Bianchi Industry BVM 351 User manual

BVM 3 5 1

CERT. N° 9191 BNVN

UNI EN ISO 14001:2004

CERT. N° 9105 BNVD

UNI EN ISO 9001: 2000

USE AND MAINTENANCE MANUAL

DECLARATI ON OF CON FORM I TY

La BI AN CH I VEN DI N G GROUP S.p .A.

Corso Africa, 9 - 24040 Zingonia di VERDELLI NO (BG) I t alia

hereby declares under it s own liabilit y that t he fam ily of coffee m achines - m odel:

BVM3 5 1

complies with the Basic Safety Reqirements as specied in the Directives listed below:

1 ) 7 3 / 2 3 CEE Low Ten sion ⇒9 3 / 6 8 / CEE - BT-

2 ) 8 9 / 3 3 6 / CEE Electromagnetic Compatibility ⇒9 1 / 2 6 3 / CEE ⇒9 2 / 3 1 / CEE ⇒

⇒9 3 / 6 8 / CEE ⇒2 0 0 4 / 1 0 8 / CEE - EM C-

3) EC REGULATION 1935/2004 on materials and articles intended to come into contact with

food.

EC COMMISSION REGULATION 1895/2005 on the restriction of use of certain epoxy derivatives

in materials and articles intended to come into contact with food, COMMISSION DIRECTIVE

2002/72/EC relating to plastic materials and articles intended to come into contact with foo-

dstuffs.

The test s/ checks have been perform ed in accordance wit h the current Harm onized/ European Regulat ions

1 ) LO W TEN SI ON ( LT Ele ct r ic Sa fe t y ) :

CEI EN 60 335- 1 : 20 04- 0 4 +

CEI EN 60335- 1/ A1/ A11: 2005 ( General Elect ric Safet y Regulat ion)

CEI EN 60 335- 2 - 75 : 20 03- 0 6 ( Special r equir em ent s f or com m er cial dispenser s an d au t om at ic

vending m achines)

EN I SO 11201 + EN I SO 3744 Measurem ent of acoust ic noise

2 ) ELECTROM AGN ETI C COM PATI BI LI TY ( EMC)

EN 55014- 1 Em issions ( conduced and irradiat ed via power supply cable)

EN 5 50 14- 1 Em issions ( int er m it t ent cond uct or )

EN 6 10 00- 3- 2 Em issions ( har m on ic)

EN61000-3-3 Emissions(ickers)

EN 6 10 00- 4- 4 I m m unit y ( ag ainst t ransien t / b ur st qu ick t rain s)

EN 6 10 00- 4- 5 I m m unit y ( ag ainst sur ge pu lse)

EN61000-4-6 Immunity(againstconducednoises,inducedbyradiofrequencyelds)

EN 6 10 00- 4- 1 1 I m m unit y ( ag ainst t en sion holes…)

EN 6 10 00- 4- 2 I m m unit y ( against elect r ost at ic dischar ges)

EN50366 Measurementoftheelectromagnetceldaroundthevendingmachine

3 ) SUI TABI LI TY OF M ATERI ALS USED FOR CON TACT W I TH FOOD

Test ing for “ Suit ability to contact w ith foodst uffs”, as provided for by I t alian legislat ion on t he

issue ⇒Min ist er ial Decr ee dat ed 21- 03 - 197 3 and all su bsequ ent am en dm en ts, ⇒Decree dat ed

4t h May 2006 no. 227, and via t he adopt ion of t he following European Directives: 82/ 711/ EEC,

85/ 572/ EEC, 93/ 8/ EEC, 97/ 48/ EC, 2002/ 72/ EC, 2004/ 13/ EC, 2004/ 19/ EC, 2005/ 79/ EC and Com -

m ission Regulat ions EC n. 1935/ 04 and EC n. 1895/ 2005.

Zin gonia di Ver dellin o ( BG) , 01/ 01/ 2010

CHI EF EXECUTI VE OFFI CER

L’Amministratore Delegato

______________________

INFORMATION TO THE USERS

Under Legislative Decree 25 September 2007, no.185 and art. 13, Legislative Decree 25 July 2005, no.151 “Implementation

of Directives 2002/95/EC, 2002/96/EC and 2003/108/EC, regarding the reduction of use of hazardous substances

in electrical and electronic equipment as well as waste disposal”.

The barred waste container symbol on the equipment means that the product, at the end of its service life, must be

disposed of separately from the other types of waste.

The user must therefore convey the equipment, at the end of its service life, to the appropriate separate collection centres for

electronic/electrotechnical waste products or return it to the dealer when purchasing a new equivalent equipment.

The appropriate separate collection and the following sending of the used equipment to recycling, treatment and eco-friendly

disposal will help avoid negative effects on the environment as well as on health along with an easier recycling of the materials

forming the equipment.

Any unauthorized disposal of the product by the user will imply the enforcement of the administrative sanctions as set out in

Legislative Decree no. 22/1997 (article 50 and following articles, Legislative Decree no. 22/1997).

Declaration of Conformity

RoHS Directive

DIRECTIVE 2002/95/EC OF THE

EUROPEAN PARLIAMENT AND OF THE COUNCIL of 27 January 2003

on the restriction of the use of certain hazardous

substances in electrical and electronic equipment

Bianchi Vending Group S.p.A. declares:

Starting from July 1st 2006 any product manufactured by “Bianchi Vending Group Spa” on the

European market is Rohs Directive compliant and do not contain concentrations exceeding limits

allowed for the following substances:

xLead (Pb)

xMercury (Hg)

xCadmium (Cd)

xHexavalent Chromium (Cr(VI))

xPolybrominated Biphenyls (PBB)

xPolybrominated Diphenyl ethers:

o Polybrominated diphenyl ethers (PBDE)

o Octabromodiphenyl ether (OctaBDE)

o Decabromodiphenyl ether (DecaBDE)

xPerfluorooctane sulfonate (PFOS)

xPolyChloro Naphthalenes (PCN)

xBis(tribromophenoxy)ethane Polychlorinated biphenyl (PCB)

xBenzene

Zingonia di Verdellino (BG), 12 January 2010

CHIEF EXECUTIVE OFFICER

5

PE

ATTEN TI ON : I m port ant safet y indicat ions

READ t he inst ruct ion m anual m achine carefully before using t he m achine

For any service or m aintenance sw it ch off the m achine

ATTEN TI ON : m achine swit ched on

ATTEN TI ON : hot parts in contact !

Earthing indicat ion

I M PORTAN T N OTI CES

OPERATOR

By “operator” we mean the person assigned to machine use and operation and to coffee relling

t asks. The oper at or m ust furt her m or e t ake car e of all t he necessar y m achine cleaning operat ions.

I n t he event of m achine breakdow ns, the operat or is required t o cont act t he inst allat ion and ser vice

technicians accordingly.

I N STALLATI ON TECH N I CI AN

The installation technician is dened as the person responsible for the installation of the coffee ma-

chine, t he st arting up operat ions and t he function set tings.

Each regulat ion operat ion is the exclusive responsibilit y of t he inst allat ion t echnician w ho also holds

t he program m ing access passw ord.

BEFORE USI NG THE MACHI NE, READ THI S MANUAL CAREFULLY FOR I TS CORRECT USE I N AC-

CORDANCE WI TH THE CURRENT safet y STANDARDS.

6

1 .0 I N TROD UCTI ON

1 .1 D ir e ct ion s a nd in st r uct io ns f or o pe r a -

t or s

This coffee brew ing m achine has been engineered and const ruct ed

in full com pliance with all t he laws and regulat ions current ly in force

on safet y issues. I t is deem ed as being safe t o m achine operat ors

that accurat ely com ply wit h all the dir ect ions and inst ruct ions

provided in t his Manual.

The user m ust not under any circum st ances rem ov e t he guards

t hat require a t ool for r em ov al.

Som e m aint enance operat ions (t o be done solely by specialized

t echnicians and indicat ed in t his m anual w it h a special sym bol)

requirethatspecicsafetyprotectionsofthemachinemustbe

swit ched off .

I n accor dance wit h t he current safet y regulat ions, cert ain opera-

tions are t he exclusive responsibilit y of the installat ion t echnician,

an d t h e or din ar y m aint enance t ech nician m ay h av e access t o

specicoperationsonwithspecicauthorization.

The acquaintance and absolut e respect, from a technical point of

view, of the safet y instructions and of the danger not ices contained

in t his m anual, ar e fundam ent al for t he ex ecut ion, in condit ions

of m inim um risk, for t he inst allat ion, use and m aint enance of

t his m achine.

1 .2 Ge ne r al I n st r u ct ion s

Kn ow led ge of t h e in for m at ion an d in st r uct ion s

cont ained in t he present m anual is essent ial for

a correct use of t he coffee m achine on t he par t

of t he user .

I nterventions by t he user on t he coffee m achine are allowed only

if t hey are of his com pet ence and if he has been duly t rained.

The inst allat ion technician m ust be fully acquaint ed wit h all t he

m echanism s necessary for t he correct operat ion of t he coffee

m achine.

– I t is t he buyer’s responsibilit y t o ascer tain t hat t he users have

been t rained and ar e infor m ed and r egulat ions indicat ed in t he

t echnical docum ent at ion supplied.

Despit e the full observance of the safety regulat ions by the

const ruct or, t hose who operat e on t he coffee m achine m ust be

fully aware of t he pot ential risks involved in operat ions on t he

m achine.

– This in st r uct ion m an ual con st it u t es an in t egr al par t of t he

coffee m achine and as such, it m ust be alw ays be on hand in

t he v icinit y of t he m achine for easy consult at ion by t he v ar ious

m achine oper at or s, right unt il t he m achine is act ually st ripped

and scr apped.

– I n case of loss or dam age of t he present m anual it is possible

receive a new copy m aking applicat ion t o t he m anufact ur er,

wit h prior indicat ion of t he dat a r egist ered on m achines’ ser ial

num ber .

– Modications to the machine not previously agreed on with the

const ruct ion com pany and undert ak en by t he inst allat ion t ech-

nician are considered t o be under his entire r esponsibility.

All the operations necessary to maintain the machine’s efcien-

cy, before and during it’s use are at the users charge.

– Any manipulations or modications made to the coffee machine

t hat ar e not previously aut hor ized by t he m anufact urer, r eliev e

t he lat t er from any responsibilit y for dam ages der iv ing fr om ,

and will autom at ically result in t he cancellat ion of t he m achine

guar ant ee t erm s.

– This manual reects the status at the moment of the emission

of t he coffee m achine on the market; possible modications,

upgrading, adapt m ent s that are done t he m achine and t hat are

subsequent ly com m ercialized do not oblige Bia n ch i Ve ndin g

Group Spa neit her t o int ervene on t he m achine previously

supplied, nor, neither to updat e t he relat ive technical docum en-

t at ion supplied t oget her w it h t he m achine.

I N D EX

1 .0 I NTRODUCTI ON

1.1 Direct ions and inst r uct ions for operat ors

1.2 General direct ions and inst ruct ions

2 .0 DESCRI PTI ON OF TH E M ACH I N ES

3 .0 TECH N I CAL SPECI FI CATI ON S

3.1 Machine dim ensions and w eight s

3.2 I t em s on issue w it h t he m achine

3.3 Mechanical safet y devices

3.4 Electrical safet y devices

3.5 Env ir onm ent al noise

3.6 Vibrat ions

4 .0 TRAN SPORT

4.1 Packing

4.2 I nspect ion on delivery

5 .0 I NSTALLATI ON

5.1 Ut ilit ies to be provided by t he cust om er

5.1.1. Power supply

5.1.2 . Wat er m ains supply

5.2 Machine posit ioning

6 .0 COMMI SSI ON I N G

6.1 Machine cont rol com m ands and devices

6. 2 Mach in e st ar t- up

7 .0 OPERATI ON

7.1 Operation

7.2 Display m essages

7.3 Pr ogram m ing

8 .0 SOFTW ARE I N STRUCTI ON S

8.1 Funct ion m anagem ent

9 .0 MAI N TEN AN CE

9.1 Soft ware funct ion m anagem ent

9.2 Daily m aint enance

9.2.1 Cleaning t he collect ion t ray

9.3 Periodic m aint enance t asks

9.3.1 Rigenerazione addolcit ori

9.4 Accesso alle part i int erne

1 0 .0 PUTTI NG TH E MACHI N E OUT OF SERVI CE

10.1 Put ting the m achine out of service tem porar ily

10.2Puttingthemachineoutofservicedenitely

1 1 .0 TROUBLE SHOOTI NG

1 1 .0 ALARM S AN D SI GN AL MESSAGES

7

Fig. 1 .1

– I t is however Bia n ch i Vendin g Gr oup‘s facult y, when dee-

m ed opport une and for v alid m ot ives, t o adj ourn t he m anuals

alr eady pr esent on t he m ark et , sending t o t heir cust om ers

adj ournm ent sheet s that m ust be kept in t he or iginal m anual.

Possible t echnical problem s t hat could occur are easily resolv able

consult ing this m anual ; For fur ther inform at ion, cont act t he

dist ributor from whom t he machine has been pur chased, or con-

tact Bianchi Vending Group’s Technical Service at t he following

num ber s:

0 3 5 - 4 5 0 2 1 1 1 - fax 0 2 7 0 0 4 8 3 3 2

Whenever the m achine servicing facilities are contacted, it is neces-

sary to quote the data on the serial num ber rating plate (Fig.1.1) .

Bianchi Vending Group S.p.A. hereby declines each and every

liabilit y w hat soev er ar isin g for dam ages t o per son s and/ or obj ect s

subsequent t o failure to observe t he following direct ions and war-

nings during inst allat ion and/ or operat ion of t he coffee machine:

. The m achine m ust be exclusively posit ioned in places w her e

use is st rict ly reserved to appropriately t rained personnel.

· Pot en t ially h azar dou s m achine pack in g m at er ial ( plast ic bags,

expanded polyst yr ene, car dboards st aples and nails, et c) m ust

st rict ly not be left on hand for access by children.

· Prior t o connect ing up t he m achine, check t o ensur e t hat the

rat ing plat e dat a is com pliant wit h the power m ains. The use

of adapt ers, m ult iple socket st rips and/ or ex tensions is st rict ly

prohibit ed.

· I n case of uncertaint y, have t he power supply syst em inspected

byqualiedpersonnel.Thesystemmustcomplywithallthe

relative pr ovisions and r egulat ions in for ce, am ongst which:

- m achine gr ounding;

- conductorsectioningtobeappropriatelysufcientfor

elect rical input ;

- circuit br eaker device, suit ed t o overload cat . 3.

· Check to ensure that t he m ains volt age does not have a displa-

cem ent gr eat er t han 6% .

· Check t o ensur e t hat the pressur e is com prised bet ween 0 .5

and 5 bar.

· The m achine is not int ended for inst allat ion in indust rial ki-

t chens, privat e consum er kit chens and t he likes.

. The m achine is not int ended for out door inst allat ion or for in-

st allation in places subj ect to water sprays and/ or wat er j et s.

· Posit ion t he m ach ine on a w at er pr oof su rface ( i. e. lam in at e,

st eel, ceram ic t ilin g, et c. ) an d f ar aw ay f rom heat sou rces

( ov ens, cook er s, ch im ney s, et c. ) , in sit es wh er e t he am bien t

t em perat ur e will not drop below 5° C.

· Posit ion t he m achine ont o a support surface so t hat t he cup

heaterislocatedataheight150cmaboveoorlevel.

· Do not expose t he m achine t o bad weat her or inst all it in en-

vironm ent s wit h excess am bient hum idity.

· Do not in any way obst ruct t he suct ion or dissipat ion grids and

particular ly do not cover the cup heat er surface wit h dishclot hs

or other obj ects.

· Whenpacked,themachinemustbestoredinsufcientlydry

st orage facilit ies w it h t em perat ur es not less t han 5 ° C. I t is pos-

sible t o st ack only up t o t hree packages of t he sam e m achine

on t op of one anot her. Avoid placing any ot her t ypes of heavy

packages on top of t he m achine package.

· To ensur e st andar d operat ions, t he appliance m ust be inst alled

in sit es where t he envir onm ent al t em perat ur e is com pr ised

bet ween a m inim um + 5° C and a m axim um + 50° C t em perat ure

and where the absolute hum idity is not in excess of 75% .

· Do not position the appliance in the vicinity of inammable

obj ect s and always keep a safety dist ance of at least 30 cm .

· Rem oval of m echanical, elect rical and/ or heat safet y guards

and prot ect ions is st rict ly prohibit ed.

· Intheeventofemergenciessuchasconagrationandre,out

of t he order noises and heat ing, et c. im m ediat ely unplug t he

m achine from t he power m ains, close any wat er and/ or gas

supply t aps and faucet s as t he case m ay be.

. I n t he event t hat during handling and transport operat ions the

m achine where t o t ransit in am bient t em perat ur es close t o or

under 0° C, t he t echnician is required t o subsequent ly em pt y

out t he hydraulic circuit .

The st andard fact ory condit ions pr ov ide for m achine deliver y

wit hout water in t he int er nal circuit s.

· To ensure fault less m achine operat ions, use only accessories

and spares as aut hor ised by the m anufact ur er.

· The coffee m achines have been engineered and const ructed for

the brewing of espresso coffee and ot her hot drinks. Any ot her

use is considered as im proper and hazardous m achine use.

· The m achines are int ended exclusively for foodst uff prepa-

rat ion purposes. The use/ int r oduction of liquids and/ or other

subst ances t hat m ay generat e hazar ds and/ or cont am inat e the

dispensers.

Bianchi Vending Group S.p.A can in no way whatsoever be held

liable t o com pensat ion for any possible dam ages arising due t o

for ced int errupt ions of m achine dispensing operat ions caused by

breakdowns and failures.

Th e op e ra t or m u st :

· Not com e int o cont act w it h any hot m achine part s and/ or wit h

the dispensing area.

· Not place cont ainer s holding liquids ont o t he m achine.

· Not undert ake m aint enance and/ or handling operat ions wit h

the m achine plug still in t he power m ains or w hen not cooled

down.

· Not wash t he m achine w it h dir ect , pressurised wat er j ets.

· Neither part ially nor entir ely subm erge t he m achine in wat er.

· Not use t he m achine if the elect ric pow er supply cable look s as

t hough it is dam aged.

· Not t ouch t he m achine w it h w et or m oist hands and/ or feet .

· Not use t he m achine if m inor s ar e pr esent in t he im m ediat e

vicinit y t hereof.

· Not allow t he m achine t o be used by m inors or disabled indivi-

duals.

· Not obstruct the heat suct ion or dissipat ion grids with dishclot hs

or ot her obj ect s.

· Not use the m achine if it is in any way w et or m oist , unless it

is t he m achine’s dispensing ar ea.

Th e m a nu fa ct u re r h e r eb y d eclin es e a ch a n d e ve r y lia bilit y

fo r d a m a g e s w h at so ev e r a r isin g t o p er son s a n d/ or t h in gs

du e t o im p r op er , w r on g o r u nr e a son a ble u se of a n y on e of

t h e m a ch in e s by n on - p ro fe ssion a l ope r a t or s.

8

2 .0 DESCRI PTI ON OF TH E M ACH I N ES

The super au t om at ic BM V 3 5 1 coffee m achin es h av e been

engineer ed and constructed for t he brewing of espr esso coffee

and ot her hot drinks. Any ot her use is held as being im pr oper or

danger ous.

The manufacturer hereby declines each and every liability

for damages whatsoever arising to persons and/or things

due to improper, wrong or unreasonable use of any one of

t h e m a ch in e s.

The m achine operat or m ust observ e all the use and m aint enance

inst ruct ions in t his m anual, at all t im es. Should any doubt s on

operat ion or anom alies arise, st op t he m achine, do not at tem pt

repairs or direct int erv ent ions on t he m achine and im m ediat ely

cont act t he service facilities accordingly.

The BM V 3 5 1 coffee m achines are available eit her in m ains wat er

supply version, or self- feeding tank wat er supply ver sion.

The dispensing group is heat set and st abilised t o ensure opt im i-

sed ut ilizat ion of all t he noble coffee com ponent s. An elect ronic

dev ice w ar rant s f or opt im ised h ot wat er au t o- lev ellin g in t he

boiler unit . Water and st eam dispensing is provided via 2 high-

perfor m ance m ult i- dir ect ion spout s t hat allow for t he pr eparat ion

of hot dr inks.

The BVM 3 5 1 m odel is provided w it h a coffee cont ainer t hat fee-

ds the coffee grinder for preparat ion of t he gr ound coffee t hat is

then conveyed int o t he coffee group subsequent t o a dispensing

request .

A m ilk int ake device is fur therm or e pr ovided, for m ilk int ake dir ect ly

from t he jug. This allows for cappuccino or frot hy m ilk supply,

directly fr om t he relat ive dispenser.

Said t echnical solutions ensur e t hat energy wastes are pr even-

t ed t her eby safeguar ding t he m achine from dangerous t her m al

shock s.

Wat er as necessary is tapped in dir ect ly from the water m ains

and is pr essur ised via a sealed or m aint enance fr ee volum et ric

pum p. Wat er heat ing is provided via conduct ive therm al exchange

in t he boiler unit .

By act ivat ing t he appr opr iat e cont rols locat ed on t he m achine’s

front let panel, opt im ally pressurised and heat ed wat er is delivered

to t he dispensers.

The m achine is pr ov ided wit h a st eel st ruct ural fram ew or k, ont o

whichallitsmechanicalandelectriccomponentsarexed.

The m achine bodywor k is in st ainless st eel and Baydur t o gua-

rant ee opt im ised pr ot ect ion and saf et y com b in ed w it h u niqu e

designing.

3 .0 TECH N I CAL SPECI FI CATI ON S

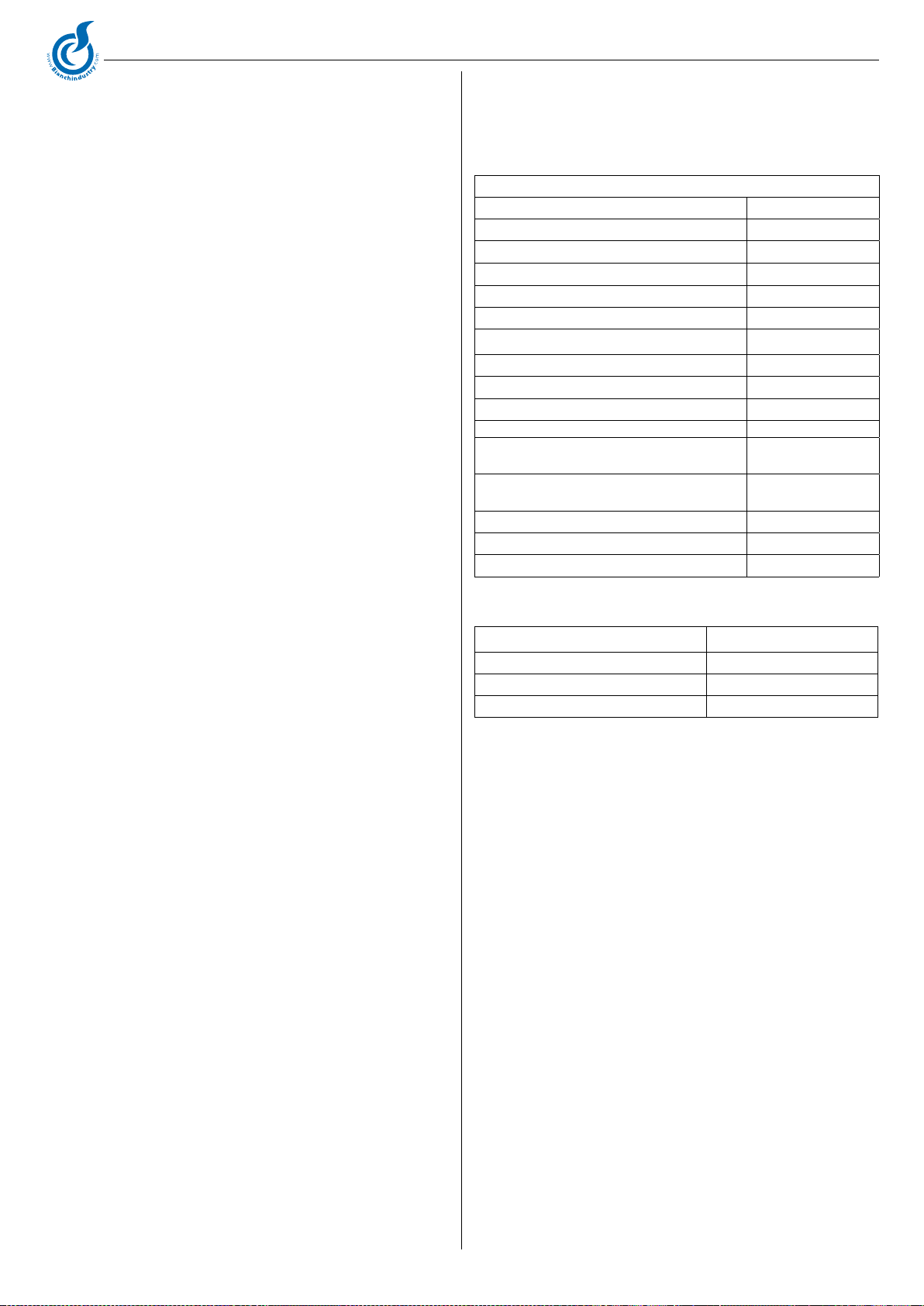

3 .1 M ach in e d im e nsion s a n d w e igh t s

3 .2 I t e m s on issu e w it h t h e m a ch in e

3 .3 M ech a nica l sa f et y de v ice s

· Com plet e safet y and pr ot ect ion panelling on all hot m achine

parts and on t he hot wat er and st eam generat or.

· Wor k surface wit h grid and liquid collection t ray.

· Expansion valve on t he hydraulic system and pressure overload

safet y valve on t he heat er.

· Non-returnvalveonthehydraulicsystemtoavoidreuxesinto

t he wat er m ains.

3 .4 Ele ct r ica l sa fe t y d ev ice s

· Low- voltage keypad controls

· Therm al overload pr ot ect ion on t he pum p m ot or

· Therm al overload pr ot ect ion on t he resist ance elem ent s

3 .5 En vir on m e n t a l n oise

Soun d pr essur e levels am ou nt ing t o 70dB( A) ar e not n or m ally

exceeded on t he m achine operat ion sit e.

3 .6 Vibr a t ion s

Th e m ach in es ar e eq uip ped w it h v ibr at ion - pr oof r ub ber f eet .

I n st andard working condit ions, t he m achines do not generat e

danger ous vibrat ions, neit her for t he operat or nor for t he env i-

ronm ent .

D I M EN SI ON S AN D W EI GH TS

Lengt h [ m m ] 660

Dept h [ m m ] 530

Heigh t ( hopper ex clu ded) [ m m ] 47 0

Weight [ kg] 50

Boiler capacity: steam area [ litres] 3,5

Boiler capacity: injector area [ lit res] 1/ 3

PACKI N G

Lengt h [ m m ] 740

Dept h [ m m ] 620

Height [ m m ] 560

Power supply

volt age 230 V

Power supply

frequency 50Hz

Power input 2500W

Rat ed pressure of t he st eam boiler 2,2 bar

Pressure of t he espr esso boiler 11 bar

I nlet tube 1.7 m long N° 1

Discharge t ube 1.5 m long N° 1

I nst ruct ion m anual N° 1

Wir ing diagram s N° 1

9

NEUTRO AZZURRO

220V MARRONE

GRIGIO

NERO

GIALLO VERDE

COLLEGAMENTO

MONOFASE

SEZIONATORE IDONEO

ALLA CATEGORIA DI

SOVRATENSIONE 3

Fig. 5 .1

4 .0 TRAN SPORT

4 .1 Pa ck ing

The m achine is deliver ed in one single car dboard package, wit h

int ernal expanded poly styrene safet y padding inserts.

The packing is provided wit h conventional sym bols to be accurately

observed during package handling and st oring operat ions.

Dur ing t ranspor t t he pack age m ust be kept in a consist ent ly ver-

tical posit ion.

Do not turn upside down or onto one side.

Transpor t car efully avoiding bum ps and im pact s and exposure t o

bad weat her.

4 .2 I n sp e ct ion on de liv e ry

Upon deliver y, check t o see t hat t he m achine com plies exact ly w it h

t he descript ion pr ov ided on t he transport docum ent s, accessories

included.

Check t o see that t he m achine has not been subj ect to t ransport

dam ag es. I f it has, im m ed iat ely r epor t t h e occu rr ence t o t he

forwarder as well as t o our custom er service depart m ent .

Pot ent ially hazar dous m achine packing m at er ial m ust st rict ly not

be left on hand for access by children.

Do not disperse t he packing m at erial in t he environm ent but en-

sure that it is accurat ely disposed of via appropriat e packing and

wast e recycling facilit ies.

5 .0 I N STALLATI ON

Themachinesarettedwithheight-adjustablefeet.Ensurethat

height is adj ust ed ident ically for all t he fou r base feet .

The posit ioning suppor t surface m ust be evenly levelled, dr y,

st rong and st able, to be posit ioned at a height of at least 110 cm

fromtheoor.

For correct m achine operat ions it is not necessary to anchor it t o

the support surface and neit her are t echnical devices requir ed t o

lim it vibrat ions.

I t is her eby recom m ended that som e free space is left all around

t he m ach ine, t o m ak e use an d m aint enance oper at ion s qu ick

and easy

Do not install t he m achine if it is wet or m oist and wait unt il t he

m achine is surely and com plet ely dry. Prior inspect ions by t he

ser vice personnel are anyw ay necessary, t o war rant t hat t he m a-

chine’s elect rical com ponent s are not dam aged.

I n t he event t hat the m achines are equipped w it h a wat er t r eat-

m ent unit , said unit m ust be hooked up by t he inst allat ion per-

sonnel in full com pliance wit h all t he ex ist ing law s and regulat ions

in force.

I n t he ev ent of inst allat ion of different wat er t reat m ent unit s not

specicallydedicatedtothemachine,makesurethatallthere-

lat ive pr oduct docum ent at ion is com plet ely observed.

5 .1 Ut ilit ie s t o be p ro vid ed b y t h e cu st om e r

All t h e u t ilit y co nn e ct ion op er a t io ns m u st b e co nd uct e d b y

qualied personnel, in full compliance of the federal, state

a nd / or loca l r u le s a n d r eg ula t ion s in f or ce .

5 .1 .1 Pow e r supply

Th e m achin e is su pplied r eady f or con nect ion t o t he on - sit e

power mains according to the specications requested upon

purchasing.

Prior t o connecting up t he m achine, check to ensure that the rat ing

plat e dat a is com pliant wit h t he power m ains volt age dat a.

The power supply cable, t hat m ust be wholly undam aged, m ust be

hooked up direct ly int o t he pr eviously prepared ut ility connections

as per all t he r ules and regulat ion in force.

The gr ounding and at m ospheric overload dischar ge safet y and

prot ect ion syst em s m ust m andat or ily be execut ed as per all exi-

st ing laws and regulat ions.

For connect ion t o t he pow er m ains, im plem ent only an up- to- st an-

dard cable, pr ovided wit h a safety ( grounding) conductor.

For t he sin gle- phase pow er su pply, use a 3 con duct or ( 3- ph ases

+ neutral + ground) connect or.

SI NGLE- PHASE

POWER SUPPLY

CI RCUI T BREAKER

DEVI CE, SUI TED TO

OVERLOAD CAT. 3.

YELLOW GREEN

NEUTRAL BLUE

220V BROWN

GREY

BLACK

10

Fig. 5 .2

Fig. 5 .4

Fig. 5 .3

I n bot h cases, a differ ent ial sw it ch m ust be arranged upst ream of

t he pow er supply cable, com plet e wit h m agnet ic release sw it ches

com pat ible wit h t he dat a provided on t he m achine rating plat e.

The relat ive cont act s m ust be pr ovided w it h an opening equal or

great er than 3m m .

We her eby r em ind t hat each m achine m ust be pr ovided w it h it s

own, individual safet y devices.

I n t h e e ve nt t h a t t h e p ow e r su pp ly ca ble is d a m a g ed , it

m u st be r e pla ce d e it h e r b y t h e m a nu fa ct u r er , b y t h e m a nu -

facturer’s technical services or by qualied personnel that

is capa ble of pr e vent in g any possible hazards.

5 .1 .2 W a ter m a ins su pply ( Fig. 5 .2 , Fig. 5 .3 a nd Fig. 5 .4 )

The wat er m ains connect ions m ust be ar ranged t o be in t he vicinit y

of t he m achine.

· Liquid ground collect ion t ank discharge tube

· Wat er supply t ube

Following is the correct procedure for connecting the ma-

chine up to the water mains:

1 lif t t he dr op collect or t r ay ( Fig. 5. 2)

2 Removescrews(Fig.5.3–item1)thenremovetheatsafety

cover plat e.

3 connect one end of t he tube t o t he tube j unct ion as illust rat ed

in Fig. 5.4.

4 connect t he ot her end of the t ube up t o the wat er m ains. Check

to m ake sure t hat there are no obstructions in t he m ains.

5 pressthegeneralswitch,themachinewillautomaticallyllin

wat er up t o t he opt im ised set level.

Fo r o pt i m i se d m a ch i n e o p e r a t i on s w e r e co m m e n d t h e

u se o f a w a t e r t r ea t m e n t / lim e sca le e lim in a t or u nit t o b e

con ne ct e d u p pr io r t o e nt r y o f t h e m a in s w a t e r in t o t h e

m achine.

5 .2 M a ch in e po sit ion in g

· Posit ion the m achine unit ont o t he hor izont al surface as arran-

ged, then carefully adj ust height via the adj ustable feet . Ensure

that t he m achine is not inclined at an angle larger t han 2° .

Prior t o proceeding wit h t he connect ion, accurat ely wash out t he

wat er m ains t ubes:

· open t he m ains wat er t ap com plet ely and let t he wat er r un for

a few m inut es.

· Proceed wit h connect ing up t he inlet and out let wat er connec-

tions.

· Hook up t he m achine t o the electrical power m ains.

Proceed wit h accurat ely washing out all the m achine wat er pi-

pes.

Formachinecleaningoperationspleaserefertothespecicin-

st ruction paragraphs provided in sect ions 7 and 8 herein.

I f t h e m a ch in e h a s n ot b e en d isp en si ng f or lon ge r t h a n 2 4

h ou r s, p rio r t o st a r t in g op er a t io ns pr oce e d w it h w a sh in g

ou t a ll t h e in t e r na l co m p on en t s b y r e pe a t in g a ll t h e op er a -

t io ns list e d a bov e .

11

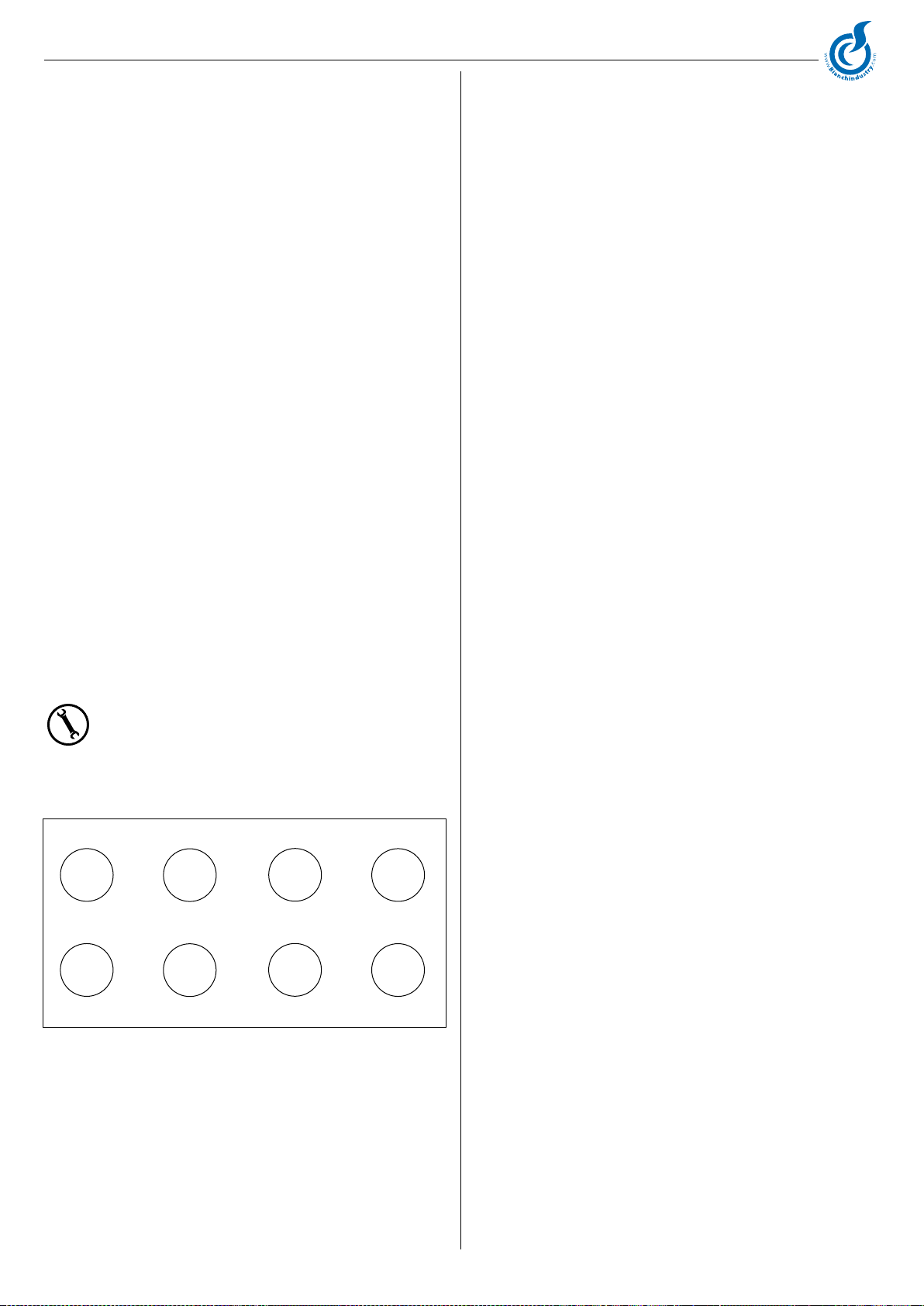

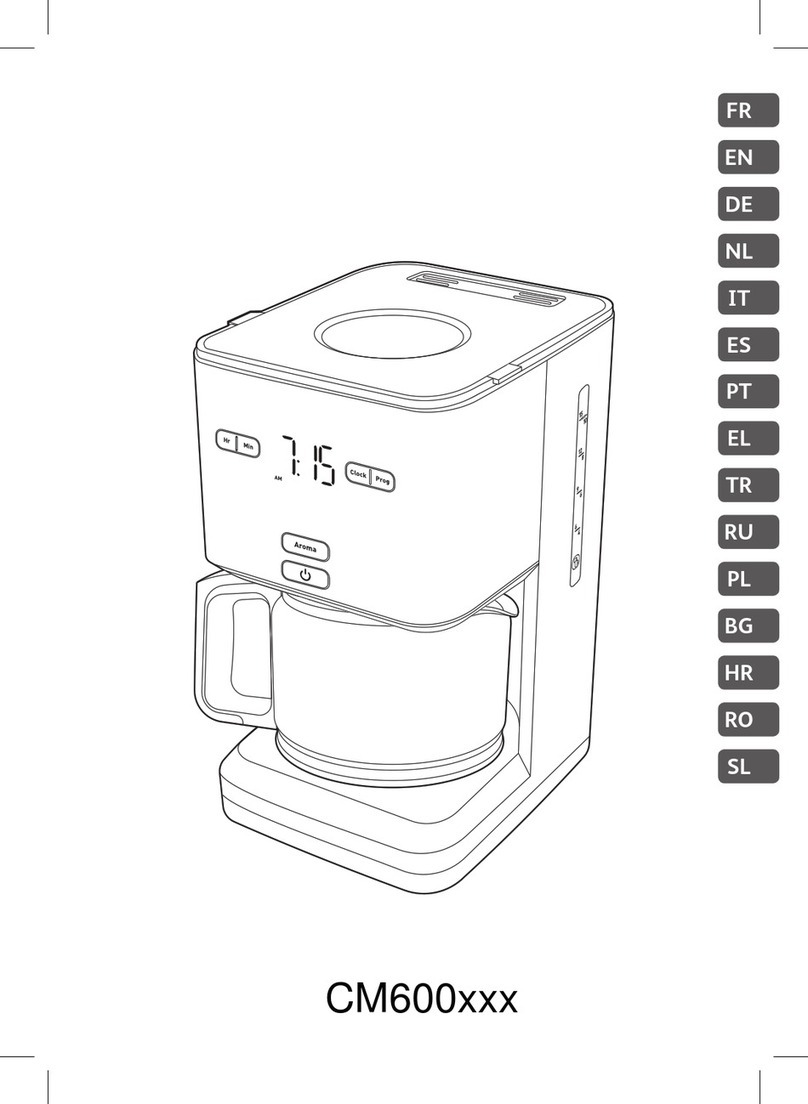

Fig. 6 .1

6 . COM M I SSI ON I N G

6 .1 Ma chine cont rol com m a nds a nd de vice s

1. St eam dispensin g t ur n- k nob

2. Boiler pressure gauge

3. Pushbut ton cont r ol panel

4. Decaffeinat ed coffee com part m ent

5. Milk dispenser nozzle

6. St eam dispenser nozzle

7. Coffee gr ounds t ray

8. Cup support grid

9. Coffee dispenser unit

10. Coffee bean container

11 . Wat er disp ensin g t ur n- k nob

12. General sw it ch

13. Wat er dispenser pipe

14. Display

Fu nct ion s:

The boiler pressure gauge ( 2) wit h a 0 to 2.5 bar scale, displays

the boiler pr essure level :

· When the indicat or is in the interval bet ween 0 and 0.8 bar

i.e. w it h t he blue back ground, t he m achine is in it s heat ing up

st age and t her efore coffee dispensing is not recom m ended.

· The int erval com prised bet ween 0.8 and 1.6 bar indicat es that

the pressure and t he tem perat ure int ernally to t he boiler are

at their ideal levels for coffee pr eparat ion.

I n t h e e v en t t ha t t h e p r essu r e in dica t e d by t h e p re ssu re

ga u ge ( 2 ) g oe s u p t o o ve r 1 .6 b ar , sw it ch t h e m a ch in e o ff

im m e dia t e ly a n d con t a ct t h e sa le s se r vice n e t w or k .

6 .2 Avvio m a cchin a

· Aft er having run anot her exam inat ion of t he elect ric and hy drau -

lic system connect ions, open the hydraulic syst em inlet t ap.

· Press the general swit ch (12) and wait unt il t he electronic power

pack that t he m achine is equipped with, execut es t he necessary

cont r ol runs and act ivates the pum p and elect ro valve for boiler

ll-up.

I f t h e bo ile r is a lr e a dy a t f ull le ve l, t he a ut om a t ic le v el co n-

t r ol w ill p r ev e nt t he pu m p f ro m st a r t in g u p a g ain .

12

1234

5678

6 .3 H ow t o h ea t u p a d r in k

· Plun ge t h e st eam dispen ser n ozzle ( 6 ) dir ect ly in to t he liq uid

that r equires heat ing.

· Open t he tap ( 1) gradually t o enable t he st eam t o exit t he

spout . This will enable t he st eam t o gradually heat t he liquid

up t o t he required t em perat ure.

· Once t he t em perat ur e has been r eached, close t he st eam t ap

( 1) .

Once done, im m ediately w ipe off the st eam dispenser nozzle

u sin g a cl ea n , dr y clot h .

W a r n in g: t h e n oz zle w ill b e v e ry h ot . T o a void sk in b ur n

h az a r ds, a v oid t ou ch in g it d ir e ct ly w h il st cle a n in g.

6 .4 H ow t o m a k e t e a s a nd infu sion s

· Open t he t ap ( 11) gradually t o allow for wat er to be dispensed

unt il t he r equired dose is reached. Then, add in t he requir ed

drink pr oduct.

7 .0 USE

7 .1 OPERATI ON

PUSH BU TTON PAN EL

The pushbut t ons provided are m eant for:

Pushbut ton 1St rong coffee

Pushbut ton 2St andard espresso coffee

Pushbutton 3“American coffee” (espresso plus a shot of water)

Pushbut ton 4Decaffeinat ed

Pushbut ton 52 st rong coffees

Pushbut ton 62 st andard espresso coffees

Pushbut ton 7Milk

Pushbut ton 8St op

7 .2 DI SPLAY MESSAGES

1 . BLOCKI N G ALARM S

Alarm

Out of order When t his m essage com es up on display it is

possible to resort to:

Pushbut t on 7 t o access t he m aint enance m ode

( by keepin g it pr essed in f or 4 sec.)

Pushbut t on 8 t o access t he pr ogram m ing

m ode ( by k eepin g it pr essed in for 4 sec. )

E00 Eeprom error

When t his m essage com es up on display it is

possible to resort to:

Pushbut t on 7 t o access t he m aint enance m ode

( by keepin g it pr essed in f or 4 sec.)

Pushbut t on 8 t o access t he pr ogram m ing

m ode ( by keepin g it pr essed in f or 4 sec.)

E01 Com m unic.

When t his m essage com es up on display it is

possible to resort to:

Pushbut t on 7 t o access t he m aint enance m ode

( by keepin g it pr essed in f or 4 sec.)

Pushbut t on 8 t o access t he pr ogram m ing

m ode ( by keepin g it pr essed in f or 4 sec.)

E03 Cong.

When t his m essage com es up on display it is

possible to resort to:

Pushbut t on 7 t o access t he m aint enance m ode

( by keepin g it pr essed in f or 4 sec.)

Pushbut t on 8 t o access t he pr ogram m ing

m ode ( by k eepin g it pr essed in for 4 sec. )

2 . RESET

Diagnosis

Reset Upon m achine start- up a m achine reset cycle is

run and the reset m essage stays on display until

cy cle- end.

3 . W ARM - UP

Please wait

War m - u p This message is displayed after the reset cycle if

the pressure swit ch input is found t o be open.

13

1234

5678

4 . W ASH I N G

Washing The above m essage is displayed once t he

washing procedure is started up and st ays on

display unt il the end of the washing operations.

For further details refer to the washing

m anagem ent paragraph under t he operat ion

sect ion.

5 . D I SPEN SI N G

Please wait

Dispensing This m essage is displayed dur ing t he drink

dispensing cycle.

6 . READ Y

Ready Ready for a select ion.

7 . N ON - BLOCKI N G ALARM S

Alarm s that are not stor ed

E02 Em pt y w at er t ank

When t his m essage com es up on display it is

possible to resort to:

Pushbut t on 7 t o access t he m aint enance m ode

( by keepin g it pr essed in f or 4 sec.)

Pushbut t on 8 t o access t he pr ogram m ing

m ode ( b y k eeping it pr essed in for 4 sec. )

E20 Pressure swit ch

When t his m essage com es up on display it is

possible to resort to:

Pushbut t on 7 t o access t he m aint enance m ode

( by keepin g it pr essed in f or 4 sec.)

Pushbut t on 8 t o access t he pr ogram m ing

m ode( by k eeping it pr essed in f or 4 sec. )

7 .3 PROGRAM M I N G

I TEM S TH AT CAN BE ACCESSED FROM TH E D I SPEN SER

The pr ogram m ing m ode is accessed by keeping pushbu tt on 8

pressed in for 4 seconds.

The pushbutt ons provided are m eant for:

Pushbut ton 1I ncrem ent

Pushbut ton 2Cur sor

Pushbut ton 3 -

Pushbut ton 4-

Pushbut ton 5Decr em ent

Pushbut ton 6Ent er

Pushbut ton 7-

Pushbut ton 8Esc

All values in t he display m essages m ust be considered as t he

m achine default values.

M EN U 0 ( M EN U SELECT I ON )

Doses m enu select ion

The sub m enus available for select ion are as follows:

1. Doses ( “ Doses ” )

2. Sales ( “ Sales ” )

3. Tem perat ure ( “ Tem perature ” )

4. Opt ion s ( “ Opt ion s ” )

5. Tim ing and thresholds (“ Tim ing and thresholds ”)

6. Clock ( “ Clock ” )

Visible only if t he clock chip is provided.

7. Pr even t iv e act ion ( “ Pr ev. Act ion ” )

M EN U 1 ( D OSES)

St r ong coffee doses

Drink select ion for relat ive dose quant it y program m ing.

1. St r on g coffee ( “ St r on g cof fee” )

2. Two st rong coffees ( “ 2 st rong coffees ” )

3. St andar d espr esso coffee ( “ St an dar d esp. cof fee” )

4. Two standard espresso coffees (“2 standard espr. coffees”)

5. Milk ( “ Milk ” )

6. “Am er ican cof fee” ( “ Am er ican cof fee” )

M EN U 1 . 1 ( STRON G COFFEE)

Coffee selec. S1

- - - cc Sets water dose for strong coffee, 14 to 100 cc.

S1xed.(*)

M EN U 1 . 2 ( TW O STRON G COFFEES)

Coffee selec. S2

- - - cc Set s wat er dose for each one of t he st rong

coffees, 14 t o 100 cc.

S2xed.(*)

M EN U 1 . 3 ( STAN D ARD ESPRESSO COFFEE)

Coffee selec. S3

- - - cc Set s wat er dose for standard espresso coffee,

14 t o 100 cc.

S3xed.(*)

M EN U 1 . 4 ( t w o ST AN D ARD ESPRESSO CO FFEES)

Coffee selec. S4

- - - cc Sets water dose for each one of the two standard

espr esso coffees, 14 t o 100 cc.

S4xed.(*)

M EN U 1 . 5 ( M I LK)

Milk A S5

- - .- s Setsthecappuccinoelectrovalverstphase

opening t im e, 00.0 to 99.9 sec.

S5xed.

Milk B S5

- - .- s Sets the cappuccino electro valve’s second phase

openingtime,00.0to99.9sec.S5xed.

M EN U 1 . 6 ( “ AM ERI CAN COFFEE”)

Coffee selec. S6

- - - cc Set s wat er dose for " Am er ican coffee", from 14

to 100 cc.

S6xed.(*)

Add. wat er S6

- - .- s Sets additional water dose for “American coffee”,

from 00.0 t o 99.9 cc.

S6xed.

Water rst S6

- - Enables dispensing of addit ional wat er before

the coffee dose, No or Yes.

S6xed.

14

M EN U 2 ( SALES)

Unreset t .t otal select ions

- Displays the unreset t able t ot al selections

count er. The m axim um value is 1677725 1.

Tot al select ions

- Displays the reset t able t otal select ions counter.

The m axim um value is 1677 725 1.

St r ong coff.select ions

- Displays t he resettable, strong coffee selections

count er. The m axim um value is 65535.

2St rong coff.select ions

- Displays the reset table, two st r ong coffees

select ions count er.

The m axim um value is 6553 5.

St andar d espr.coff.select ions

- Displays the resettable, standard espresso coffee

select ions count er. The m axim um value is

65535.

2St andard espr.coff.select ions

- Displays t he reset t able, two st andard espresso

coffees select ions count er.

The m axim um value is 6553 5.

Milk select ions

- Displays t he reset table, m ilk select ions count er.

The m axim um value is 6553 5.

Am er . Coffee select ions

- Disp lay s t he r eset t able, “Am erican coffee”

select ions count er.

The m axim um value is 6553 5.

Dekaf. coff. select ions

- Displays the reset table, decaffeinat ed coffee

select ions count er.

The m axim um value is 6553 5.

St andar d deka.coff.select ions

- Displays the reset t able, standard decaffeinat ed

coffee select ions count er.

The m axim um value is 6553 5.

Am er ican dek a.coff.select ions

- Displays the resettable, American decaffeinated

coffee select ions count er.

The m axim um value is 6553 5.

Code

- - - - Password ent ry code is r equest ed t o access

the audit dat a cancellat ion procedure.

The m axim um value is 9999 .

Replace code?

- - Asksforconrmationofpossiblereplacement

of t he password ent ry code required t o access

the audit dat a cancellat ion procedure.

The entry dat a allow ed here is: NO or YES.

Code

- - - - Set a new password entry code for access to the

audit dat a cancellat ion procedure.

The entry dat a allow ed here is: 0 t o 9999

Visible only if YES is set under t he “ Replace

Code”dataeld.

Set t o zero?

- - Conrmonlyiftheauditdatamustberesetto

zero.

The entry dat a allow ed here is: NO or YES.

The count er s under go an increm ent al updat e at t he end of t he

dispensing cycle.

The audit dat a ar e st or ed bot h on t he ( r ed) Audit k ey and on t he

VSPS. A .txt format le is generated via the relative windows

program s. I t is for m at t ed as follow s:

AUDI T File:

Machine num ber 000000

Lease num ber 00000

Second t o last discharge 00/ 00/ 00 00: 00

Last discharge 00/ 00/ 00 00: 00

Descr ipt ion Unresettable Resettable

Tot al select ions 0 0

St r ong coffee select ions 0 0

Two st rong coffee select ions 0 0

St andar d espr esso coffee select ions 0 0

Two st andard espresso coffee selections 0 0

Milk select ions 0 0

“Am erican coffee” select ions 0 0

Decaffeinat ed st rong coffee select ions 0 0

Decaffeinat ed st andard espresso 0 0

coffee selections

Decaffeinat ed “Am erican coffee” select ions 0 0

Thesecondtolastdischargedataeldissetonlyiftheclockchip

was im plem ent ed for t he last discharge.

Thelastdischargedataeldissetonlyiftheclockchipispro-

vided.

M EN U 3 ( OPT I ON S)

Language

English Set s V.M. language. I t is possible to set eit her

[ I talian, French, English, Spanish, Germ an,

Port uguese, ] . The m essage displayed in

line2ismessageno.0inthemessagele.

Coffe disp. t im e

- - .- s Set s t he r eference tim e for espresso coffee

dispensing.

The ent ry data allowed here is: 0.0 to 35.0 s.

I ndependent pum p

- - Enables independent pum p m anagem ent .

The ent r y dat a allowed here is: NO or YES.

Machine num ber

- - - - - - - Set s t he m achine serial num ber

The entry dat a allow ed here is: 0 t o 9999999

Lease num ber

- - - - - Set s t he V.M. lease num ber

The ent r y dat a allowed here is: 0÷ 65535.

Preset Washing

- - Enables m achine cleaning cycle tim e sett ings,

based on t he t im e ranges pr ogram m ed in t he

m enu Clock Wash cy cles ( 6 .2) .

The ent r y dat a allowed here is: NO or YES.

Wash cycle

- - Enables m achine wash cycle.

The ent r y dat a allowed here is: NO or YES.

Probe Sensitivit y

- - - Set s level t hreshold probe sensitivit y.

The entry dat a allow ed here is: 20 t o 200

( where 20 is m ax sens. - 200 is m in. sens.)

Default dat a?

- - Conrmwhetherdefaultdataistobereinstated.

Thedefaultdataisthedataspeciedinthis

m anual. Fur therm or e, t he r eset table sales

dat a is set back t o zero.

The ent r y dat a allowed here is: NO or YES.

M EN U 4 ( TI M I N G AN D TH RESH OLD S)

Grinder threshold

- - .- Gr in der cur r ent r ead - of f t hr eshold.

The entry dat a allow ed here is: 05.0 t o 18.0

Grinder tim eout

- - .- s Set s grinder t im eout .

The ent ry data allowed here is: 0.0 to 25.5 s.

Group t im eout

- - .- s Set s group t im eout .

The ent ry data allowed here is: 0.0 to 10.0 s.

Group speed

- - Set s gr oup speed expressed in percent age.

The entry dat a allow ed here is: 20 t o 100

Esp. pum p t im eout

- - - s Set s t he espresso pum p t im eout .

The ent ry data allowed here is: 0 t o 250 s.

15

Wat er load t im eout

- - - s Set s t he wat er load m anagem ent t im eout.

The entry dat a allow ed here is: 0 t o 250 s.

Boiler load t im eout

- - - s Set s t he heat er load m anagem ent t im eout .

The entry dat a allow ed here is: 0 t o 250 s.

I nd. pum p t im eout

- - s Set s t he independent pum p t im eout .

The entry dat a allow ed here is: 0 t o 60 s.

Cleaning cy cle t im e

- - .- s Set s t he cleaning cycle t im e.

The entry dat a allow ed here is: 0.0 t o 25.5 s.

M EN U 5 ( CLOCK)

Clock

Set s hour s/ m inut es

The sub m enus available for select ion are as follows:

1. Set data ( “ Set dat a ” )

2. Set hour s and m inut es ( “ Set hrs/ m inut es ” )

3. Wash cy cles ( “ Wash ing ” )

4. Swit ch off ( “ Switch off ” )

M EN U 5 . 1 ( SET D ATE)

Set date

- - / - - / - - Changes t he clock chip dat e.

The for m at provided is: dd/ m m / yy .

The days go from 1 to 31, t he m ont hs from 1

to 12 and t he years from 0 t o 99.

M EN U 5 . 2 ( SET H OU RS AN D M I N U TES)

Set s hour s/ m inut es

- - : - - Changes t he clock chip t im e.

The for m at provided is: hour s: m inut es.

The hours go from 0 t o 23 and the m inutes

go from 0 t o 59.

M EN U 5 . 3 ( CLEAN I N G)

Cleaning “ x ”

- - : - - Sets the “ x ” cleaning cycle tim e.

Wher e “ x ” = 1 or 2 .

The for m at provided is: hour s: m inut es.

The hours go from 0 t o 23 and the m inutes go

from 0 t o 59.

M EN U 5 . 4 ( SW I TCH OFF)

St op 1

- - : - - Set s machine Stop 1 or Stop 2.

The for m at provided is: hour s: m inut es.

The hours go from 0 t o 23 and the m inutes go

from 0 t o 59.

St art 1

- - : - - Set s sw it ch- on t im e “ x ”. Wher e × = 1 or 2

The for m at provided is: hour s: m inut es.

The hours go from 0 t o 23 and the m inutes go

from 0 t o 59.

St op 2

- - : - - Sets m achine St op 2 × . Where “× ” = 1 or 2.

The for m at provided is: hour s: m inut es.

The hours go from 0 t o 23 and the m inutes go

from 0 t o 59.

St art 2

- - : - - Sets the t im e for swit ch- on “ × ”.

Wher e “ × ” = 1 or 2

The for m at provided is: hour s: m inut es.

The hours go from 0 t o 23 and the m inutes go

from 0 t o 59.

M EN U 6 ( PREV EN TI V E ACTI ON )

Coffee grounds

- - Displays coffee grounds decounter value.

Wat er t reat m ent unit

- - - - - - - Set s t he w at er t reat m ent unit decount er value.

The entry dat a allow ed here is: 0 t o 9999999

Coffee grinder

------- Set s the coffee grinder decounter value.

The entry dat a allow ed here is: 0 t o 9999999

Coffee lters

- - - - - - - Setsthecoffeelterdecountervalue.

The entry dat a allow ed here is: 0 t o 9999999

Elect r o valves

- - - - - - - Set s t he elect ro valve decounter value.

The entry dat a allow ed here is: 0 t o 9999999

Seals

- - - - - - - Setstheltersealsdecountervalue.

The entry dat a allow ed here is: 0 t o 9999999

Boiler

- - - - - - - Set s t he boiler decounter value.

The entry dat a allow ed here is: 0 t o 9999999

HACCP

- - - - - - - Set s t he HACCP sanit isat ion decount er value.

The entry dat a allow ed here is: 0 t o 9999999

Coffee gr ounds r echar ge

- - - - - - - Set s t he coffee grounds recharge lim it value.

The entry dat a allow ed here is: 0 t o 50

16

8 .0 SOFTW ARE I N STRUCTI ON S

8 .1 FUN CTI ON M AN AGEM EN T

M AN AGEM EN T O F RESET AT M ACH I N E SW I TCH - O N

Upon m ach in e sw it ch- on, t her e is a sy st em r eset t h at consist s in

activat ing t he group so t hat it goes into it s rest posit ion.

DATA DI SPLAY

Du rin g t he sy st em r eset at m achin e sw it ch- on, t he follow ing m es-

sages com e up on display:

Diagnosis

Reset

M AN AGEM EN T O F M ACH I N E ST AN D - BYS

DATA DI SPLAY

Dur ing t he st andard m achine st and- by m ode, t he following m es-

sages com e up on display:

Ready

AI R BREAK LO AD M AN AGEM EN T

I nputs and output s involved:

I n p ut s Ou t pu t s

Tray m icro: I NPUT2: 5 Wat er entry EV: OUT3: 1

Wat er em pt y: I NPUT2: 4

Managem ent is execut ed if the independent pum p act ivat ion m ode

t hat can be pr ogram m ed w it h t he opt ions m enu, is set to NO.

Reading off t he tray m icro input at a frequency equal t o t he read-

off t im e det er m ines whet her t he w at er ent ry elect ro valve is on

or off.

Dur ing w at er ent ry elect ro valve act ivat ion, t he w at er load t im eout

is checked.

Once t he wat er load t im eout has expired, t he wat er ent ry elect ro

valve is t ur ned off even if t he t ray m icr o input st ill appears t o be

open and t he wat er load at tem pt t im eout am ount ing to 15 m inut es

has been init ialised.

The m anagem ent m ode also m anages t he wat er em pt y alarm

( E02 wat er em pt y ) t hat goes off w hen ev er t he wat er em pt y in put

st ays open cont inuously for t he overall wat er em pt y t im eout . Said

alar m is an aut o- r eset alar m , t her efor e if t he w at er em p ty inpu t is

det ect ed as being cont inuously closed for the ov erall wat er em pt y

t im eout , t he alar m is r eset . Anot her way in which t o r eset t he alar m

is to use t he reset funct ion in t he m aintenance m ode.

Param et ers:

1. Read- off t im e: t em porary value 2.0 s

2. Wat er load t im eout : t o be pr ogram m ed in t he t im ing and thre-

sholds m enu

3.Wateremptytimeout:xedvalue2.0s

4.Waterloadattempttimeout:xedvalue15minutes

I N D EP EN DEN T PU M P M AN AGEM EN T

I nputs and output s involved:

I n p ut s Ou t pu t s

Tray m icro: I NPUT2: 5 Wat er entry EV: OUT3: 1

Wat er em pt y: I NPUT2: 4

Managem ent is execut ed if the independent pum p act ivat ion m ode

t hat can be pr ogram m ed w it h t he opt ions m enu, is set to YES.

Reading off t he tray m icro input at a frequency equal t o t he read-

off t im e det er m ines whet her t he wat er pum p is on or off.

Dur in g ind epen den t p um p act iv at ion , t h e in dep endent pu m p

t im eout is checked. Upon said tim eout expiry, the independent

pum p is swit ched off.

The m anagem ent m ode also m anages t he wat er em pt y alarm ( E02

wat er em pty) t hat goes off w henever t he w at er em pt y input st ay s

open cont inuously for t he overall wat er t im eout . Said alarm is an

aut o- reset alar m , t herefor e if t he wat er em pt y input is det ect ed

as being cont inuously closed for the overall wat er em pt y t im eout ,

the alarm is reset . Anot her way in which to reset t he alarm is to

use the reset funct ion in t he m aintenance m ode.

Param et ers:

5. Read- off t im e: t em porar y value 2. 0 s

6. I ndependent pum p t im eout : t o be pr ogram m ed in t he t im ing

and t hr esholds m enu

7.Wateremptytimeout:xedvalue2.0s

8.Waterloadattempttimeout:xedvalue15minutes

CLEAN I N G CYCLE M AN AGEM EN T

I nputs and output s involved:

I n p ut s Ou t pu t s

Cappuccino m aking unit EV: OUT3: 3

“Am erican coffee” EV: OUT3: 4

Group m ot or r educer : OUT3: 6

PROCEDURE ACTI VATI ON

The m achine cleaning pr ocedure can be act ivat ed in t he following

ways:

●Ifthewashcycleisenabled(OptionsMenu)theprocedureis

act ivat ed 30 m inut es subsequent to m achine st ar t and sub-

sequent ly ther eaft er at 180 m inutes from the end of t he last

dispensing or wash cycle.

●Ifthetime-setwashcycleisenabled(OptionsMenu)thepro-

ced ur e is act ivat ed at t he set t im e ( Cleaning Menu) pr ov ided

t hat ther e are no dispensing or m aint enance operat ions unde-

rway.

●Iftheappropriatecontrolkeyispressedduringmaintenance

operat ions.

PROCEDURE

The cappuccino m aking unit elect ro valv e and t he “Am erican cof-

fee” elect ro valve are act ivat ed in sequence for a t im e t hat is set

and ent er ed under t he “ wash cy cle t im e” param et er in t he Tim ing

and t hr esholds m enu.

Ther eaft er, t he group m ot or reducer is act ivat ed for one com plet e

rot ation.

TROU BLE SH OOTI N G

●Thegrouptimeoutexpire(Timingandthresholdsmenu),the

“ E61 Gr oup” sy st em - st or ed sig nal is gener at ed an d t he w ash

cycle is brought to an end.

BOI LER LOAD M AN AGEM EN T

I nputs and output s involved:

I n p ut s Ou t pu t s

Thr eshold pr obe: I NPUT1: 1 Boiler load pum p OUT2: 2

Managem ent is not t aken int o considerat ion if t he wat er em pt y

alarm is present .

Provided above condit ion is not present , t he boiler load pum p swill

be m anaged by t he level t hreshold pr obe. Reading off t he input

w it h a fr equen cy equ al t o t he r ead- of f t im e, det er m in es wh et her

the boiler load pum p is on or off.

The m anagem ent m ode also m anages the boiler load alarm ( E21

Boiler load) that goes off w henever t he t hreshold probe input

st ays open cont inuously for t he overall boiler load t im eout . This

is a st ored alar m , t herefor e to reset it , it is necessary to use the

reset funct ion in t he m aint enance m ode.

Param et ers:

9. Read- of f t im e: t em porar y valu e 2. 0 s

10. Boiler load t im eout : t o be pr ogram m ed in t he t im ing and

t hr esholds m enu

RESI STAN CE U N I T M AN AGEM EN T

I nputs and output s involved:

I n p ut s Ou t pu t s

Pressur e sw it ch: I NPUT2: 9 Resist ance: OUT1: 1

Threshold pr obe: I NPUT1: 1

17

Managem ent is not t aken int o considerat ion if either the boiler load

alar m ( E2 1) or t he pr essu re sw it ch alar m ( E20 ) is pr esent .

The resist ance is swit ched off independently to the pressure switch

and t he p ressu re sw it ch t im eou t is r e- in it ialised if t h e lev el t hr e-

shold probe st ays low for t he overall probe t im e.

This param et er m ust be pr ogram m able for t est ing. Once t he t im e

hasbeenassessedbytesting,itwillstayxed.Thevaluerange

m ust go from 0 t o 255 s.

Provided above condit ion is not present , t he resist ance will be

m anaged by t he pr essure sw it ch, r eading off t he pr essur e sw it ch

input at a fr equency equal t o t he read- off t im e det erm ines w het her

t he resist ance is on or off. The m anagem ent m ode also m anages

t he pr essur e sw it ch alar m ( E20 pr essu re sw it ch ) t h at goes of f

whenever t he pr essure swit ch input st ay s open continuously for

t he overall pr essure sw it ch t im eout . The pr essure sw it ch t im eout

count er st art s from w hen t he resist ance is swit ched on. This is a

st or ed alarm , t herefor e t o reset it, it is necessary t o use the reset

funct ion in t he m aint enance m ode.

Param et ers:

11. Probe t im e: t em porar y value 2.0 s

12. Read- off t im e: t em porary value 2.0 s

13.Pressureswitchtimeout:xedvalue15minutes

COFFEE ESPRESSO M AN AGEM EN T

Th is fu nct ion w ill w or k as f ollow s: d ur in g st and ar d d ispenser

oper at ion s, w hen ev er t he r esist ance ou t pu t ( OUT1 : 1) st ay s on

cont in uou sly f or 5 and a half m in ut es ( i. e. 33 0 sec) , t h e disp en ser

disable funct ion will kick in and last for 40 m inutes.

DATA DI SPLAY

Dur ing this phase, t he follow ing m essages will com e up on di-

splay:

Please wait

War m - u p

DECAFFEI N ATED COFFEE PRE- SELECTI ON

The decaf coffee pre- selection option is applicable to all st rong cof-

fee, st andard espresso coffee and “Am er ican coffee” select ions.

Two opt ions are available for decaf coffees:

– Open unit door, insert t he decaf product , close the unit door.

Aft er said operat ion , “ Decaf feinat ed” w ill com e up on display

and only t hen will it be possible t o press keys 1, 2, 3.

I f not changed, t he Decaffeinat ed m ode will st ay on display

innitely.Toexit thedecaffeinatedmode, the operatormust

press t he St op pushbutt on, or press the decaffeinat ed push-

but t on once again.

The m achine Ready m essage will com e up on display. Pr essing

any one of t he select ion key s (1, 2, 3, 5, 6) , t he group will,

prior t o dispensing t he drink , run a com plet e cy cle. I f for any

reason aft er t he above procedure ( i.e. opening and t hen closing

the dispenser door) the operator were t o pr ess the stop key,

t he “ Decaff einat ed ” cof fee pr e- select ion opt ion w ill fail and t h e

group will run a com plet e cycle.

Should t he door not be closed back up again or should it for

any reason st ay open, t he following m essages will com e up on

display :

Close the door

Decaffeinat ed

– Pr ess t h e d ecaf k ey ( Decaf feinat ed ) , open u nit door, inser t t h e

decaf product , close t he unit door. Upon closing t he door, it is

expect ed that one of t he select ion key s allow ed, is pressed.

TheDecaffeinatedmodemessagewillstayondisplayinnitely.

Said m ode is r eset back t o st andard only if the decaffeinat ed

pu shb ut t on or t h e St op pu sh bu t t on is pr essed on ce again.

Once t he m achine decaf m ode select ion has been rem oved, t he

m achine Ready m essage will com e up on display. Pr essing any

one of the select ion keys ( 1, 2, 3, 5, 6) , the group will, prior t o

dispensing t he dr ink, run a com plet e cycle.

The above procedure can be int er rupt ed in t he following ways:

●Pressthedecaffeinatedmodepre-selectionkey(Key4)asecond

t im e ( if t he g rou p does not det ect door open in g an d closin g t he

group will not run a com plet e cycle at subsequent select ion)

●Pressthedispensingstopkey(Key8).(ifthegroupdoesnot

det ect door opening and closing, t he group will not run a com -

plet e cycle at subsequent selection)

●Pressanon-allowedselectionkey.Inthiscase,thedecafpre-

select ion funct ion will not be reset back to st andar d. The non-

consent ed keys will not have any effect .

DATA DI SPLAY

Phase A

Ready

Decaffeinat ed

STRON G AN D ST AN D ARD ESPRESSO COFFEE ( D ECAF) D I -

SPEN SI N G

I f the select ion is not for a decaf coffee, pressing key 1 or 2 will

activate the grinder until the coffee dose unit is lled. Subse-

quent ly, a 1 second w ait ing int erval m ust go by, whereupon t he

coffee release function is act ivat ed for 1 second. Anot her 1 second

int erval m ust go by prior to act ivat ing t he gr oup, unt il t he group

m icro input swit ches over.

Once t he gr oup has reached it s dispensing posit ion, the overall

hot dr ink select ion m anagem ent is act ivat ed. Once m anagem ent

functionsarecomplete,a1secondxedtimemustgobyforgroup

act ivat ion, unt il t he group m icro input sw it ches over.

Once the group has gone back int o its rest posit ion, the dispensing

cycle is over.

TROU BLE SH OOTI N G

●The grinder timeout expires (Timing and thresholds menu),

t he “ E60 Gr in der ” sy st em - st or ed sig nal is g en erat ed an d t he

dispensing cycle is br ought t o an end.

●The coffee doser unit input has not reverted subsequent to

doser m agnet act ivat ion. The “ E63 Doser ” sy st em - st or ed sign al

is generat ed and the dispensing cycle is brought t o an end.

●Thegrouptimeoutexpires(Timingandthresholdsmenu),the

“ E61 Group” syst em - stor ed signal is generat ed and the dispen-

sing cycle is brought t o an end.

●The express pump timeout expires (Timing and thresholds

m enu) , t he dose of wat er t hat is dispensed is checked and if it

is less or eq ual t o 1 0 cc, t he “ E62 Esp. Pum p ” sy st em - st or ed

signal is generat ed and the dispensing cycle is br ought t o an

end.

This err or is m anaged in t he overall hot dr ink select ion m anage-

m ent m ode.

DATA DI SPLAY

Dur ing t he dispensing cycle, t he following m essages com e up on

display :

Please wait

Dispensing

D OU BLE STRON G AN D STAN D ARD ESPRESSO COFFEE D I -

SPEN SI N G

Pressing key 5 or 6 will act ivate t he gr inder unt il the coffee doser

unitislledup.

Subsequent ly, a 1 second wait ing int er val m ust go by, w her eupon

the coffee release function is act ivat ed for 1 second. Anot her 1

second int erval m ust go by pr ior t o act ivat ing t he group, unt il t he

group m icro input swit ches over. One second after group activation,

t he grinder will st art up a second t im e unt il t he coffee doser unit

haslledup.Oncethegrouphasreacheditsdispensingposition,

t he ov erall hot dr ink select ion m anagem ent is act ivat ed. Once m a-

nagementfunctionsarecomplete,a1secondxedtimemustgoby

for gr oup act ivat ion, unt il t he group m icr o input swit ches over. Once

the gr oup has reached its rest posit ion, a 1 second wait ing interval

m ust go by, w her eupon t he coffee release funct ion is act ivat ed for

1 second. Anot her 1 second interval m ust go by prior t o act ivat ing

t he group, unt il t he gr oup m icro input swit ches over.

Once t he gr oup has reached it s dispensing posit ion, the overall

hot dr ink select ion m anagem ent is act ivat ed. Once m anagem ent

functionsarecomplete,a1secondxedtimemustgobyforgroup

act ivat ion, unt il t he group m icro input sw it ches over.

Once the group has gone back int o its rest posit ion, the dispensing

cycle is over.

18

Fig. 8 .1

TRO UBLE SH OOTI N G

●The grinder timeout expires (Timing and thresholds menu),

t he “ E60 Gr in der ” sy st em - st or ed sig nal is g en erat ed an d t he

dispensing cycle is br ought t o an end.

●The coffee doser unit input has not reverted subsequent to

doser m agnet act ivat ion. The “ E63 Doser ” sy st em - st or ed sign al

is generat ed and the dispensing cycle is brought t o an end.

●Thegrouptimeoutexpire(Timingandthresholdsmenu),the

“ E61 Group” syst em - stor ed signal is generat ed and the dispen-

sing cycle is brought t o an end.

● Theexpresspumptimeoutexpires(Timingandthresholdsmenu),

the dose of water that is dispensed is checked and if it is less or

equal to 10 cc, t he “ E62 Esp. Pum p” syst em-stored signal is gene-

rated and the dispensing cycle is brought to an end. This error is

m anaged in t he overall hot drink select ion m anagem ent m ode.

DATA DI SPLAY

Dur ing t he dispensing cycle, t he following m essages com e up on

display :

Please wait

Dispensing

MI LK D I SPEN SI N G

Pressing key 7 w ill act ivat e t he m ilk elect ro valve out put for t im e

T1 as pr ogram m ed in t he t im ing and doses m enu.

I f during t his t im e range key 7 is pressed once again, t im e T2 will

be added ont o tim e T1.

The dispensing of t his dr ink can be sim ult aneous t o t he ot her

select ions.

Pressing t he STOP key during t he dispensing cycle will provide for

im m ediat e dispensing cy cle int errupt ion.

DATA DI SPLAY

Dur ing t he dispensing cycle, t he following m essages com e up on

display :

Please wait

Dispensing

( DECAF) “AM ERI CAN COFFEE” DI SPEN SI N G. ADDI TI ON AL

W ATER BEFORE COFFEE D OSE = N O

I f t he select ion is not for a decaf coffee, pr essing key 3 will act ivat e

thegrinderuntilthecoffeedoseunitislled.Subsequently,a1

second wait ing int erval m ust go by, whereupon t he coffee release

funct ion is activat ed for 1 second. Anot her 1 second interval m ust

go by pr ior to act ivat ing t he group, unt il t he gr oup m icro input

swit ches over.

Once t he gr oup has reached it s dispensing posit ion, the overall

hot dr ink select ion m anagem ent is act ivat ed. Once m anagem ent

functions are complete, a 1 second xed time must go by for

group act ivat ion, unt il t he gr oup m icro input swit ches over and

t he “Am er ican coffee” elect ro valve out put is act ivat ed t o dispense

t he dose as pr ogram m ed.

Once t he addit ional wat er dose as pr ogram m ed by t he “Am erican

coffee” electro valve has been dispensed and t he group has gone

back into it s rest posit ion, t he dispensing cycle is over.

TROU BLE SH OOTI N G

●The grinder timeout expires (Timing and thresholds menu),

t he “ E60 Gr in der ” sy st em - st or ed sig nal is g en erat ed an d t he

dispensing cycle is br ought t o an end.

●The coffee doser unit input has not reverted subsequent to

doser m agnet act ivat ion. The “ E63 Doser ” sy st em - st or ed sign al

is generat ed and the dispensing cycle is brought t o an end.

●Thegrouptimeoutexpire(Timingandthresholdsmenu),the

“ E61 Group” syst em - stor ed signal is generat ed and the dispen-

sing cycle is brought t o an end.

●The express pump timeout expires (Timing and thresholds

m enu) , t he dose of wat er t hat is dispensed is checked and if it

is less or eq ual t o 1 0 cc, t he “ E62 Esp. Pum p ” sy st em - st or ed

signal is generat ed and the dispensing cycle is br ought t o an

end. This error is m anaged in t he overall hot dr ink select ion

m anagem ent m ode.

DATA DI SPLAY

Dur ing t he dispensing cycle, t he following m essages com e up on

display :

Please wait

Dispensing

( D ECAF) “ AM ERI CAN COFFEE “ D I SPEN SI N G. AD D I TI ON AL

W ATER BEFORE COFFEE D OSE = YES

I f t he select ion is not for a decaf coffee, pr essing key 6 will act ivat e

thegrinderuntilthecoffeedoseunitislledandthe“American

coffee” elect ro valve out put is act ivat ed.

Subsequent ly, a 1 second wait ing int er val m ust go by, w her eupon

the coffee release function is act ivat ed for 1 second. Anot her 1

second int erval m ust go by pr ior t o act ivat ing t he group, unt il t he

group m icro input sw it ches over.

Once the group has reached it s dispensing position and dispensing

of t he dose as program m ed for t he “Am er ican coffee” elect ro valve

has com e t o an end, t he overall hot dr ink select ion m anagem ent is

act ivat ed. Once m anagem ent funct ions are com plet e, a 1 second

xedtimemustgobyforgroupactivation,untilthegroupmicro

input swit ches over.

Once the group has gone back int o its rest posit ion, the dispensing

cycle is over.

TROU BLE SH OOTI N G

●The grinder timeout expires (Timing and thresholds menu),

t he “ E60 Gr in der ” sy st em - st or ed sig nal is g en erat ed an d t he

dispensing cycle is br ought t o an end.

●The coffee doser unit input has not reverted subsequent to

doser m agnet act ivat ion. The “ E63 Doser ” sy st em - st or ed sign al

is generat ed and the dispensing cycle is brought t o an end.

●Thegrouptimeoutexpire(Timingandthresholdsmenu),the

“ E61 Group” syst em - stor ed signal is generat ed and the dispen-

sing cycle is brought t o an end.

The ex press pum p t im eout ex pir es ( Tim ing and t hr esholds m enu) ,

the dose of wat er that is dispensed is checked and if it is less

or equal t o 10 cc, t he “ E62 Esp. Pum p” system -stor ed signal is

generat ed and t he dispensing cycle is brought t o an end. This

err or is m anaged in the overall hot dr ink select ion m anagem ent

m ode.

DATA DI SPLAY

Dur ing t he dispensing cycle, t he following m essages com e up on

display :

Please wait

Dispensing

D I SPEN SI N G ST OP KEY M AN AGEM EN T.

I f pressed during t he dispensing cycle, the STOP key m ay have two

effect s, depending on w hether t he syst em is in phase A or phase

B. I f in phase A, t he dispensing cycle is br ought t o an end and t he

select ions counter is not increased. I f in phase B, t he dispensing

cycle is brought t o an end and t he select ions count er is not increa-

sed, t he gr oup is act ivat ed for one com plet e rot at ion.

19

Fig. 8 .2

COFFEE GRO UN D S D ECO UN TER M AN AGEM EN T

I nputs and output s involved:

I n p ut s Ou t pu t s

Coffee gr ounds door: I NPUT1: 11

Each dispensing cycle group rotat ion, decreases the count er that is

display ed in t he pr ev en tiv e act ion m enu ( 7) . When t he decoun t er

is down t o zero, the dispensing cycle underway is brought t o an

end, t hen the syst em t r iggers off the det ect ion repor t and t he

follow ing m essages w ill com e up on display :

Em pt y

Coffee grounds

whilst t he st andard m achine funct ions ar e inhibit ed by t he m a-

chine.

I f t he coffee gr ounds door m icro st ay s open cont inuously for 5

sec, t he decount er is charged back up again.

Once the decount er is char ged up and aft er t he door m icro has

been closed back up again, check once again to ensure that t he

decounter has been char ged back up again.

When the coffee gr ounds t ray is closed it can be assert ed t hat t he

coffee grounds door is at a low logic level.

M OT ORI SED GRI N D ER- D OSER UN I T M AN AGEM EN T

I nputs and output s involved:

I n p ut s Ou t pu t s

Clockw ise rot at ion: OUT3: 7

Ant iclockwise r ot at ion: OUT3: 8

This m anagem ent m ode is dev ised for the following drink s:

●Short(condensed)coffeedose(Key1)

Set t ing of t he coffee dispensing t im e, wit h a ± 3 seconds t olerance

t im e. The m ot or act ivat ion t im e for grinder- doser unit adj ust m ent

mustbe0.4secondsfornergrindingand0.9secondsforcoarser

grinding.

Thersttwocoffeeservingsstraightafterthevendingmachine

has been sw it ch ed on or aft er gr in der - doser un it adj ust m en t ope-

rat ions, m ust never be t aken int o considerat ion.

The gr in der - doser u nit ad j ust m en t oper at ion s should be don e at

the end of t he coffee dispensing cycle, whilst t he group goes back

int o its rest position.

Exam ple w it h dispensing t im e set at 18 seconds

Swit ch on t he vending m achine: set dispensing t im e is 18”. The

rsttwocoffeeservingsdispensedbythemachineandthetwo

coffee ser vings dispensed st raight aft er the adj ust m ent operat ions

cannot be t aken int o consideration.

I f in t he 3 subsequent select ions t he coffee dispensing t im e does

not r each 1 8” ( ± 3 ” if t he cof fee is less t h an 6 0 cc and ± 4 ” if t he

coffee is com prised bet ween 60 and 80 cc) , the mot or reducer w ill

be act ivat ed back up again for 0.4 sec in a clockwise direction.

I f in t he 3 subsequent select ions t he coffee dispensing t im e goes

ov er 1 8” ( ± 3 ” if t he coff ee is less t h an 60 cc and ± 4 ” if t h e cof fee

is com pr ised bet w een 6 0 an d 80 cc) , t he m ot or redu cer w ill b e

activat ed for 0.9 sec in an ant iclockwise direct ion.

The above pr ocess shall have t o be repeat ed unt il t he set t im e

is reached.

When t he coffee dispensing t im e am ount s t o 18 ” ( or at least lies

w it h in t he t oleran ce) , t h e m ot or r educer will no longer need t o

be activat ed.

The program will consist ently read- off the dispensing cycle duration

based on t he cof fee elect r o v alve open in g ( OUT3 : 2 ) and , in t h e

event t hat t he last 3 select ions are found t o be less than or m ore

t han the set dispensing t im e plus a ± 3” t olerance if t he coffee is

less than 60 cc and ± 4” t olerance if the coffee is com prised between

60and80cc,(withnergrinding)toincreasethedispensingtime

and for 0.9 sec in an anticlockwise direct ion (with coarser grinding)

so as t o decrease t he dispensing t im e.

The pr ogram m able, coffee dispensing t im e range w ill be [ 2.9 t o

35. 0 s] and can be set v ia the opt ions m enu.

Se le ct ion n o. Disp en sin gt im e Re su lt

1

2

11”

13”

Dispensed st raight after

vending m achine swit ch-

on.

Not considered.

3

4

12”

13”

Disp en sed at less t h an

t he set t im e

Themotorreducerisactivatedclockwisefor0.4sec(withner

grinding)

5

6

13”

14”

Disp ensed af ter adj u st -

m ent . Not considered.

7 15” Only one is out of tim e

lim it s. Not considered.

8 16.5” OK

9 16” OK

10 16.5” OK

11 17” OK

12 21” Only one is out of tim e

lim it s. Not considered.

13 18” OK

14 19” OK

15 20” OK

16

17

21”

22”

Tw o con secut iv e selec-

t ions out of t im e lim it s.

The m ot or redu cer is act ivat ed ant iclock wise for 0. 9 sec( w it h

coarser grinding)

18

19

22”

21”

Disp ensed af ter adj u st -

m ent . Not considered.

20 19” OK

21 19” OK

22 18.5” OK

23 19” OK

20

AU TO MATI C D RI N K- STOP M AN AGEM EN T

This m anagem ent m ode is dev ised for the following drink s:

●Short(condensed)coffeedose

I n t he event t hat t he real dispensing t im e is in excess of t he

program m ed dispensing t im e by m ore t han 6 seconds, t he drink

dispensing cycle will be int errupt ed via t he STOP function. Said

dispensin g cy cle w ill an yw ay be cou nt ed for gr in ding adj u st m ent

purposes.

FI RST- TI ME I N STALLATI ON MAN AGEM ENT

I nputs and output s involved:

I n p ut s Ou t pu t s

Flow m et er: I NPUT2: 2 Pum p: OUT2: 1

Tray m icro: I NPUT2: 5 Coffee elect r o valve: OUT3: 2

Wat er em pt y: I NPUT2: 4 Resist ance: OUT1: 1

Pressur e sw it ch: I NPUT2: 9 Boiler load pum p OUT2: 2

Threshold pr obe: I NPUT1: 1

The procedure is act ivat ed by keeping key 8 pressed in while the

m achine powers on, unt il you hear t he beep.

When the m achine powers on, t he group is reset and t he boiler

load is m anaged.

Wit h t he t ray m icro nor m ally closed, once t he boiler load and

the group r eset funct ions have ended, t he espr esso pum p and

coffee electro valve outputs are activated to dispense a xed

dose am ou nt in g t o 2 00 cc ( VM) . I n t his phase it is n ecessar y t o

check t he espr esso pum p tim eout and if it expir es, set -adj ust t he

relative error.

Once the VM dose is ser ved up, t he resist ance m anagem ent is

activatedtocompletetherstinstallation.

TRO UBLE SH OOTI N G

●Thegrouptimeoutexpires(Timingandthresholdsmenu),the

“ E61 Group” syst em - stor ed signal is generat ed and the dispen-

sing cycle is brought t o an end.

●The espresso pump timeout expires (Timing and thresholds

m enu) , the “ E62 Esp. pum p” sy stem - st ored signal is generat ed

and t he m anagem ent cycle is brought to an end.

●Thepressureswitchtimeoutexpires(xed),the“E20pressure

sw it ch” sy st em - st or ed sig nal is gener at ed an d t he p ressu re

sw it ch t im eou t coun t st ar t s f rom r esist an ce sw it ch- on . This is

a st ored alar m , t herefor e t o reset it , it is necessary t o use the

reset funct ion in t he m aint enance m ode.

DATA DI SPLAY

Whilst in phase A and once t he group reset has ended, the following

m essages will com e up on display :