Hengmei PJMP215 User manual

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

Shandong Hengmei Better Ennovation Equipment Co., Ltd

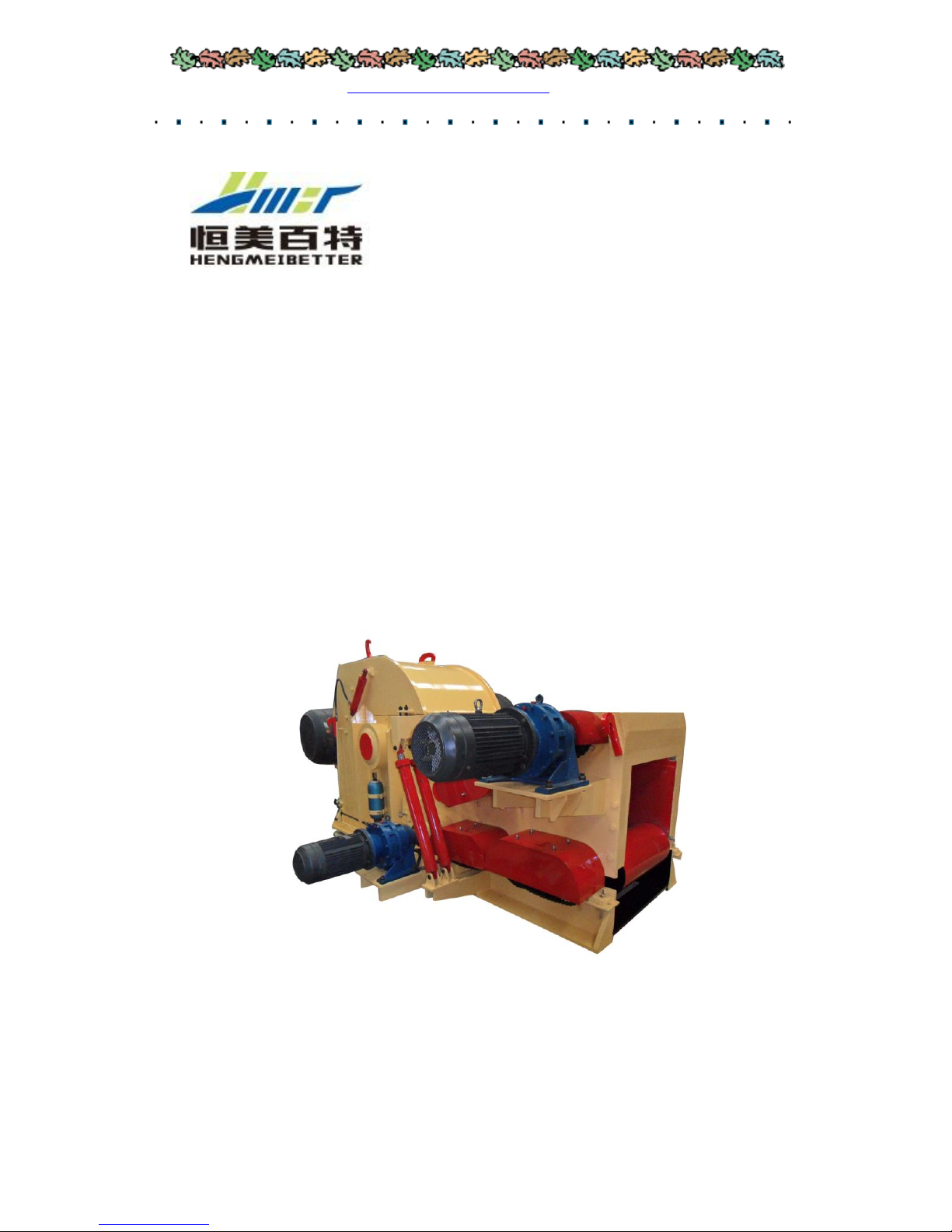

PJMPSeries

DrumWood Chipper

OPERATING INSTRUCTIONS

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

Shandong Hengmei Better Ennovation Equipment Co., Ltd

SHANDONG CHINA

About us

Shandong Hengmei Better Ennovation Equipment Co., Ltd is

a nation-appointed professional manufacturer of machine for

agriculture, forest, pasturage, fishery for many years. Now it

becomes a technology enterprise that integrates scientific research,

exploitation and manufacture as a whole. This company has not only

researched three series of pellet mill, briquette press, crushers,

hammer mill, mixer, cooler and pasture machinery but also the

complete sets of feed, forest, fertilize, energy machinery equipments

with more than ten kinds of high-quality products. They have been

exported to Southeast Asian, Europe, Africa, and America, and so

on.

This company is always improving his design to confirm to

the world market. High quality, creativeness, reliability are our

strong points.

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

Your satisfaction is our permanent pursue!

PREFACE

Thank you for using PJMP Series Drum Wood Chipper made by

Shandong Hengmei Better Ennovation Equipment Co., Ltd. Our

product provides you with high quality, low noise and

multi-functional that can fully satisfy your various demands.

Before operation, be sure to read this manual carefully to ensure

correct operation and make full use of this machine’s advantages.

Besides, this manual is deliveried together with the machine. Be

sure to keep it properly after using for the sake of future reference

when repair and maintenance are needed.

Every machine has passed strict test and check before delivery.

The performance of this product in updating, if change, forgive us

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

for not issuing a separate notice.

Warnings for Security

1. Before use machines, please fully examine if the

rotating parts can turn agilely and if the joints are

fixed firmly, after that start the machine.

2. Do not put hands in the rotating part and the inner

part of the uppercase when it works.

3. If one machine shocks, vibrates violently, or there is

some unusual sound of bump or blocked-up

situations, DO stop running and check it immediately

to remove the trouble.

4. The power should be earthed, preventing accidents.

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

Content

I. MainCharacteristics ……………………………………(1)

II. Installation and Feeding & Discharging System …………(1)

III. Main Structure ……………………………………………(2)

IV.Operation preparation ……………………………………(4)

V. Instalation and Assemble……………………………………(5)

VI. Hydraulic press cushion system……………………………(9)

VII. Electric Control…………………………………………(10)

VIII. Lubricating System …………………………………(12)

IX. Attention Points During Operation … ……… …… … (12)

X. Main Spare Parts ………………………………………(14)

Ⅺ. Catalogue of attached drawings…………………………(16)

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 1 -

I. Main Characteristics

“Hengmei” brand PJMP series Drum Wood Chipper is one kind of special equipment for producing

wood chips, widely used in the raw material preparing process in the factories of flakeboard, fiberboard,

papermaking and wood chips making plant. Small drum type wood chipper is the best equipment for

factory’s laboratory preparing material.

Raw material for Drum type wood chipper cutting is mainly small trail wood, lumbering remainds ( such

as branches, twigs, tress etc) and woodworking remainds ( such as slab, plank, log core, waste veneer etc).

It also can be used to chip non-lignin raw material (such as flax pole, bulrush, bamboo etc).

II. Installation and Feeding & Discharging System

1. Installation

(1) Installation

Wood chipper can be installed on the concrete or steel structural support foundation, and fixed by land bolt.

In order to open cover to replace rotary blade and assemble and dismantle bottom blade base, must

according to the size supplied by “installation foundation sketch up”, and ensure there is enough space.

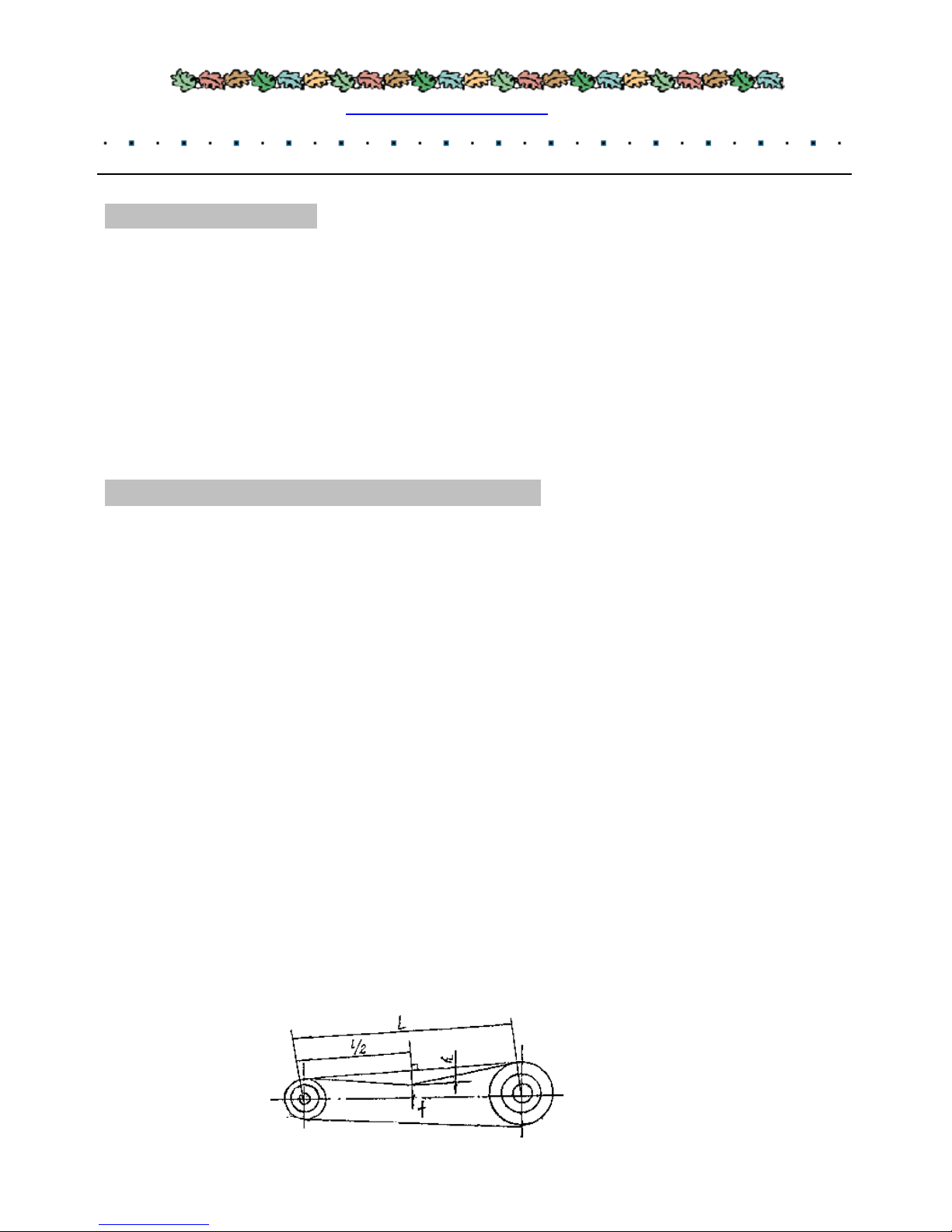

(2) Triangle belt’s Installation

A) Before installing the triangle belt, in order to load the triangle belt conveniently, the space between the

belts must be reduced suitably. DONOT force to install with iron rod, preventing of damaging triangle

belt.

B) Inspect two wheels end surface's straight lines with the straightedge, guarantee two wheels end surface

in the identical plane.

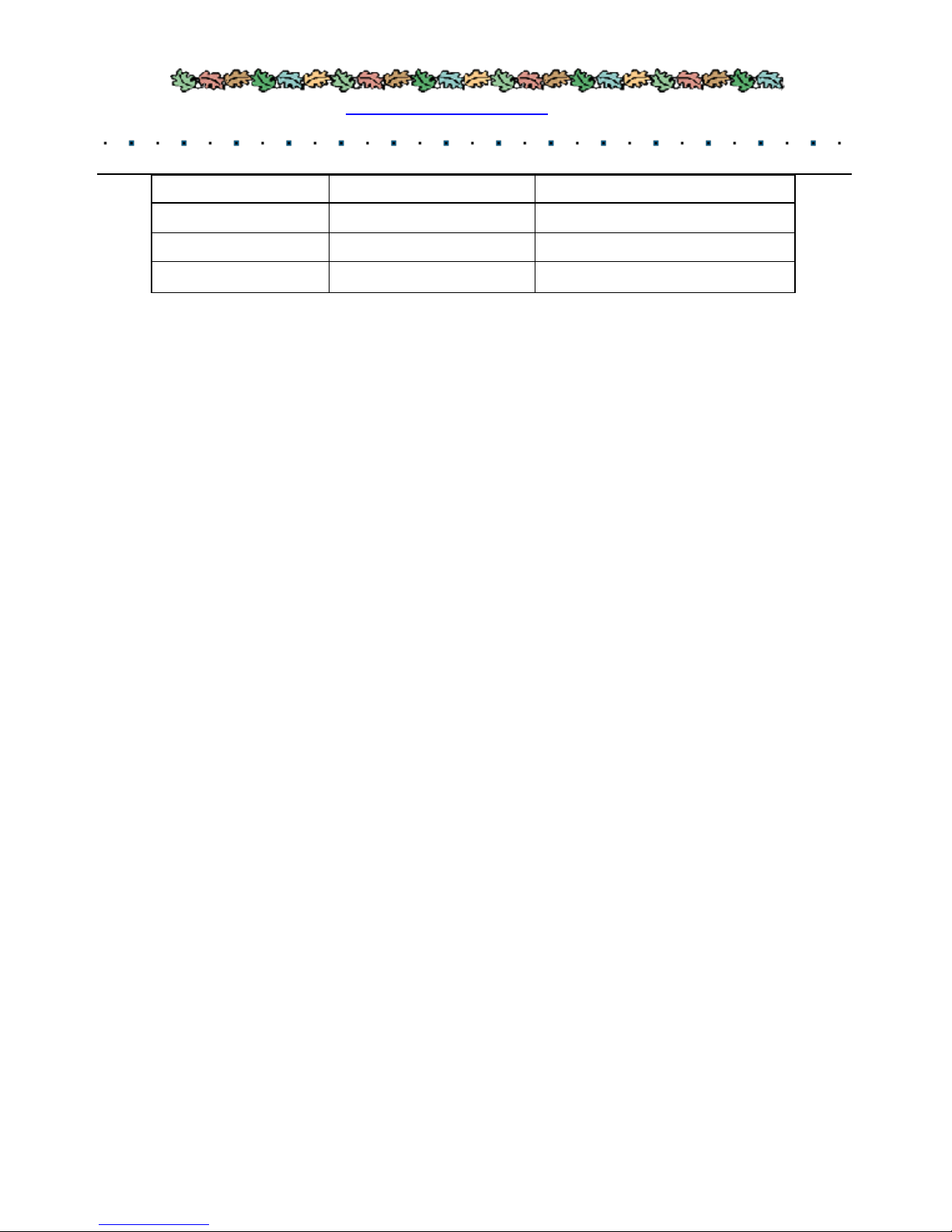

(3) Triangle belt’s tension inspection

A) Adopting to press the lax side, check the bobbin to inspect the degree.

B) After machine 2-3 hours full-load running, check the V belt tension rate, and carry on essential

regulation.

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 2 -

Table 1

2. Feeding device

The belt conveyor or vibrating feeding machine supply the material evenly to the chipper.

3. Discharging device

Discharging device has many kinds of forms, such as air-flow transportation, the chain type trigger

transportation, belt conveyor, bucket elevator transportation etc. But anyway, the discharging quantity

should be according to production arrangement. That is the cuted wood chips should be discharged

promptly to avoid of stock. jam. If choosing the air current transportation, this pointed must be paid

much more attention to.

III. Main Structure

Drum wood chipper is composed of base, blade roller, upper and nether (below) feeding organization,

feeding equipment, hydraulic press cushion system and electric control system.

1. Base

The machine base is welded by high strength steel plate, which is the support foundation of whole

machine. The fixed blade base support is welded together with the machine base and used for place bottom

blade base. The fixed blades is fixed on the bottom blade base through pressed block by a screw. The

bottom blade base can extract freely through hole in base wall plate side, it is fixed by two spline. The

wood chips fall through holes in sieve, then discharge from the machine base. The oversized wood chips

can be cutted again through fragment pole on the machine base.

2. Blade roller

The blade roller is working part of wood chipper, it is welded by steel plate (small wood chipper roller is

overall solid structure). It has better steel nature and inertia and after dynamic balance test.

Model

Force

f

(

N

)

Single Belt Flexibility

h

(

mm

)

V-Belt

Model

、

Length

V- Belt Qty

pcs

PJMP215

58.96

17.3

C2800

4

PJMP216

63.2

21.2

C3400

4

PJMP218

66.7

22.4

C3700

6

PJMP2113

102.4

32.3

SPC-6300

8

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 3 -

The main axle and the blade roller join together through locking equipment and the flat spline. Its structure

is simple, the assembling and dismantling is convenient, operation is reliable. Both sides of main axle are

supported by automatic self aligning roller bearing, bearing base is fixed on machine base.

There are two rotary blades on the blade roller, it is fixed on the blade roller by special rotary blade bolts

through pressed block.

3. Upper and nether feeding organization

The upper feeding organization is composed of upper feed roller base, feed roller, feed roller axle,

pendulum shaft and reducer.

The nether feeding organization is composed of feed roller, support roller, feed roller axle and reducer.

The feed roller diameter is big, the weight is heavy and the surface has thick tooth, then can compact raw

material, so that the raw material can enter the cutting position in balanced speed to keep the wood chips

length and quality, the upper and nether feed roller stagger mutually to clean up the scraping.

The upper feed roller is tightened with axel through locking equipment, the axel is supported by spherical

surface roller bearing, bearing base is fixed on the upper feed roller base. The upper feed roller is fixed on

the machine base through pendulum shaft, and can swing circling pendulum shaft to ensure it can adapt

the feeding altitude automatically.

The nether feed roller is tightened with axel through locking equipment, axel and supporting roller is

supported by spherical surface roller bearing, bearing, bearing base is fixed on the machine base.

The upper and nether reducer drive the upper and nether feed roller respectively. The upper feed roller’s

rotation direction is same to blade roller rotation direction, the nether feed roller’s rotation direction is

opposite to blade roller rotation direction.

4. Feeding equipment

The feeding equipment has the belt conveyor and vibrating feeding machine two types.

The belt conveyor is composed of head wheel, rear wheel, belt and rack. The head wheel is driven by

nether feed roller axle through chain link. The head wheel drive belt to send raw material to feed inlet.

Vibrating feeding machine is composed of feed groove, base and driving part. Motor drives

crank-connecting rod mechanism, make the feed trough simple harmonic oscillation through eccentricity

revolving, make the raw material move ahead to feed inlet.

5. Hydraulic press cushionsystem

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 4 -

Medium or big model drum wood chipper have the hydraulic press cushion system,

expectthe small drum wood chipper.

IV. Operation Preparation

1. Afterinstallment finished, inspect shoule be carried out before start.

(1) Inspect rotary blade and bottom blade fasten or not according to stipulation tight torque.

(2) The distance between rotary blade and fixed blade should be 0.5-1mm (examine by caliber gauge).

(3) There is no metal sundries in the machine.

(4) There is nocollision sound after the belt pulley turning more than one circle by hand.

(5) The triangle belt tension rate is moderate, and should install the belt cover.

(6) The electrical system is at normal state.

(7) Hydraulic system’s joint place seal is good, no oil leak phenomenon.

(8) Blade roller and Feed roller operating direction is right.

2. Start aftereach above items normal inspection.

3. Start the machine empty for 1-4 hours, and check the following items:

(1) No abnormal sound. If having, please stop and remove it.

(2) The bearing temperature rises not more than 35℃

(3) The machine base do not shake obviously, the fastener do not loose, the moving part is nimble, no

block phenomenon.

(4) The electric parts is nimble.

4. After normal revolve without anything in the machine, then carry on load cutting.

V. Instalation and Assemble

1. Replacement of rotary blades

(1) The rotary blade dismantling sequence

When machine stops, open the cover, then inserts the clevis pin from the holes which is fixed knife blade

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 5 -

roller from machine base side, lock the blade roller. Clean holes on press blade board and fasten bolt

forehead. Turn the rotary blade to tighten the screw (or tighten bolt), take (or press) pressed blade block

and take out the rotary blades.

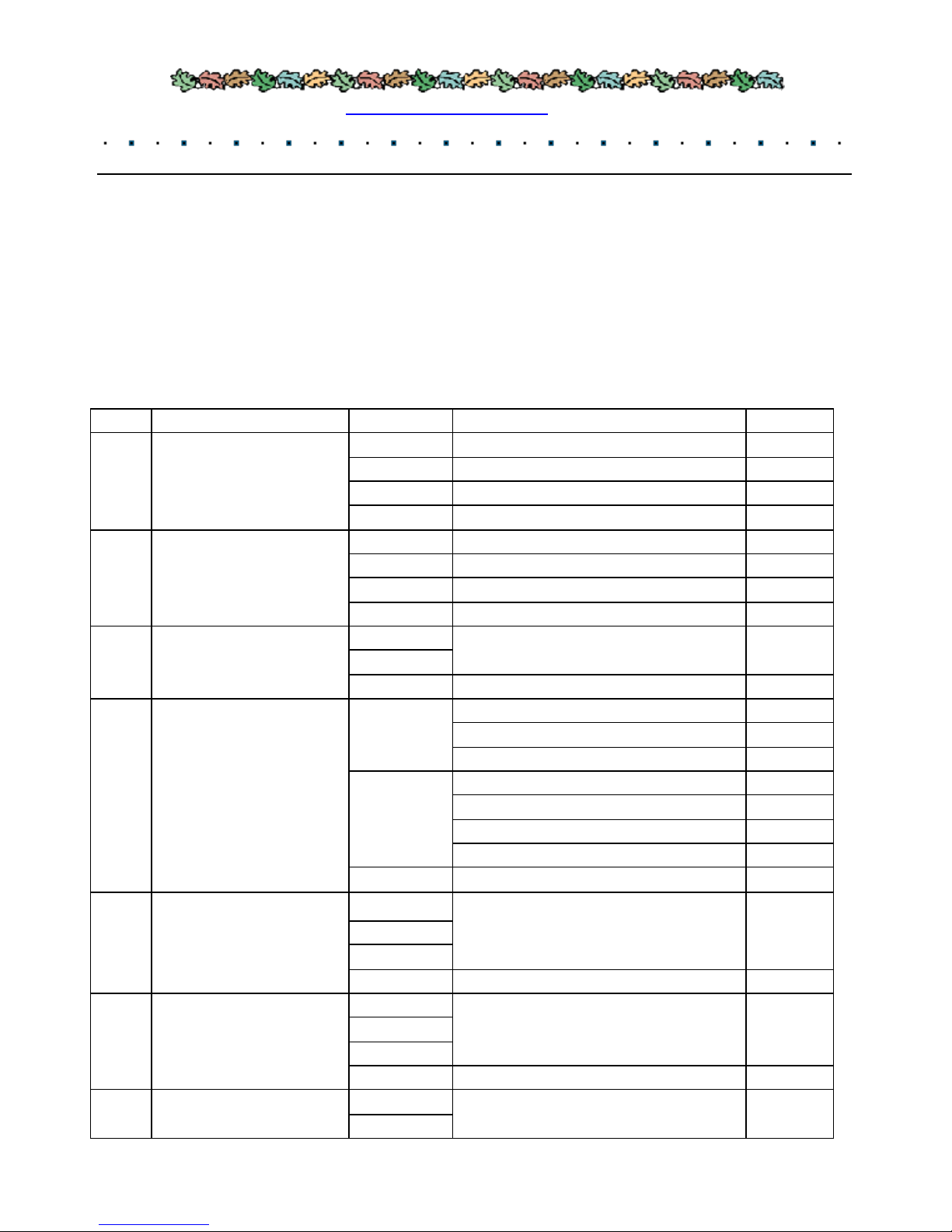

(2) When rotary blades should be sharped again, must make sure of knife edge angle in Table 2, and must

adding refrigerant when sharpening.

(3) Rotary blade sharpened must adjust to size stipulated in Table 2.

(complete adjusting before leaving factory). (BX213 rotary blade adjust on blade roller).

(4) Rotary blade permission biggest sharpeed quantity may refer to stipulation in Table 2. Wen total

sharpened quantity surpasses 40mm, the bolt on the rotary blade must exchange the hexagon bolt of

M10x90 (or M10x85).

(5) Rotary blade installation sequence

A. Please clean carefully the joint placing rotary blades in the blades roller using compressed air or the

other efficacious method.

B. Install the rotary blade on the blade roller, tighten gently the two fastened bolts on both sides, tip blade

edge with the rubber hammer or the mallet, making the rotary blade back’s two adjusting bolts close to

localization bolt head on blade roller.

C. Use the torsional spanner and increased torsional equipment along with the machine to tight the rotary

blade fastened bolt according to Table 3 request.

Table 2

Model

Rotary blade

edge angle

Rotary blade permission

sharpening quantity (mm)

Rotary blade

adjustment size(mm)

PJMP215

32º

35-40

157+0.5

0

PJMP216

32º

60

198+0.5

0

PJMP218

32º

60

233+0.5

0

PJMP2113

32º

60

225+0.5

0

Table 3

Model

Rotary blade bolt tight moment of

force N·m

Torsion wrench adjustment value

N·m

PJMP215

392

98

PJMP216

392

98

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 6 -

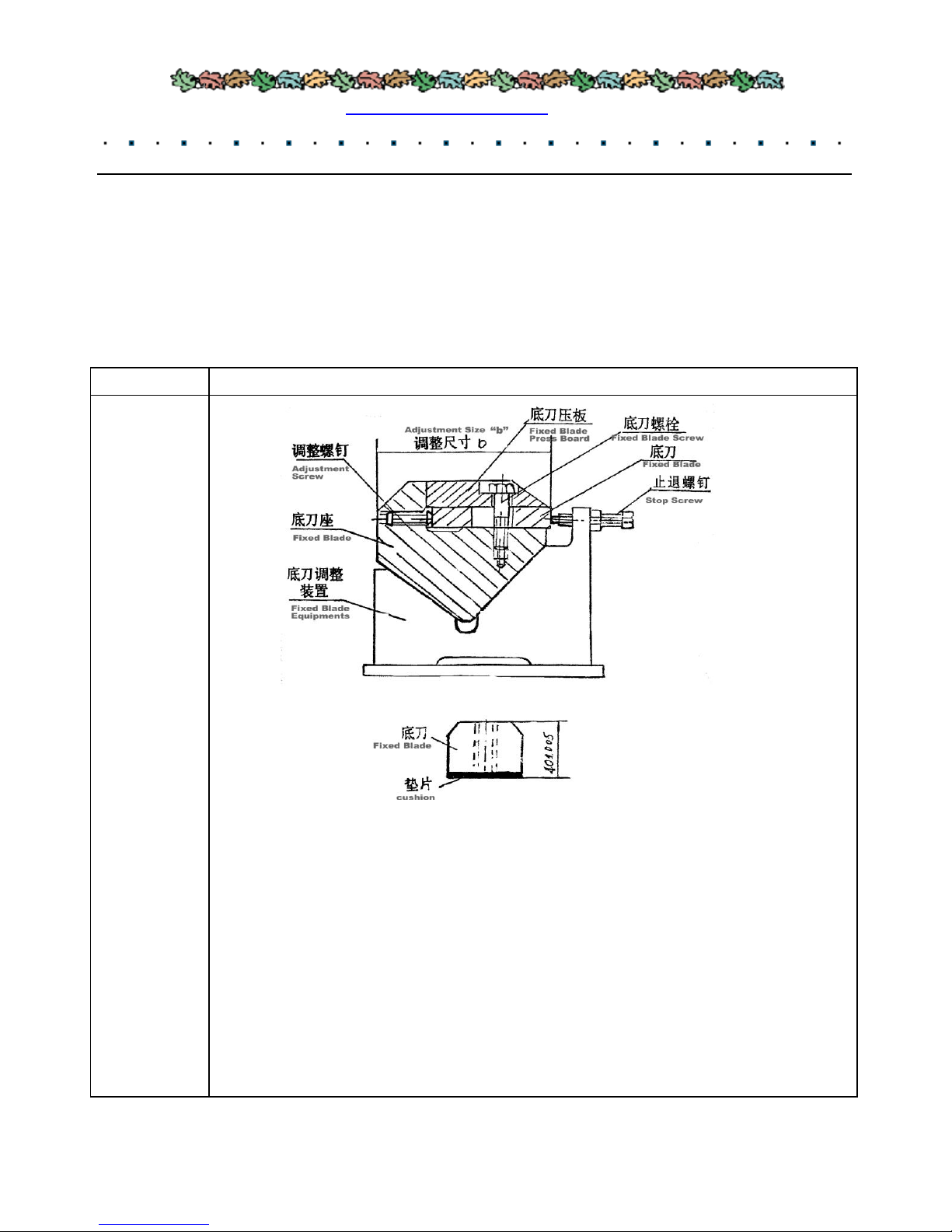

2. Replacement of fixed blade

1)Disassembly sequence of bottom blade

A. Loosen and take down the twoclamp key (or fastening screw) on the machine base.

B. Pull the fixed blade base using the bottom blade disassembly tool or by hand directly.

C. Loosen the bottom blade fastened bolt and take down the bottom blade.

2) Bottom blade sharpening

The bottom blade has 2-4 cutting edges as the following chart, once one cutting edge goes blunt, change

another cutting edge, when all cutting edges go blunt, then sharpen them. When sharpening must use the

refrigerant and guarantee the blade edge angle. If necessary, after sharpened, survey with gauge which

provide stochastically.(for example BX2113).

3) Fixed blade adjustment

PJMP218

480

130

PJMP2113

580

150

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 7 -

Need to adjust after bottom blade sharpened, the adjustment method please see the following Table 5.

Table 5

Model

Fixed BladeAdjustment Way

PJMP215

PJMP216

PJMP218

Ajusted at the fixed blade device, put the fixed blades abd the fixed blade base in the

fixed blade device, adjust the screw, make the bedge next to retreat bolt, tighten the fixed

blade screw.

Adjustment size “b” confirmation:

1. Fix the bottom blade to the base, tighten it by bolt.

2. Clean the bottom blade base, and push it into supporting.

3. Check the space between fixed blade and rotary blade whether 0.5-1mm, by the caliber

gauge. If not, adjust the screw to get it. So this szie “b” is the fixed blade size, adjust the

fixed blade based on it.

4. Size “b”does not change once confirmed, but when the blade roller reset, this zie

shoule be adjusted again.

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 8 -

4) Assemble of fixed blade

A. Tighten adjusted fixed blade and base with bolt. The bolt fasten force and the torque wrench adjustment

value sees the table 6.

B. Clean the fixed blade and daub the suitable amount lubricating oil, pushit to bottom blade base’s

supporting on the machine base.

C. Fill the clamp key after oiled, and screw the bolt on both sides simultaneously or alternately, and

tighten it.

Table 6

Model

bottom blade bolt tight moment of force

N.M

Torsion wrench adjustment value N.M

PJMP215

98

98

PJMP216

98

98

PJMP218

120

120

PJMP2113

355

300

3. The blade roller, feed roller and supporting roller’s bearing base installation

(1) Fixedend bearing installation (the end to belt pulley or reducer)

A. Install bearing base on machine base wall plate, tighten by bolt.

B. Install bearing , tightened bush, gasket and round nut on the axel and fasten round nut. When fastening,

check and adjust the space between bearing outer ring and roller to be within the stipulation scope on the

following Table.

C. Fill lubricant reach 1/4 room space (lubricant is lithium lubricant grease)

D. Install the paper gasket, bearing cover, tighten bolt.

Table 7

Model

Bearings radial space (mm)

PJMP215

0.06-0.0

PJMP216

0.06-0.09

PJMP218

0.065-0.1

PJMP2113

0.07-0.11

PJMP2113

Fill up adjusting shim same thick as sharpening quantity under the

bottom blade (provide along with the machine), guaranting that the

bottom blade and the filling piece thick is 40±0.05 millimeter.

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 9 -

(2)Moving end bearing base installation

A. Bearing base installs in machine base wall plate, fix the bolt, not tighten, keep the distance between

bearing base and wall plate 2mm, then according to the fixed end method to load bearing, tightened bush,

gasket, retreat bolt and round net, then tighten.

B. Fasten the bearing base and fix the bolt.

C. Fill lubricant reach 1/4 room space.

D. Install the paper gasket, bearing cover, tighten bolt.

4. Locking equipment assembling and dismantling

Locking equipment is used for joint blade roller andaxel, feed roller and axel.

1) Assembly sequence

①Clean the locking equipment and placed axel and the hole surface, add little grease (DONOT use grease

including disulfidized aluminum).

②Push locking equipment covering axel, then push into the hole base.

A. Tighten until feel there is slight resistance by hand, this step is very important, decides the proper

alignment.

B. Use wrench.tighten the bolt in the turns of diagonally chiasmus.

C. Then tighten whole as the step above.

2)Disassembling sequence

A) Loosen tightened bolt, stick lightly cover, so the circle will be loose.

B) If the outer and inner circle still grip, screw four bolts into the screwing holes in inner circle, force the

outer circle down.

5. The sieve disassemble and installation

(1) Disassemble

A. Loosen cover bolt and take down the cover

B. Loosen clamp bolt and take down the clamp.

C. Loosen the fragment pole bolt and take down the fragment pole.

D. Take out the sieve

(2) The sieve assembly sequence and the disassembly sequence is opposite.

VI. Hydraulic press cushion system

1. Open cover

When blade roller stops completely, loose the second fixed bolt on the cover. Open cut-off valve on the

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 10 -

small oil cylinder, and close cut-off valve on the big oil cylinder. Start oil pump to put oil into small oil

cylinder until the cover open. Close the cut-off valve after hooking.

The cover dropping speed can be adjusted oil pump’s switch knob or throttle valve. The cover dropping

should be slow and steady.

2. Adjust the upper feed roller pressure

Feeding raw materia different, upper feed roller (pendulum) pressure should be adjusted accordingly.

When cutting the small round wood or big material, the upper feed roller pressure is smaller (i.e enter

flowing oil pressure to cylinder smaller). Contrariwise, when cuts smaller material, board or waste board,

the upper roller pressure is bigger (i.e enter flowing oil pressure to cylinder bigger).

When chipper working, enter stated oil pressure through oil pump (shows in Table 8).

A) When the pressure is lower than needed, open the cut-off valave on the big oil cylinder, start the oil

pump to supply the oil. When pressure achieves needed data(on pressure gauge demonstration), then close

the cut-off valve.

B) When pressure is higher than needed, open the cut-off valve, place the oil pump switch to the oil

discharge position, cylinder’s pressure can be lower.

3. Accumulator’s function

Accumulator has both storing up energy and release shock functions.

when wood chipper working, the cut-off valve should be closed. When the “pendulum” lifts, the

accumulator discharge to the cylinder. When “the pendulum” drops, the oil returns to the accumulator

from cylinder.

Because there are certain pressure nitrogen in accumulator which plays cushioning effect, thus the

“pendulum” drop steadily and no impact.

The nitrogen pressure entering accumulator is according to Table 8.

Table 8

Model

Nitrogen pressure enter (Pa)

Oil pressure enter (Mpa)

PJMP215

1

1.3

PJMP216

1.2

1.6-1.8

PJMP218

2

2.7-3

PJMP2113

2.5

4.5-5

4. The speed of “pendulum” is controled by unilateralism cut-off valave. It should be slow drop, but no

stop.

5. The Accumulator can be taken down after all the oil pressure discharge whole.

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 11 -

VII. Electric Control

1. Main motor overload protection

The main motor starts through”Y-△”transferring switch, there is overload protection in the lines, when

overload operation, automatic turn off the circuit will work.

The main motor’s overload protection is controlled by heat relay. When the main driving motor’s current

surpasses the rated data and continues for a certain time, the alarm can sound the warning. Once this things

omes, make sure to stop feeding system and reverse, withdrawing the raw material, eliminate trouble, then

start the feeding system to continue.

2. Interlock condition

When the control push-button dials in “the link” position, the machine is at the interlock condition. At this

time, only the main motor operates, the feed motor can work. If the main motor stops, the other motors

will stop expect thedischarge motor working.

When wood chipper works normally, two feeder motors and conveyor motors ( shaking groove motor)

working together.

When material blocks (machine alarms), feeding system stop and need to back up, two feeder motors and

conveyor motor reverse together ( shaking groove in stop condition).

3. Feed motor starting

Feeding system transmission motor’s stop and restart are controlled by current reply, it depends on main

transmission motor’s load size.

When surpassing the finite current, the relay makes the feeding motor stop, and makes the supporting

feeding belt stop through interlocking equipment. When current dropping the limitation value data, the

relay operates, the feeding motor restarts, the process is automatic.

When feeding system need to back up, must firstly press the “stop” button,, when feeding system stops,

then press the “back up” switch.

4. “Pendulum” upper limit switch

when feeding height is too high to make the “pendulum” lift and surpasse stipulated limit of Table 9, the

limit switch will be touched so that the feeding system will stop. After pressing down “reverse” button,

feeding system will reject material backwards. After “pendulum” drops, the limit switch reposition, and

the limit circuit will be on. Press “FWD” button again, feeding system will continue to supply material.

Table 9

Model

“pendulum” upper limit

height mm

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 12 -

Attention: The limit switch installation position can

not change at will.

5. Emergency Stop Botton

There is an emergency stop button on machine base wall and control cabinet outside, when emergency

case comes, please press this button, the machine will stop operation.

VIII. Lubricating System

1. The blade roller, feeding roller, supporting roller, bearing on pendulum shaft need disassemble and clean

and exchange new lubricant, after half an year working. The blade roller bearing lubricant is the lithium

base lubricant, the other bearings can use ZG2 or the ZG3 lubricant.

2. The chain link in the feeding system after working 2000 hours, must be cleaned. When normal work, it

should be added lubrication regularly.

3. The belt conveyer supporting roller bearing should regularly lubricate, the lubricant trademark is ZG2

or ZG3.

4. The decelerator's oil level should maintain certain altitude, may observe from the oil gauge, upper

decelerator's oil level is on the upper oil gauge middle line, nether decelerator’s oil is on the nether oil

gauge middle line. Decelerator's oil should the periodic inspected, added or exchanged.

5. Electric motor maintenance refer to related instructions.

IX. Attention Points During Operation

1. The big input size can fit for many kinds of raw materials, such as the crooked branches, plank or the

bundle of small batten and so on. But DONNOT put the heavy log in section on it because of the big

feeder, otherwise it will damage the blade and machine.

The biggest diameter or the sectional area of input materials, please see Table 10. When near to the biggest

diameter in section, the cut wood chips can’t surpass 2m.

The moisture of cutted raw material had better at 40%.

Table 10

Model

Cut Total Diameter in

Section (cm2)

Diameter of Single Log(cm)

PJMP216

180

PJMP218

225

PJMP2113

400

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 13 -

PJMP215

≤86.5

≤10.5

PJMP216

≤110

≤12

PJMP218

≤200

≤16

PJMP2113

≤420

≤23

2. When tighten the blade, please make sure to use the torsional spanner which can concretely show the

torsional spanner and increased torsional equipment (along with this machine).

3. When tighten the fixed blade, please make sure to use the torsional spanner which can concretely show

the torsional moment.

4. The tightening bolts of the rotary blades and fixed blades must be adopt the special high-strong bolts

supplied by us ( which top of bolt shows the ZL). DOONOT use the common bolts. The lifetime of

high-strong bolt is one year, PLEASE change all by new ones after one year.

5. The rotary blade change must be in sets. When sharpening the blade edge, two rotary blades sharpeded

qutity should be the same, make sure the weight of two blade is consistent, avoid unnecessarily shaking.

When deliveried, two rotary blades have been matched already. If found blades confused, please weight

and match them again. Please pay more attention to each set of rotary blades, make sure the different

weight between these two blades less than 25 gram.

6. When the rotary blades and fixed blades sharpening, pelase add the refrigerant, otherwise the blade

edges will be wicked because of too hot or curled, causeing the durability of blade reduced. Generally

speaking, the rotary blades should sharped every one or two shift. After rotary blades changed four times,

please take out the fixed blade and do these two things: check the fixed blades if necessary to change the

cutting edge; Lubricate contact surface of fixed blade base.

7. When the nitrogen pressure in accumulator is lower than the regulated value in Table 8, please fill the

nitrogen. Please check the pressure and air filled by the aerated tool.

Note: Please aerate the nitrogen to accumulator, DONNOT aerate the oxygen or air, otherwise will lead

to explode. Details should be acted according to the description of manufacturer. When aerating the

nitrogen by the nitrogen bottle directly, the switch should open slowly, prevent the high-pressure nitrogen

enter into bottle and damage gallbladder.

8. Electric apparatus should be checked termly, make sure the correct action of them, avoid the

unnecessary damage.

9.When the machine chips overload, the operation current should not surpass the rated current (the

instantaneous overloading is permitted).

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 14 -

10. When start the machine, please start the motor of discharging materials system first, then start the main

motor. When the blades rollers work stably, start the feeder motor. When stop the machine, please close

the feeding system first, after the blade rollers can’t cut the wood, close the main motor. Please

DONNOToverturn the upper order.

11. Please check and maintain the machine after working per shift, especially check the tightening bolts

outside firm or not, the hydraulic pressure systemwork well or not. Examine all the bolts per month.

12. Checked parts of this machine in the breaking-in period should refer to the upper feeding rollers(-)

X. Main spare parts

1. Blades

Items

Name

Model

Code in drawings

1

Rotary blade

PJMP215

B18·2-4

PJMP216

B 12·2-12

PJMP218

PJMP218·02·300-01

PJMP2113

B36·2-10

2

Fixed blade

PJMP215

B18·1·3-2

PJMP216

B12·1·3-2

PJMP218

PJMP218·01·400-02

PJMP2113

B33·1-13

3

Sieve

PJMP215

B18·1·2

PJMP216

B12·1·2

PJMP218

PJMP218·01·200

PJMP2113

B36·1·2

4

Base of fixed blade

PJMP215

B18·1·3-3

PJMP216

B12·1·3-2

PJMP218

PJMP218·01·400-03

5

Rotary Blade Bolts

PJMP215

B36·2-13

PJMP216

PJMP218·02-10

PJMP218

PJMP2113

PJMP36·2-13

6

Fixed blade Bolts

PJMP215

PJMP218·01·400-04

PJMP216

PJMP218

PJMP2113

B36·1-12

Tel:+86-18615559369 Web: www.pellet-machine-mill.com E-mail: lingfengzhuri@gmail.com

- 15 -

2. Bearing list

Item

Name

Model

Bearings model

Qty

1

Bearing of Blade Roller

PJMP215

113524

2

PJMP216

113524

2

PJMP218

113530

2

PJMP2113

3113736 import model:23136SKMB

2

2

Bearing of feeding roller

PJMP215

113516

6

PJMP216

113516

10

PJMP218

113518

12

PJMP2113

3113722 import model:23122K·MB

18

3

Bearing of supporting

roller

PJMP215

113515

2

PJMP216

PJMP2113

113518

2

4

Bearing of Reducer

PJMP215

PJMP216

PJMP218

32309

2

3056308

2

7508

4

220

4

PJMP2113

5

Bearing of Belt

Conveyor Driven

(Or shaking groove)

PJMP215

90515

2

PJMP216

PJMP218

GBX2113

90516

2

6

Bearing of Tighting

Roller in Belt

PJMP215

90512

2

PJMP216

PJMP218

PJMP2113

90514

2

7

Bearing of supporting

roller in belt conveyor

PJMP215

C0108

2

PJMP216

This manual suits for next models

3

Table of contents

Popular Chipper manuals by other brands

EMB

EMB Wallenstein CR Series Operator's manual

Echo

Echo SC5670B (75524) Specifications

Echo

Echo Bear Cat CH922DH owner's manual

Farmi Forest

Farmi Forest CH10 OPERATION, MAINTENANCE AND SPARE PARTS MANUAL

Farmi

Farmi 381 HFC OPERATION, MAINTENANCE AND SPARE PARTS MANUAL

Troy-Bilt

Troy-Bilt CS4265 Operator's manual

Billy Goat

Billy Goat Termite KD512SP Operator owner's manual

DK2 Power

DK2 Power OPC505AE Assembly guide

Farmi Forest

Farmi Forest CH180 AVANT Operation and maintenance manual

Farmi Forest

Farmi Forest FARMI 260 OPERATION, MAINTENANCE AND SPARE PARTS MANUAL

Bearcat

Bearcat 71020 owner's manual

Forest-Master

Forest-Master FM13WC user manual