RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

Page 2 INSTALLATION - OPERATION - MAINTENANCE

GENERAL INFORMATION

Preface..............................................................................3

Design Limitations ............................................................3

Job Inspection...................................................................3

Transit Damage Claims .....................................................3

Compressor/Unit Identification..........................................3

INSTALLATION

Foundation ........................................................................4

Handling and Moving ........................................................4

Skid Removal ....................................................................5

Motor Mounting .................................................................5

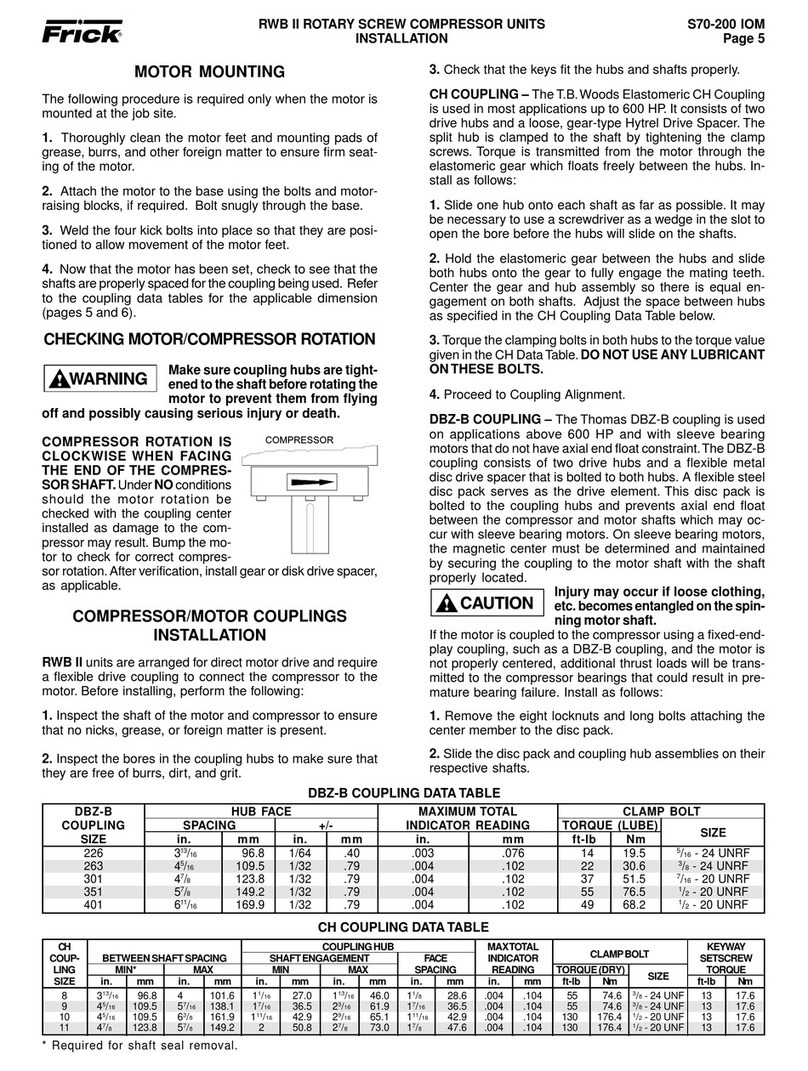

Compressor/Motor Coupling Installation ..........................5

Coupling Alignment Procedure .........................................6

Hot Alignment of Compressor/Motor ................................8

Checking Motor/Compressor Rotation..............................8

Holding Charge and Storage ............................................8

Compressor Oil .................................................................8

Oil Charge.........................................................................8

Oil Heater..........................................................................8

Liquid Injection Oil Cooling ...............................................9

Dual Dip Tube Method.......................................................9

Level Control Method........................................................9

Water-Cooled Oil Cooling ...............................................10

Thermosyphon Oil Cooling .............................................10

Economizer - High Stage ................................................12

Electrical .........................................................................13

Motor Starter Package ....................................................13

Current Transformers (CT) Ratios ...................................14

Minimum Burden Ratings................................................14

Battery Backup ...............................................................14

OPERATION

General Information ........................................................15

Microprocessor Control Panel.........................................15

Keys and Key Functions .................................................16

To Change The Adjustable Setpoints..............................18

How To Determine Adjustable Setpoints.........................18

Temperature-Pressure Control Program.........................22

Lead-Lag (Option)...........................................................24

Communications Troubleshooting ...................................24

How The Microprocessor Works - Summary ..................25

Multiple Compressor Sequencing...................................26

Microprocessor Telecommunications..............................27

Communications Protocol Specifications .......................27

RXB Compressor ............................................................30

Compressor Lubrication System.....................................30

Full-Lube Oil System ......................................................30

Compressor Oil Separation System ...............................30

Compressor Hydraulic System .......................................31

Compressor Oil Cooling Systems...................................32

Single-Port Liquid Injection .............................................32

Dual-Port Liquid Injection................................................33

Liquid Injection Adjustment Procedure ...........................33

Prestart Checklist............................................................34

TABLE OF CONTENTS

Initial Start-up Procedure ................................................35

Normal Start-up Procedure.............................................35

Restarting Unit After Power Failure.................................35

MAINTENANCE

Normal Maintenance Operations ....................................36

Compressor Shutdown and Start-up ..............................36

General Instructions For Replacing

Compressor Unit Components....................................36

Suction Check Valve Bypass Valve .................................36

Oil Filter, Single...............................................................36

Oil Filter, Dual .................................................................37

Strainer, Oil Return .........................................................37

Strainer, Oil Pump (Optional) ..........................................37

Strainer, Liquid Injection .................................................37

Coalescer Filter Element ................................................38

Changing Oil ...................................................................38

Recommended Maintenance Program ...........................38

Vibration Analysis ...........................................................39

Oil Quality and Analysis..................................................39

Motor Bearings ...............................................................39

Operating Log .................................................................39

Maintenance Schedule ...................................................40

Troubleshooting Guide ....................................................41

Abnormal Operation Analysis and Correction ................41

Troubleshooting The Microprocessor..............................42

EPROM Memory I/C Chip Replacement ........................45

SBC Board Replacement................................................45

Microprocessor Display Replacement ............................45

Output Fuse Replacement ..............................................45

Pressure Transducers - Testing.......................................45

Pressure Transducer Conversion Data ...........................45

Pressure Transducers - Replacement.............................46

Volumizer Potentiometer - Replace/Adjust .....................47

Temperature/Pressure Adjustment .................................47

Bare Compressor Mounting ............................................47

Troubleshooting The RXB PLUS:

Compressor.................................................................48

Oil Separator System ..................................................48

Hydraulic System ........................................................48

Full-Time Pump Systems ............................................49

Liquid Injection Oil Cooling .........................................49

Thermal Expansion Valves .............................................50

Temperature Control Valve..............................................51

Wiring Diagrams .............................................................52

P and I Diagrams ............................................................58

PROPER INSTALLATION OF ELECTRONIC

EQUIPMENT ...............................................................61

SPARE PARTS LIST.......................................................64

OPERATING LOG ..........................................................65