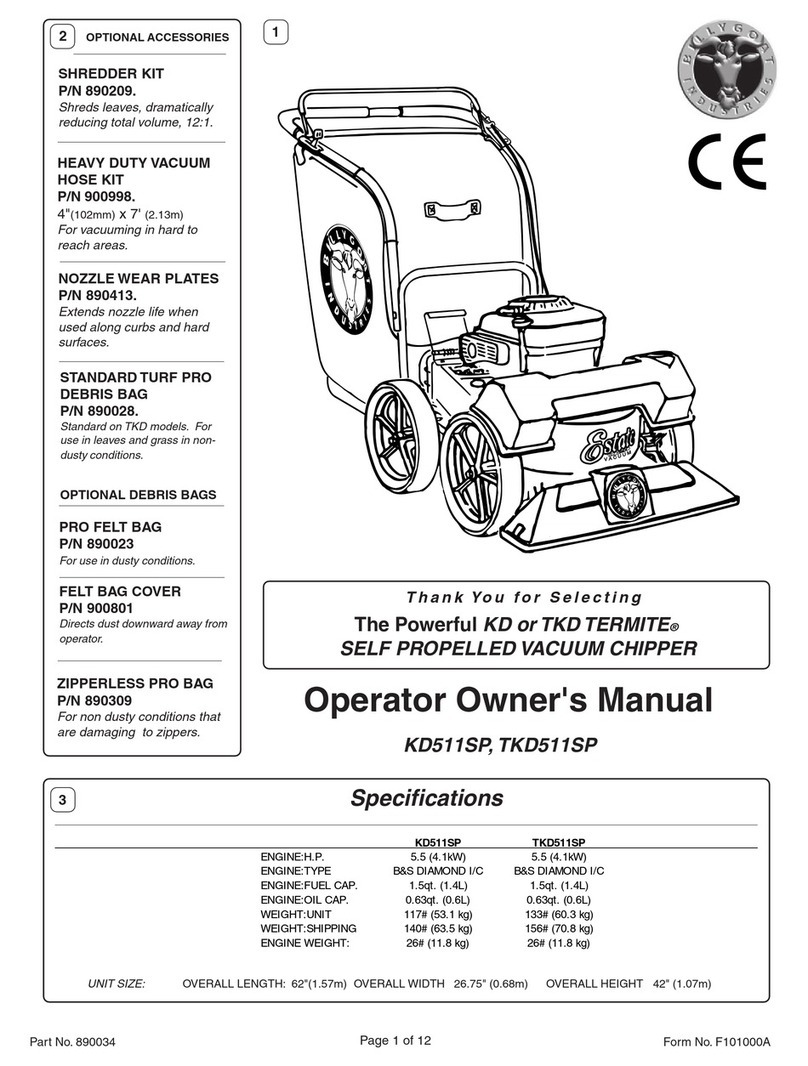

Betstco FHM BX42 Series Application guide

Specifications subject to change without notice.

Specifications subject to change without notice.

OPERATION & PARTS MANUAL

Revision 1-2016

Please read these instructions carefully before using!

Always grease all fittings and be sure to always check and fill

with oil before operating! Retain this manual for future

reference.

BX42 SERIES WOOD CHIPPERS

2

Revision 1-2016

1 INTRODUCTION

Congratulations on your choice of a Farmer-Helper 3 Point Hitch Wood Chipper to compliment your

operation. This equipment has been designed and manufactured to meet the needs of a discerning

timber or landscaping industry.

Safe, efficient and trouble free operation of your Farmer-Helper Wood Chipper requires that you and

anyone else who will be using or maintaining the chipper, read and understand the Safety, Operation,

Maintenance Trouble Shooting information contained within the Operator's Manual.

BX42

This manual covers the Farmer-Helper 3 Point Hitch Wood Chipper BX42 Use the Table of

Contents or Index as a guide to locate required information.

Keep this manual handy for frequent reference and to pass on to new operators or owners.

OPERATOR ORIENTATION - The directions left, right, front and rear, as mentioned throughout this

manual, are determined when sitting in the tractor driver's seat and facing in the direction of travel.

3

Revision 1-2016

SAFETY ALERT SYMBOL

This Safety Alert symbol means

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The Safety Alert symbol identifies

important safety messages on the

Farmer-Helper 3 Point Hitch

Wood Chipper and in the manual.

When you see this symbol, be

alert to

the possibility of personal injury or

death. Follow the instructions in the

safety message.

Why is SAFETY important to you?

3 Big Reasons

Accidents Disable and Kill

Accidents Cost

Accidents Can Be Avoided

SIGNAL WORDS:

Note the use of the signal words DANGER,

WARNING and CAUTION with the safety

messages. The appropriate signal word for

each message has been selected using the

following guide-lines:

DANGER - Indicates an imminently hazardous

situation that, if not avoided, will

result in death or serious injury. This

signal word is to be limited to the

most extreme situations typically for

machine components which, for

functional purposes, cannot be

guarded.

WARNING -Indicates a potentially hazardous

situation that, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may

also be used to alert against unsafe

practices.

CAUTION -Indicates a potentially hazardous

situation that, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

4

Revision 1-2016

YOU are responsible for the SAFE operation and

maintenance of your Farmer-Helper 3 Point

Hitch Wood Chipper. YOU must ensure that you

and anyone else who is going to use, maintain or

work around the 3 Point Hitch Wood Chipper be

familiar with the using and maintenance

procedures and related SAFETY information

contained in this manual. This manual will take

you step-by-step through your working day and

alerts you to all good safety practices that should

be used while using the 3 Point Hitch Wood

Chipper.

Remember, YOU are the key to safety. Good

safety practices not only protect you but also the

people around you. Make these practices a

working part of your safety program. Be certain

that EVERYONE using this equipment is familiar

with the recommended using and maintenance

procedures and follows all the safety precautions.

Most accidents can be prevented. Do not risk

injury or death by ignoring good safety practices.

• 3 Point Hitch Wood Chipper owners must give

operating instructions to operators or

employees before allowing them to operate

the machine, and at least annually thereafter.

• The most important safety device on this

equipment is a SAFE operator. It is the

operator’s responsibility to read and

understand ALL Safety and Operating

instructions in the manual and to follow these.

Most accidents can be avoided.

• A person who has not read and understood all

using and safety instructions is not qualified

to use the machine. An untrained operator

exposes himself and bystanders to possible

serious injury or death.

• Do not modify the equipment in any way.

Unauthorized modification may impair the

function and/or safety and could affect the life

of the equipment.

• Think SAFETY! Work SAFELY!

2.1 GENERAL SAFETY

1. Read and understand the

Operator’s Manual and all

safety signs before using,

maintaining, adjusting or

cleaning the

3 Point Hitch Wood Chipper.

2. Have a first-aid kit available

for use should the need

arise and know how to use

it.

3. Have a fire extinguisher

available for use should the

need arise and know how to

use it.

4. Do not allow riders.

5. Wear appropriate

protective gear. This

list includes but is not

limited to:

- A hard hat

- Protective

shoes with slip

resistant soles

- Protective glasses,

goggles or face shield

- Heavy gloves

- Wet weather gear

- Hearing Protection

- Respirator or filter mask

6. Install and secure all guards

before starting.

7. Wear suitable ear protection

for prolonged exposure to

excessive noise.

8. Turn machine off, stop and

disable engine, remove ignition key and place

in your pocket, set park brake and wait for all

moving parts to stop before servicing,

adjusting, repairing or unplugging.

9. Clear the area of people, especially small

children, before using the unit.

10. Review safety related items annually with all

personnel who will operating or maintaining

the 3 Point Hitch Wood Chipper.

2 SAFETY

5

Revision 1-2016

2.2 EQUIPMENT SAFETY GUIDELINES

1. Safety of the operator and bystanders is one

of the main concerns in designing and

developing equipment. However, every year

many accidents occur which could have been

avoided by a few seconds of thought and a

more careful approach to handling equipment.

You, the operator, can avoid many accidents

by observing the following precautions in this

section. To avoid personal injury or death,

study the following precautions and insist

those working with you, or for you to follow

them.

2. In order to provide a better view, certain

photographs or illustrations in this manual

may show an assembly with a safety shield

removed. However, equipment should never

be used in this condition. Keep all shields in

place. If shield removal becomes necessary

for repairs, replace the shield prior to use.

3. Replace any safety sign or instruction sign

that is not readable or is missing. Location of

such safety signs is indicated in this manual.

4. Never use alcoholic beverages or drugs which

can hinder alertness or coordination while

using this equipment. Consult your doctor

about using this machine while taking

prescription medications.

5. Under no circumstances should young

children be allowed to work with this

equipment. Do not allow persons to use or

assemble this unit until they have read this

manual and have developed a thorough

understanding of the safety precautions

and of how it works. Review the safety

instructions with all users annually.

6. This equipment is dangerous to children and

persons unfamiliar with its operation. The

operator should be a responsible, properly

trained and physically able person familiar

with machinery and trained in this equipment's

operations. If the elderly are assisting with

work, their physical limitations need to be

recognized and accommodated.

7. Never exceed the limits of a piece of

machinery. If its ability to do a job, or to do so

safely, is in question - DON'T TRY IT.

8. Do not modify the equipment in any way. Un-

authorized modification may result in serious

injury or death and may impair the function

and life of the equipment.

9. In addition to the design and configuration of

this implement, including Safety Signs and

Safety Equipment, hazard control and

accident prevention are dependent upon the

awareness, concern, prudence, and proper

training of personnel involved in the operation,

transport, maintenance, and storage of the

machine. Refer also to Safety Messages and

operation instruction in each of the appropriate

sections of the tractor and machine manuals.

Pay close attention to the Safety Signs affixed

to the tractor and the machine.

6

Revision 1-2016

2.3 SAFETY TRAINING

1. Safety is a primary concern in the design and

manufacture of our products. Unfortunately,

our efforts to provide safe equipment can

be wiped out by a single careless act of an

operator or bystander.

2. In addition to the design and configuration of

equipment, hazard control and accident

prevention are dependent upon the

awareness, concern, prudence and proper

training of personnel involved in the operation,

transport, maintenance and storage of this

equipment.

3. It has been said, "The best

safety feature is an

informed, careful operator."

We ask you to be that

kind of an operator. It is the

operator's responsibility to read and under-

stand ALL Safety and Using instructions in the

manual and to follow these. Accidents can be

avoided.

4. Working with unfamiliar equipment can

lead to careless injuries. Read this manual

before assembly or using, to acquaint

yourself with the machine. If this machine

is used by any person other than yourself,

or is loaned or rented, it is the machine

owner's responsibility to make certain that

the operator, prior to using:

a. Reads and understands the operator's

manuals.

b. Is instructed in safe and proper use.

5. Know your controls and how to stop tractor

and machine quickly in an emergency. Read

this manual and the one provided with tractor.

6. Train all new personnel and review

instructions frequently with existing workers.

Be certain only a properly trained and

physically able person will use the machinery.

A person who has not read and understood all

using and safety instructions is not qualified to

use the machine. An untrained operator

exposes himself and bystanders to possible

serious in- jury or death. If the elderly are

assisting with the work, their physical

limitations need to be recognized and

accommodated.

2.4 SAFETY SIGNS

1. Keep safety signs clean and legible at all

times.

2. Replace safety signs that are missing or have

become illegible.

3. Replaced parts that displayed a safety sign

should also display the current sign.

4. Safety signs displayed in Section 3 each have

a part number in the lower right hand corner.

Use this part number when ordering

replacement parts.

5. Safety signs are available from your

authorized Distributor or Dealer Parts

Department or the factory.

How to Install Safety Signs:

• Be sure that the installation area is clean and

dry.

• Be sure temperature is above 50°F (10°C).

• Determine exact position before you remove

the backing paper.

• Remove the smallest portion of the split

backing paper.

• Align the sign over the specified area and

carefully press the small portion with the ex-

posed sticky backing in place.

• Slowly peel back the remaining paper and

carefully smooth the remaining portion of the

sign in place.

• Small air pockets can be pierced with a pin

and smoothed out using the piece of sign

backing paper.

7

Revision 1-2016

2.5 PREPARATION

1. Never use the machine until you have read

and completely understand this manual, the

tractor Operator's Manual and each of the

Safety Messages found on the safety signs on

the tractor and machine.

2. Personal pro-

tection equip-

ment including

hard hat, safety

glasses, safety

shoes, and

gloves are rec-

ommended dur-

ing assembly,

installation, operation, adjustment, maintain-

ing, repairing, removal, cleaning, or moving

the unit. Do not allow long hair, loose fitting

clothing or jewellery to be around equipment.

3. PROLONGED EXPOSURE

TO LOUD NOISE MAY

CAUSE PERMANENT

HEARING LOSS!

Power equipment with or

without equipment attached

can often be noisy enough

to cause permanent, partial

hearing loss. We recommend that you wear

hearing protection on a full-time basis if the

noise in the Operator's position exceeds 80db.

Noise over 85db on a long-term basis can

cause severe hearing loss. Noise over 90db

adjacent to the Operator over a long-term ba-

sis may cause permanent, total hearing loss.

NOTE: Hearing loss from loud noise (from

tractors, chain saws, radios, and other such

sources close to the ear) is cumulative over a

lifetime without hope of natural recovery.

4. Clear working area of stones, branches or

hidden obstacles that might be hooked or

snagged, causing injury or damage.

5. Use only in daylight or good artificial light.

6. Be sure machine is properly mounted, adjust-

ed and in good operating condition.

7. Ensure that all safety shielding and safety

signs are properly installed and in good condi-

tion.

2.6 MAINTENANCE SAFETY

1. Good maintenance is your responsibility.

Poor

maintenance is an invitation to trouble.

2. Follow good shop practices.

- Keep service

area clean and

dry.

- Be sure electrical

outlets and tools

are properly

grounded.

- Use adequate

light for the job at

hand.

3. Make sure there is

plenty of ventilation. Never operate the en-

gine of the towing vehicle in a closed

building.

The exhaust fumes may cause asphyxiation.

4. Before working on this machine, shut off the

engine, set the brake, and turn fuel valve off.

5. Never work under equipment unless it is

blocked securely.

6. Always use personal protection devices such

as eye, hand and hearing protectors, when

performing any service or maintenance work.

Use heavy or leather gloves when handling

blades.

7. Where replacement parts are necessary for

periodic maintenance and servicing, genuine

factory replacement parts must be used to

restore your equipment to original specifica-

tions. The manufacturer will not be responsi-

ble for injuries or damages caused by use of

unapproved parts and/or accessories.

8. A fire extinguisher and first aid kit should be

kept readily

accessible while

performing main-

tenance on this

equipment.

9. Periodically tighten all bolts,

nuts and screws and check that all electrical

and fuel connections are properly secured to

ensure unit is in a safe condition.

8

Revision 1-2016

2.7

OPERATING

SAFETY

1. Please remember it is important that you read

and heed the safety signs on the 3 Point Hitch

Wood Chipper. Clean or replace all safety

signs if they cannot be clearly read and under-

stood. They are there for your safety, as well

as the safety of others. The safe use of this

machine is strictly up to you, the operator.

2. All things with moving parts are potentially

hazardous. There is no substitute for a cau-

tious, safe-minded operator who recognizes

potential hazards and follows reasonable

safety practices. The manufacturer has

designed this 3 Point Hitch Wood Chipper to

be used with all its safety equipment properly

attached, to minimize the chance of accidents.

Study this manual to make sure you have all

safety equipment attached.

3. Close and secure rotor cover before operat-

ing.

4. Close and secure all guards, deflectors and

shields before starting and operating.

5. Read and understand operator's manual

before starting. Review safety instructions

annually.

6. Personal protection equipment including hear-

ing protection, hard hat, safety glasses, safety

shoes, and gloves are recommended during

assembly, installation, operation, adjustment,

maintaining, repairing, removal, or moving.

Do not allow long hair, loose-fitting clothing, or

jewelery to be around moving parts.

7. Keep hydraulic lines and fittings tight, in good

condition and free of leaks.

8. Never place any part of your body where it

would be in danger if movement should occur

during assembly, installation, operation, main-

tenance, repairing, unplugging or moving.

9. Turn machine off, stop and disable engine,

remove ignition key and place in your pocket,

set park brake and wait for all moving parts to

stop before servicing, adjusting, repairing or

unplugging.

10. Do not run machine inside a closed building to

prevent asphyxiation from engine exhaust.

11. Use care when feeding material into chipper.

Do not send metal, bottles, cans, rocks, glass

or other foreign material into wood chipper. If

foreign material enters chipper, stop machine,

turn engine off and place ignition key in your

pocket and wait for all moving parts to stop

before removing material and/or unplugging.

Inspect machine for damaged or loose parts

before resuming work.

12. Never use alcoholic beverages or drugs which

can hinder alertness or coordination while

operating this equipment. Consult your doc-

tor about operating this machine while taking

prescription medications.

13. Do not allow riders on this machine at any

time. There is no safe place for any riders.

14. Never allow children or unauthorized people

to operate or be around this machine.

15. Do not reach into rotor or feed hopper open-

ings when the engine is running. Install and

secure access covers before starting engine.

16 Keep the working area clean and free of de-

bris to prevent tripping. Operate only on level

ground.

17 Do not point discharge at people, animals or

buildings. Rotor can expel wood chips fast

enough to cause injury.

18. Do not move or transport chipper when the

rotor is turning.

19. Do not exceed a safe travel speed when

transporting.

9

Revision 1-2016

2.8 STORAGE SAFETY

1. Store the unit in an area away from human

activity.

2. Do not children to play on or around the

stored machine.

3. Store the unit in a dry, level area. Support the

frame with planks if required.

2.9 TRANSPORT SAFETY

1. Comply with state and local laws governing

safety and transporting of machinery on public

roads.

2. Check that all the lights, reflectors and other

lighting requirements are installed and in good

working condition.

3. Do not exceed a safe travel speed. Slow

down for rough terrain and cornering.

4. Fold up and secure feed hopper before mov-

ing or transporting.

5. Be sure the machine is hitched positively to

the tractor and a retainer is used through the

mounting pins.

6. Do not drink and drive.

7. Be a safe and courteous driver. Always yield

to oncoming traffic in all situations, including

narrow bridges, intersections, etc. Watch for

traffic when operating near or crossing road-

ways.

8. Never allow riders on the machine.

10

Revision 1-2016

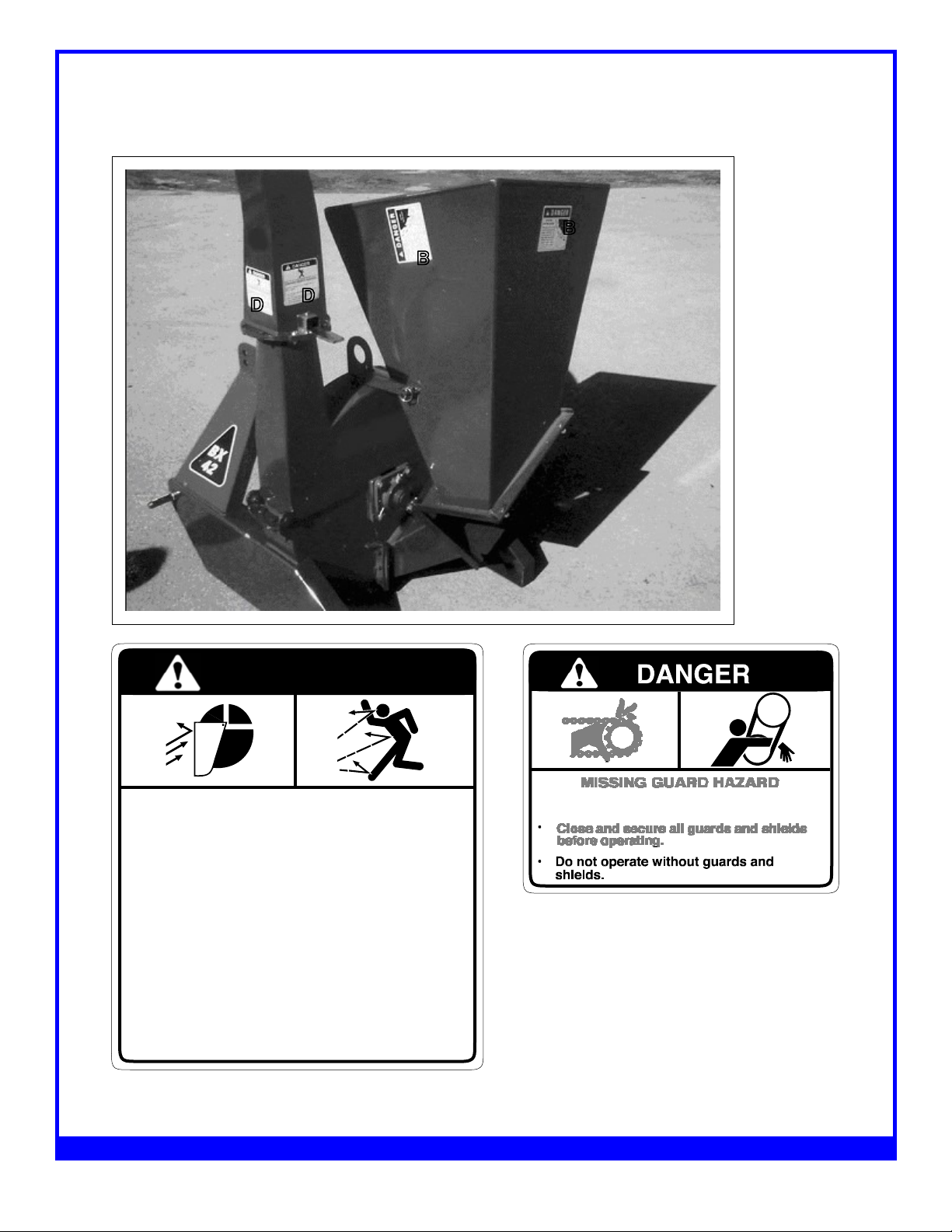

3 SAFETY SIGN LOCATIONS

The types of safety signs and locations on the equipment are shown in the illustrations that follow. Good

safety requires that you familiarize yourself with the various safety signs, the type of warning and the

area, or particular function related to that area, that requires your SAFETY AWARENESS.

• Think SAFETY! Work SAFELY!

D

AF

B

A

B

Z9400

Z94006

REMEMBER - If safety signs have been damaged, removed, become illegible or parts replaced without

safety signs, new signs must be applied. New safety signs are available from your authorized dealer.

11

Revision 1-2016

The types of safety signs and locations on the equipment are shown in the illustrations that follow. Good

safety requires that you familiarize yourself with the various safety signs, the type of warning and the

area, or particular function related to that area, that requires your SAFETY AWARENESS.

B

B

DD

CD

DANGER

THROWN OBJECT HAZARD

To prevent serious injury or death from

thrown objects:

• Turn machine off, stop and disable en-

gine, remove ignition key and place in

your pocket, set park brake and wait for

all moving parts to stop before adjusting,

servicing, maintaining, repairing or un-

plugging.

• Do not direct discharge duct towards

people, animals or property. Always wear

appropriate safety gear. Keep hands and

feet out of discharge openings.

Z940 3

• Keep others away. Z9400

REMEMBER - If safety signs have been damaged, removed, become illegible or parts replaced without

safety signs, new signs must be applied. New safety signs are available from your authorized dealer.

12

Revision 1-2016

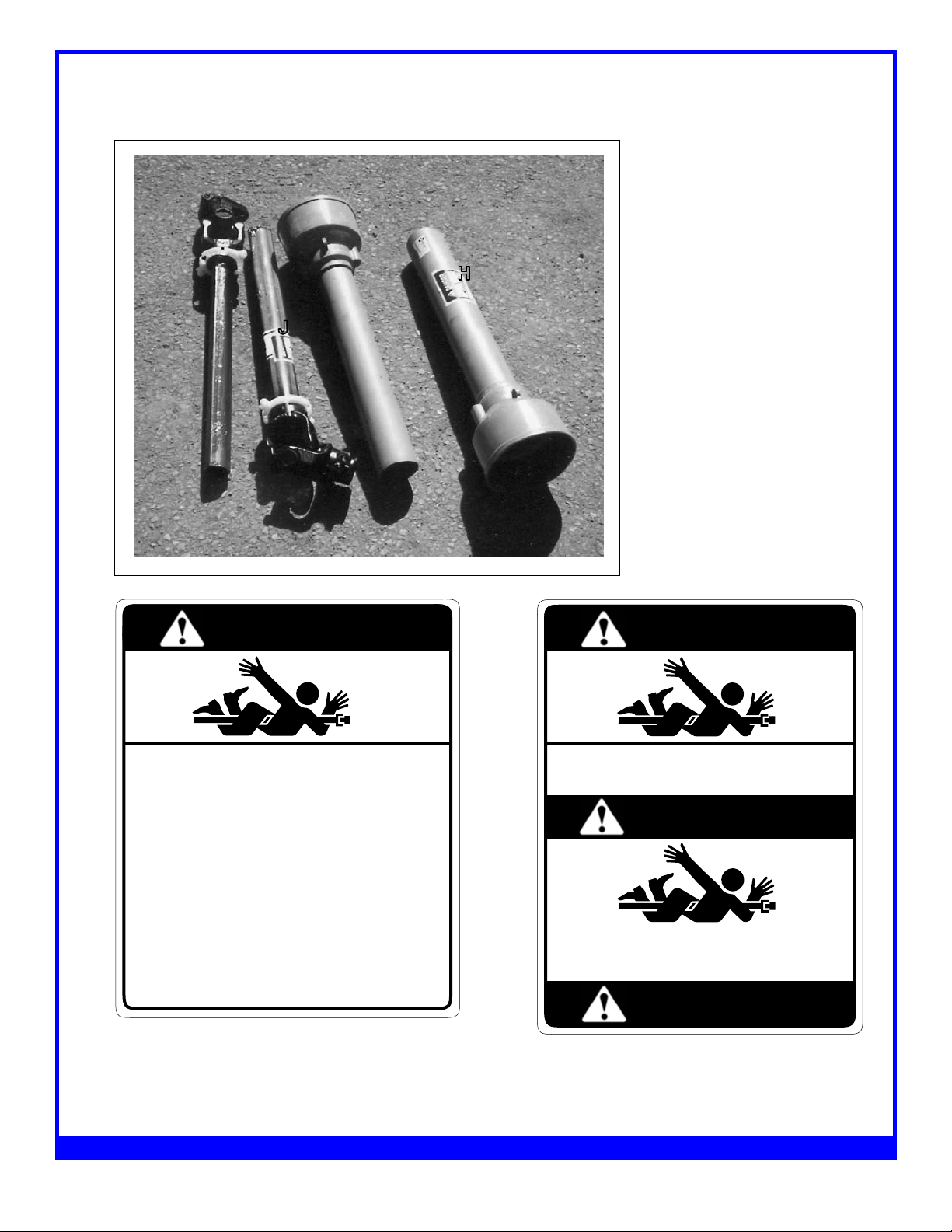

The types of safety signs and locations on the equipment are shown in the illustrations that follow. Good

safety requires that you familiarize yourself with the various safety signs, the type of warning and the

area, or particular function related to that area, that requires your SAFETY AWARENESS.

H

J

HJ

DANGER DANGER

ROTATING DRIVELINE HAZARD

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT:

• ALL DRIVELINE, TRACTOR AND

EQUIPMENT SHIELDS IN PLACE.

• DRIVELINES SECURELY AT-

TACHED AT BOTH ENDS.

• DRIVELINE SHIELDS THAT TURN

GUARDS MISSING

DO NOT OPERATE

DANGER

GUARDS MISSING

DO NOT OPERATE Z940 3

FREELY ON DRIVELINE. Z940 0 DANGER

REMEMBER - If safety signs have been damaged, removed, become illegible or parts replaced without

safety signs, new signs must be applied. New safety signs are available from your authorized dealer.

13

Revision 1-2016

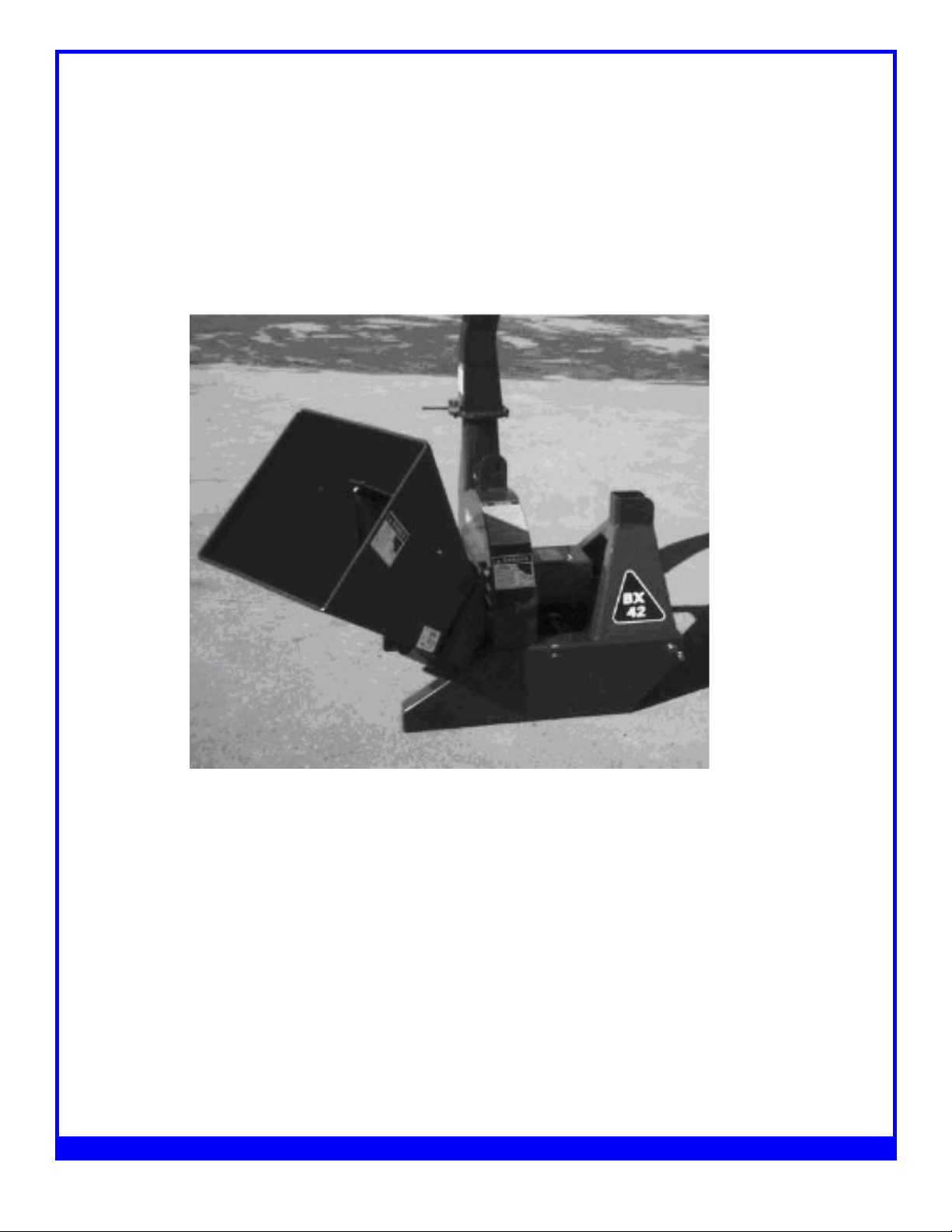

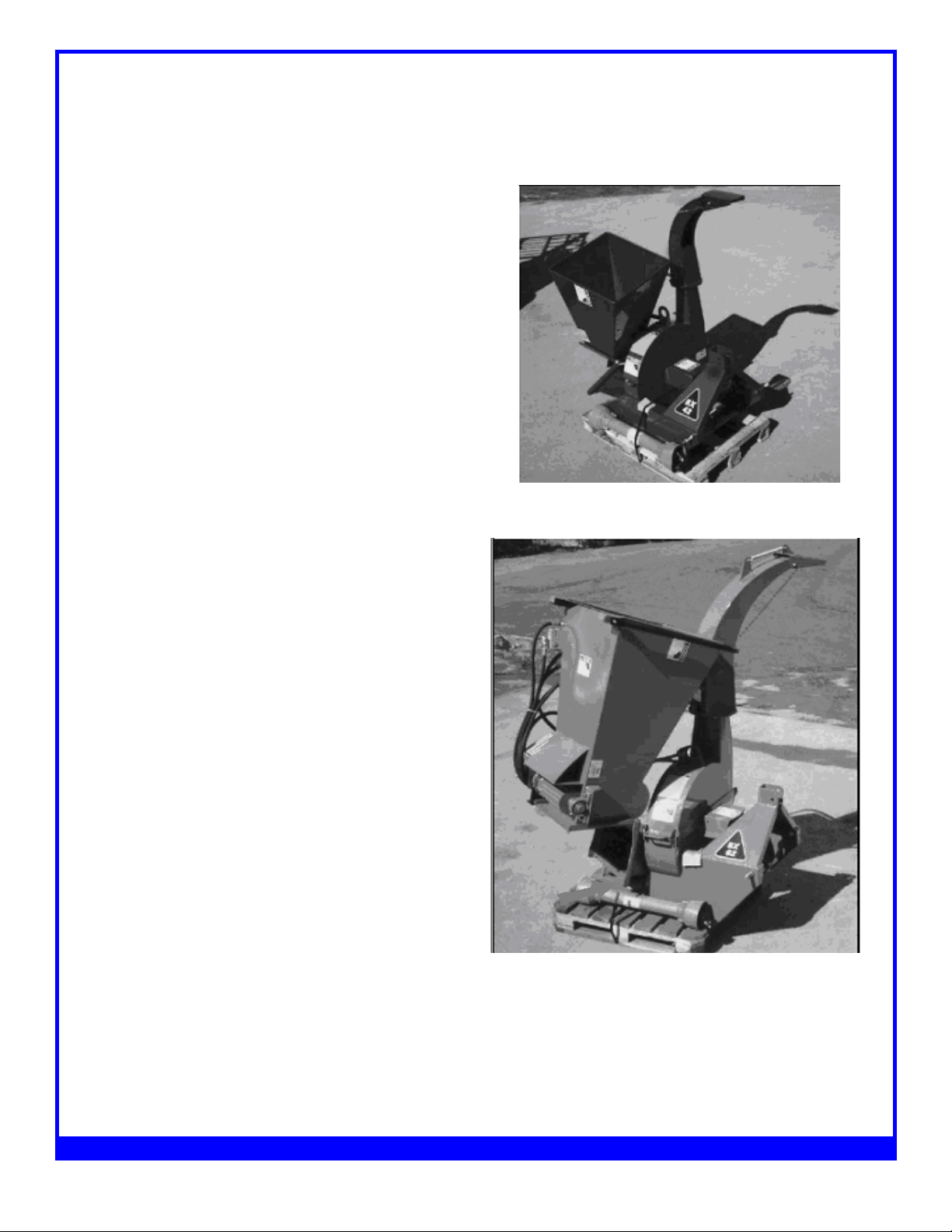

4 ASSEMBLING

The machine comes from the factory in a shipping

configuration. Always use tools equipment and

forklifts of appropriate size and capacity for the

job. Always use 2 men when lifting, moving and

assembling the machine.

When the machine is shipped, follow this proce-

dure when preparing for the customer:

1. Clear the area of bystanders especially small

children before starting.

2. Use a forklift to lift the pallet/machine from the

truck. Carry the load close to the ground.

3. Move the machine to the assembly area. Be

sure there is sufficient clearance to access the

machine from all sides.

BX42

Fig. 1 SHIPPING

4. Cut the tie-down straps.

Fig. 2 TIE-DOWNS

5. Lay-out components next to machine.

14

Revision 1-2016

6. Use a forklift to raise and lift the frame.

7. Or alternatively attach a lifting device to the

lifting bracket on top of the frame.

8. Remove pallet and place machine on the

ground.

Fig. 4 LIFTING

Forklift

Bracket

Fig. 5 PALLET REMOVED

15

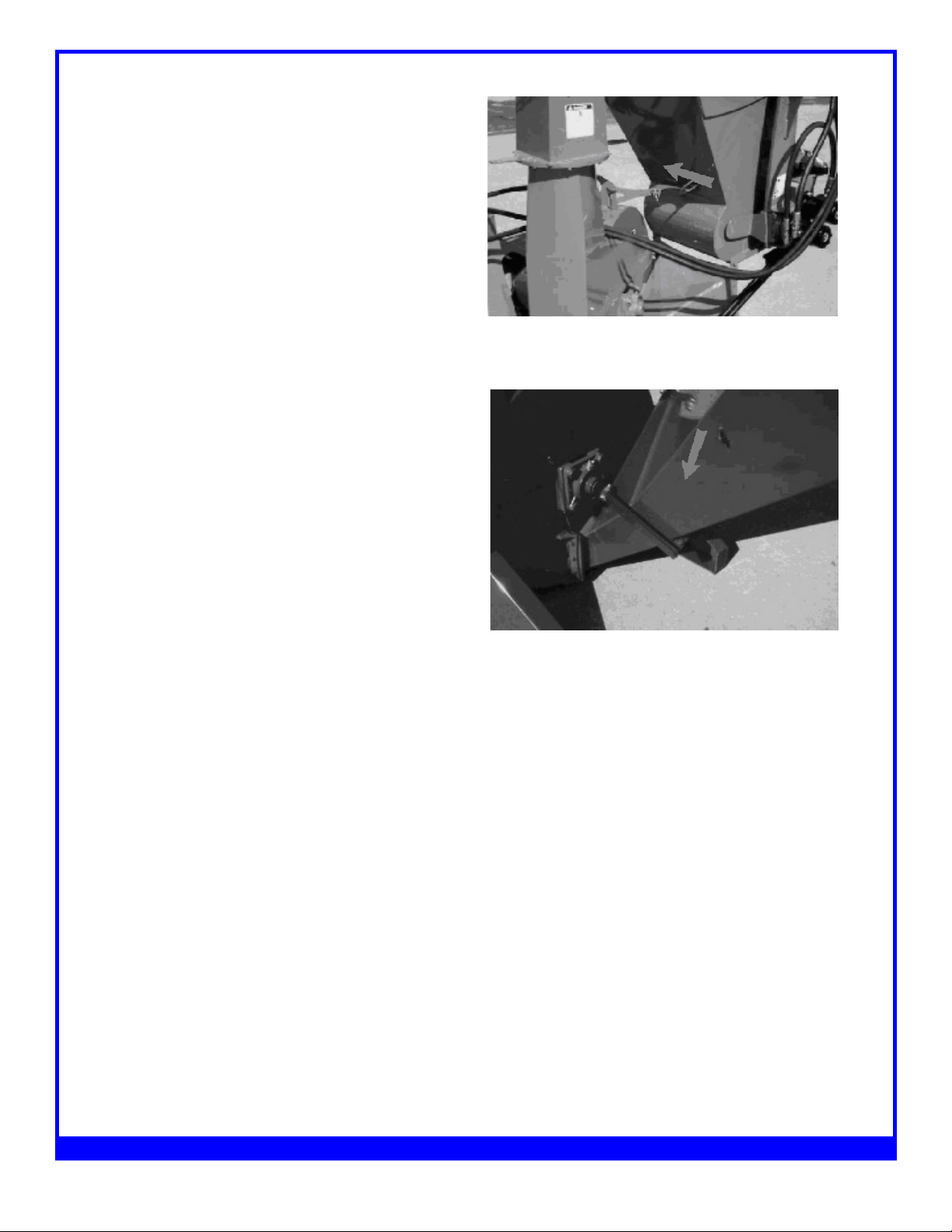

Revision 1-2016

9. Release feed hopper transport latch and lower

hopper into the working position. Stow anchor

latch.

Fig. 6 HOPPER TRANSPORT LATCH

10. Tighten anchor bolts to their specified torque.

Fig. 7 ANCHOR BOLTS (TYPICAL)

16

Revision 1-2016

11. Connect the PTO drivline:

a. Raise the input shaft guard.

b. Check that the driveline telescopes eas-

ily and that the shield rotates freely.

c. Attach the driveline to the chipper input

shaft by depressing the lock pin, slide

yoke over the shaft and pushing on the

yoke until the lock pin clicks into posi-

tion.

NOTE

Be sure the yoke with the shear pin

is attached to the machine shaft.

Aligning

d. Lower the guard to cover the input shaft.

Installed

Fig. 8 DRIVELINE (TYPICAL)

12. Depress handle on discharge chute

latch and turn assembly to its desired

position. Turn until latch seats in its

detent.

Fig. 9 DISCHARGE CHUTE

17

Revision 1-2016

5 OPERATION

OPERATING SAFETY

• Please remember it is important that

you

read

the operator's manual and heed the

safety signs on the 3 Point Hitch Wood Chip-

per. They are there for your safety, as well

as the safety of others. The safe use of this

machine is strictly up to you, the operator.

• Personal protection equipment including

hearing protection, hard hat, safety glasses,

safety shoes, and gloves are recommended

during assembly, installation, operation, ad-

justment, maintaining, repairing, or plugging.

Do not allow long hair, loose-fitting clothing,

or jewellery to be around moving parts.

• Turn machine off, stop and disable engine,

remove ignition key and place in your pocket,

set park brake and wait for all moving parts

to stop before servicing, adjusting, repairing

or unplugging.

• Do not run machine inside a closed building

to prevent asphyxiation from engine exhaust.

• Use care when feeding material into chipper.

Do not send metal, bottles, cans, rocks, glass

or other foreign material into wood chipper. If

foreign material enters chipper, stop ma-

chine, turn engine off and place ignition key

in your pocket and wait for all moving parts to

stop before removing material and/or unplug-

ging. Inspect machine for damaged or loose

parts before resuming work.

• Never use alcoholic beverages or drugs

which can hinder alertness or coordination

while operating this equipment. Consult

your doctor about operating this machine

while taking prescription medications.

• Do not allow riders on this machine at any

time. There is no safe place for any riders.

• Never allow children or unauthorized people

to operate or be around this machine.

• Do not reach into rotor or feed hopper open-

ings when the engine is running. Install and

secure access covers before starting en-

gine.

• Do not move or transport chipper when the

rotor is turning.

• Do not exceed a safe travel speed when

transporting.

• Keep hydraulic lines and fittings tight, in

good condition and free of leaks.

• Keep the working area clean and free of

debris to prevent tripping. Operate only on

level ground.

• Do not point discharge at people, animals or

buildings. Rotor can expel wood chips fast

enough to cause injury.

5. 1 TO THE NEW OPERATOR OR OWNER

The Farmer-Helper 3 Point Hitch Wood

Chippers

are designed to chip or chop scrap lumber, small

trees, brush, limbs and other wood debris. The

chipped material is fine enough to be composted

or used in a variety of ways.

It is the responsibility of the owner or opera-

tor to read this manual and to train all other

operators before they start working with the

machine. Follow all safety instructions exact-

ly. Safety is everyone's business. By follow-

ing recommended procedures, a safe working

environment is provided for the operator,

bystanders and the area around the worksite.

Untrained operators are not qualified to use

the machine.

Follow all safety instructions exactly. Safety

is everyone's business. By following recom-

mended procedures, a safe working environ-

ment is provided for the operator, bystanders

and the area around the worksite. Untrained

operators are not qualified to operate the

machine.

Many features incorporated into this machine are

the result of suggestions made by customers like

you. Read this manual carefully to learn how to

use the chipper safely and how to set it to provide

maximum field efficiency. By following the using

instructions in conjunction with a good mainte-

nance program, your 3 Point Hitch Wood Chipper

will provide many years of trouble-free service.

18

Revision 1-2016

5.2 MACHINE COMPONENTS

The Farmer-Helper 3

Point Hitch Wood

Chipper

is a rotor with

blades

for chip- ping

wood. A

hinged feed

hopper

moves

the wood

material into the rotor.

Each rotor

is

designed

with

4

blades

and a twig-break-

er to

generate

the small

pieces of wood. A station-

ary

knife

at the rear of the

rotor

housing

is

placed

by

the

moving knives

to

shear,

chip or

chop

the material.

The

tractor

provides

rotational

power

through

a PTO

shaft

on

the front

of the

frame

and

hydraulic

power for the hydraulic

feed hopper.

A Manual Feed Hopper

B Discharge Hood

C Rotor Housing

D Rotor Blade

E Stationary Blade

F Twig Breaker

G Hood Deflector

H Hydraulic Feed Hopper

J Hydraulic Feed Control

K Hydraulic Motor

L PTO Driveline

M Rotor

N Paddle

O 3 Point Hitch

Fig. 1 0 PRINCIPLE COMPONENTS

19

Revision 1-2016

5.3 MACHINE BREAK-IN

Although there are no operational restrictions on

the Wood Chipper when used for the first time,

it is recommended that the following mechanical

items be checked:

A. After operating for 1 hour:

1. Torque all fasteners and hardware.

2. Check condition of rotor bearings.

3. Check the condition and clearance of the

twig-breaker, rotor and stationary blades.

Adjust or replace as required.

4. Check for entangled material. Remove all

entangled material before resuming work.

5. Lubricate all grease fittings.

B. After operating for 10 hours:

1. Repeat steps 1 through 5 listed above.

(Section A)

2. Go to the normal servicing and mainte-

nance schedule as defined in the Mainte-

nance Section.

5.4 PRE-OPERATION CHECKLIST

Efficient and safe operation of the Farmer-Helper

3 Point Hitch Wood Chipper requires that each

operator reads and understands the using proce-

dures and all related safety precautions outlined

in this section. A pre-operation checklist is pro-

vided for the operator. It is important for both the

personal safety and maintaining good mechanical

condition that this checklist is followed.

Before operating the Wood Chipper and each time

thereafter, the following areas should be checked

off:

1. Lubricate the machine per the schedule out-

line in the Maintenance Section.

2. Check the rotor, blades and twig-breaker.

Remove any twine, wire or other material that

has become entangled.

3. Check the condition and clearance of the twig-

breaker, rotor and stationary blades. Adjust or

replace as required.

4. Check that all bearings turn freely. Replace

any that are rough or seized.

5. Make sure that all guards and shields are in

place, secured and functioning as designed.

6. Check the condition of the curtain in the feed

hopper. It must be in good condition to pre-

vent chips from flying out.

20

Revision 1-2016

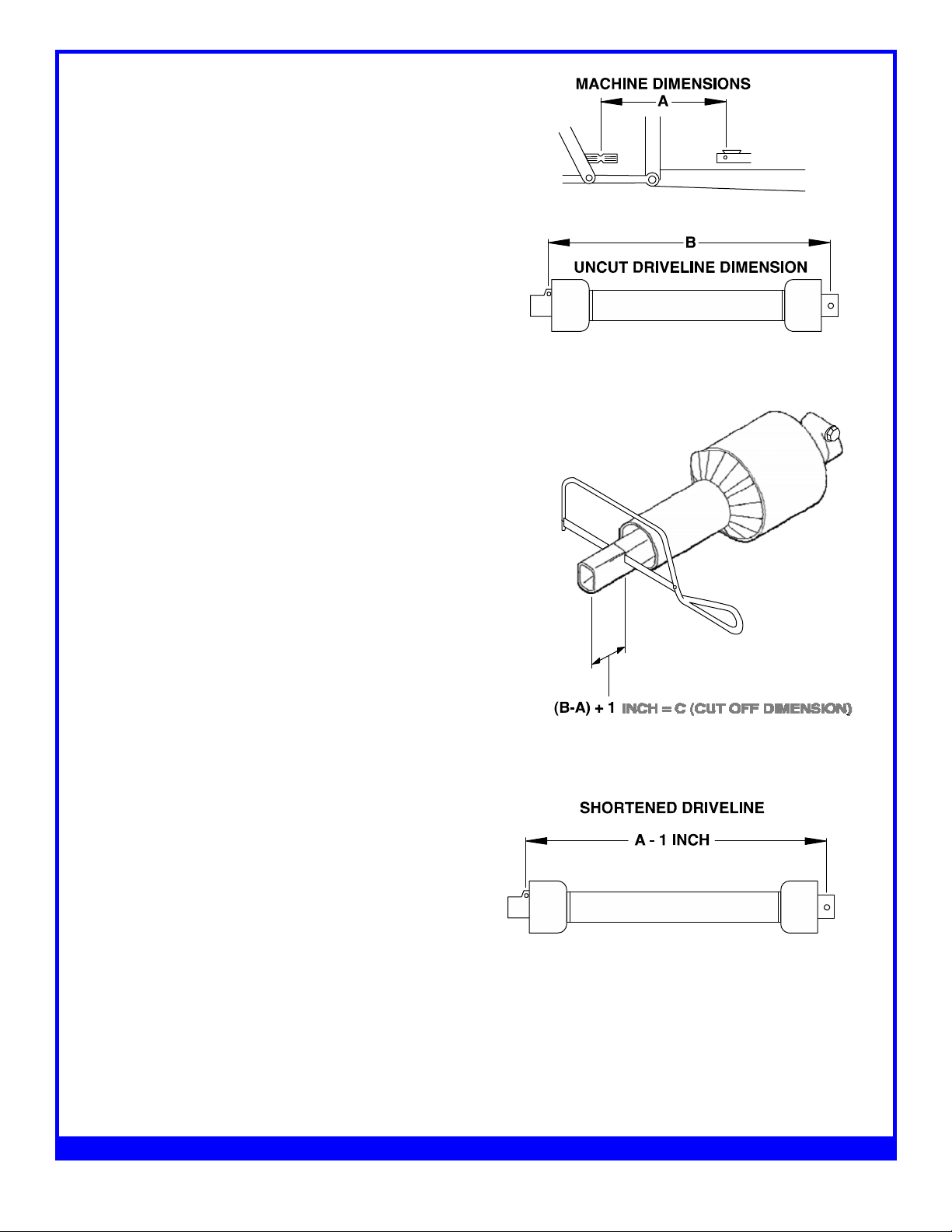

5. 5 DRIVELINE DIMENSION

A PTO driveline is supplied with the machine. To ac-

company the variety of 3 point hitch geometry available

today, the driveline can be too long for most machines

or too short for others. It is very important that the drive-

line be free to telescope but not to bottom out when

going through its working range. If the driveline bottoms

out, the bearings on both the machine and tractor PTO

shaft will be overloaded and fail in a short time.

1. To determine the proper length of the driveline,

follow this procedure:

a. Clear the area of bystanders, especially small

children.

b. Attach the chipper to the tractor (see section

5.8) but do not attach the driveline.

Fig. 11 DRIVELINE DIMENSIONS

c. Raise the machine until the input shaft is level with

the tractor PTO shaft.

d. Measure the dimension between the locking

grooves on the tractor PTO shaft and the machine

input shaft.

e. Measure the same dimensions on the compressed

driveline.

f. If the compressed driveline dimension exceeds the

machine dimension, the driveline will have to be cut.

2. When cutting the driveline, follow this procedure:

a. Subtract the machine dimension (A) from the uncut

driveline dimension (B) or (B-A). This dimension

determines how much too long the driveline is.

b. Add another inch (25 mm) to the dimension

to be sure it doesn't bottom out, to determine

(C) the cut off dimension.

c. Use a hacksaw to cut dimension (C) from

both ends. Cut both the plastic tubes and

the metal cores.

Fig. 1 2 CUT OFF DIMENSION

d. Use a file to remove the burrs from the

edges that were cut.

e. Assemble the 2 ends of the shaft.

Fig. 1 3 SHORTENING

f. Make sure the shaft can telescope freely. If it does

not, separate the 2 parts and inspect for burrs or

cuttings on the shaft ends. Be sure it telescopes

freely before installing.

This manual suits for next models

1

Table of contents

Other Betstco Chipper manuals