1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

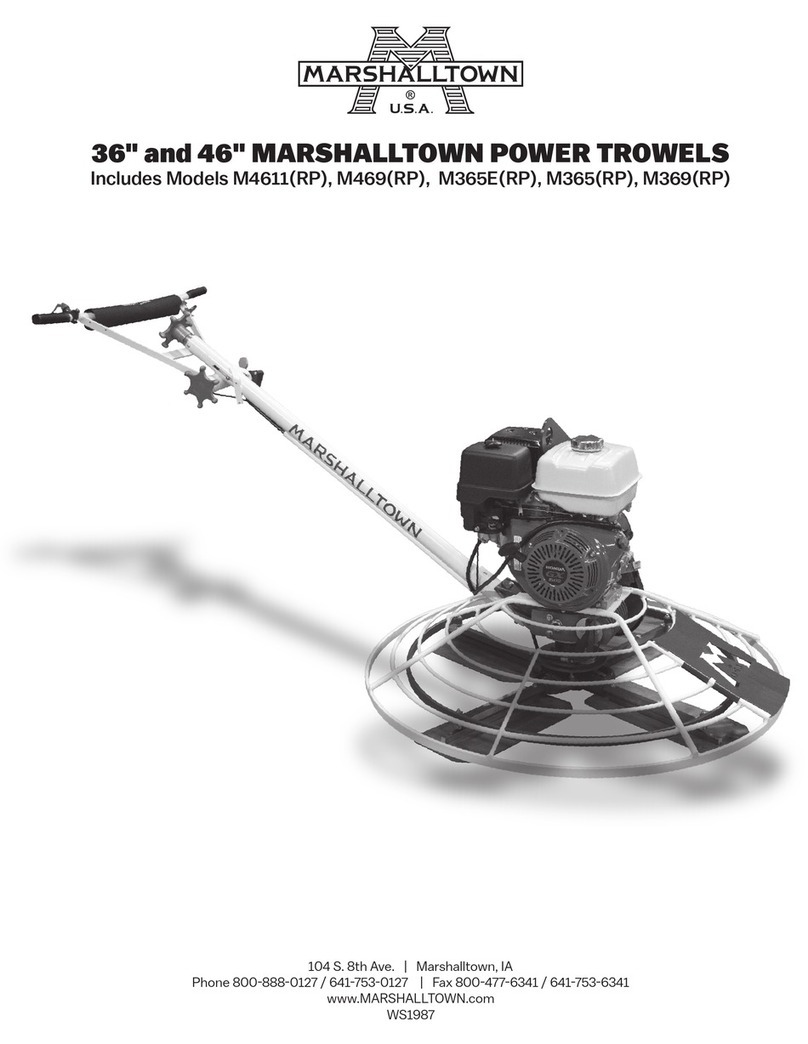

Safety Precautions

Always keep unauthorized, inexperienced, untrained people away from this

machine.

Rotating and moving parts will cause injury if contacted. Make sure guards are

in place. Keep hands and feet away from moving parts.

Fuel the machine only when the engine is stopped, using all necessary safety

precautions.

The engine must always be stopped before attempting any repair or

adjustments. Ignition key should be off.

Danger: Never operate the machine in an explosive atmosphere,

near combustible materials or where ventilation does not clear

exhaust fumes. Repair fuel leaks immediately.

Refer to your engine owner’s manual for more safety instructions.

Be careful not to come in contact with the muffler when the engine is hot,

serious burns may result!

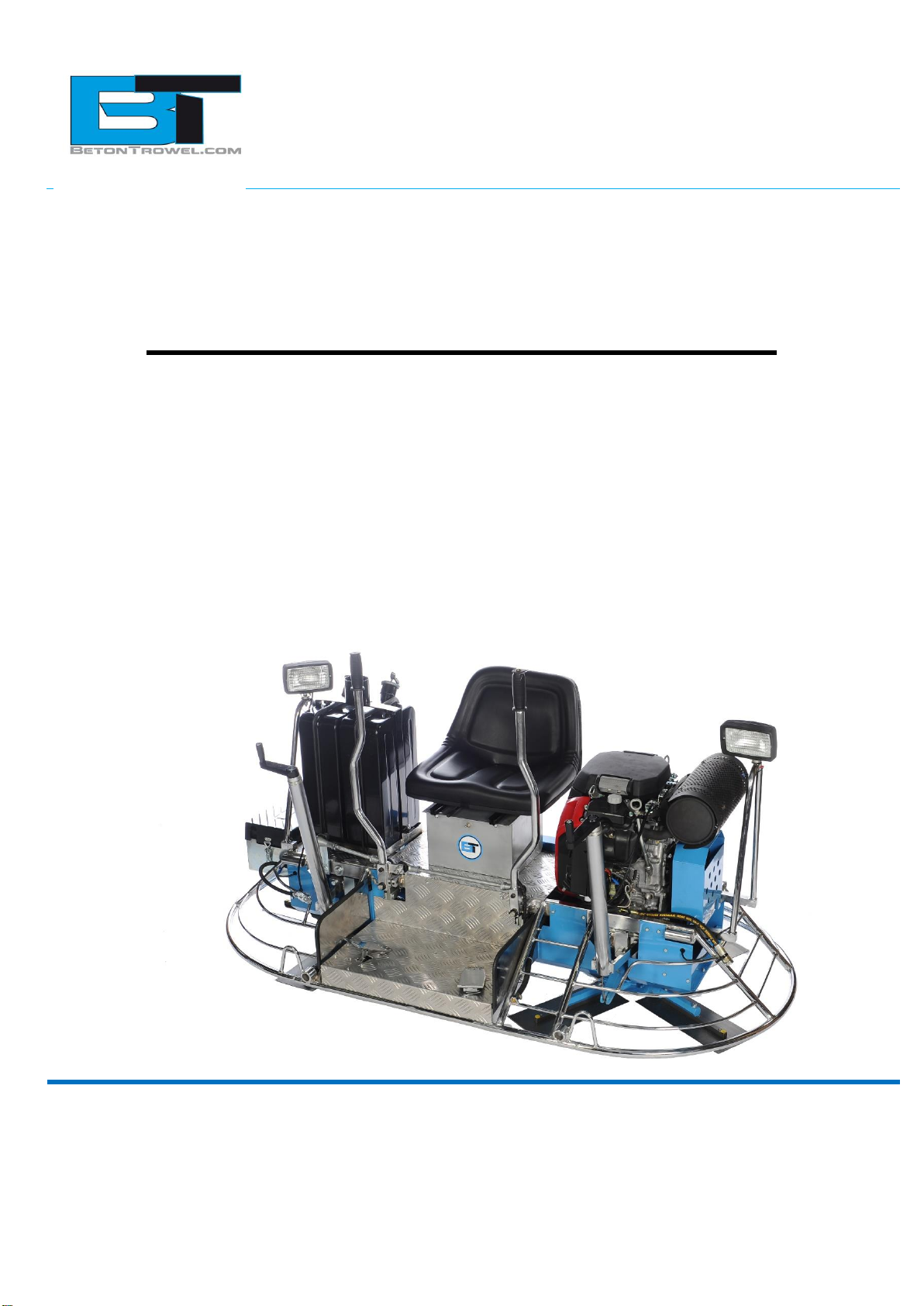

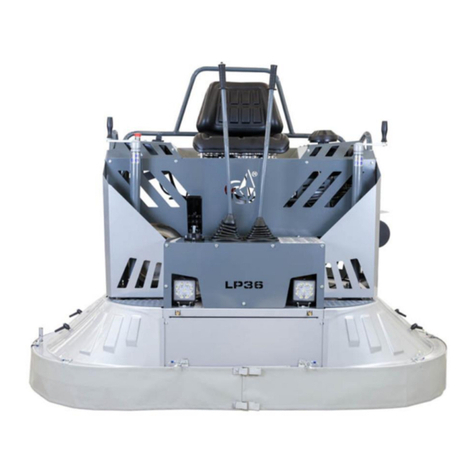

Always operate the machine in a seated position to maintain machine balance.

The transporter is designed for moving the unit around the job site only. It is

not to be used for towing the Ride-On unit off-site.

When starting the trowel, do not exceed the ¼ throttle position as

recommended. A higher setting could cause the centrifugal clutch to engage,

turning the trowel blades.

Be careful with the trowel around stub pipes or other obstructions on the floor.

Should the machine catch, or hit such an obstruction, serious damage may

result to the machine, or operator may be thrown from the machine.

Excess surface water may result in sudden loss of control of steering.

Disconnect battery before attempting any electrical maintenance.

Ensure that the electrical dead-man switch, located on the right hand steering

lever is operating. Placing your right hand on the steering lever will engage the

safety switch. Removing your hand from the Lever will disengage the safety

switch and stop the engine. The engine will not start unless the safety switch

is depressed. This safety feature must be used as designed