BGS technic 8471 User manual

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

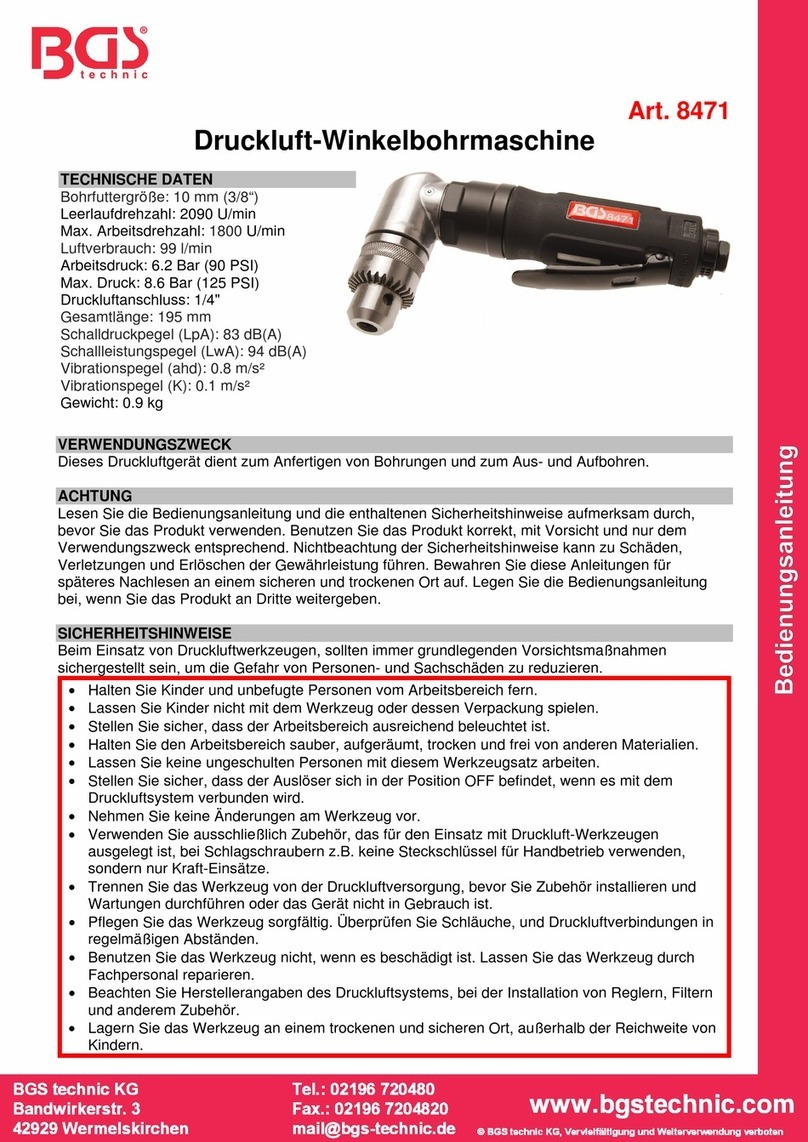

BGS 8471

Air Angle Drill

INTENDED USE

This air tool is used to make holes, to drill out studs and to make holes bigger.

ATTENTION

Read the operating instructions and all safety instructions contained therein carefully before using the

product. Use the product correctly, with care and only according to the intended purpose. Non-

compliance of the safety instructions may lead to damage, personal injury and to termination of the

warranty. Keep these instructions in a safe and dry location for future reference. Enclose the

operating instructions when handing over the product to third parties.

SAFETY INFORMATIONS

When using pneumatic tools, fundamental precautionary measures must always be ensured in order

to reduce the risk of personal injury and property damage.

•Keep children and unauthorised persons away from the work area.

•Do not let any children play with the tool or its packaging.

•Make sure that the work area is sufficiently illuminated.

•Keep the work area clean, organised, dry and free from other materials.

•Do allow untrained persons work with this tool set.

•Ensure that the trigger is located in the OFF position when being connected to the compressed

air system.

•Do not carry out any modifications on the tool.

•Use only accessories that are dimensioned for use with compressed air tools, e.g. with impact

wrenches, for manual use do not use conventional sockets, use only power sockets.

•Disconnect the tool from the compressed air supply before installing accessories, when carrying

out maintenance work or the device is not being used.

•Maintain the tool with care. Check hoses and compressed air connections at regular intervals.

•Do not use the tool if it is damaged. Have the tool repaired by specialist personnel.

•When installing regulators, filters and other accessories, observe the manufacturer

specifications of the compressed air system.

•Store the tool in a dry and safe location out of the reach of children.

TECHNICAL DATA

Chuck size: 10 mm (3/8“)

Free speed: 2090 rpm

Max. working speed: 1800 rpm

Air consumption: 99 l/min

Working pressure: 6.2 bar (90 psi)

Max. pressure: 8.6 bar (125 psi)

Air inlet: 1/4"

Total length: 195 mm

Sound pressure level (LpA): 83 dB(A)

Sound power level (LwA): 94 dB(A)

Vibration level (ahd): 0.8 m/s²

Vibration level (K): 0.1 m/s²

Weight: 0.9 kg

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

IMPORTANT NOTES ON PERSONAL SAFETY

•Operate the tool using common sense.

•Do not wear loose clothing or jewellery that can be caught by moving parts and cause serious

injury.

•Only operate the tool at a safe distance from yourself and other persons

•Always ensure a firm foothold in order to be able to maintain your balance at all times.

•Never reach through or over electric cable or air hoses.

•Always work with a second person present; in event of an accident, this person can call for help

or medical assistance.

•Do not use this tool if you are under the influence of medication, alcohol or drugs, or if you are

tired. Read the package insert of your medicine in order to rule out an impairment of your

judgement or reflexes.

•Do not use the device if there is any doubt about the functionality of this tool.

•Always stay aware. During work, observe your workplace and carry out work with utmost care.

•Before use, check the tool for damage. If a part is damaged, use the tool again only after all

damaged parts have been repaired by an authorised specialist.

OCCUPATIONAL SAFETY

Always wear suitable protective equipment when using pneumatic tools.

Always wear anti-slip safety shoes if you are working with pneumatic tools.

Always wear work gloves if you are working with pneumatic tools.

If you have long hair, always wear a hair net if you are working with pneumatic tools

that are equipped with motorised rotating or moving components.

Always wear approved safety glasses if you are working with pneumatic tools.

Always wear approved hearing protection if you are working with pneumatic tools.

Always wear an approved dust mask if you are working with pneumatic tools where

dust can be stirred up or dust is produced.

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

RECOMMENDED AIR SYSTEM

No.

Description

No.

Description

1

Air tool

6

Unit for draining / filtering

2

Air hose

7

Draining valve

3

Quick coupler

8

Shut-off valve

4

Oiler

9

Dryer / filter unit

5

Pressure regulator

10

Compressor

MAINTENANCE

•Air tools should be operated on air systems that have an automatic oiler.

When using air systems that do not have an automatic oiler, air tools

must be regularly added oil to the air tool via the air connection.

•Before first use, add 4 to 5 drops of air device oil to the air connection of

the device.

•Do not use engine or gear oil to oil pneumatic tools; only use oil for

pneumatic tools.

•Drain the compressed air system before each use. Water in the air lines

leads to a loss of performance and damage to the air tool.

•Clean or replace the air filter on the compressor at the prescribed

intervals.

•Only operate the air tool with the maximum pressure specified in the

chapter "Technical data".

UNPACKING

When unpacking, make sure that all parts are present.

Contact your dealer if parts are missing or damaged.

SAFETY WHILE OPERATING

Take enough time for a careful selection of a working area. Take care that your workplace is near to

the compressor and blasting material. Attention! Always stay aware. Remove the device or other

objects from the working area. Persons and animals must not remain in the working area. Never

direct the air tool against persons or animals. Always wear safety equipment like safety glasses and

dust masks when working with this air tool (see chapter “Occupational Safety”).

SW-Stahl und Werkzeugvertriebs GmbH Tel. +49 (0) 2191 / 46438-0

F56essartSresukreveL ax +49 (0) 2191 / 46438-40

ed.lhatsws@ofni:liaM-EdiehcsmeR79824-D

CE-Erklärung

BGS technic KG

Bandwirkerstr. 3

42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

www.bgstechnic.com

EU-KONFORMITÄTSERKLÄRUNG

EC DECLARATION OF CONFORMITY

DÉCLARATION „CE“ DE CONFORMITE

DECLARATION DE CONFORMIDAD UE

Wir erklären in alleiniger Verantwortung, dass die Bauart des Produktes:

We declare that the following designated product:

Nous déclarons sous propre responsabilité que ce produit:

Declaramos bajo nuestra sola responsabilidad que este producto:

folgenden einschlägigen Bestimmungen entspricht:

complies with the requirements of the:

est en conformité avec les réglementations ci-dessous:

esta conforme a las normas:

Angewandte Normen:

,GHQWL¿FDWLRQRIUHJXODWLRQVVWDQGDUGV

Norme appliquée:

Normas aplicadas:

ppa.

Frank Schottke, Prokurist

BGS technic KG, Bandwirkerstrasse 3, D-42929 Wermelskirchen

Wermelskirchen, den

Druckluft-Winkelbohrmaschine (Art. 8471)

Air Angle Drill

Perceuse d'angle pneumatique

Amoladora neumática angular

Machinery Directive 2006/42/EC

EN ISO 12100:2010

EN ISO 11148-3:2012

EN ISO 15744:2008

EN ISO 28927-5:2009

Certification No.: SPT-2017-12-11 / ST-225

Test Report No.: SPT-2017-12-11-JY-SS

19.10.2020

Other manuals for 8471

1

Other BGS technic Drill manuals

Popular Drill manuals by other brands

Chicago Electric

Chicago Electric 96299 operating instructions

Chicago Pneumatic

Chicago Pneumatic CP9285 Series Operator's manual

Bosch

Bosch Professional GBH 18V-28 C Original instructions

Milwaukee

Milwaukee M18 Original instructions

Clas Ohlson

Clas Ohlson DJC-119A-SZ20-144-UK user manual

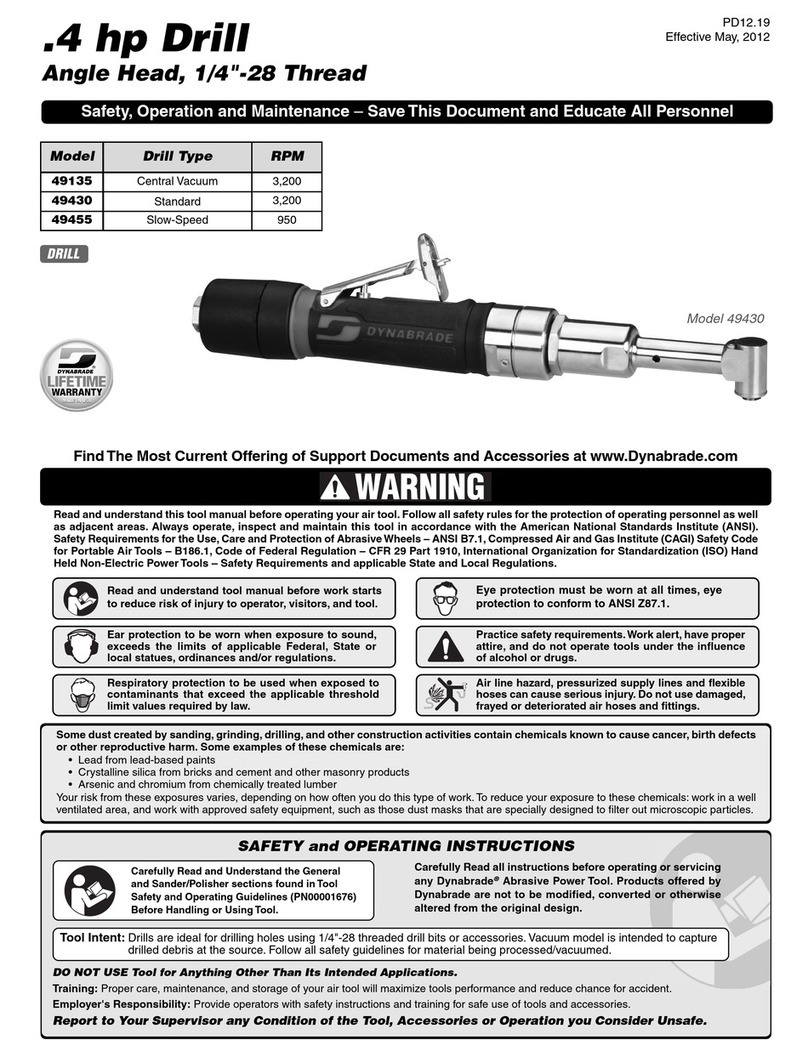

Dynabrade

Dynabrade 49135 Safety, operation and maintenance