Beverage-Air PH User manual

INSTALLATION AND OPERATING INSTRUCTIONS

for all

PH Warming Cabinets

3779 CHAMPION BLVD, WINSTON-SALEM, NC 27105

Phone: (888) 845-9800 | Fax: (800) 253-5168 | Web: beverage-air.com

809-212A 01/14/2021 SEE BACK COVER FOR

WARRANTY REGISTRATION

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21Beverage-Air2

WELCOME

Contents

Safety .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..3

Safety .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..4

Important Information .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..5

Clearance and Placement.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..6

Unpacking and Set Up . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..7

Unit Set-up for Roll In Units .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..8

Shelf Installation.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..9

Electrical. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..10

Preheating & Recommended Food Storage Periods ..11

Recommended food storage periods .. .. .. .. .. .. .. .. .. ..12

Using The Unit .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..13

Electronic Controller Parameter Changes .. .. .. .. .. .. ..14

Setting the Real Time Clock. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..15

Controller Flow Chart .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..16

Alarm Codes. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..17

Sequence of Operations . .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..18

Cleaning and Maintenance . .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..20

Methods For Cleaning Stainless Steel .. .. .. .. .. .. .. .. ..21

Help. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..22

Help Continued.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..23

For The Service Tech - Wiring Diagram. .. .. .. .. .. .. .. ..24

Limited Warranty .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..25

Limited Warranty (continued).. .. .. .. .. .. .. .. .. .. .. .. .. ..26

Important Information

• PLEASE READ THESE INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR USING, IF RECOMMENDED

PROCEDURES ARE NOT FOLLOWED, WARRANTY

CLAIMS MAY BE DENIED.

• Your warranty registration information is located with

this manual. Please complete the card and submit it to

Beverage-Air within TEN days of installation. Failure

to properly register equipment may limit or void the

warranty.

• Beverage-Air reserves the right to change

specications and product design without

notice. Such revisions do not entitle the buyer to

corresponding changes, improvements, additions, or

replacements for previously purchased equipment.

Congratulations on your purchase of Beverage-Air food

service equipment. Every employee welcomes you to the

family of satised Beverage-Air customers.

From the earliest stages of production design, to focused

steps in fabrication and assembly, rigid standards of

quality are maintained by our sta of skilled employees.

Beverage-Air strives to supply superior products through

strict quality control guidelines exceeding industry

standards, this means that each unit, given the proper

maintenance will provide years of trouble free experience

to its owner.

Additionally, Beverage-Air food service equipment has

one of the best warranties in the food service industry,

and backed by a professional sta of service technicians

across the country.

We thank you for your choice and condence in Beverage-

Air Equipment.

For part inquiries or orders please call our Technical

Service Department at (800) 684-1199. 8:00 AM to 5:00

PM EST.

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21 Beverage-Air 3

SAFETY

Observe the Caution and Warning notices. They are indicators of

important safety information. Keep this manual for future reference.

Important Information to Add

Record the model number, serial number and the date of installation here for future reference. The model and serial

numbers are on the unit's serial number dataplate, which is located on the left inside wall.

Model Number

Serial Number

Date of Installation

Purchased From

CAUTION

WARNING

CAUTION

CAUTION

This appliance has been designed with your safety in mind. It has many features to keep you from being harmed. However,

safe operation and maintenance are your responsibilities. This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

Use: When using this unit, please:

• Move it carefully. If on casters be sure the casters

do NOT run over the power cord.

• Lock the casters when in use.

• Seek help. This machine is heavy! Be sure to move

with enough help to avoid tipping or dropping the

cabinet.

• Prevent children from playing in or on the cabinet.

Persons unable to use this product must be

prevented access.

• Follow all instructions. There are many safety

labels and directions on the unit. Heed them.

• Watch your ngers. There may be pinch points near

the door hinges.

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21Beverage-Air4

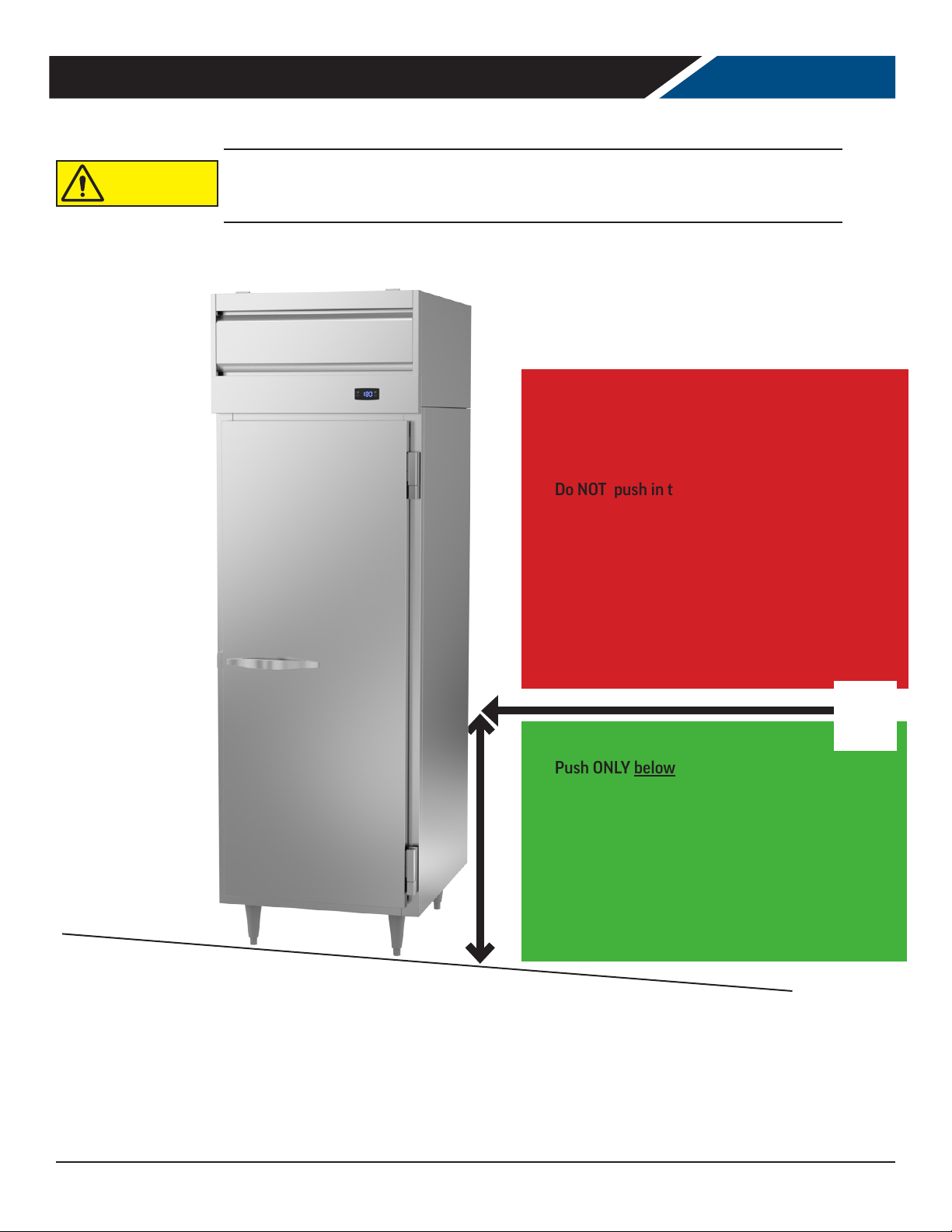

CAUTION: If it is necessary to move the Cabinet after removal from the skid, remove all

doors and carefully push the unit at a point of no more than 36” from the bottom to avoid

damage.

CAUTION

SAFETY

Push ONLY below the 36 inch / .91 meter height

Height

will vary

by model

Do NOT push in this area.

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21 Beverage-Air 5

IMPORTANT INFORMATION

This unit is intended to be used in a commercial

application. That includes bars and restaurants.

If installed in a residence some commercial service

companies may not be able to service it on site.

The manufacturer has designed and produced this

machine with the nest in materials. The manufacturer

assumes no liability for units that have been altered in

any way. Alterations or part substitutions will void the

warranty.

Limitations

The machine is designed for use indoors in a controlled

environment. It must be kept dry, not overheated or

subjected to excessive cold. May only be connected to

a dedicated electrical circuit. Extension cords are not

permitted.

Minimum Maximum

Voltage 208 240

Room Air Temp 60º F 100º F

Agency Approvals

These marks appear on the dataplate or serial tag, located

in the inside of the left wall. The dataplate also contains

the model and serial numbers as well as electrical

requirements.

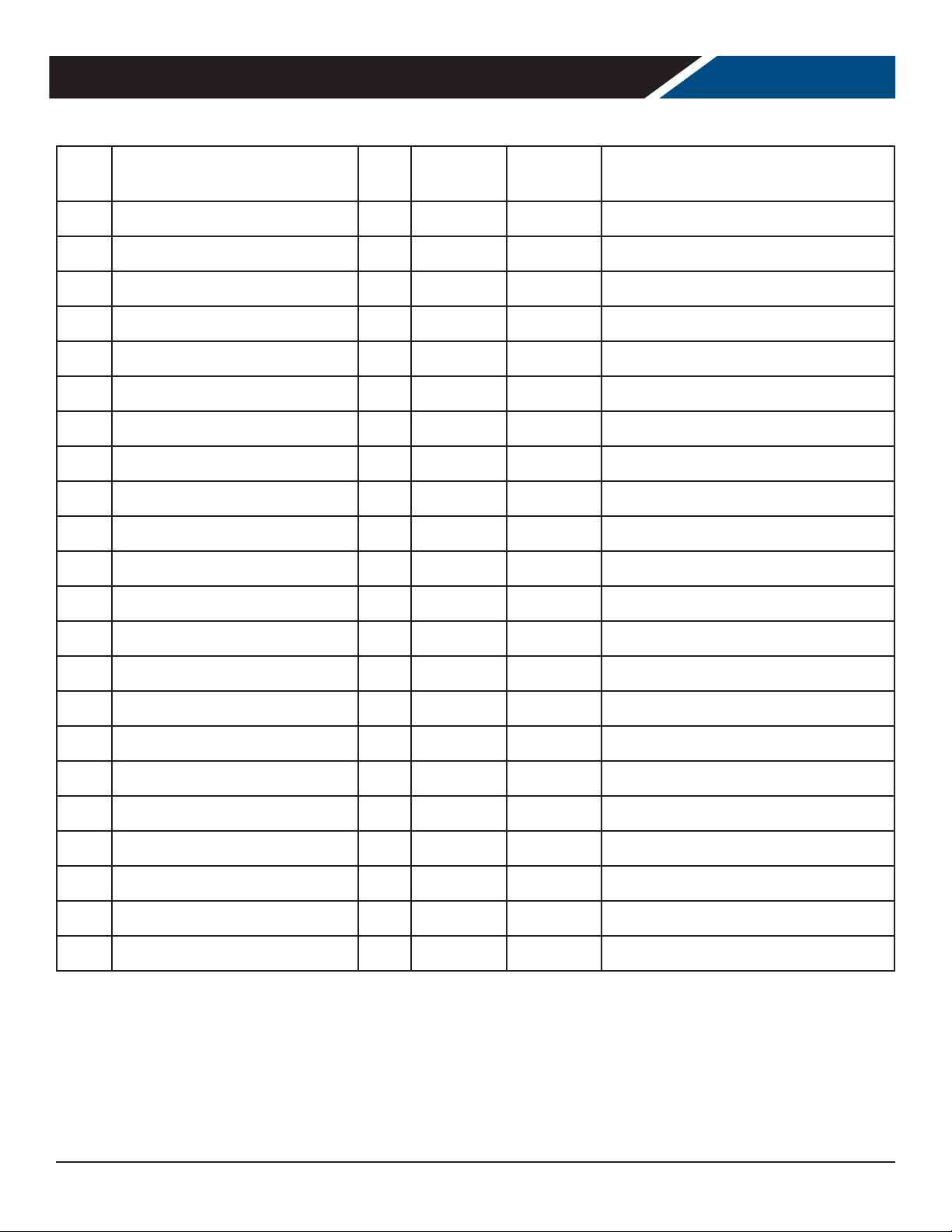

Model Cabinet Dimensions

w x d x h (Inches) Pass Thru Doors Glass or Solid

Door

Full Load

Amps

Power Cord

Plug (NEMA)

PH1-1BHG 26 1/2 x 34 3/8 x 83 3/4 Half Glass

6.3

6-20P

PH1-1S-PT

26 1/2 x 38 3/8 x 83 3/4

Yes Full Solid

PH1-1HS-PT Yes Half Solid

PH1-1BG-PT Yes Full Glass

PH1-1BHG-PT Yes Half Glass

PH2-1S

52 1/8 x 34 5/8 x 83 3/4

Full Solid

13

PH2-1HS Half Solid

PH2-1BG Full Glass

PH2-1BHG Half Glass

PH2-1S-PT

52 1/8 x 38 5/8 x 83 3/4

Yes Full Solid

PH2-1HS-PT Yes Half Solid

PH2-1BG-PT Yes Full Glass

PH2-1BHG-PT Yes Half Glass

Height includes legs

• All models are 208-240 volts, 60 Hz AC.

• ALWAYS REFERENCE YOUR EQUIPMENT DATA PLATE AMPS, FOR THE MOST UP TO DATE AND ACCURATE VALUES.

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21Beverage-Air6

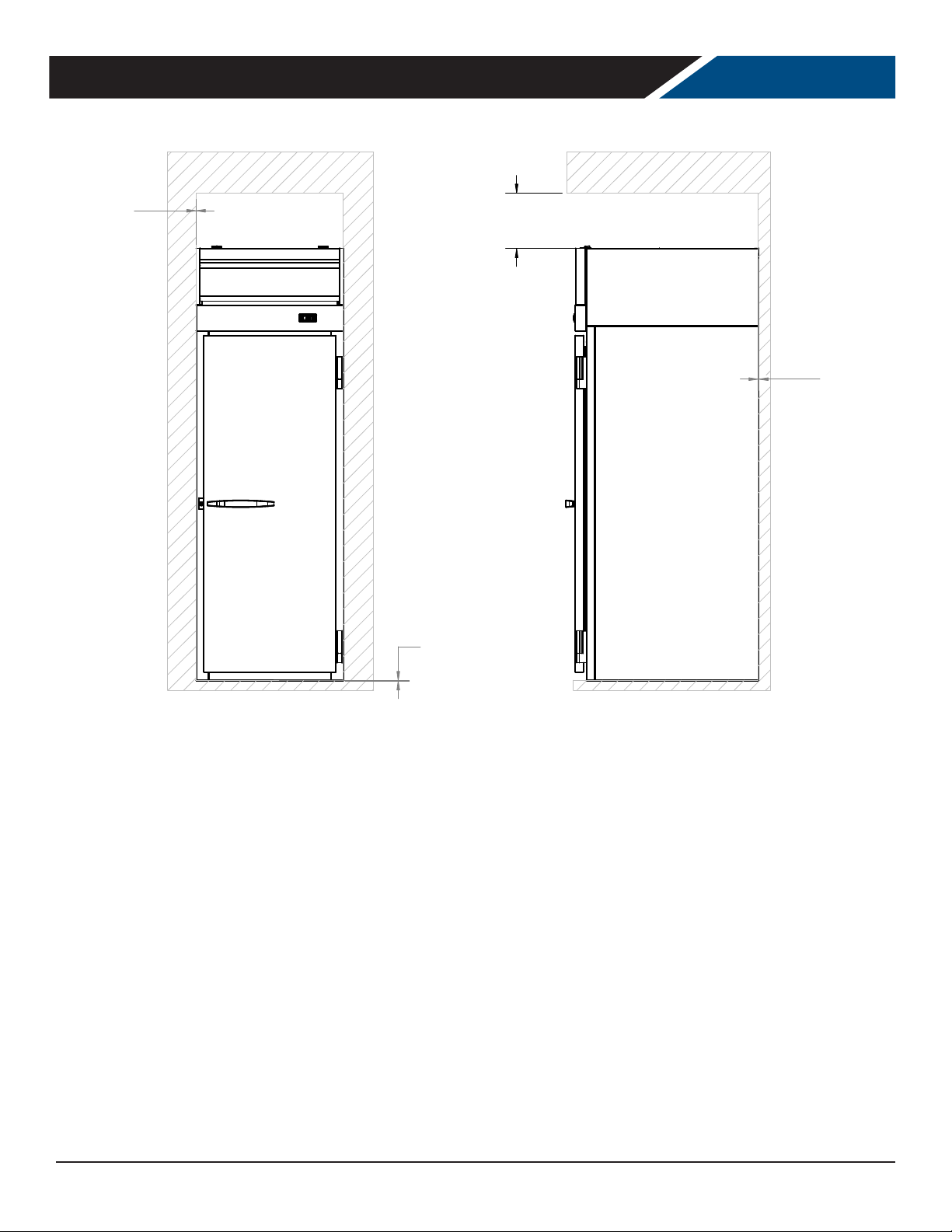

CLEARANCE AND PLACEMENT

Placement

Consider the following when selecting a location for your Cabinet:

Clearance:

• 10 in. at the top

• 0.0 in. at the rear,

• 0.0 in. at the left side

• 0.0 in. at the right side

• 0.0 in at the bottom

Floor Load: the oor on which the Cabinet is located must be even and level, free from vibrations, and strong enough to

support the combined weights of the unit and maximum product load.

Ventilation: Grille area at front must be free and clear of any object or wall.

Power Outlet: The installation of this appliance requires a dedicated power outlet located within the length of the unit's

power cord and be accessible for the purpose to disconnect power.

0"

REAR

MINIMUM

CLEARANCE

10" TOP

MINIMUM

CLEARANCE

MINIMUM

BOTTOM

CLEARANCE

0"

0"

LEFT/RIGHT

MINIMUM

CLEARANCE

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21 Beverage-Air 7

UNPACKING AND SET UP

Carefully inspect the shipping carton for damage. This is the only time that shipping damage may be claimed. If damage is

suspected, open the carton immediately and, if there is damage, retain the carton and contact the shipper to make a claim.

Do NOT contact the manufacturer.

Uncrating

Tools Needed: ¾” box wrench, adjustable wrench, level, at

head screw driver, and box cutter.

1. Remove the cardboard top capping, all clear tape,

and all staples including those at the bottom of the

cardboard carton and skid.

2. Start from the top of the carton. Using the box cutter,

carefully make one continuous cut to the bottom of the

skid. Remove cardboard carton and discard.

Note: additional clear plastic protective wrap is applied

directly to any product with a glass door.

3. Move unit as close to nal position as possible before

removing the skid.

Note: The skid must be removed before the casters or legs

can be attached.

Skid Removal and Caster Attachment

Tip the unit forward and remove the skid.

Risk of personal injury.

Unit must be securely supported

while attaching casters or legs.

WARNING

1. Remove the shipping bolts using the ¾” box wrench while

cabinet is held in one direction. Repeat the process while

the cabinet is held in the opposite direction.

2. None of the threads on the leg or caster stem should be

visible once screwed in.

3. Tilt the cabinet in one direction approximately 8” and

block it securely with pieces of 2x4 lumber or other

suitable material.

4. Thread the stem casters or legs into the ½ -13 holes in

the bottom of the cabinet. Tighten by hand as much

as possible. Some models may already have levelers

installed. If so, then the levelers will need to rst be

removed and discarded.

5. Once the caster or leg cannot be turned any further,

use a 3/4 inch wrench to tighten the nut in between

the mounting plate and the wheel of the caster until

snug.

6. Repeat this procedure with unit secured in the

opposite direction so as to access the remaining legs/

casters/levelers

7. If plate casters or legs are installed instead of stem

casters or legs, then repeat step 3 above and secure

the plate with either #14 AB screws, or ¼-20 screws,

depending upon which are required.

8. If levelers are employed, then repeat step 3 above and

thread the leveler in place. Then repeat step 6.

Leveling:

Cabinets must be leveled when installed. Level should be

measured on the headrail.

Failure to level your cabinet may result in door not sealing,

closing correctly,.

For cabinets with legs, rotate the foot of the leg with an

adjustable wrench to achieve desired height for leveling.

For cabinets with casters, leveling can be achieved by

placing large washers in between the ½’ stud and the holes

located on the bottom of the case.

Do NOT loosen casters to level the cabinet. Casters MUST

be tightly secured to cabinet for

full strength.

Install or attach any accessories

that will be used

Remove any plastic covering the stainless steel.

CAUTION

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21Beverage-Air8

UNIT SET-UP FOR ROLL IN UNITS

Important: The oor where the new roll-in/roll-thru cabinet

is to be permanently located must be level, at surface

prior to installation. Failure to properly level the install your

equipment can void equipment warranty.

If necessary to move the unit after removing it from the

skid, remove all doors and carefully push the cabinet at a

point no more than 36” (inches) from the bottom to avoid

damage.

It is an NSF requirement that roll-in/roll-thru models are

sealed to the oor upon installation.

1. Locate roll-in/roll thru model in exact position in which it

is to be set permanently.

2. Level unit, inserting metal shims under unit where

required. It is important that an accurate carpenter’s level

be used when leveling cabinet

3. Construct a wood form to act as a retainer for the

grouting compound around the entire base of the cabinet.

Pour the grout mixture at various intervals around the form

to assure complete ll under the cabinet

4. Using a wide blade putty knife, taper the grout to a

feather edge.

5. A tube of NSF approved silicone sealer, having an

applicator type nozzle, is highly suited for sealing roll-in/

roll-thru models to the oor. Apply a small uniform bead

completely around the base of the cabinet.

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21 Beverage-Air 9

1. Determine the proper location for the shelf clips.

The reference numbers on the pilaster can serve as a

guide to ensure all clips are properly located.

2. Insert the top tab of the shelf clip into the desired

hole of the pilaster. The retaining tab MUST be facing

up as shown.

3. Rotate the clip downwards and insert the bottom tab

into the matching hole in the pilaster. The clip may

need to be squeezed slightly during installation.

4. Install all remaining clips.

5. Install shelves onto clips with the product retention

bar facing up. Be careful not to dislodge clips during

installation.

6. Place shelves so that the retaining tab on the clip

captures the shelf as shown.

7. Conrm that the shelf is resting on ALL 4 clips and

that the clips are securely attached to the pilasters.

8. Improper shelf clip installation could cause the shelf

and / or the product on it to fall, resulting in damage

to the unit and possible bodily injury.

9. Do NOT overload the shelves. The unit is designed to

use all shelves that are supplied in an equally spaced

manner. Contact Beverage-Air customer service if

fewer shelves or a dierent conguration to ensure

shelf overloading will not occur.

SHELF INSTALLATION

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21Beverage-Air10

This is a cord-connected unit, and must be connected to

its own dedicatedpower supply. Check the dataplate on

the machine to conrm the voltage and per the dataplate

use the correct fuses or circuit breakers.

Note: Do not connect to GFI / GFCI outlets. Connection to that type of outlet can result in product loss due to unsafe

cabinet temperature when GFI device trips from moisture.

Power Cords

This 220 volt model is equipped with a power cord and type

6-20P plug.

If a power cord becomes damaged, it must be replaced

with the identical cord.

Follow All National and Local Codes

This Unit Must Be Grounded. Do not use extension cords

and do not disable or by-pass ground prong on electrical

plug.

Prior to use, the interior and exterior surfaces of the

cabinet should be cleaned thoroughly with warm water,

mild detergent, and a soft cloth. Apply with a dampened

cloth and wipe in the direction of the metal grain. Then

allow to air dry with the doors open. Only use a clean soft

cloth. See detailed cleaning instructions in the cleaning

and maintenance section

Initial Start Up

After the cabinet has been installed, leveled, and cleaned

as described above, refer to the following check list:

• Check for proper electrical hook-up.

• Check that all clearances are in line with the

aforementioned guidelines.

• Check that cabinet is level.

NOTE: Once the unit has been started and reaches proper

storage temperatures, it may be loaded with product. For

proper energy eciency and airow we recommend a

minimum1” clearance between product and side walls, 4”

clearance between product and ceiling, and 1” clearance

from the bottom of the unit.

ELECTRICAL

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21 Beverage-Air 11

PREHEATING & RECOMMENDED FOOD STORAGE PERIODS

Food should not be placed in a cold warming cabinet. To

preheat the warming cabinet, turn it on one (1) hour before

it will be needed. See page 13 on how to use the control

display panel to assist in preheating and operation.

If the food has been cooked in the same pan in which it

will be served, it should be left in the same pan when being

placed in the warming cabinet. However, if food is cooked

and served in dierent pans, the food should be panned as

soon as the cooking is completed and placed in the warmer.

Although the two methods mentioned may not necessarily

pertain to the requirements of daily foodservice activity,

another approach for good food quality is to place the food

directly to a serving counter after cooking. The warmer

keeps the food in good condition during the interval

between cooking and serving. It is recommended that food

should be stored within the cabinet and in its original pan in

which it will be served.

The food should be placed in the cabinet while hot, but not

until it stops giving o steam

Note: if steam is excessive, use a lid on pots or pans.

It is possible to reheat some food without further

deterioration if sucient time is allowed for the heat to

slowly penetrate the entire mass.

Most food can be kept in best condition at a temperature

of approximately 160°F, but the exact temperature varies

depending upon the kind of food and method of its

preparation; therefore, it is impossible to give any exact

instructions which will t all conditions. It is necessary to

experiment by increasing or decreasing the temperature

of the unit until you nd the temperature at which the

majority of the food kept in the unit will keep in the best

condition. Once this setting is determined, the controller

should always be kept at this setting.

Some food, such as breaded meats, sh, etc., when kept at

proper temperature, requires less degree of moisture in the

cabinet to prevent sogginess. For this reason, all cabinets

are equipped with vents or dampers. The damper should

be opened for such food by turning the knob in the desired

direction for opening and closing. This knob opens or

closes the vent in the top of the cabinet. By looking into the

cabinet when operating the knob, you can fully understand

its function and adjustment.

Some foods can be kept in good condition much longer than

others, and certain foods cannot be satisfactorily kept at

all in any manner. French fried potatoes, roasts, waes and

similar foods, where the outside must be crisp and centers

steaming hot must be prepared immediately before serving.

Do not expect the impossible from the warming cabinet, but

if used intelligently it will keep food over a longer period of

time and with less deterioration than is possible with any

other equipment. By reducing the deterioration between

the time the food is cooked and the time it is served,

the warming cabinet will assure serving the food to the

customer in proper condition. See the recommended food

storage periods table as a reference guide.

CAUTION Risk of personal injury from hot

pans or racks.

User proper hot container handling

materials.

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21Beverage-Air12

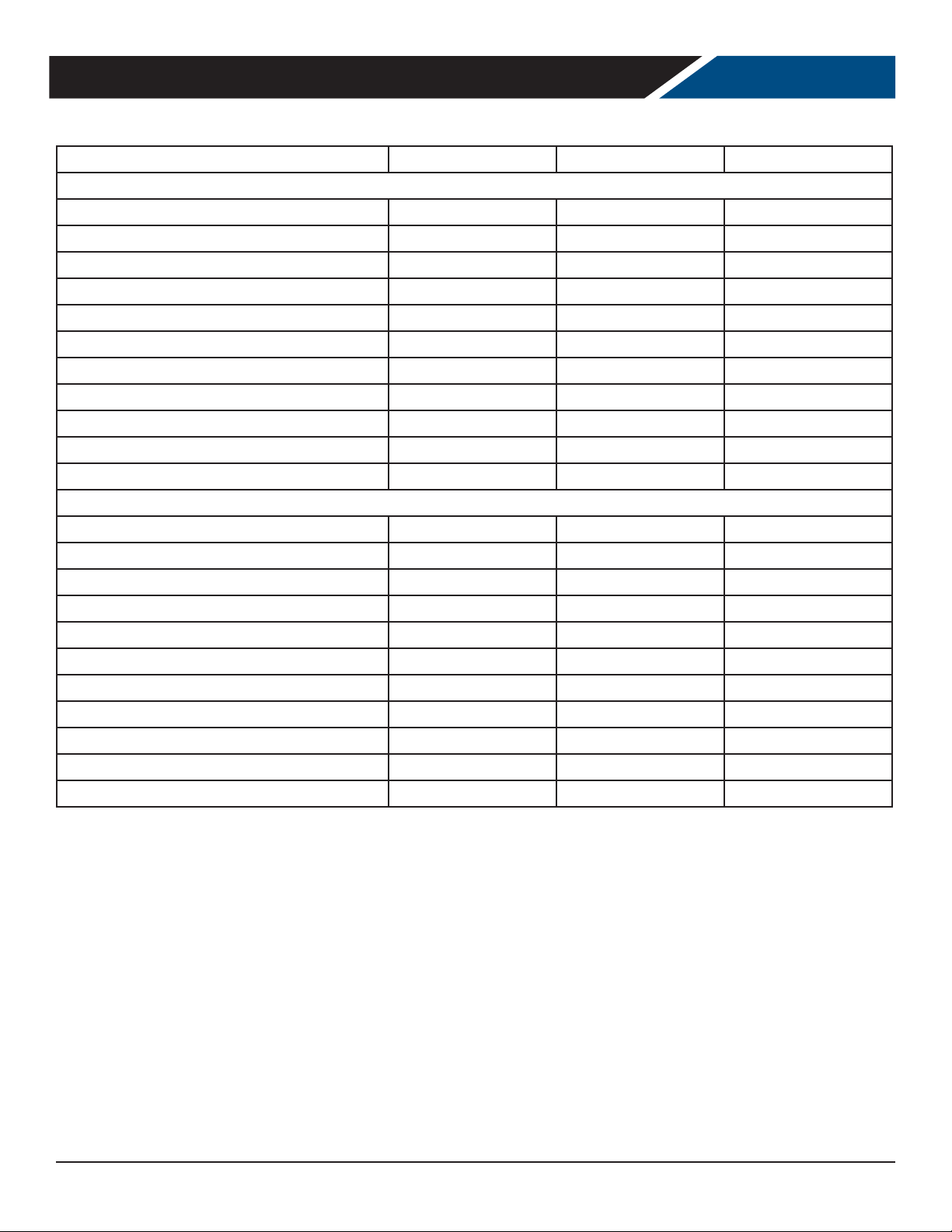

Product Longest Time Kept Average Time Kept Approximate Temp. °F

*Crispy or Dry Foods

Baked Potatoes 2 hours 30 minutes 170 -180

Corn Stick 2 hours 1 hour 140 - 150

Crackers 8 hours 5 hours 140 - 150

Chicken Pies 6 hours 3 hours 170 - 180

Club Sandwiches (wrapped) 1 hour 30 minutes 160

Fried Chicken 6 hours 3 hours 170 -180

Fried Seafood 6 hours 2 hours 170 -180

Hard Rolls 8 hours 4 hours 140 - 150

Hot Mince or Apple Pie 6 hours 4 hours 160

Meat Pies 6 hours 3 hours 170-180

Popcorn & Potato Chips 10 hours 5 hours 150

*Moist Foods

Baked Beans 8 hours 4 hours 170 -180

Baked Stu Lobster 3 hours 2 hours 170 -180

Biscuits 1 hour 30 minutes 150 - 175

Casserole (without top crust) 8 hours 4 hours 170 - 180

Chop Suey 6 hours 4 hours 180

Deviled Crabs 5 hours 3 hours 170 -180

Frankfurter 6 hours 3 hours 160 - 175

Hash 4 hours 2 hours 170 -180

Mashed Potatoes 3 hours 2 hours 160 - 180

Vegetables (ready for serving) 6 hours 2 hours 170 -180

Sweet Rolls 4 hours 2 hours 140 - 150

RECOMMENDED FOOD STORAGE PERIODS

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21 Beverage-Air 13

USING THE UNIT

Operation is simple, just keep it connected to the correct

power supply and the warming cabinet will maintain the

internal temperature it has been set to. Keep the doors

closed as much as possible to avoid unnecessary run time.

Adjusting the set temperature higher will NOT cause the

system to raise the temperature faster.

The cabinet temperature was set at the factory at 160ºF.,

but you can adjust it to your own selected temperature.

Push and release the Increase or Decrease buttons to

make a change. 30 seconds after adjustment, the display

automatically reverts to showing the current temperature.

If equipped with glass doors, holding the SC button in will

turn the cabinet light on or o.

Icons

Increase

Decrease

Changes begin with SET

Display

On – Heating element energized

Blinking – delay, protection or

start blocked

O – heating element o

On – circulating fans active

O – circulating fans o

On – active alarm condition

Blinking – alarm acknowledged

O – no active alarms

On – current temperature scale

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21Beverage-Air14

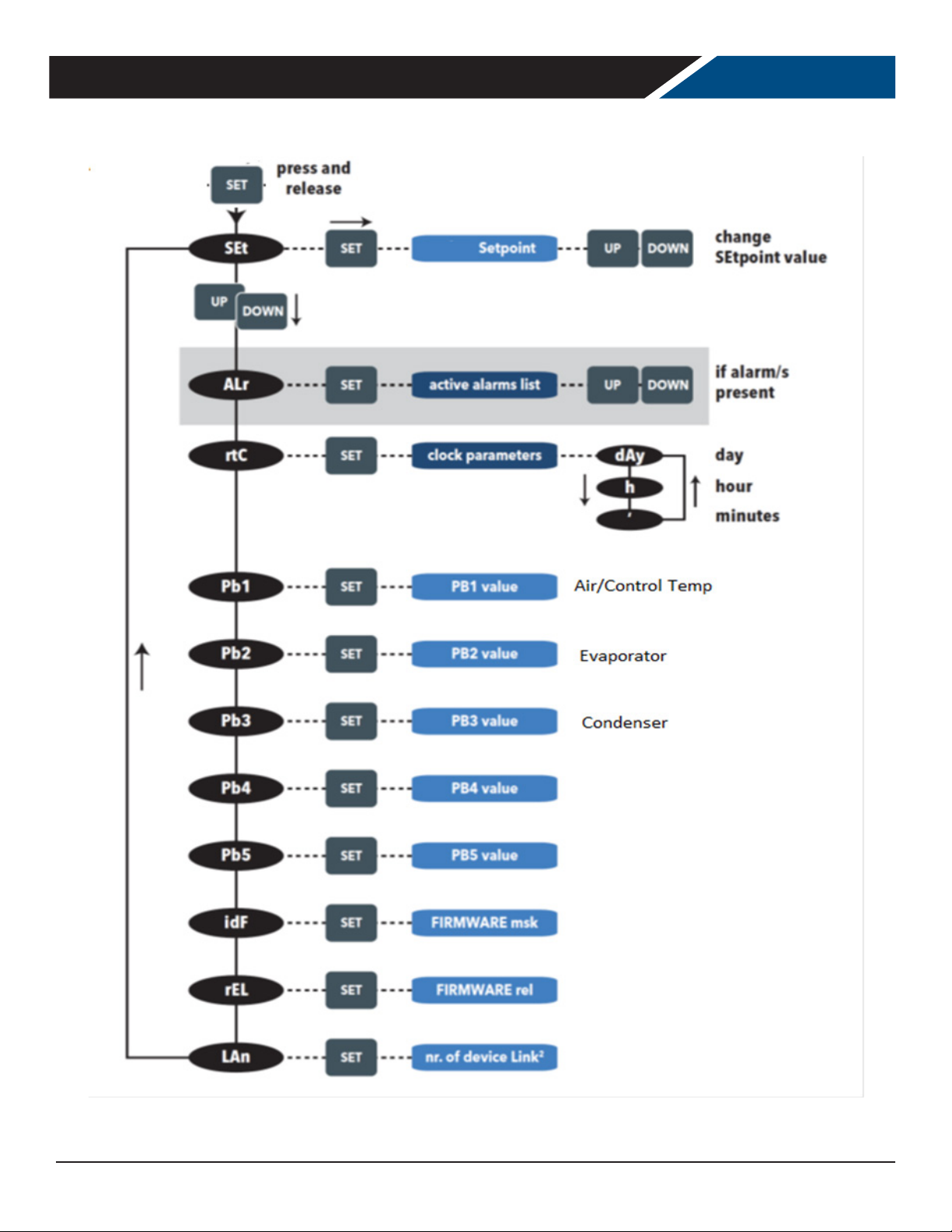

ELECTRONIC CONTROLLER PARAMETER CHANGES

Note: Key pad has a 3 second lock feature. Set key must be pressed for 3 seconds and released before keys will become

active. Key pad will beep when unlocked and normal key pad operations performed.

Setting the Operating Set Point

To change the operating set point, press and release the set button to enter the machine menu. “set” will appear on the

display.

Press and release the set button again to view the set point.

Use the up and down button to change the set point. When adjustment is nished, use the escape button to exit out of the

machine status menu.

160

160

LIGHT STANDBY UP DOWN ESC SET (Enter)

Press and Hold Press and Hold Press and Release Press and Release Press and Release Press and Release

Long press (>5

sec) Toggles light

on and o.

Places unit in

Standby Mode. If

LED is on. Device

is o.

Scrolls the menu

items Increases

the values.

Scrolls the menu

items Decreases

the values.

Returns up one

level with respect

to the current

menu. Conrms

the parameter

value

Accesses

the machine

status menu

and displays

any alarms (if

present)

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21 Beverage-Air 15

SETTING THE REAL TIME CLOCK

To set the real time clock, press and release the set button to enter the machine status menu. “Set will appear on the

menu.

Use the up and down button to scroll to the real time clock menu folder. “Rtc” will appear on the display.

Press the set button to enter into the clock setup menu. “Day” will appear on the display. Use the up and down buttons to

scroll to the hour (h), minute (‘) or day (day) that needs to be changed.

Press the set button to display the value and use the up or down button to change the value. Once the value has been

selected, use the escape button to conrm the new value and return the pervious menu level. Repeat the previous steps to

change the remaining parameters.

Viewing Alarm Codes

To view the alarm codes, press the set button to enter the machine status menu. “Set” will appear on the display.

Use the up and down button to scroll the alarm folder in the menu. ALr will appear on the display.

Press the set button to enter into the list of active alarms. Use the up and down button to scroll thru the alarms. Once

alarm codes have been viewed, use the escape button to exit out the menu and view set point.

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21Beverage-Air16

CONTROLLER FLOW CHART

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21 Beverage-Air 17

Code Description LED Relay Reset Parameters involved to Enable alarm

E1 Probe Pb1 failure ON Active Automatic Ont, Oft

E2 Probe Pb2 failure ON Active Automatic Ont, Oft

E3 Probe Pb3 failure ON Active Automatic Ont, Oft

E4 Probe Pb4 failure ON Active Automatic Ont, Oft

E5 Probe Pb5 failure ON Active Automatic Ont, Oft

EL LINK2 probe failure ON Active Automatic Ont, Oft

Ei Virtual probe failure ON Active Automatic Ont, Oft

AH1 HIGH temperature 1 alarm ON Active Automatic SP1, Att,Afd,HA1,PAO,dAO,OAO,tA1

AL1 LOW temperature 1 alarm ON Active Automatic SP1, Att,Afd,HA1,PAO,dAO,OAO,tA1

AH2 HIGH temperature 2 alarm ON Active Automatic SP2, Att,Afd,HA2,PAO,dAO,OAO,tA2

AL2 LOW temperature 2 alarm ON Active Automatic SP2, Att,Afd,HA2,PAO,dAO,OAO,tA2

EA External alarm ON Active Automatic PEA, EAL

OPd Door open alarm ON not active Automatic PEA, tdO

Ad2 End of defrost due to time-out ON not active Automatic dE1, dE2, dAt

Prr Preheating alarm ON not active Automatic

E10 Clock alarm ON not active Automatic

HiP HIGH voltage alarm ON not active Automatic SPH, SPL, dFL, SoU

LoP LOW voltage alarm ON not active Automatic SPH, SPL, dFL, SoU

nPA General pressure switch alarm ON not active Automatic PEn, PEi

LPA High pressure switch alarm ON not active Automatic PEn, PEi

HPA Low pressure switch alarm ON not active Automatic PEn, PEi

PA General pressure switch alarm ON not active Manual PEn, PEi

ALARM CODES

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21Beverage-Air18

SEQUENCE OF OPERATIONS

The cooler operates based on the air temperature measured by the probe located at the return air.

Operation Controller Action Operation Controller Action

Heating Elements Elements turn on

when the cabinet

temperature is below

the dierence of the

set point and the dead

band

The element Contact is

energized

Elements turn o

when the cabinet tem-

perature is equal to or

above the set point.

The element Contact is

de-energized

RTN400 terminals

10, 11

RTN400 terminals

10, 11

Circulating Fan The Circulating fan runs continuously when the unit is plugged in

Light The light will turn

on when the door is

open or door button is

pressed

The Light Contact is

energized

The light will turn

o when the door is

closed or the door

button is pressed

The Light Contact is

de-energized

RTN400 terminals

13,14

RTN400 terminals

13,14

Condition Heating

Element

Circulating

Fan

Lights

Cabinet Temp <

Set point - dead-

band

ON ON ON or OFF

Cabinet Tem-

perature >= Set

point

OFF ON ON or OFF

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21 Beverage-Air 19

CONTROLLER

Relay/Probe Description Terminal

Out 1 Heating Elements 10,11

Out 2 Circulating fan 4, 5

Out 3 not used 7, 9

Out 4 Light (or alarm relay if electronic lock) 13, 14

PB1 – Air/control probe 18, 19

PB2 not used 20, 21

PB3 not used 22, 23

PB4&5 not used

DI digital input/Door switch 26, 27

KEYB Display connection 15, 16, 17

User Manual for PH Warming Cabinets Beverage-Air

Rev. 01/21Beverage-Air20

CLEANING AND MAINTENANCE

Cleaning Schedule:

Cabinet

Daily wipe down

Weekly interior

Gaskets

Daily inspection, check

that hinges are tight to

the cabinet.

Routine maintenance

Annually

Daily Exterior Cleaning

It is much easier to clean on a regular basis than to have

to remove stains once they have built up.

1. Wash with a clean sponge and a mild detergent that

does not contain chlorine.

2. Rinse with clean water.

3. Dry with a soft cloth.

4. Polish with a soft cloth, wiping with the grain.

5. Wipe weekly with stainless steel cleaner.

Weekly Interior Cleaning

1. Remove all food, food related items and shelves. Store

the food at a safe temperature.

2. Disconnect power to the unit (unplug it or switch the

breaker o).

3. Remove all loose food particles from the inside walls,

oor, door liner and ceiling.

4. Scrub all interior surfaces and door gaskets with a

warm (100oF to 110oF) detergent solution and a soft

scrub brush.

5. Rinse with clean water and allow to air dry.

6. Return the shelves to the unit and secure them.

7. Restore power.

8. Return food to the unit when it has reached a safe

temperature.

Periodic, Gaskets

1. Visually inspect the door gaskets for a tight seal on all four sides. Inspect for any type of damage such as rips, tears,

stiness, or cracks.

2. If any such condition exists, the magnet will not seal and the gasket will need replaced.

3. Cleaning the gasket requires the use of mild dish detergent and warm water. Next, thoroughly rinse and dry the

gasket.

This manual suits for next models

13

Table of contents