed in us by purchasing a

Beton Trowel machine and wish you many years of satisfied use.

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

4/32

Table of contents

Foreword 3

Operation 5

1 Use 5

2 Safety precautions 5

3 BT90E 6

4 OPERATION (Floating) 7

5 OPERATION (Finishing) 7

6 STARTING PROCEDURE: *WARM CLIMATE 7

7 STARTING PROCEDURE: *COLD CLIMATE 8

8 STOPPING PROCEDURE 8

9 TRANSPORTING 8

10 Lubrication 8

11 Storage 9

Maintenance 10

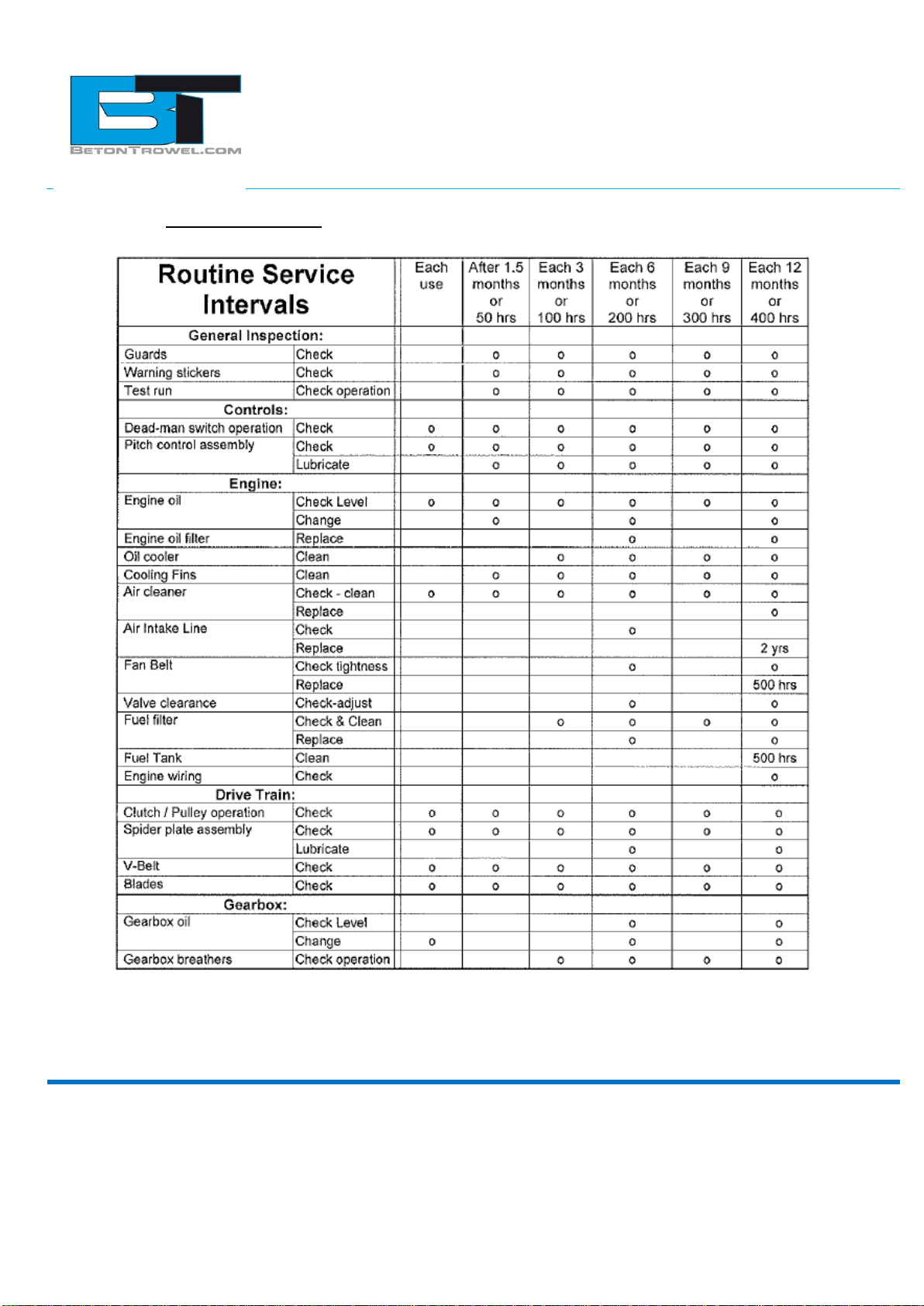

1 Preventative maintenance and routine service plan 10

2 Maintenance plan 11

3 Service 12

Labels 13

Specifications 14

1 Technical data sheet 14

2 Parts 15-31

Declaration of Conformity 32

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

5/32

Operation

1 Use

The trowel has been developed to float and finish the edges of concrete floors, up to

perimeter walls, around columns and small areas, eliminating tiring hand troweling and

increasing overall productivity and quality.

2 Safety precautions

❖Always keep unauthorized, inexperienced, untrained people away from this machine.

❖Rotating and moving parts will cause injury if contacted. Make sure guards are in

place. Keep hands and feet away from moving parts.

❖Fuel the machine only when the engine is stopped, using all necessary safety

precautions.

❖The engine must always be stopped before attempting any repair or adjustments.

Ignition switch should be off.

❖To avoid slipping and loss of control when starting the trowel, the operator should

maintain good footing. It is recommended that the operator wear safety shoes for

added protection.

❖Be careful when working around pipes or ducts protruding from the floor or slab

edges. If the trowel blades hit such obstacles, damage to the machine or possible

operator injury may result.

❖When starting the machine, do not exceed 1/3 throttle position. A higher setting may

cause the centrifugal clutch to engage and the handle to rotate.

❖Be careful not to come in contact with the muffler when the engine is hot, serious

burns may result!

❖Over time, the blades will form a sharp edge. Be careful when handling the old

blades.

Never operate the machine in an explosive atmosphere, near combustible

materials or where ventilation does not clear exhaust fumes. Repair fuel leaks

immediately. Refer to your engine owner’s manual for more safety instructions.

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

6/32

3 BT90E Electric Power Trowel Operating Instructions.

The BT90 Electric 230v Power Trowel is driven by a 2.2 Kw Motor. As such it

requires a correct power source to operate the machine. Note that the machine can

draw as much as 24 Amperes on initial start up if the machine has been standing

stationary on wet concrete.

The plug socket provided on the machine is the EU blue three pin safety 32 amp

socket. Plug in your extension cable into the socket. Please ensure the extension

cable is not coiled nor unreasonably long as this will cause power drop to the

machine.

To start rotation of the machine pull in the red hand lever on the left side of the

handle bar. To increase or lower speed use the speed dial on the right side of the

handle bar.

For emergency stop release the red lever.

When operating the machine ensure the power cable is running over the handle bar

and always behind the machine to avoid contact of the cable with the blades. If

contact is made then immediately stop the machine and disconnect the extension

cable and inspect the insulation. If it is damaged then do not continue to use the

machine until the cable is replaced.

If the cable is badly damaged or if the amperes to the machine are insufficient then

the machine has a trip switch that will cut off the power.

Special Note: If the power trowel is fitted with a float pan then the machine may

settle into the wet surface of the concrete and this will create a suction that will put

resistance on the rotation of the electric machine. To avoid this break the machine

free of the concrete prior to starting.

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

7/32

4 OPERATION (Floating)

When the slab has set sufficiently firm that the operator’s footprint leaves a very slight

depression on the surface of the slab, it is ready for the floating operation.

Guiding the machine on the slab is very simple, a slight upward lift of the handle causes the

machine to travel to the left. Holding the handle in the neutral position, will slowly cause the

machine to spin in one spot. Slight downward pressure on the handle causes the machine to

travel to the right. Best results are obtained by covering approximately 4” on each turn. In

other words, let the machine move right or left, backwards or forwards, approximately 4” with

each revolution of the trowels. To fill a hole or cut down a hump, move the unit back and forth

over the problem area.

Under normal operating conditions the machine should cover as much as 1000 sq. ft. in

about 15 minutes. It is recommended that a slight tension on the trowel control cable, (but

not a definite tilt), during the floating operation will cause the machine to operate much

smoother. After the floated slab has set sufficiently, it is ready for the finishing operation.

CAUTION:

Do not let the machine stand in one spot on the soft cement. Lift from the slab

when the floating operation is complete.

5 OPERATION (Finishing)

When starting the finishing operation, never set the trowels up over 1/4” pitch.

After the floating operation, the first thing to do is to remove the floating disc from the blades.

Clean the blades, spider plate and disc from cement paste collected during the floating

operation. Increase the blade pitch up to a maximum of 1 cm for the first finishing operation

and then continue to increase the pitch on the following finishing operations. Continue the

finishing passes until you obtain the desired floor finish. The time required between each

finishing pass is again dependent on the weather conditions and water content of the

concrete etc. If some areas of the concrete set/harden too fast you may apply a small

amount of water using a hand brush as an aid to achieving the finish.

6 STARTING PROCEDURE: *WARM CLIMATE

Open fuel valve on gas tank. Set throttle lever to “Fast” idle position, set choke to closed

position, start engine. Open choke slightly to prevent flooding. Move to “Open” or “Run”

position when engine is warm, increase throttle to maximum operation position (3600 rpm).

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

8/32

7 STARTING PROCEDURE: *COLD CLIMATE

Follow same procedure as above but allow longer warm-up period –3 to 5 minutes. In cold

weather, oil is much heavier to move and requires more time to work its way into the moving

parts. If maximum power is not attained, allow further warm-up time.

8 STOPPING PROCEDURE

❖Throttle engine down.

❖Turn off stop switch.

9 TRANSPORTING

When transporting the trowel, always keep the handle folded and the blades flat on the floor to prevent

damage to the pitch control system. Always keep the floating disc underneath the blades to protect

them against damage.

CAUTION:

Never lift the trowel by the rotating ring; use the hoist hook or handle provided

on the trowel. Remove the float disc when lifting machine more than 100cm

(40in). The floating disc could fall off.

10 LUBRICATION

❖ENGINE OIL: The long life and successful operation of any piece of machinery is

dependent on frequent and thorough lubrication. Before using the trowel, always

check your engine for oil. Use proper engine oil as recommended in the engine

manufacturer’s manual. Fill crankcase to levels as recommended.

❖SPIDER PLATE : The trowel arm on the spider plate does not require lubrication. If a

trowel arm becomes jammed, this is probably due to a bent arm, which will require

replacement. Appropriate “winterize” steps should be taken if the machine is going to

be stored for long periods of time.

❖GEARBOX: In operation the gearbox lubricant is in a fluid state. When the machine is

stopped the lubricant returns to a gel state. It will only be necessary to inspect the

sealed components if the outside of the gearbox gets too oily or otherwise shows

evidence of a leak. If this happens, clean the machine thoroughly and look for leaks.

Effect necessary repairs immediately. Use SHELL TIVELA COMPOUNDS ‘A’ (0.3L,

10.1oz.) gear oil or equivalent to top up the gear box after any maintenance to the

internal components.

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

9/32

11 STORAGE

The following steps should be taken to prepare your trowel for extended storage.

❖Close fuel shut off valve.

❖Siphon excess gasoline from tank.

❖Start engine until it stops from lack of fuel. This will use up all the fuel in the

carburetor and prevent formation of deposits due to evaporation of fuel.

❖Remove spark plug and pour 2 oz. of SAE-30 or SAE-40 motor oil into the cylinder.

Slowly crank the engine 2 or 3 times to distribute the oil throughout the cylinder. This

will help prevent rust during storage. Replace spark plug.

❖Store the unit in an upright position in a cool, dry, well ventilated area.

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

10/32

Maintenance

1 Preventative maintenance and routine service plan.

This trowel has been assembled with care and will provide years of service. Preventative

maintenance and routine service are essential to the long life of your trowel. Your dealer is

interested in your new machine and has the desire to help you get the most value from it.

After reading through this manual thoroughly, you will find that you can do some of the

regular maintenance yourself. However, when in need of parts or major service, be sure to

see Beton Trowel.

❖AIR CLEANER - Keep air filter clean at all times. Wash away dust and debris using a non-oil

based cleaning solvent. Let the filter dry before re-installing.

❖LUBRICATION –Always check engine oil regularly. Use proper engine oil as recommended.

See chart on this page. Fill crankcase to levels as recommended in manufacture’s engine

manual.

❖SPARK PLUG –Check and clean spark plugs regularly. A fouled, dirty or carboned spark

plug causes hard starting and poor engine performance. Set spark plug gap to recommended

clearance. Refer to engine manual.

❖BELT TENSION –IMPORTANT!

When the engine is switched off, and the machine has stopped, the normal belt play should be

loose. This is due to the clutch type. When the machine is running at full throttle, the clutch will

close in, which tightens the belt causing the gearbox to engage.

When adjusting the belt make sure that the clutch is in alignment with the follower pulley.

Secure belt guard. Tighten all engine mount bolts, and tighten lock nuts.

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

11/32

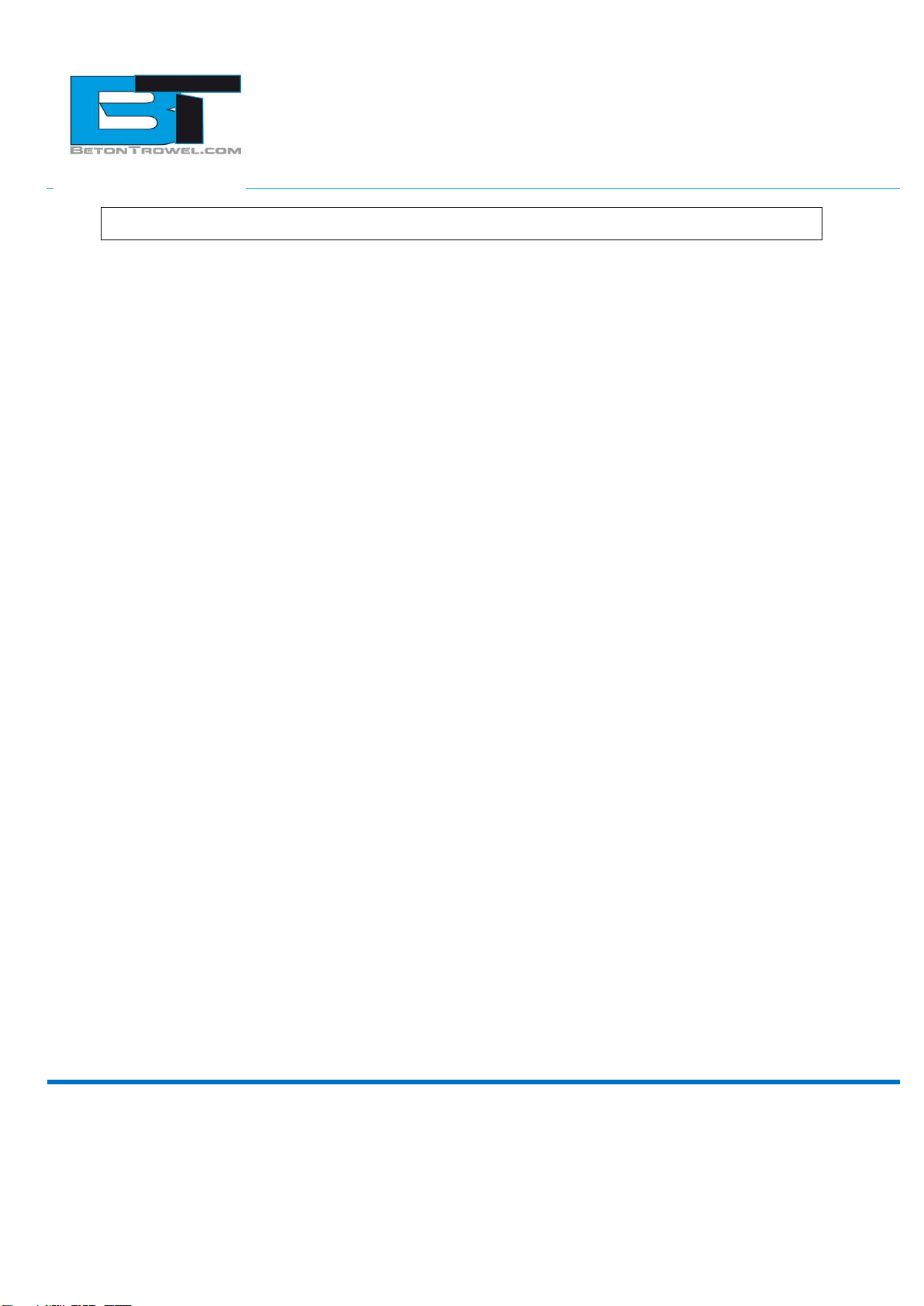

2 Maintenance plan

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

12/32

3 Service

Due to the nature and environment of use, the machines could be exposed to severe

operating conditions. Some general maintenance guidelines will extend the useful life of your

trowel.

❖The initial service for your trowel should be performed after 25 hours of use, at which

time your mechanic (or authorized repair shop) should complete all of the

recommended checks in the schedule above.

❖Regular service according to the schedule above will prolong the life of the trowel and

prevent expensive repairs.

❖Keeping your trowel clean and free from debris is the single most important regular

maintenance operation, over and above the checks in the service schedule above,

that can be performed. After each use your trowel should be cleaned to remove any

dust and debris from the undercarriage and surrounding components. Use of a power

washer will make clean up quick and easy, especially if a non-stick coating was

applied prior to use.

❖In the Service Schedule above, items that should be checked, replaced or adjusted

are indicated by “o” in the appropriate column. Not all trowel models include the same

features and options and as such not all service operations may have to be

performed. For ease of recording place a checkmark (√) through the “o” when the

item is complete. If an item is not required or not completed place an “x” through the

“o” in the box.

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

13/32

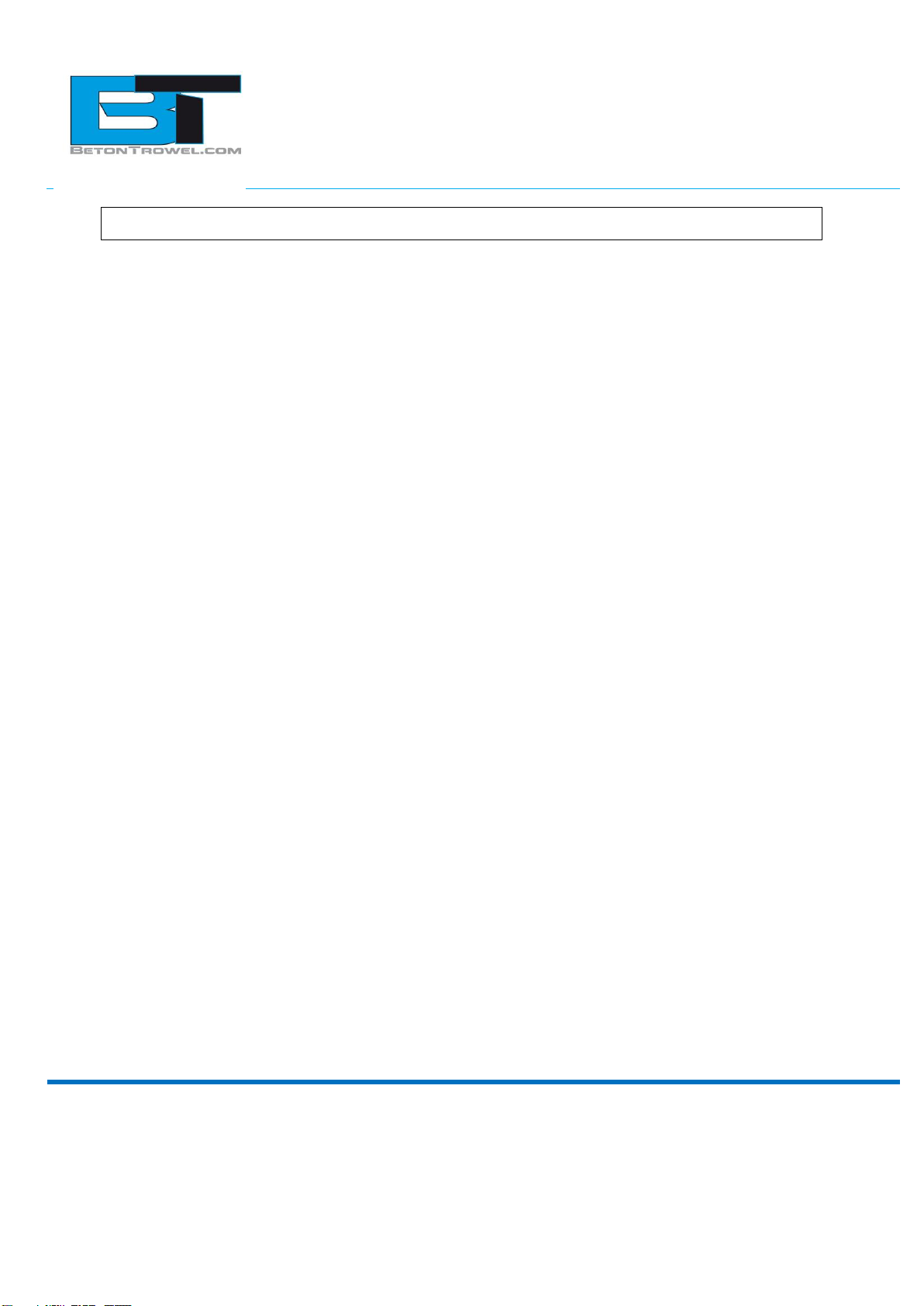

Labels

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

14/32

Specifications

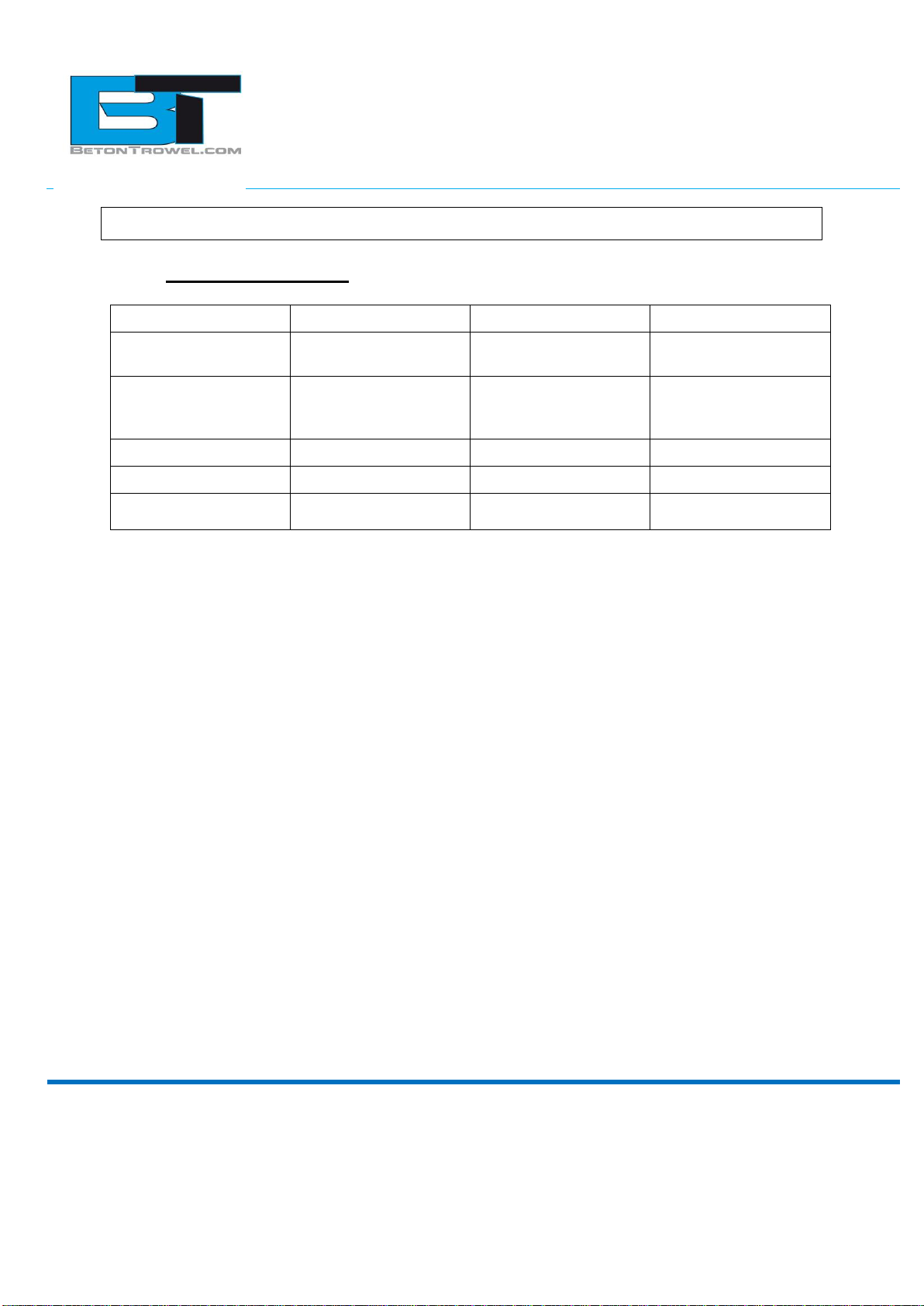

1 Technical data sheet

MODEL

BT90H(F)160

BT90H(F)270

BT90E

OPERATING

DIAMETER

90 CM (36”)

90 CM (36”)

90 CM (36”)

ENGINE OPTIONS

HONDA GX160

5.5 HP

HONDA GX270

9 HP

ELECTRIC 3 PHASE

2.2 KW

VARIABLE SPEED

WEIGHT

78 KG

82 KG

84 KG

HANDLE VIBRATION

1.1 –1.5 M/S

1.1 –1.5 M/S

1.1 –1.5 M/S

SOUND

97 –103 LWA (dB)

82 -86 LPA (Db)

97 –103 LWA (dB)

82 -86 LPA (Db)

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

15/32

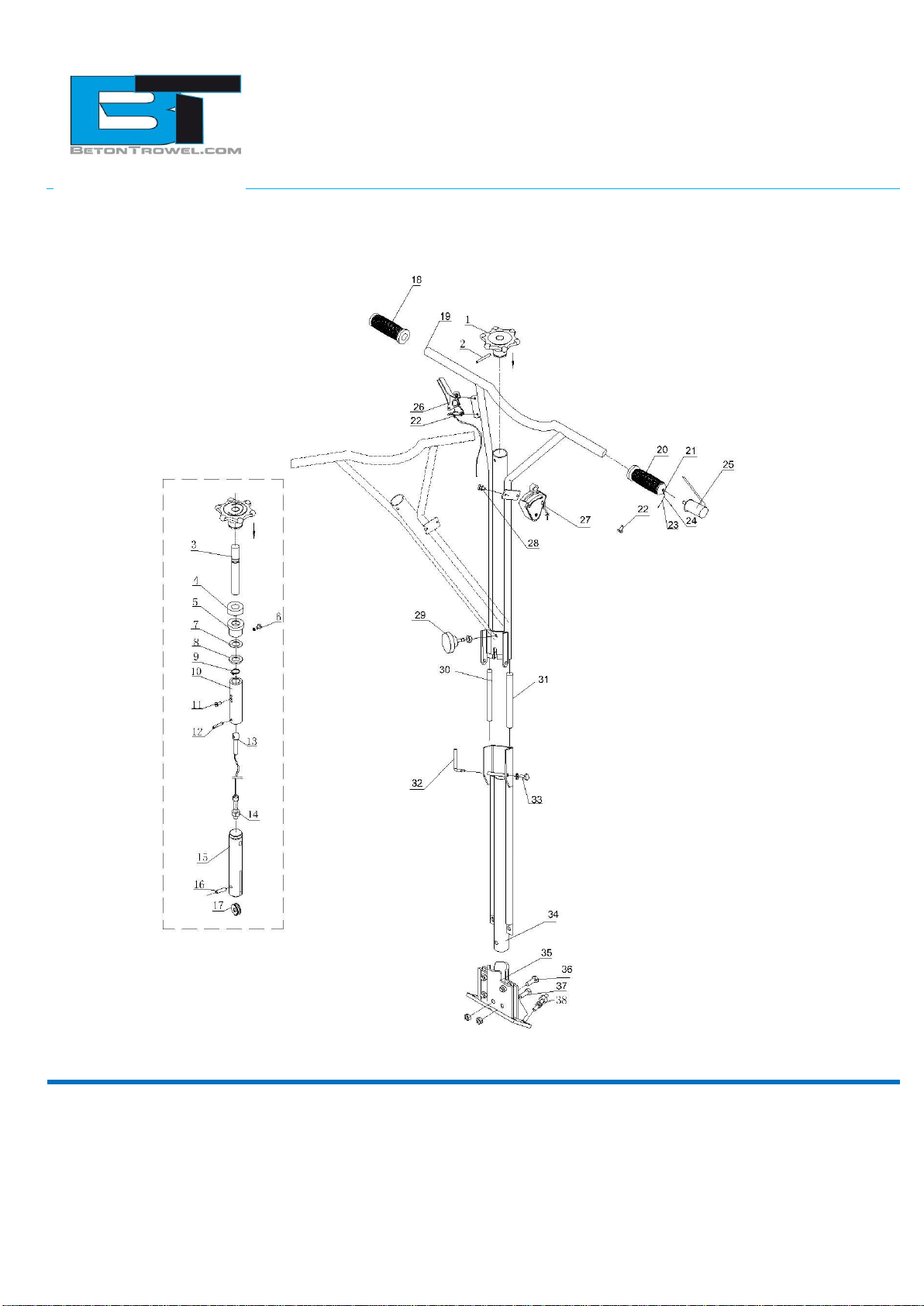

2 Parts

Standard Handle Assembly.

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

16/32

Item No.

Part No.

Description

Qty.

1

4365501

KNOB

1

2

9024

PIN

1

3

4365503

Threaded Rod

1

4

9025

BEARING

1

5

4365502

BUSHING

1

6

9026

BOLT

1

9022

SPRING WASHER

1

7

9033

SPRING WASHER

1

8

4365504

WASHER

1

9

9027

WASHER

1

10

4365505

ALUMINIUM BUSHING

1

11

9028

BOLT

1

12

9030

PIN

1

13

4405512

PITCH CONTROL CABLE

1

14

9016

NUT

1

15

4365511

CABLE PULLEY BUSHING

1

16

9031

PIN

1

17

4365508

CABLE PULLY

1

18

9035

GRIP

1

19

4405100

BARE HANDLE

1

20

9035a

GRIP

1

21

9126

SLEEVE

1

22

9021

BOLT

3

9011

WASHER

2

9128

SPRING WASHER

1

23

9119

WIRE

2

24

9570

WIRE CONNECTOR

2

25

1165200A

DEADMAN SWITCH

1

26

4365200

SAFTY SWITCH CENTRIFUGAL

1

27

9010

BOLT

2

9011

WASHER

2

28

4365400

THROTTLE ASSY

1

29

4365301

UPPER BRACKET

1

30

4405303

LOWER BRACKET

1

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

17/32

31

9017

BOLT

1

32

9018

BOLT

4

9016

NUT

5

33

9044

BOLT

4

9045

NUT

4

9046

SPRING WASHER

4

9047

WASHER

4

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

18/32

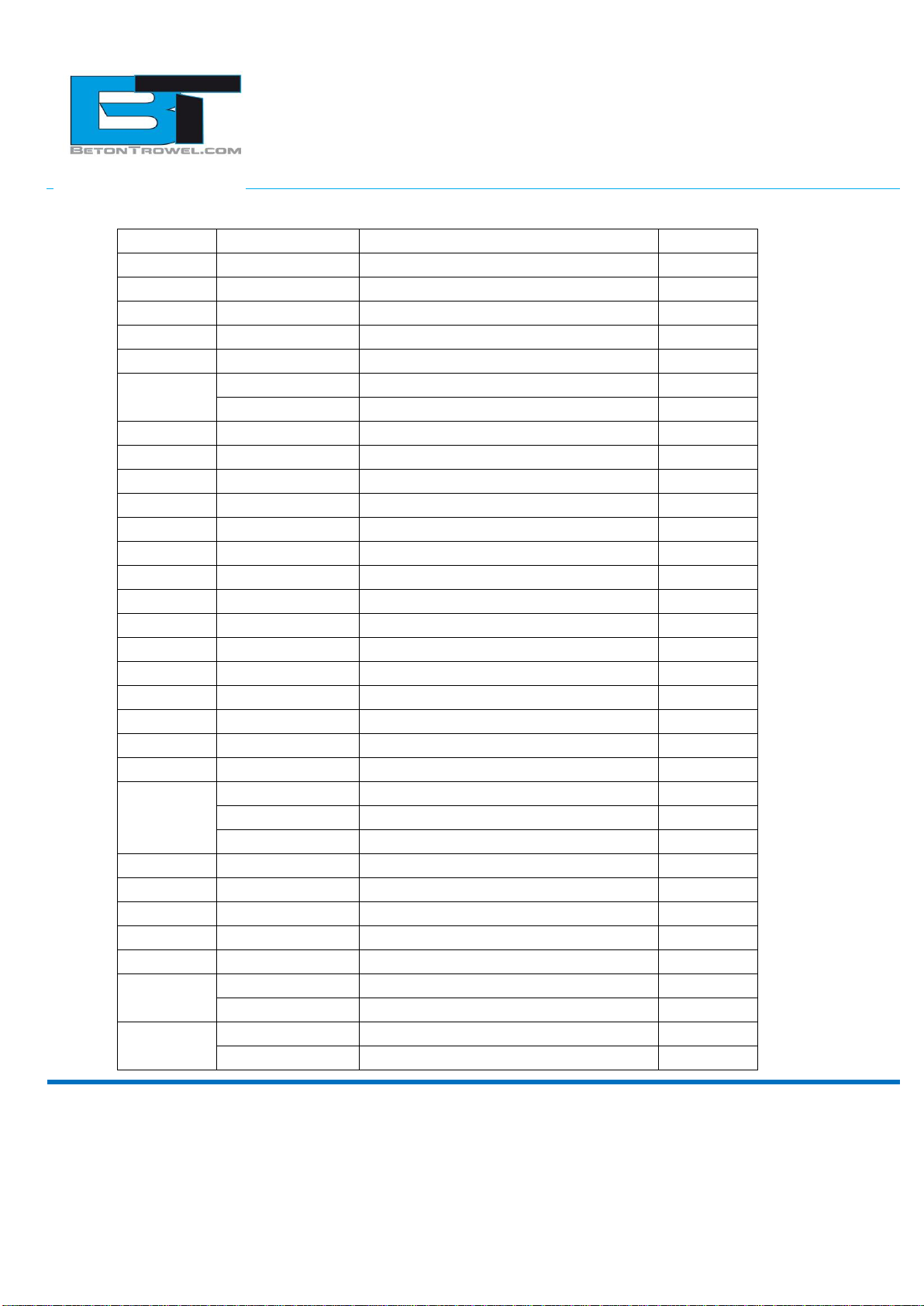

Folding handle assembly

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

19/32

Item No.

Part No.

Description

Qty.

1

4365501

KNOB

1

2

9024

PIN

1

3

4365503

THREADED ROD

1

4

9025

BEARING

1

5

4365502

BUSHING

1

6

9026

BOLT

1

9022

SPRING WASHER

1

7

9033

SPRING WASHER

1

8

4365504

WASHER

1

9

9027

WASHER

1

10

4365505

ALUMINIUM BUSHING

1

11

9028

BOLT

1

12

9030

PIN

1

13

4405512

PITCH CONTROL CABLE

1

14

9016

NUT

1

15

4365511

CABLE WHEEL BUSHING

1

16

9031

PIN

1

17

4365508

CABLE WHEEL

1

18

9035

GRIP

1

19

4405100S

UPPER HANDLE

1

20

9035a

GRIP

1

21

9126

SLEEVE

1

22

9021

BOLT

3

9011

WASHER

2

9128

SPRING WASHER

1

23

9119

WIRE

2

24

9570

WIRE CONNECTOR

2

25

1165200A

DEADMAN SWITCH

1

26

4365400

THROTTLE ASSY

1

27

4365200

SAFTY SWITCH CENTRIFUGAL

1

28

9010

BOLT

2

9011

WASHER

2

29

9381

LOCKING KNOB

1

9045

NUT

1

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

20/32

30

9784

PLASTIC TUBE

1

31

9800

PLASTIC TUBE

1

32

4365110

LOCKING GRIP

1

33

9098

BOLT

1

9038

WASHER

1

34

4405100X

LOWER HANDLE ASSY

1

35

4405300

BRACKET

1

36

9017

BOLT

1

37

9018

BOLT

4

9016

NUT

5

38

9044

BOLT

4

9045

NUT

4

9046

SPRING WASHER

4

9047

WASHER

4

This manual suits for next models

5

Table of contents

Other Beton Trowel Trowel manuals