Biber OSKA9563 User manual

SB-520-1

Open screw compressors for NH3 applications

Translation of the original Operating Instructions

English....................................................................................................................................................... 2

Offene Schraubenverdichter für NH3-Anwendungen

Originalbetriebsanleitung

Deutsch ..................................................................................................................................................... 16

Compresseurs à vis ouverts pour applications NH3

Traduction des instructions de service d'origine

Français..................................................................................................................................................... 30

OSKA9563

OSKA9583

OSKA9593

OSKA95103

OSNA9563

OSNA9583

OSNA9593

OSNA95103

Installer

Monteur

Monteur

SB-520-12

Table of contents

1 Introduction............................................................................................................................................................4

1.1 Also observe the following technical documents ...........................................................................................4

2 Safety ....................................................................................................................................................................4

2.1 Authorized staff..............................................................................................................................................4

2.2 Residual hazards...........................................................................................................................................4

2.3 Safety references...........................................................................................................................................4

2.3.1 General safety references ................................................................................................................. 4

3 Application ranges.................................................................................................................................................5

4 Mounting................................................................................................................................................................5

4.1 Transporting the compressor.........................................................................................................................5

4.2 Installing the compressor...............................................................................................................................5

4.3 Direct drive via coupling.................................................................................................................................5

4.4 Connecting the pipelines ...............................................................................................................................6

4.4.1 Pipe connections................................................................................................................................ 6

4.4.2 Pipelines ............................................................................................................................................ 6

4.4.3 OSKAB (booster version)................................................................................................................... 7

4.5 Connections and dimensional drawing..........................................................................................................8

4.5.1 Additional connections for evacuation ............................................................................................... 9

4.5.2 Capacity control and start unloading.................................................................................................. 9

5 Electrical connection..............................................................................................................................................9

5.1 Mains connections.........................................................................................................................................9

5.2 Safety and protection devices........................................................................................................................9

5.2.1 Compressor control module............................................................................................................... 9

5.2.2 Motor safety and protection devices .................................................................................................. 9

5.2.3 High pressure switches.................................................................................................................... 10

6 Commissioning ....................................................................................................................................................10

6.1 Checking the strength pressure...................................................................................................................10

6.2 Checking tightness ......................................................................................................................................10

6.3 Charging with oil ..........................................................................................................................................10

6.4 Evacuation...................................................................................................................................................10

6.5 Charging with refrigerant .............................................................................................................................11

6.6 Tests prior to compressor start....................................................................................................................11

6.7 Compressor start .........................................................................................................................................11

6.7.1 Checking the rotation direction ........................................................................................................ 11

6.7.2 Start ................................................................................................................................................. 11

6.7.3 Checking the oil level ....................................................................................................................... 11

6.7.4 Setting high pressure and low pressure switches (HP + LP)........................................................... 12

6.7.5 Setting the condenser pressure control ........................................................................................... 12

6.7.6 Checking the operating data ............................................................................................................ 12

6.7.7 Vibrations ......................................................................................................................................... 12

6.7.8 Particular notes on safe compressor and system operation ............................................................ 12

7 Operation.............................................................................................................................................................13

7.1 Regular tests................................................................................................................................................13

SB-520-1 3

8 Maintenance........................................................................................................................................................13

8.1 Integrated pressure relief valve ...................................................................................................................13

8.2 Integrated check valve.................................................................................................................................13

8.3 Oil filter.........................................................................................................................................................13

8.4 Oil change....................................................................................................................................................13

8.5 Shaft seal.....................................................................................................................................................13

8.6 Coupling.......................................................................................................................................................14

8.6.1 Elastomer elements ......................................................................................................................... 14

8.6.2 Checking the elastomer elements for wear...................................................................................... 14

8.7 Roller bearings.............................................................................................................................................14

8.7.1 Checking the roller bearings ............................................................................................................ 14

8.7.2 Replacement of the roller bearings .................................................................................................. 14

9 Decommissioning ................................................................................................................................................14

9.1 Standstill ......................................................................................................................................................14

9.2 Dismounting the compressor.......................................................................................................................15

9.3 Disposing of the compressor .......................................................................................................................15

9.4 Dismounting the oil separator and oil cooler................................................................................................15

SB-520-14

1 Introduction

These refrigeration compressors are intended for incor-

poration into refrigeration systems in accordance with

the 2006/42/EC Machinery Directive. They may only be

put into operation if they have been installed in the refri-

geration systems according to these Mounting/Operat-

ing Instructions and if the overall system complies with

the applicable legal provisions (applied standards: see

declaration of incorporation).

The compressors have been built in accordance with

state-of-the-art methods and current regulations. Partic-

ular importance was placed on user safety.

These Operating Instructions must be kept available

near the refrigeration system during the whole lifetime

of the compressor.

1.1 Also observe the following technical documents

SW-100: Tightening torques for screw fixings.

ST-150: Compressor monitoring module CM-SW-01.

2 Safety

2.1 Authorized staff

All work done on compressors and refrigeration sys-

tems may only be performed by qualified and author-

ized staff who have been trained and instructed accord-

ingly. The qualification and expert knowledge of the

personnel must correspond to the local regulations and

guidelines.

2.2 Residual hazards

The compressor may present unavoidable residual

risks. That is why any person working on this device

must carefully read these Operating Instructions.

The following rules and regulations are mandatory:

• the relevant safety regulations and standards (e.g.

EN 378-2, EN 60204, EN 60335 and EN953),

• generally accepted safety rules,

• EU directives,

• national regulations.

2.3 Safety references

are instructions intended to prevent hazards. Safety ref-

erences must be stringently observed!

!

!

NOTICE

Safety reference to avoid situations which may

result in damage to a device or its equipment.

CAUTION

Safety reference to avoid a potentially hazard-

ous situation which may result in minor or mod-

erate injury.

WARNING

Safety reference to avoid a potentially hazard-

ous situation which could result in death or seri-

ous injury.

DANGER

Safety reference to avoid an imminently hazard-

ous situation which may result in death or seri-

ous injury.

2.3.1 General safety references

State of delivery

CAUTION

The compressor is filled with a holding charge:

Overpressure 0.5 .. 1 bar.

Risk of injury to skin and eyes.

Depressurize the compressor!

Wear safety goggles!

For work on the compressor once it has been

commissioned

DANGER

Hair, hands or clothes may get caught in the

coupling!

Serious injuries are possible.

Secure the coupling zone with a separating

cover (protective grid)!

CAUTION

Surface temperatures of more than 60°C or be-

low 0°C.

Risk of burns or frostbite.

Close off accessible areas and mark them.

Before performing any work on the compressor:

switch it off and let it cool down.

SB-520-1 5

!

!

NOTICE

Risk of compressor failure!

Operate the compressor only in the intended ro-

tation direction!

WARNING

The compressor is under pressure!

Serious injuries are possible.

Depressurize the compressor!

Wear safety goggles!

3 Application ranges

Allowed refrigerant: R717 (NH3)

Oil charge: Reniso KC68, Reflo 68A, SHC226E

Application limits: See brochure SP-520 and

BITZER SOFTWARE

Risk of air penetration during operation in the vacuum

range

!

!

NOTICE

Potential chemical reactions as well as in-

creased condensing pressure and rise in dis-

charge gas temperature.

Avoid air penetration!

WARNING

A critical shift of the refrigerant ignition limit is

possible.

Avoid air penetration!

4 Mounting

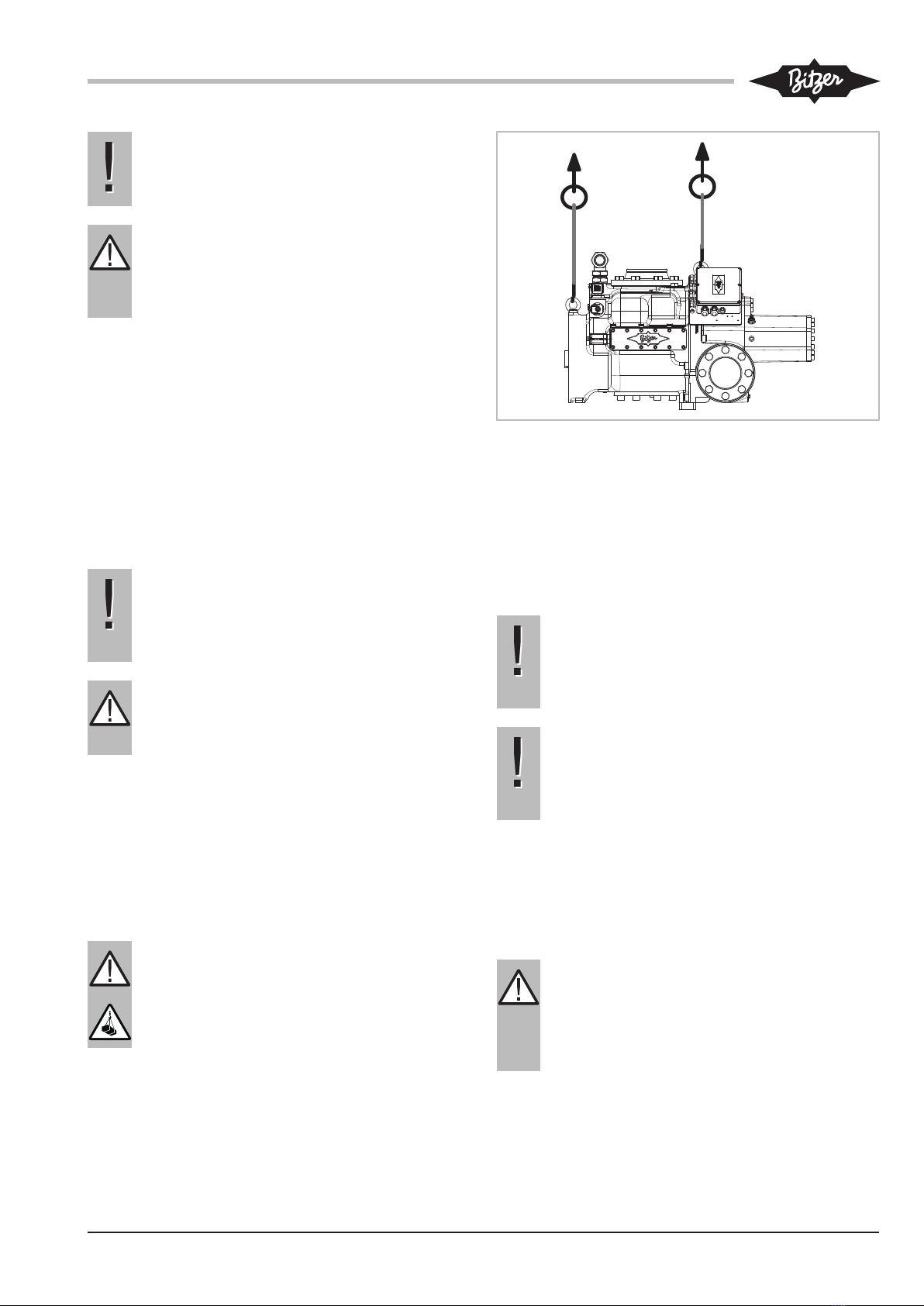

4.1 Transporting the compressor

Either transport the compressor screwed onto the pallet

or lift it using the eyebolts, see figure 1, page 5.

DANGER

Suspended load!

Do not step under the machine!

Fig.1: Lifting the compressor

4.2 Installing the compressor

Install/mount the compressor horizontally. Take suit-

able measures if the compressor is operated under ex-

treme conditions (e.g. aggressive atmosphere, low out-

door temperatures, etc.). Consultation with BITZER is

recommended.

!

!

NOTICE

Do not mount the compressor solidly on the

heat exchanger!

Risk of damage to the heat exchanger (fatigue

fractures).

!

!

NOTICE

Potential chemical reactions due to air penetra-

tion!

Proceed swiftly and keep shut-off valves closed

until evacuation.

Provide sufficient free space under the suction gas filter

housing for dismounting and mounting the suction gas

filter (>450mm).

4.3 Direct drive via coupling

DANGER

Hair, hands or clothes may get caught in the

coupling!

Serious injuries are possible.

Secure the coupling zone with a separating

cover (protective grid)!

SB-520-16

Information

Observe safety standards EN ISO 13857 / EN

294 / EN 349 and national regulations.

Use only couplings with elastic intermediate ele-

ments which can compensate for slight shifts in

axial direction, but do not exert their own axial

force.

!

!

NOTICE

Risk of damage to the compressor due to wrong

couplings!

Use only couplings approved by BITZER!

Approved coupling:

• KS900

The compressor is connected to the motor via the

coupling housing:

• Clean mating surfaces on the compressor, motor

and coupling housing.

• Install the motor on rails.

• Slide the coupling half for the compressor side (in-

cluding parallel key) on the compressor shaft, make

sure that it is flush and fasten it with screws, fasten

the compressor to the coupling housing.

• Slide the coupling half for the motor side (including

parallel key) loosely on the motor shaft, fasten the

coupling housing to the motor.

• Remove protective grid from the coupling housing,

move the coupling half on the motor side until the

clearance is 2 .. 5 mm, then fasten it with screws.

• Make sure to re-install the protective grid afterwards!

!

!

NOTICE

Poor coupling alignment may cause premature

coupling failure and damage to bearings and

shaft seal!

Carefully align the motor and compressor shaft!

!

!

NOTICE

Risk of damage to compressor and coupling!

Firmly tighten the fixing elements of both coup-

ling halves to prevent them from getting loose

during operation!

Tightening torque: 15Nm.

Provide additional support for the compressor on the

base frame.

Direct drive without coupling housing is possible, but it

requires a very stable base frame and an exact align-

ment of the compressor shaft and motor shaft. The

shaft ends must not touch each other. For height ad-

justment, use stable supports (flat sheets).

Special drives (e.g. combustion engines) require indi-

vidual consultation with BITZER.

4.4 Connecting the pipelines

WARNING

The compressor is under pressure!

Serious injuries are possible.

Depressurize the compressor!

Wear safety goggles!

!

!

NOTICE

Potential chemical reactions due to air penetra-

tion!

Proceed swiftly and keep shut-off valves closed

until evacuation.

4.4.1 Pipe connections

The pipe connections are designed in way that they are

suitable for pipes in all common dimensions in milli-

metres and inches.

!

!

NOTICE

Do not overheat the shut-off valves!

Cool the valve body and the welding adapter

during and after the welding operation.

For welding, dismount the pipe connections and

the bushes.

4.4.2 Pipelines

Use only pipelines and system components which are

clean and dry inside (free from slag, swarf, rust and

phosphate coatings) and which are provided with an

air-tight seal on delivery.

As standard, the compressors are supplied with blank-

ing plates on the pipe connections. These must be re-

moved before performing the strength pressure and

tightness tests and commissioning the system.

!

!

NOTICE

For systems with rather long pipelines or for

welding operations without protective gas:

Install the suction-side cleaning filter (mesh size

<25μm).

Information

The blanking plates are only designed to serve

as a transport protection. They are not suitable

as a separation between different system sec-

tions during the strength pressure test.

SB-520-1 7

!

!

NOTICE

Risk of compressor damage!

Evacuate the system and flush it once or sev-

eral times with dry nitrogen, if necessary.

Mount pipelines in such a way that the compressor is

protected from flooding with oil or liquid refrigerant dur-

ing standstill. Strictly observe the instructions indicated

in the manual SH-510.

Lines for economiser (ECO) and liquid injection (LI):

The ECO connection is arranged on the top side of the

compressor housing, therefore a bridge for protection

against oil migration is not required. Guide the line hori-

zontally or downwards from the connection. See Tech-

nical Information ST-600.

When retrofitting the ECOshut-off valve:

Information

To increase the corrosion protection, it is recom-

mended to paint the ECO shut-off valve.

4.4.3 OSKAB (booster version)

An external oil pump may be necessary in systems

where a sufficient oil pressure difference cannot be

built up directly after the compressor start. This may

apply, for example, to large parallel compounding sys-

tems with extremely low condensing temperature or to

boosters.

SB-520-18

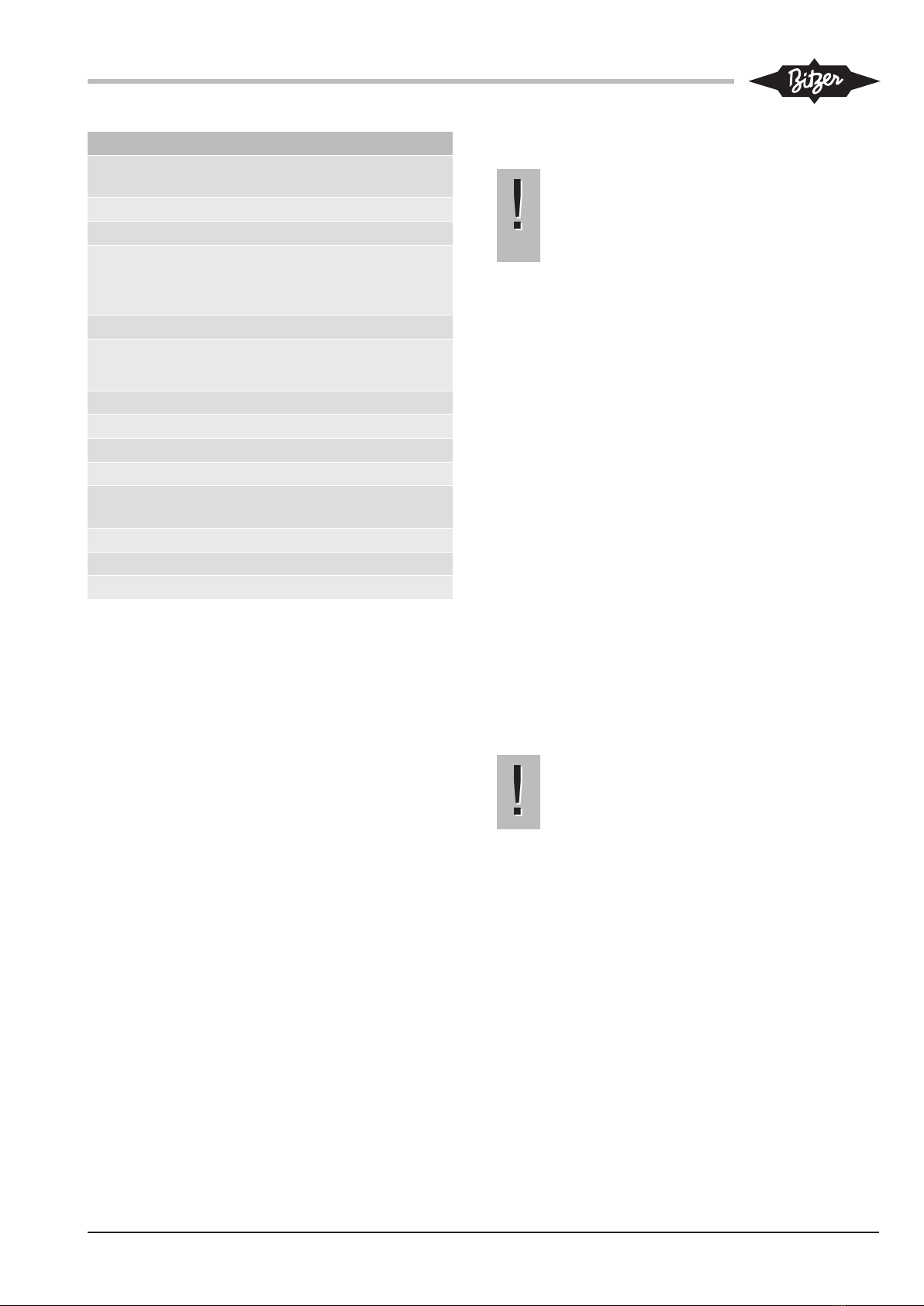

4.5 Connections and dimensional drawing

1a (HP)

1/8-27 NPTF

3 (HP)

1/8-27 NPTF

7a

M22x1,5

1/8-27 NPTFG 1/4

2b (LP) 2a (LP)

1/8-27 NPTF

Ø21

Ø12

1/8-27 NPTFG 1/4

1b (HP)

19 5

20

Vi (–)Vi (+)

17

M22x1,5

Ø332

Ø370

M16

Ø65

94

SL

466

170

55

450

822

217

599

632

664

458

356

535

1055

155

315 580

30

117

332

198

206

DL

41 (HP)2 (LP)

161

12°

Ø294

Ø288

17

7b

1/8-27 NPTF

CR (–) CR (+)

18

187

1/8-27 NPTF

50

94

611

206

44

7c

14

Fig.2: Dimensional drawing OS.A95103

Connection positions

1 High pressure connection (HP)

1a Additional high pressure connection (HP)

1b Connection for high pressure transmitter

(HP)

2 Low pressure connection (LP)

2a Additional low pressure connection (LP)

2b Connection for low pressure transmitter

(LP)

3 Connection for discharge gas temperature

sensor (HP)

4 Connection for economiser (ECO) or liquid

injection (LI)

HS.85 and OS.85: Connection for econo-

miser (ECO)

Connection positions

HS.85: ECO valve with connection line

(option)

OS.85 and OS.95: ECO valve (option)

5 Connection/valve for oil injection

6 Oil pressure connection

HS.85 and OS.85: Oil drain (compressor

housing)

7 Oil drain (motor housing)

7a Oil drain (suction gas filter)

7b Oil drain from shaft seal (maintenance con-

nection)

7c Oil drain hose (shaft seal)

8 Threaded bore for foot mounting

SB-520-1 9

Connection positions

9 Threaded bore for pipe fixture (ECO and LI

lines)

10 Maintenance connection for oil filter

11 Oil drain (oil filter)

12 Monitoring of oil stop valve

OS.85: Monitoring of rotation direction and

oil stop valve

13 Oil filter monitoring

14 Oil flow switch

OS.95: Oil level monitoring

15 Earth screw for housing

16 Oil drain (oil filter chamber)

17 Maintenance connection for shaft seal

18 Liquid injection (LI)

19 Compressor monitoring module

(CM-SW-01)

20 Slider position indicator

SL Suction gas line

DL Discharge gas line

Tab.1: Connection positions

Dimensions (if specified) may have tolerances accord-

ing to ENISO13920-B.

The legend applies to all open and semi-hermetic

BITZER screw compressors and contains connection

positions that do not occur in every compressor series.

4.5.1 Additional connections for evacuation

In case of a great system volume, install generously

sized, lockable additional connections on the pressure

and suction side. Sections locked by check valves must

have separate connections.

4.5.2 Capacity control and start unloading

The OS.A95 compressors are equipped with an "infinite

capacity control" (slide control). The compressor control

module controls the solenoid valves.

For the detailed descriptions of the capacity control,

see Technical Information ST-150.

For the start unloading, the compressor control module

sets the capacity slider to the minimum displacement.

For this, a time period of approx. 5 min in the system

control must be provided.

5 Electrical connection

!

!

NOTICE

Risk of short-circuit due to condensation water

in the terminal box!

Use only standardised cable bushings.

When mounting, pay attention to proper sealing.

General information

Compressors and electrical equipment comply with the

EU Low Voltage Directives 2006/95/EC and 2014/35/

EU.

Connect mains cables, protective earth conductors and

other cables according to the description, see Tech-

nical Information ST-150. Observe the safety standards

EN60204, IEC60364 and national safety regulations.

5.1 Mains connections

When dimensioning motor contactors, feed lines and

fuses:

• Use the maximum operating current or maximum

power consumption of the motor as a basis.

• Select the contacts according to the operational cat-

egory AC3.

Compare the voltage and frequency specifications on

the motor type plate with the data of the mains supply.

The motor may be connected only if the values match.

Wire the terminals according to the instructions of the

motor manufacturer.

!

!

NOTICE

Risk of compressor failure!

Operate the compressor only in the intended ro-

tation direction!

5.2 Safety and protection devices

5.2.1 Compressor control module

The compressor control module monitors the essential

operating parameters and protects the compressor

from operation under critical conditions, see Technical

Information ST-150.

5.2.2 Motor safety and protection devices

Provide motor safety and protection devices according

to the regulations of the motor manufacturer or the dir-

ectives on the protection of drive motors.

SB-520-110

5.2.3 High pressure switches

A pressure limiter and a safety pressure limiter are re-

quired for securing the compressor's application range

in order to avoid unacceptable operating conditions.

The low pressure can be secured using the built-in low

pressure transmitter, see Technical Information

ST-150.

6 Commissioning

The compressor has been carefully dried, checked for

tightness and filled with a holding charge (N2) before

leaving the factory.

DANGER

Risk of explosion!

Never pressurize the compressor with oxygen

(O2) or other industrial gases!

WARNING

Risk of bursting!

A critical shift of the refrigerant ignition limit is

possible in case of excess pressure.

Do not add a refrigerant (e.g. as a leak indic-

ator) to the test gas (N2 or air).

Environmental pollution in case of leakage and

when deflating!

!

!

NOTICE

Risk of oil oxidation!

Check the entire system for strength pressure

and tightness, preferably using dried nitrogen

(N2).

When using dried air: Remove the compressor

from the circuit – make sure to keep the shut-off

valves closed.

6.1 Checking the strength pressure

Check the refrigerant circuit (assembly) according to

EN378-2 (or other applicable equivalent safety stand-

ards). The compressor had been already tested in the

factory for strength pressure. A tightness test is there-

fore sufficient, see chapter Checking tightness, page

10.

If you still wish to perform a strength pressure test for

the entire assembly:

DANGER

Risk of bursting due to excessive pressure!

The pressure applied during the test must never

exceed the maximum permitted values!

Test pressure: 1.1-fold of the maximum allow-

able pressure (see name plate). Make a distinc-

tion between the high-pressure and low-pres-

sure sides!

6.2 Checking tightness

Check the refrigerant circuit (assembly) for tightness,

as a whole or in parts, according to EN378-2 (or other

applicable equivalent safety standards). For this, create

an overpressure, preferably using dried nitrogen.

Observe test pressures and safety reference, see

chapter Checking the strength pressure, page 10.

6.3 Charging with oil

Oil type: see chapter Application ranges, page 5. Ob-

serve information in manual SH-510.

Charged quantity: Quantity required for the operation of

oil separator and oil cooler plus the volume of the oil

lines. The additional quantity for oil circulation in the re-

frigerant circuit is approx. 1 .. 2% of the refrigerant

charge; in systems with flooded evaporators the share

of the additional quantity may be greater.

To prevent dry running of the shaft seal during the com-

pressor start, charge approx. 1l oil in the connection

for oil injection (see figure 2, page 8, pos. 5).

Before evacuation, charge oil directly in oil separator

and oil cooler. Open shut-off valves of oil separator / oil

cooler. The filling level in the oil separator must be

within the sight glass area.

Information

The compressor control module controls the

solenoid valve in the oil injection line, see Tech-

nical Information ST-150.

6.4 Evacuation

Switch on oil heater in the oil separator.

Open the shut-off valves. Keep the shut-off valve in the

oil injection line closed. Use a vacuum pump to evacu-

ate the entire system, including the compressor, on the

low and the high pressure sides. With the vacuum

pump shut off, a "standing vacuum" lower than

1.5mbar must be achieved. Repeat the operation sev-

eral times if necessary. After the evacuation, open the

shut-off valve in the oil injection line.

SB-520-1 11

6.5 Charging with refrigerant

DANGER

Risk of bursting of components and pipelines

due to hydraulic excess pressure while feeding

liquid.

Serious injuries are possible.

Avoid overcharging the system with refrigerant

under all circumstances!

!

!

NOTICE

Risk of wet operation during liquid feeding!

Measure out extremely precise quantities!

Maintain the discharge gas temperature well

above the condensing temperature:

with NH3 at least 30K.

!

!

NOTICE

Lack of refrigerant causes low suction pressure

and superheat condition!

Observe the application limits.

• Before charging with refrigerant:

– Use approved refrigerants only (see chapter Ap-

plication ranges, page 5).

– Switch on the oil heater.

– Check the oil level in the oil separator.

– Do not switch on the compressor!

• Charge condenser or receiver, on systems with

flooded evaporator, also the evaporator or liquid sep-

arator directly with liquid refrigerant.

• After commissioning, it may be necessary to add re-

frigerant: While the compressor is running, charge

with refrigerant on the suction side, preferably at the

evaporator inlet or in the liquid separator.

6.6 Tests prior to compressor start

• Oil level in the oil separator (in the sight glass area).

• Oil temperature in the oil separator (approx. 15 ..

20K above ambient temperature).

• Setting and functions of safety and protection

devices.

• Setpoints of the time relays.

• Cut-out pressure values of the high-pressure and

low-pressure limiters.

• Cut-out pressure values of the pressure switches.

Record the setting.

• Are shut-off valves in the oil injection line open?

!

!

NOTICE

Do not start the compressor if it was flooded

with oil due to faulty operation! It is absolutely

necessary to empty it!

Internal components may be damaged.

Close shut-off valves, depressurize the com-

pressor and drain oil via drain plug on the com-

pressor.

6.7 Compressor start

6.7.1 Checking the rotation direction

!

!

NOTICE

Risk of compressor failure!

Operate the compressor only in the intended ro-

tation direction!

Check the rotation direction during the first compressor

start:

• Connect the pressure gauge to the suction shut-off

valve. Close the valve spindle and open again by

one turn.

• Let the compressor start for a short time (approx.

0.5 .. 1 s).

• Correct rotation direction: Suction pressure drops im-

mediately.

• Incorrect rotation direction: Suction pressure in-

creases.

Reverse the polarity of the terminals on the common

feed line.

6.7.2 Start

Restart, slowly open the suction shut-off valve and ob-

serve the sight glass in the oil injection line. If there is

no oil flow within 5 s, switch off immediately. Check oil

supply!

6.7.3 Checking the oil level

Immediately after commissioning, carry out the follow-

ing checks:

• During operation, the maximum and recommended

oil level is within the sight glass area of the oil separ-

ator (the minimum oil level is secured by the oil level

switch).

• During the start phase, oil foam may appear which,

however, should decrease after 2 to 3min. Other-

wise high proportions of liquid in the suction gas are

suspected.

SB-520-112

!

!

NOTICE

Risk of wet operation during liquid feeding!

Measure out extremely precise quantities!

Maintain the discharge gas temperature well

above the condensing temperature:

with NH3 at least 30K.

If the oil level switch is triggered during the start phase

of the oil monitoring system or after the delay time has

elapsed (10 s), this indicates an acute lack of oil. This

may be caused by a too large share of refrigerant in the

oil. Check the suction gas superheat.

!

!

NOTICE

Risk of compressor failure due to liquid slug-

ging!

Before adding larger quantities of oil: check the

oil return!

6.7.4 Setting high pressure and low pressure

switches (HP + LP)

Perform a test to check the exact cut-in and cut-out

pressure values according to the application limits.

6.7.5 Setting the condenser pressure control

Set the condenser pressure so that the minimum pres-

sure difference is reached within 20s after the start (for

application limits, see BITZER SOFTWARE). Avoid

quick pressure reduction with finely stepped pressure

control.

6.7.6 Checking the operating data

• Evaporation temperature

• Suction gas temperature

• Condensing temperature

• Discharge gas temperature:

– Min. 30K (NH3) above condensing temperature

– Max. 100°C

• Oil temperature:

– Reniso KC68, Reflo 68A, SHC226E: max. 60°C

• Cycling rate

• Motor current

• Motor voltage

• For operation with ECO:

– ECO pressure

– Temperature at the ECO connection

• Creation of data protocol

For application limits, see brochure SP-520 or

BITZER SOFTWARE.

To prevent motor failures, the following requirements

are specified:

• Maximum cycling rate, motor current, motor voltage:

Observe the notes of the motor manufacturer.

• Desirable minimum running time: 5 min

!

!

NOTICE

Risk of motor failure!

The specified requirements must be ensured by

the control logic!

6.7.7 Vibrations

When operating with frequency inverter, check the en-

tire speed range of the system for abnormal vibration.

Speeds at which resonances still occur must be

avoided in the programming of the frequency inverter. If

required, take additional safety measures.

!

!

NOTICE

Risk of burst pipes and leakages on the com-

pressor and system components!

Avoid strong vibrations!

6.7.8 Particular notes on safe compressor and

system operation

Analysis show that compressor failures are most often

due to an inadmissible operating mode. This applies

especially to damage resulting from lack of lubrication:

• Always maintain oil heater operation in the oil separ-

ator when the system is at standstill. This is valid for

all applications.

When installing the system in zones where the tem-

peratures are low, it may be necessary to insulate

the oil separator. At compressor start, the oil temper-

ature, that is measured under the oil sight glass,

should be 15 .. 20 K above the ambient temperature.

• Automatic sequence change for systems with sev-

eral refrigerating circuits (approximately every 2

hours).

• Install an additional check valve in the discharge gas

line behind the oil separator if temperature and pres-

sure compensation is not reached even after long

standstill times.

• If needed, mount a time and pressure-dependant

controlled pump down system – particularly for high

refrigerant charges and/or when the evaporator may

SB-520-1 13

become hotter than the suction gas line or the com-

pressor.

For further information about pipe layout, see manual

SH-510.

7 Operation

7.1 Regular tests

Examine the system at regular intervals according to

national regulations.

• Operating data, see chapter Checking the operating

data, page 12.

• Oil supply, see chapter Checking the operating data,

page 12.

• Safety and protection devices and all components

for compressor monitoring, see chapter Safety and

protection devices, page 9 and see chapter Check-

ing the operating data, page 12.

• Tightness of the integrated check valve.

•Check the elastomer elements of the coupling after

the running-in period and then once a year.

• Tight seat of electrical cable connections and

screwed joints.

• Screw tightening torques (see SW-100).

• Refrigerant charge.

• Tightness

• Prepare data protocol.

8 Maintenance

DANGER

Hair, hands or clothes may get caught in the

coupling!

Serious injuries are possible.

Secure the coupling zone with a separating

cover (protective grid)!

WARNING

The compressor is under pressure!

Serious injuries are possible.

Depressurize the compressor!

Wear safety goggles!

8.1 Integrated pressure relief valve

The valve is maintenance-free.

However, after repeated venting, it may leak perman-

ently because of abnormal operating conditions. The

consequences are reduced performance and a higher

discharge gas temperature.

Recommended replacing interval: 100,000h.

8.2 Integrated check valve

If the check valve is defective or contaminated, the

compressor runs for some time in reverse direction

after it has been switched off. The valve must then be

changed.

Recommended replacing interval: 20,000 .. 40,000h.

8.3 Oil filter

It is recommended to change the oil filter for the first

time after 50 .. 100 operating hours. During operation,

the degree of contamination can be permanently

checked by the oil filter monitoring (option).

8.4 Oil change

The listed oils (see chapter Application ranges, page 5)

are characterised by a particularly high degree of stabil-

ity. With NH3 operation, it is recommended to change

oil once a year or after each 5,000 operating hours.

Impurities stemming from the plant components or op-

erating outside the application ranges are the only

things that can cause deposits to form in the lubricating

oil, causing it to darken. In this case, change the oil.

Also renew the oil filter. Determine the cause of operat-

ing outside of the application area and eliminate it.

Oil types: see chapter Application ranges, page 5.

WARNING

Oil separator and oil cooler are under pressure!

Serious injuries are possible.

Depressurize oil separator and oil cooler!

Wear safety goggles!

Dispose of waste oil properly!

8.5 Shaft seal

A routine check of the shaft seal is generally not re-

quired.

However, with regard to the operational reliability, a

check in connection with oil change or faults in the lub-

ricating circuit is recommended.

In doing so, pay particular attention to:

• hardening and cracks on the O-rings

SB-520-114

• wear

• corrugations

• material deposits

• oil carbon

• copper plating

Leakage oil quantities up to approx. 0.2cm3 per operat-

ing hour are within the tolerance range. Leakage oil

which may escape can be drained via an oil drain pipe

at the flange of the shaft seal.

Increased oil leakage is possible during the running-in

period of the shaft seal (approx. 250 hours).

Recommended replacing interval: 20,000 .. 40,000h.

8.6 Coupling

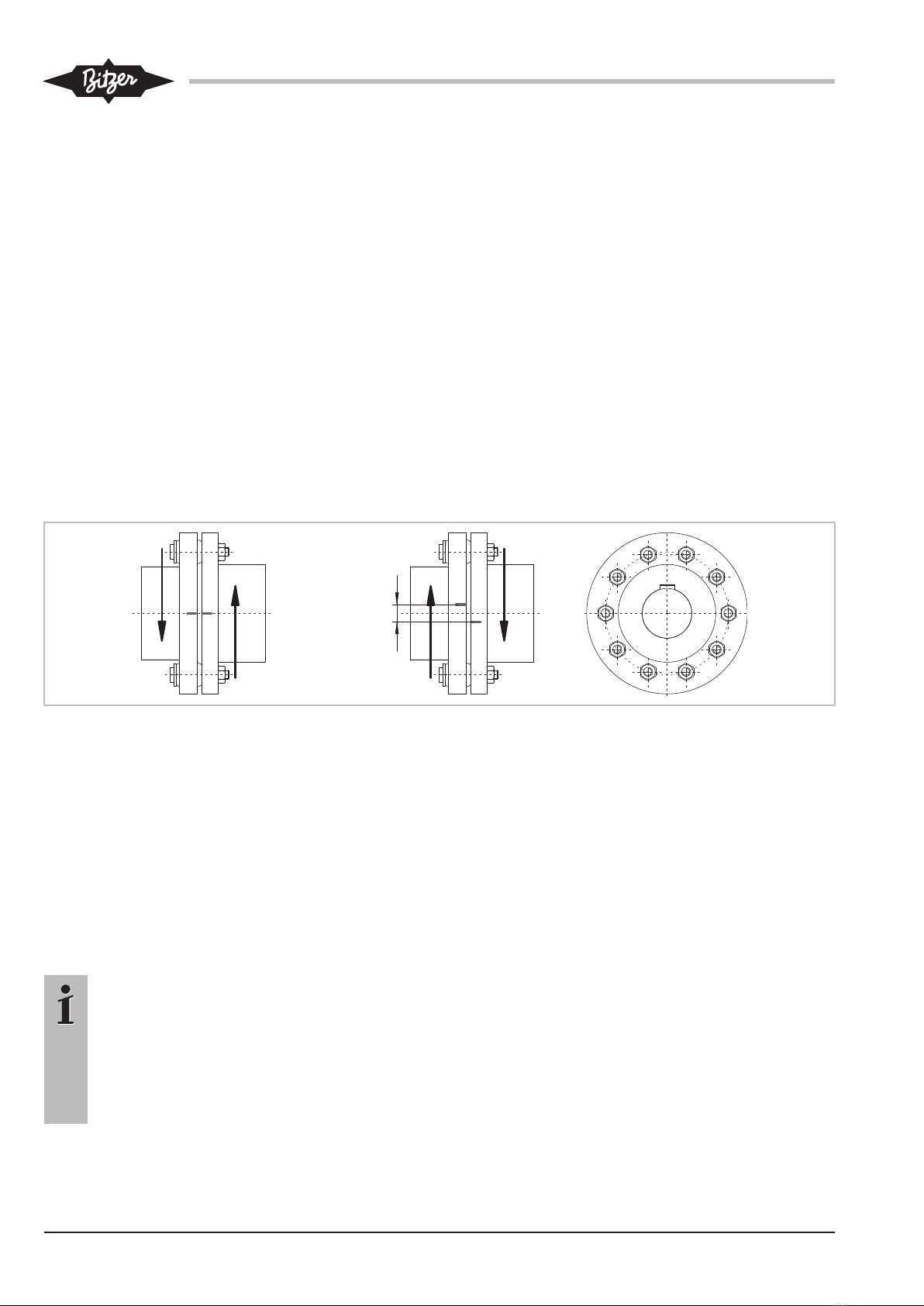

8.6.1 Elastomer elements

Check the elastomer elements of the coupling after the

running-in period and then once a year, see figure 3,

page 14.

8.6.2 Checking the elastomer elements for wear

• Turn both coupling halves without torque against

each other to the stop.

• Mark both halves.

• Turn coupling halves also without torque to the other

direction to the stop.

• Measure radial distance between the two marks.

• Replace all elastomer elements if the distance is

more than 4mm.

ma x . 4 m m

Fig.3: Checking the elastomer elements of the coupling

8.7 Roller bearings

BITZER screw compressors are equipped with durable

roller bearings. Therefore, a replacement is generally

not required.

8.7.1 Checking the roller bearings

The roller bearings are checked by means of the noise

analysis.

Recommended test interval: 10,000h.

Information

When replacing the roller bearings, visually

check the rotors, the housing and the discharge

flange.

In case of deep corrugations or abnormal wear,

a general overhaul of the compressor by

BITZER or Green Point or its replacement is re-

commended.

8.7.2 Replacement of the roller bearings

Recommended replacing interval: 40,000 .. 50,000h.

In this case, the entire service life of the roller bearings

is not used.

The bearings may need to be replaced due to occa-

sional deviations from the standard operation, such as

lack of oil, wet operation or thermal overload.

9 Decommissioning

9.1 Standstill

Leave the oil heater switched on until disassembly.

This prevents increased refrigerant concentration in the

oil.

SB-520-1 15

9.2 Dismounting the compressor

WARNING

The compressor is under pressure!

Serious injuries are possible.

Depressurize the compressor!

Wear safety goggles!

In the case of repair work requiring dismounting or in

the event of decommissioning:

Close the shut-off valves on the compressor. Extract

the refrigerant. Do not deflate the refrigerant, but dis-

pose of it properly!

Open screwed joints or flanges on the compressor

valves. Remove the compressor using hoisting equip-

ment.

9.3 Disposing of the compressor

Drain the oil from the compressor. Dispose of waste oil

properly!

Have the compressor repaired or dispose of it properly.

9.4 Dismounting the oil separator and oil cooler

WARNING

Oil separator and oil cooler are under pressure!

Serious injuries are possible.

Depressurize oil separator and oil cooler!

Wear safety goggles!

Drain oil when performing repair work or decommis-

sioning the oil separator and oil cooler.

If possible, block refrigerant and oil lines in front of and

behind the oil separator and oil cooler.

Prepare a pan: Drain oil, collect oil and dispose of it

properly.

In case of damage, the oil separator or oil cooler must

be separated from the refrigerator system and re-

placed. For this, extract the refrigerant and drain the

coolant.

Dispose of contaminated substances properly!

BITZER Kühlmaschinenbau GmbH

Eschenbrünnlestraße 15 // 71065 Sindelfingen // Germany

Tel +49 (0)70 31 932-0 // Fax +49 (0)70 31 932-147

[email protected] // www.bitzer.de

Subject to change // Änderungen vorbehalten // Toutes modifications réservées // 80450801 // 02.2017

80450801 // 02.2017

Subject to change

Änderungen vorbehalten

Toutes modifications réservées

This manual suits for next models

7

Table of contents

Popular Air Compressor manuals by other brands

California Air Tools

California Air Tools 8010SPC owner's manual

Craftsman

Craftsman 16923 owner's manual

Emerson

Emerson Copeland Discus Series Application guidelines

GEA

GEA FK40/560 N Assembly instructions

BLACKMER

BLACKMER NGH1013 Installation, operation and maintenance instructions

BUSCH

BUSCH Mink MM 1202 AP Installation and operating instructions