MANUAL INTRODUCTION

Version: 1.0 (21-09-2005) 7

1.3 About the unit

1.3.1 Applications

The Comfort Circle is designed for heating, cooling and/or

ventilating rooms.

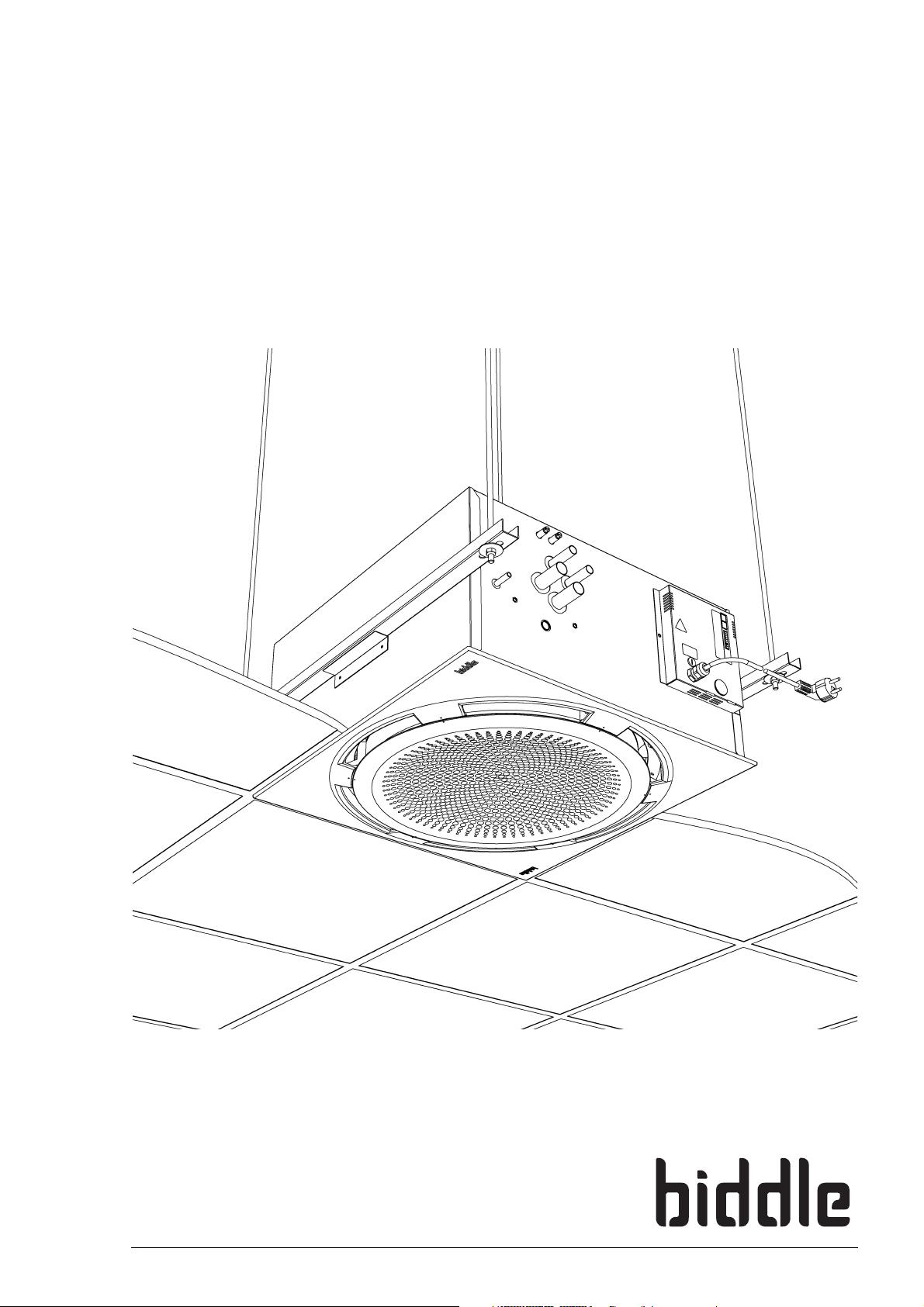

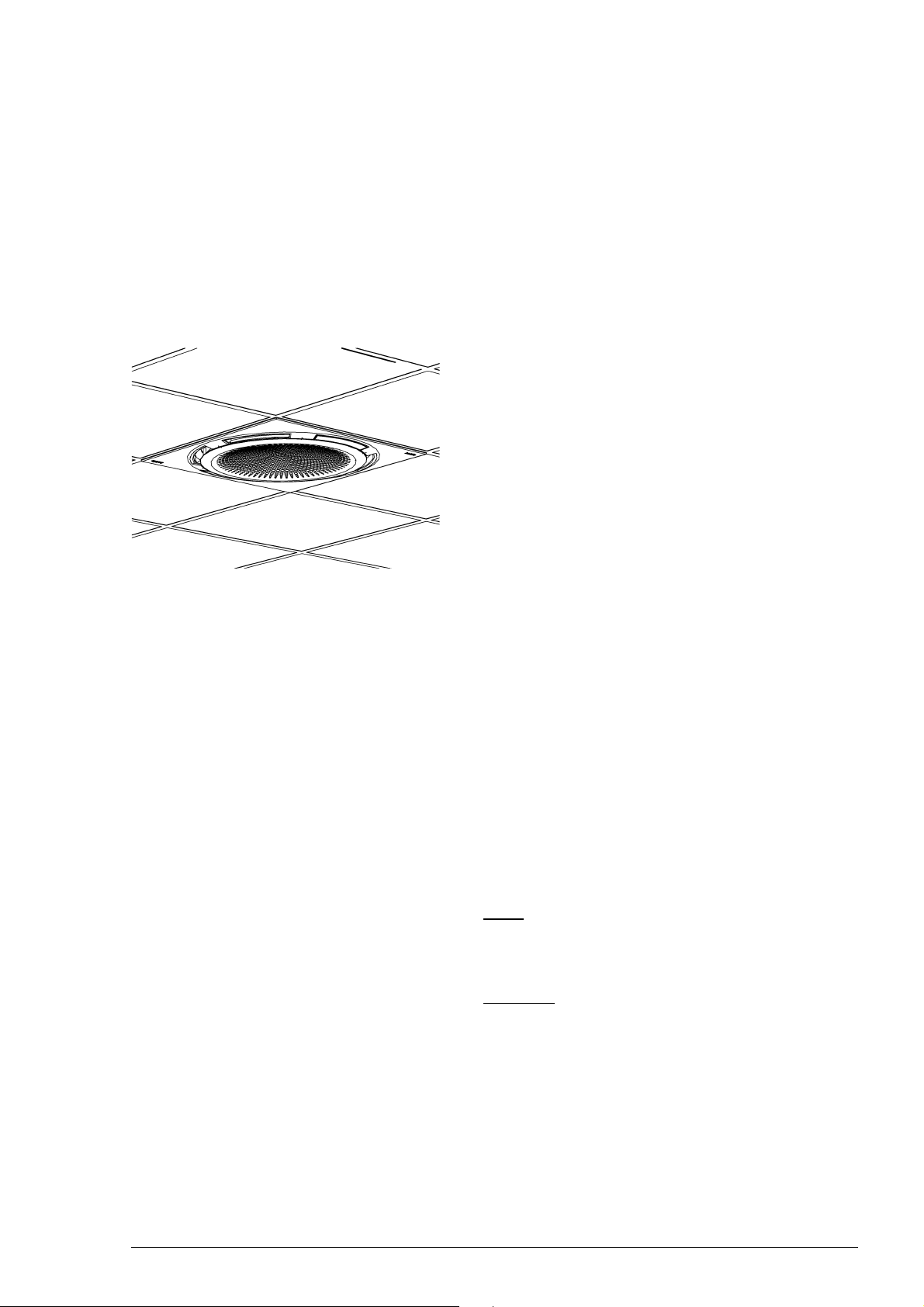

The model is designed for integration into suspended ceilings

but can be used in other ceilings as well. The unit is designed

to be mounted at a height of 2.0 to 3.5 m (from floor to dis-

charge grille).

The recirculation unit draws air from the room, heats or cools

it, and blows it back into the room.

The ventilation unit draws air from elsewhere, heats it, and

blows it into the room. This may be either unconditioned out-

side air or preconditioned air supplied by an A/C system. The

ventilation unit is available in two models: air intake from a

side, and air intake from above.

1.3.2 Working

The Comfort Circle blows out a flow of heated or cooled air,

creating a comfortable climate in the room.

The units that can both heat and cool have automatic dis-

charge angle control, which determines the discharge angle

based on the mode (cooling or heating). The other units have

a fixed discharge angle setting.

The units that can cool come standard with an integrated con-

densate draining pump.

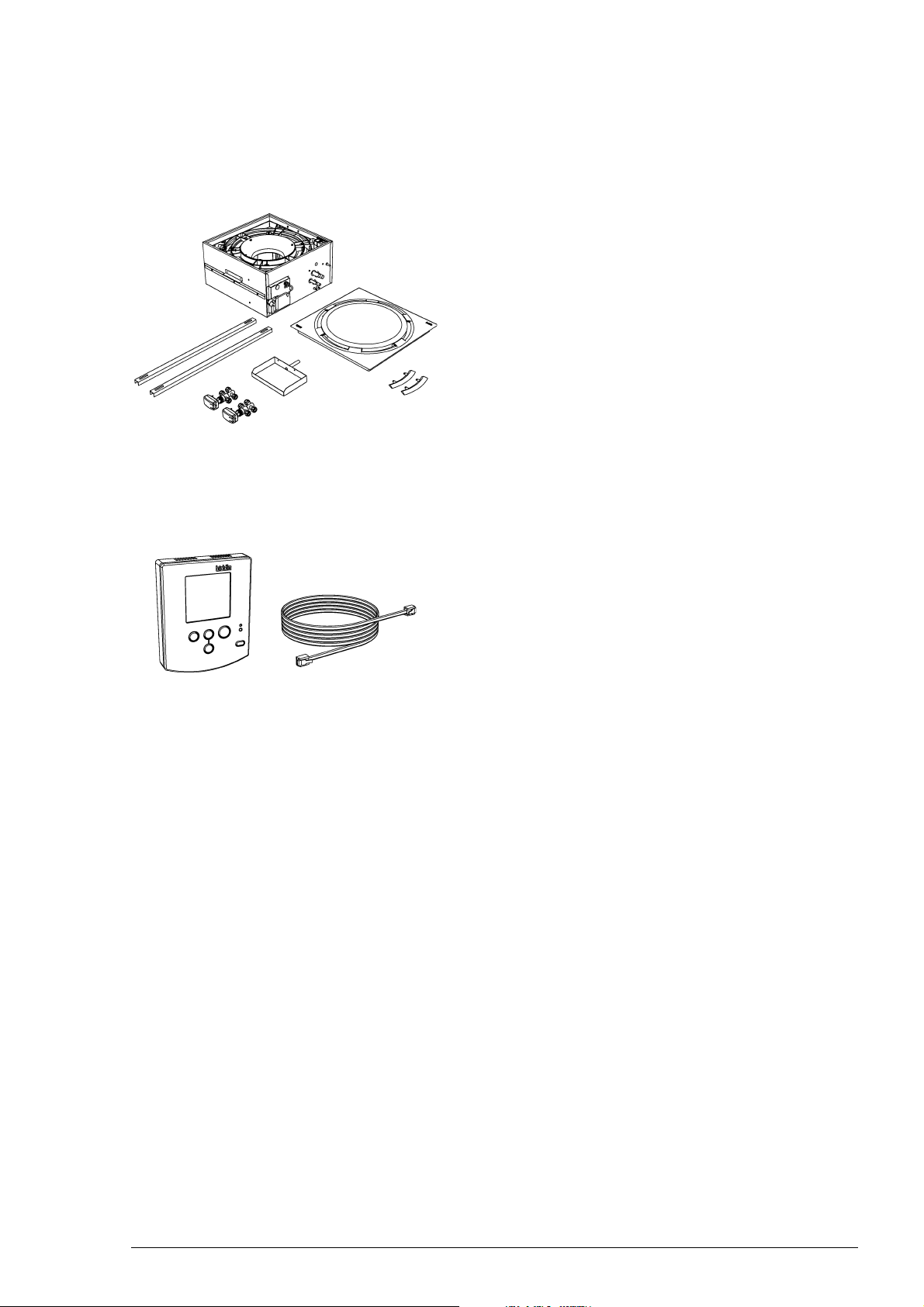

The unit can be delivered with two types of control: a modu-

lating control and an On/Off control. The modulating control

controls both the fan speed and the discharge temperature to

reach the desired room temperature. The On/Off control

controls only the fan speed to achieve this goal. The ventila-

tion units come with modulating control only.

1.3.3 Models and type references

Table 1-2 provides an overview of available models of the

Comfort Circle and corresponding type references. Com-

bined, the type references constitute the type code, for

instance, CC 90-H2-M1.

CC V-H

CC V-V