Better Packages BP555e User manual

Model BP555e

Tape Dispenser

BP555eSERVICE MANUAL

B

BB

B

ETTER

ETTER ETTER

ETTER

P

PP

P

ACKAGES

ACKAGESACKAGES

ACKAGES

®

255 Canal Street Shelton, CT 06484

Web Site: www.betterpackages.com

File Name: BP555e Service Manual Rev06.doc

Better Packages Inc. 2

This manual is a non-controlled document.

Information in this manual does not constitute a warranty of performance. Futhermore Better

Packages reserves the right to revise this publication and make changes from time to time, in its

content.

Better Packages ASSUMES NO LIABILITY WHAT SO EVER FOR ANY LOSSES OR

DAMAGES INCURRED AS A RESULT OF INFORMATION CONTAINED IN THIS MANUAL

Proprietary Notice

This publication contains information proprietary and confidential to Better Packages. Any

reproduction, disclosure, or use of this publication is expressly prohibited except as Better

Packages may otherwise authorize in writing.

Better Packages

255 Canal Street

Shelton, CT 06484

Telephone: 800/237-9151

Web Site: http://www.betterpackages.com

Better Packages Inc. 3

TABLE OF CONTENTS

Safety Precautions

Technical Data

Maintenance and Repair

Recommended Periodic Maintenance

Brush Cleaning

Blade Oiling

Cleaning

Heater Replacement.

Motor Brush Replacement

Motor Replacement

Shear Blade Replacement

Feed Wheel / Blade Height Adjustment

Keypad and membrane Replacement

Key pad only

Connector plate

Motor Chain Adjustment

Circuit Board

Front and Rear Cover

Length Sensor

Water Tank Adjustment

Tape Sensor

Feed Wheel

Fuses

Solenoid

Blade Oiler

Better Packages Inc. 4

Troubleshooting Tape Feed Problems

Tape Jams

Tape Strips too short

Constant Feed or Extremely Long Tape Piece

Tape Feeds too slowly

No Tape Feed

Tape Hits Blade or Left Hand Corner of Tape Folded

Tape Strips not Correct Lengths

Wiring Diagrams

Spare Parts List

Better Packages Inc. 5

SAFETY PRECAUTIONS

Must read before servicing equipment.

Always

unplug the machine

before performing any maintenance or

repair. Line voltages may be present even with power switch in Off

position.

This machine is designed for sealing cartons with water activated tape. Any other use will

void all warranties and any responsibility or liability of Better Packages, Inc.

Read all Safety Precautions and Operating Instructions before powering on and using the

machine.

Any operator of this machine must be fully trained in the operation and safety.

In the event of a malfunction or breakdown, grounding provides a low resistance path for

electric current to reduce the risk of electric shock. This machine is equipped with an electric

cord having an equipment-grounding conductor and a grounding plug. The plug must be

plugged into a matching outlet that is properly installed and grounded in accordance with all

local codes and ordinances.

Before connecting the machine to the power mains verify that the electrical ratings of the

machine match the electrical supply intended for connection, otherwise do not connect. If the

correct power is not available contact the reseller.

Before maintenance or repair, disconnect the power cords from the electrical supply and

protect the cables from any possible accidental connection carried out by unauthorised

personnel.

Keep the machine away from children and from personnel who are not authorised or

adequately instructed in the use of it.

Better Packages Inc. 6

TECHNICAL DATA

Size: 20”Lx12.5”Wx12”H (51 x 32 x 30 cm)

.

Dispensing Speed: Up to 45” (114 cm) per second

Water Bottle Capacity: 2 pints 2 oz. (1 liter)

Shipping Weight: 32 lbs. (15 kg)

Power Requirements: 555es, eSA, eL, eLA – 115 volts, 60 Hz, 4 Amps

555eMA, eFA – 220/240v, 50 Hz, 2 Amps

555eJA – 100V, 50/60 Hz, 4 Amps

Tape Width: 1-1/2” to 3” (3.8 to 7.7 cm) wide

Maximum Roll Size: Up to 1000 ft. of tape

Up to 10” diameter roll(25 cm)

All specifications subject to change without notice

Better Packages Inc. 7

MAINTENANCE AND REPAIR

The machine is designed for easy maintenance. Regular maintenance will insure a long

dependable machine life.

Recommended Preventative Maintenance

Clean Brushes and Tank - Weekly

Clean the brushes on a weekly basis or when glue build up effects proper moistening of

the tape. The glue can prevent sufficient and even water flow to the tape causing poor

moistening of the tape. Regular cleaning will extend the life of the brushes and insure that

glue build up will not cause tape jams or poor tape moistening.

Procedure:

1.

Unplug power from the machine!

Remove the water bottle and water tank.

Twist the tank up over the lip on the tank shelf that prevents it from sliding out of the

machine.

Caution: Heater may stay hot for a period after machine is off.

Remove the brushes from the tank to remove any dried adhesive. You will need to tilt

the brushes to clear the retaining bracket. Notice how the brushes are positioned in

the tank because the must be replace correctly.

2. Wash the brushes and tank with warm water and soap.

3. Place the brushes back into the water tank. It is extremely important that they are

positioned correctly. Brushes must be sloped toward the front of the dispenser in

order to work properly. The top of the brushes are cut at an angle. Shorter brushes

go in the back. The longer length bristles must be toward the front of the machine

(tank).

Notice: Installing the brushes backwards will cause excessive tape jams.

Never cut the brush tips to remove glue as they are cut at a specific angled

and flagged to facilitate proper moistening and cutting will most likely cause

tape jams.

Better Packages Inc. 8

Lubricating the Felt Blade Oiler - Monthly

The blade oiler is a felt pad soaked with oil that presses lightly on the back of the shear blade.

The oil will keep your shear blades lubricated for clean, fast cutting and prolong the life of the

blades. It also extends the time between blade cleanings.

1. Unplug power from the machine!

2. Pull back gently on the blade oiler to move it away from the shear blade.

3. Keep the felt pad slighly moist by adding several drops of light machine oil,e.g. 3-in-1 oil,

at weekly or monthly intervals depending on use. Do not over oil.

Notice: If the felt pad is missing, contact you Better Pack representative for a new oiler Better

Pack P/N SA10XX

Cleaning the Shear Blades

When using reinforced tapes laminated with glue or resin, this material can accumulate on the

blades and interfere with cutting the tape. Even paper tape with no reinforcement can cause an

accumulation of dust and glue on the blades.

Use a small brush and a suitable solvent to remove accumulation.

Never scrap the cutting edge with a hard object because the blade may become dull and need

replacement.

Warning:

Be sure the dispenser is UNPLUGGED

before performing any cleaning

procedures.

General Machine Cleaning

The feed wheel pushes tape through the machine. Obstructions such as dirt or dried glue can

divert the tape and cause it to jam. Periodical cleaning the tape path will mitigate tape jams.

1. Remove the upper tape plate that sets on the tape next to the feed wheel. Pull tape off

from the lower tape plate if it hasn’t already been removed. Clean any dirt and glue from

the upper and lower tape plates.

2. Lift the heater up and clean the bottom of it.

Better Packages Inc. 9

Heater

It is recommended that the Heater be replaced by a Better Packages supplied

Heater to maintain safety compliance.

(Note: Always unplug machine when performing service to machine)

Procedure

1. Remove the water bottle and tank and brushes.

2. Remove the right side cover from the machine by the (5) screws that

fasten cover to the side frame.

3. Remove left side cover from machine by removing (5) screws that fasten

cover to frame. When removing this cover lift gently and remove the

membrane switch from the pc board.

4. On the right side frame loosen the screw that locks the bracket onto the

shaft that goes through the heater assembly.

5. Cut the tie-rap that fastens heater to frame. Remove heater plug from pc

board.

6. From the right side remove the shaft holding the heater in place. Remove

your old heater and take off the lower heater plate.

7. Place the lower plate on your new heater and reinstall your heater back

onto machine. Be sure to lock the bracket back into the groove in the shaft

and tighten screw on bracket.

8. Plug your heater back into the pc board and tie-rap the heater back onto

frame.

9. Replace membrane switch back onto pc board and fasten left cover back

onto frame with (5) screws.

10.Replace right side cover back onto frame with (5) screws.

11.Replace tank, water bottle and plug machine back in.

Loosen retainer

Better Packages Inc. 10

Motor Brush

The motor brushes will last a long time but usually not as long as the rest of the machine.

If the motor stops working or runs excessively slow, the motor brushes may need

replacing.

(Note: Always unplug machine when performing service to machine)

Procedure

1. Remove the water bottle, tank and brushes

2. Remove the right side cover from the machine by removing the (5)

screws that fasten the cover to the frame.

3. The motor should now be visible. Locate the (2) black slotted brush

caps on the top and bottom of the motor. Remove them with a flat

screwdriver by turning them counterclockwise.

4. Pull the brushes out of the motor. Attached to the cover is a spring,

which is attached to a small rectangular shaped carbon brush. Make

sure the brush comes out before inserting the new brush in. Usually the

brush will come right out, but if it doesn’t, insert a small object, e.g. a

paper clip into the hole to free it up. If necessary tip the machine up so

that the brush will fall out. If you have compressed air now is a good

time to blow the residual carbon dust out of the motor. If air is not

available, just tap on the motor with it positioned so the dust can fall

out of the brush holder.

5. If either brush is less than ¼” long, both brushes should be replaced.

Insert the brush into the brush holder being sure to match the concave

of the brush with the motor. Screw the brush caps back onto the motor.

Remove caps to

Change brushes

Better Packages Inc. 11

Motor

(Note: Always unplug machine when performing service to machine)

Procedure

1. Remove the water bottle, tank and brushes

2. Remove the right side cover from the machine by removing

the (5) screws that fasten the cover to the frame.

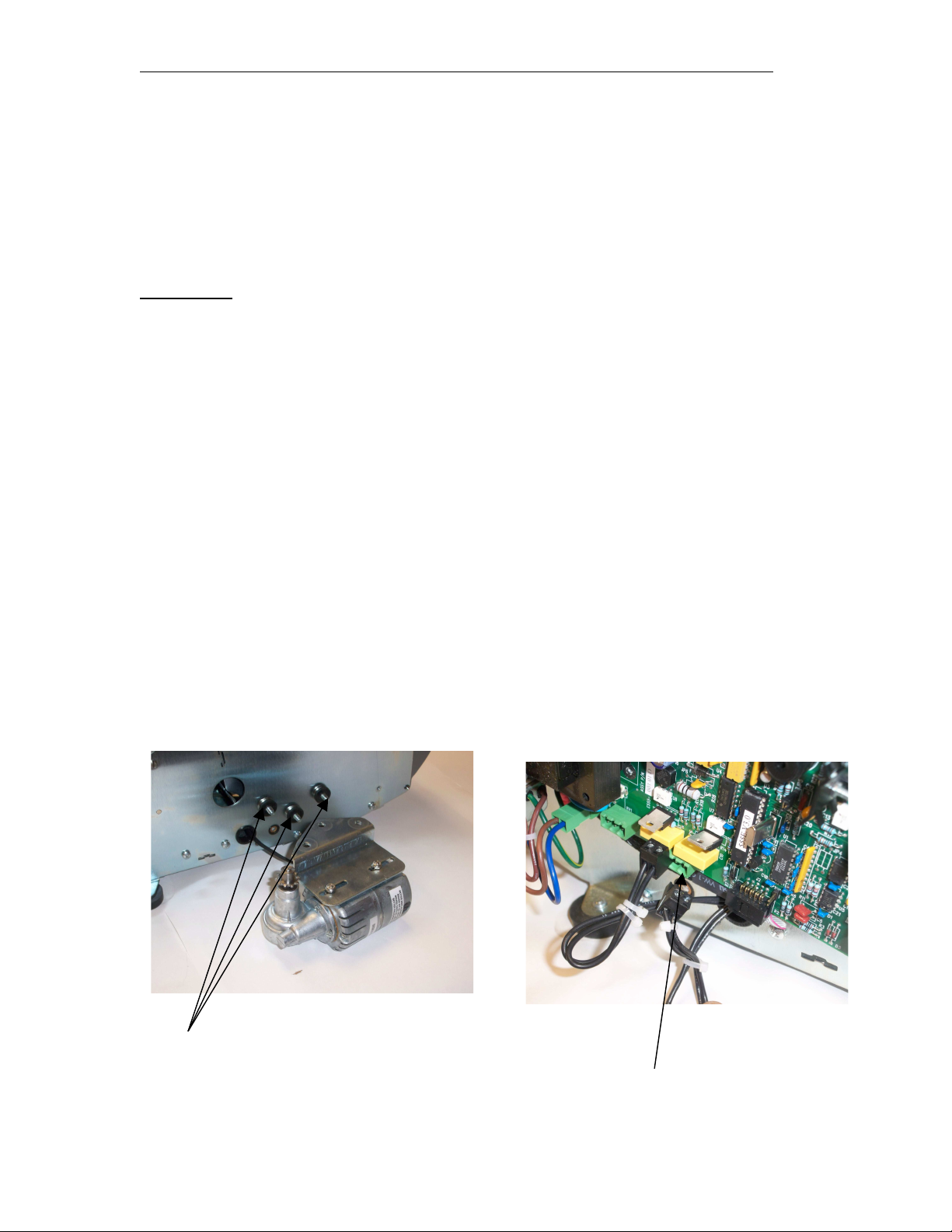

3. The motor should now be visible. Loosen the 3 nuts that are

fastening the motor to the frame.

4. Remove the 5 screws from the left side cover. Be sure not to

let the cover fall off because the keypad cable will break off.

Once the cover is off, take the keypad cable off the board

and remove the connector from the board that is marked mtr.

Now run the new motor wire through the machine and

connect it to the board. Fasten the motor chain to the

sprocket and fasten the motor to the frame.

5. Get the motor snug and tighten the 2 screws on the motor

bracket.

6. Connect the keypad cables and put left side cover back on.

7. Put right side cover back on .

8. Add tank, water bottle and plug cord back into machine.

Remove nuts remove right connector

Better Packages Inc. 12

Shear Blade

(Note: Always unplug machine when performing service to machine)

Procedure

1. Remove the water bottle, tank and brushes

2. Remove the right side cover from the machine by removing the (5) screws

that fasten the cover to the frame

3. Remove the left side cover from the machine by removing the (5) screws

that fasten the cover onto the machine. Gently lift the cover and remove

the membrane switch from the pc board.

4. Remove the (2) screws that hold the baffle plate onto the machine. Take

the baffle plate out.

5. Loosen the screw on the right side frame that locks in the shaft holding the

heater and blade oilier in place.

6. Remove the heater and blade oiler by pulling out the shaft from the right

side.

7. Remove tank shelf by inserting flathead screwdriver in-between tank shelf

and frame.

8. Remove the spring that is fastened to the cutter yoke.

9. Loosen the pin that holds the blade in place by turning it counter clockwise

with a flathead screwdriver. If the pin doesn’t turn loosen the pin with a

pair of vise grip pliers. Once the pin is loose remove it and remove the

blade.

10.Remove the spring from the upper blade by unhooking the springs from

the pins. Remove the blade.

11.Replace the upper blade and hook the springs back onto the pins.

12.Replace the lower blade with the new shaft.

13.Replace spring back onto yoke assembly.

14.Replace tank shelf back onto machine.

15.Replace baffle plate back onto machine and fasten with (2) screws.

16.Replace heater assembly and blade oiler and lock pins back on right side

frame.

17.Replace membrane switch back into pc board.

18.Replace left side cover with (5) screws.

19.Replace right side cover with (5) screws

20.Replace tank, water bottle and plug in machine

Better Packages Inc. 13

Feed Wheel / Blade Height Adjustment

When a dispense key is pressed the tape cutter blade and the lower feed wheel

lift up.

The machine has an adjustment set screw that sets the height of the blade and

lower feed wheel. The adjustment sets the amount of pinch force between the

upper and lower feed wheels. If the feed wheel does not grip the tape sufficiently,

the tape can slip. When the tape slips an inaccurate measurement of the tape

length occurs, resulting in a shorter than normal tape piece. If short or erratic

tape lengths occur, the adjustment described below may need to be performed to

correct the problem.

Procedure

1. Unplug! the power cord from the back of the machine.

2. Open the top cover then remove the roll of tape and tape guides.

3. Insert a 3/32” Allen wrench through the access hole in the in the plate

(Vertical Tie Plate) at the front of the tape basket area and into the adjustment

set screw.

Note: The set screw is located about 2-1/4” in front of the access hole and

can be hard to locate. The set screw can be partially seen by viewing through

the slots from back of the tape machine between the rear cover and the side

of the machine.

4. Turn the set screw clockwise ½ turn to tighten the feed wheel.

5. Reassemble and test machine, repeat if still slips.

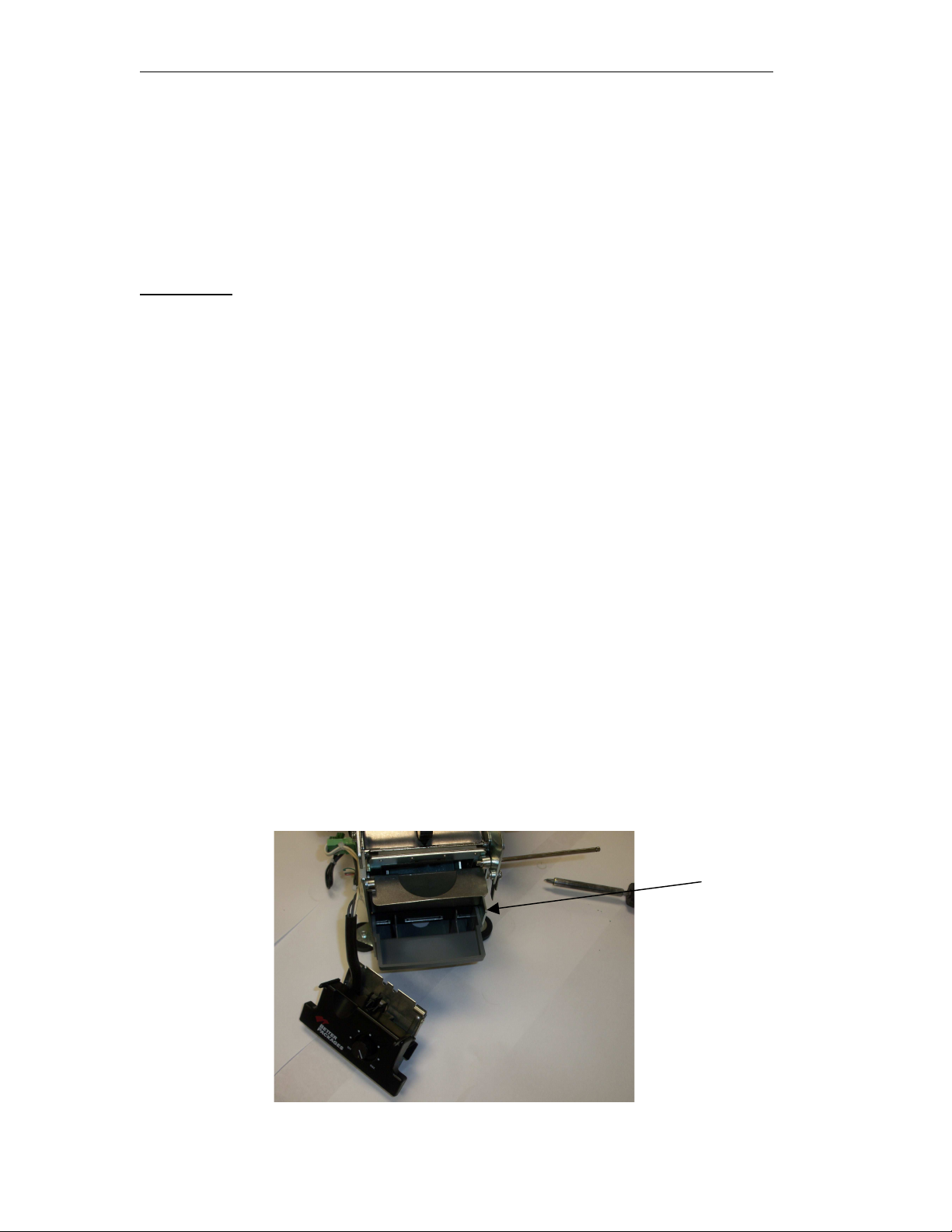

3/32” Allen Wrench in

Access Hole

Better Packages Inc. 14

Keypad and Membrane Switch

(Note: Always unplug machine when performing service to machine)

Procedure

1. Remove the water bottle ,tank and brushes

2. Remove the (5) screws that fasten the left side cover

onto the frame. Gently lift the cover and remove the

membrane switch from the pc board.

3. Remove the keypad bezel by inserting a thin flathead

screwdriver in-between the keypad bezel and the cover.

Lift the bezel up and remove it from the cover. Remove

the keypad and membrane switch.

4. Place new membrane switch assembly and keypad back

in and replace bezel back on cover.

5. Connect the membrane switch back into the pc board

and replace left side cover back onto the frame using the

(5) screws.

6. Replace tank, water bottle and plug machine back in.

Remove keypad membrane

From board

Better Packages Inc. 15

Replace Keypad Only

1. Unplug machine and remove water bottle.

2. Insert a thin flathead screwdriver in-between the keypad

bezel and the cover . Lift the bezel up with your fingers and

remove the old keypad and replace it with the new keypad.

3. Place the bezel back onto the cover and lock it in

replace tank, water bottle and plug machine back in

Connector Plate Assembly

(Note: Always unplug machine when performing service to machine)

Procedure

1. Remove the 5 screws holding the left side cover on

2. Remove keypad membrane and remove the 2 screws holding

the connector to the frame

3. Remove the connectors from the board

4. Place new assembly back onto the frame and fasten with the 2

screws

5. Replace the wire connectors back onto the board

6. Replace the keypad membrane back onto the board

7. Replace the cover back onto machine with the 5 screws

8. Plug machine back in

Better Packages Inc. 16

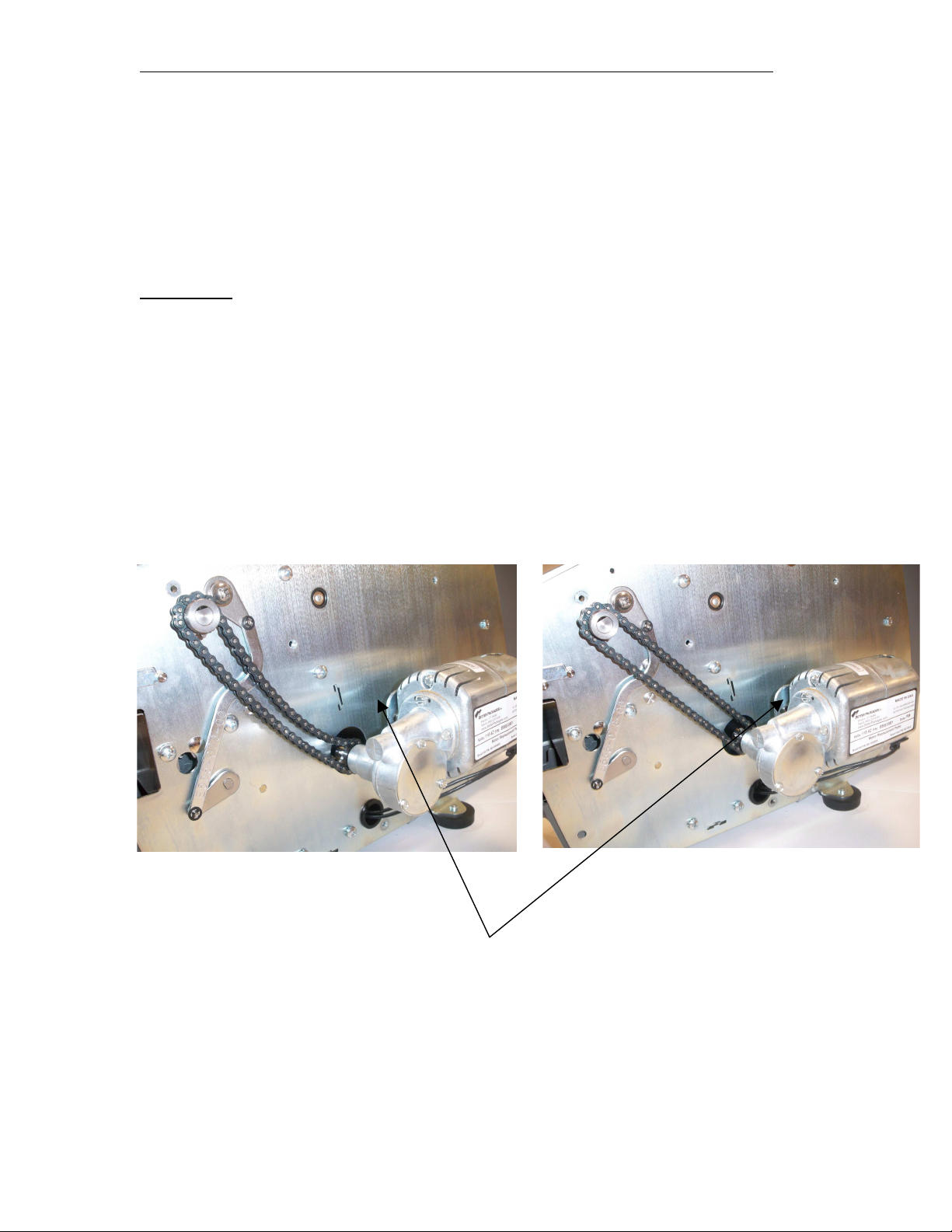

Motor Chain Adjustment

( Note: Always unplug machine when performing service to machine)

Procedure

1. Remove water bottle and water tank assembly

2. Remove the left side cover

3. Loosen the 2 nuts that hold the motor onto the motor bracket

(Be sure not to remove the nut completely)

4. Push the motor towards the rear of the bracket until there is no

more slack on the motor chain

5. Tighten the nuts on the motor chain bracket until snug. Do not

over tighten

6. Replace cover, tank and water bottle.

Loosen nuts behind bracket

To adjust

Better Packages Inc. 17

Control Board

( Note: Always unplug machine when performing service to machine)

Procedure

1. Remove bottle, tank and brushes

2. Lay machine onto right side

3. Remove the 5 screws from the left side cover, lift the cover and

remove the keypad membrane from the board

4. Lay the cover down and remove all the connectors from the board

5. Remove the 5 screws holding the board to the frame and place the

new board in its place and fasten with the 5 screws

6. Replace the connectors back onto the board (the solenoid and motor

both have black wires so when replacing these back on the shinier wire

connected to the motor)

7. Connect the keypad membrane and close the cover. Be sure that no

wires are being pinched

8. Fasten cover with the 5 screws

9. Replace the water tank and brushes and the water bottle

10.Plug in machine

REMOVE 5 SCREWS

Better Packages Inc. 18

Front and Rear Cover Assembly

(Note: Always unplug machine when performing service to machine)

Procedure

1. Remove bottle, tank and brushes

2. Remove right cover. Remove left cover and remove keypad membrane

from board

3. Remove the 2 retaining rings holding the bracket assembly to the right

and left frame. Be sure not to lose the washers and retaining rings

4. Remove the retaining ring from the pin holding the rear cover in place.

Slide the pin to the left and remove from machine.

5. Remove the spring from the cover and put it on the new cover

6. Replace the new cover on machine and push the pin through the frame

and cover until it gets through to the other side and than fasten the

retaining ring back onto pin

7. Attach the brackets back onto the side frames using the washers and

retaining ring that were taken off

8. Replace the keypad membrane onto the pc board

9. Replace the right and left side covers

10.Replace the tank, brushes and water bottle

Remove retaining ring

For upper ring remove from both side frames

Better Packages Inc. 19

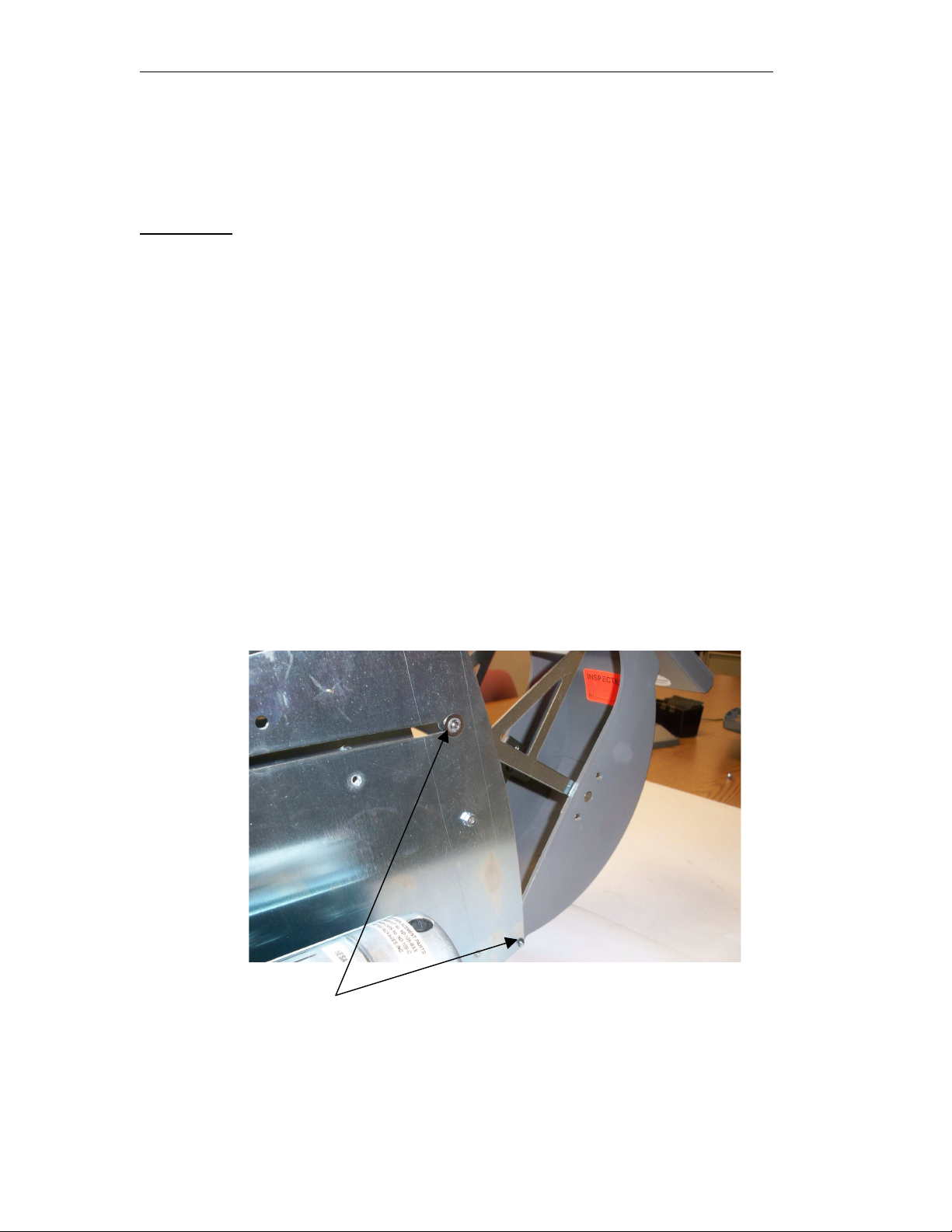

Length Sensor

(Note: Always unplug machine when performing service to machine)

Procedure

1. Remove left side cover. Remove the keypad membrane from the

control board and lay the cover on the bench

2. Remove the 2 screws holding the sensor in place and remove

connector from board

3. Place new sensor on machine and fasten with the screws and replace

the connector to the board

4. Replace the keypad membrane back onto the board

5. Replace the cover back onto machine

2 SCREWS

Water Level Adjustment

To adjust the water in the tank to the desired level slide the water level adjuster

to the left to decrease the water level and slide adjuster to the right to increase

the water level in the water tank.

adjuster

Better Packages Inc. 20

Tape Sensor

(Note: Always unplug machine when performing service to machine)

Procedure

1. Remove left side cover

2. Remove sensor from back of heater assembly and remove connector

from board

3. Replace sensor onto the back of the heater assembly

4. Replace connector back onto board

5. And fasten with a cable tie

6. Replace cover back onto machine

PUSH OUT

Table of contents

Other Better Packages Dispenser manuals

Better Packages

Better Packages BP500 User manual

Better Packages

Better Packages Better Pack 755eMA User manual

Better Packages

Better Packages Better Pack 755eS User manual

Better Packages

Better Packages PS2A User manual

Better Packages

Better Packages 555e User manual

Better Packages

Better Packages Better Pack 755e Series User manual

Popular Dispenser manuals by other brands

Cornelius

Cornelius IntelliBlue R134 Kuwait Series operating instructions

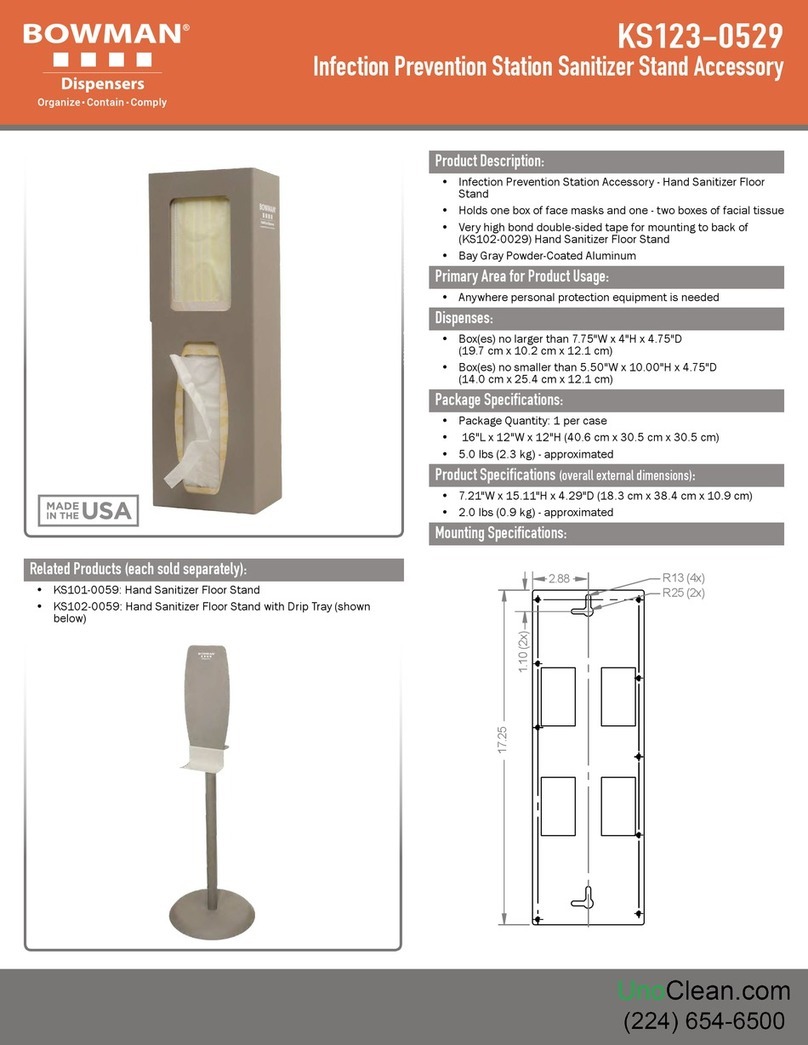

BOWMAN

BOWMAN KS123-0529 quick start guide

Silver King

Silver King SK1IMP Technical manual & replacement parts list

Perlick

Perlick Draft Arm installation instructions

Star

Star HPDE1 Installation and operation instructions

ESINO

ESINO Z88 user manual