BIDELI BD-06WT/NT User manual

Instruction manual

Model: BD-06WT/NT

Name:6KG Coffee Roaster

GAS

P1

Thank you for choosing Guangzhou Bide General Equipment

Co., Ltd.! and we thank you for the trust and openness that has

shown us.

Before starting the machine, we recommend you read carefully

the instruction that explain how the use, clean and maintain the

machine. We remain at your disposal for any information.

IMPORTANT : The warranty is one year from the day you

purchase the roster. During the warranty, if the roster breaks

down during normal operation, our company will response for

repairs of the roster for free.

Under the circumstances below, we don’t offer free repair

during warranty.

1.The damage by fire, earthquake, flood, typhoon, lightning,

other natural disasters, Abnormal voltage, pollution,

and .chemical erosion.

2.The damage by using the roster under rugged environment

( Fumes, dust, moisture, outdoor, etc), or unfollowing the

instruction.

3.The damage by improper installation of power and gas.

4.The damage by falling, transformation, collision, self

dismantling repair, etc.

5.The damage by replacement of counterfeited parts and

components, or cleaning machine in a wrong way.

P2

Warranty Instruction

Model NO.

BD-06WT/NT(Gas)

Roasting Type

Semi-hot blast &Half Direct Fire

Heating Type

LPG or Natural Gas

Power

1600W

Roasting Time

10-15mins

Weight

615KG

Votage&Frequency

Single phase AC 220V 50-60Hz

Outside Dimension

2200*1300*2200mm

Roasting Capacity

3-6kg / Batch

Drum Rotation Speed

55-65 circles (61circles/min)-standard

Drum Power

0.37KW

Cooling Mix Rate

10.8 circles/min

Cooling Mix Power

0.12KW

Exhaust Motor Power

0.55KW

Exhaust Pipe Diameter

Φ100mm

Cooling Motor Power

1.1KW

Cooling Pipe Diameter

Φ102mm

Package Dimension

2020 * 1120 * 1830 mm

Package Weight

720KG

P3

Catalog

1. Device Information

(1)The purpose of the equipment

(2)The features of the equipment

2. Safety matters

(1)General safety information

(2)Safety tags

(3)Safety device

3. installation

(1)transportation

(2)Check before installation

(3)The installation

4. equipment usage profile

(1)General requirements

(2)Equipment structure

(3)Operation method

(4)Baking method

5. Cleaning and maintenance

(1)Clean up the parts

(2)Daily maintenance

6.remedy of the trouble

P4

1.Device Information

(1)Device Uses

uThis device is specialized in batch green coffee bean.

uindoor Use

(If use at outdoor , it could cause failure baking, machine failure, accident)

uCan not be used in batch other thing except green coffee bean.

(2)Device feature

uSemi-direct fire and semi-blast coffee roasting machines utilized the design of

Double drum, double insulation shell and stable radiant heat and rich hot to

puffed the coffee bean.

u High thermal efficiency utilized could made deep roaster within 15 minutes as

well as keep the inherent taste and aroma.

uUsing an exhaust valve to control the displacement, you can bake their own

unique flavor.

uUsing high-power fan for fast cooling, cooling time is about 2 minutes.

uEquip with a safety control system, if the machine reaches the set

temperature the machine automatically stop heating. After the temperature

dropped 10 ℃ (could change according to the customer requirements), continue

automatic heating . It allows devices to maintain a constant temperature.

P5

2.Safety Precautions

(1)General safety information

uWhen using the device with a good protection gloves

uWhen a device fails, turn off the power and gas supply equipment, do not

use.

uEquipment must be used with single-phase 220V power supply ground wire,

Do not turn on the power if there is no ground wire

uBefore release the coffee beans, remember to start cooling stirring, open

cooling damper then cooked beans could be putted out, in order to avoid

making the stainless steel of the cooling tray damage variants.

uIn the cooling coil mixing process, can not put your hand on the position of

stirring blade rotation .

uWithin the drum during rotation, can not put hand inner of the drum after

the release coffee bean’s door opened.

uAfter the device is heated, the body shell, the surrounding of perspective

window, the hopper base, semi-cylindrical part of the dust, and all of the

exhaust pipe has a high temperature, can not touch or use a cloth to clean,

to avoid burns.

uWhen checking or cleaning the equipment, you must cut off the power and

gas supply.

uInside and around the machine Do not store flammable.

uPower lines and gas pipes do not touch the hot surface of the machine.

P6

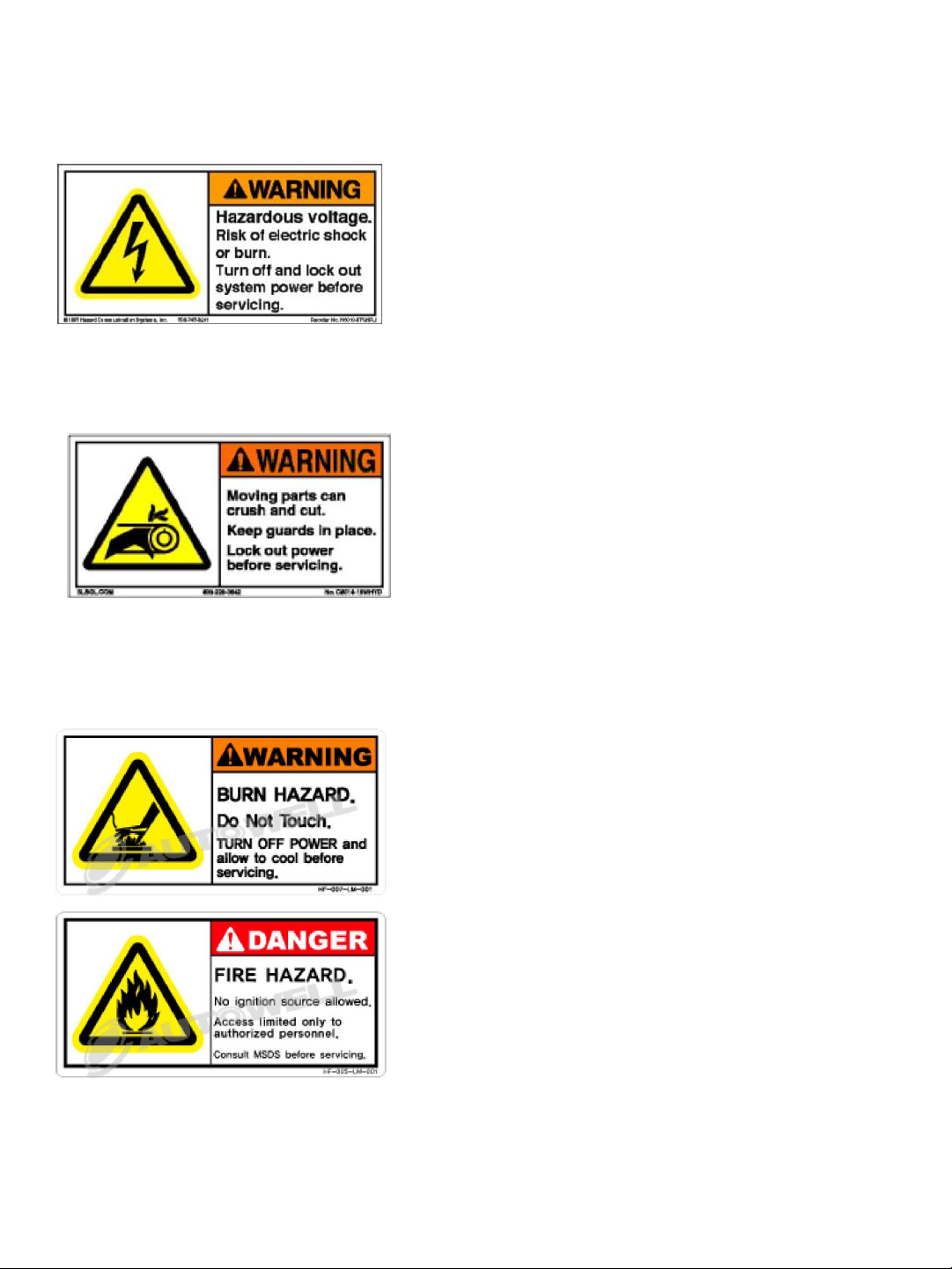

(2) Security tag

1)Be careful of electric shock

This label indicates electrical shock caution.

We must cut off the power if there exists any

hazard of fire injury or electric shock or fire injury

hazard exists before use.

2)Drive parts

This label indicates Note Drive site.

It will occur injuries at the part of drive. Please

add the safety device when using it and turn on

the power switch

3) Caution burns

This is a careful burns flag.

Due to surface hot, do not touch.

4)Note Fire

This is the note that fire signs.

Attention of electric safty and gas leak.

Do not store combustible materials around here.

P7

(3) Safety devices

1) Driving wheel cover

uEquipt the protective cover on the drive wheel configured at the place of

drum and Distribution Box

uthe protective cover can not be opened when the machine using

2) Prevent overheating device (factory set to 250 ° C)

uWhen the drum temperature reaches the set temperature, the machine

automatically stops heating, gas type baking will stop gas supply. Drop by 10

℃, it will automatically resume heating, gas type baking opportunity to

restore the gas supply and automatic ignition.

3) Prevent electric leakage devices

uThe machine cut off the power automatically when the short circuit and

leakage and other electrical anomalies

3. Installation

(1) Transport

1) Package

u The use of wooden packaging, after removed the packaging, in accordance

with local state regulations, recycling or disposal.

uconfirm roaster dust collector, simple chimney, manual, random tools

2) Transport

uWeight about 615kg

uusing trolleys on the ground.

P8

(2)Pre-installation check

1)Check Item

uPower supply and plug

Using ordinary GB three-pin plug.

u Gas Pressure

Using the household low-pressure liquefied petroleum gas

u Exhaust conditions

Selecting the location of the exhaust pipe where less bends. ,if not use the existing

ventilation facilities, according to the size of the exhaust pipe to decide the

location of the hole

3) Preparation before installation roaster

1) Equipment Placement

uBaking machine placed on the flat ground.

2) Exhaust duct

uThis baking equipment must be placed in a dry, well-ventilated place away

from short exhaust, ventilation ducts should not be shared with other food

machines, if used central ventilation facilities, it will cause the exhaust changes

baked

uMust have ventilation or window within one meter radius of the machine, if

ventilation is not good, it will happen worker poisoning, suffocation and other

accidents

uThis device uses the exhaust pipe at Φ102mm.

P9

P10

3)Connection method

uInsert the three-pin plug in household tripod socket with ground.

uGas hose connection: use dedicated gas hose(diameter Ø9mm), one end links

to roasting machine on the back of the trachea joints, air supply valve at the

other end, joint with pipe hoop banding. Gas hose mustn’t place on the

machine, skim the shell or through the bottom of the machine. Rigid bending

is not allowed either.

uLiquified petroleum gas pot must be with qualified pressure reducing

valve(rated pressure: 2800KPA), the distance between roaster and gas pot

shouldn’t less than 100cm, and the advisable hose length is 100 cm to 150

cm.

uConnected with natural gas, maximum is less than 1.2KPA), the distance

btween roaster and gas should not less than 100cm.

uLeak test: Use soap coated in the pipe joint, open the air supply valve, if

there are air bubbles, it means leak; Close the air supply valve, moderate

tone tight coupling (or nut) to try again, until the rear can be used without

any leakage.

P11

P12

(2)Equipment structure

P13

LED Lamp

Hopper

Hopper Valve

Electrical

Control Box

Vewing Window

Front

Bearing

Adjust

Claff

Collector

Cyclone

Bean

Release

Lever

Cooling Tray

Discharged Bean Switch

Sample Spoon

Control Panel

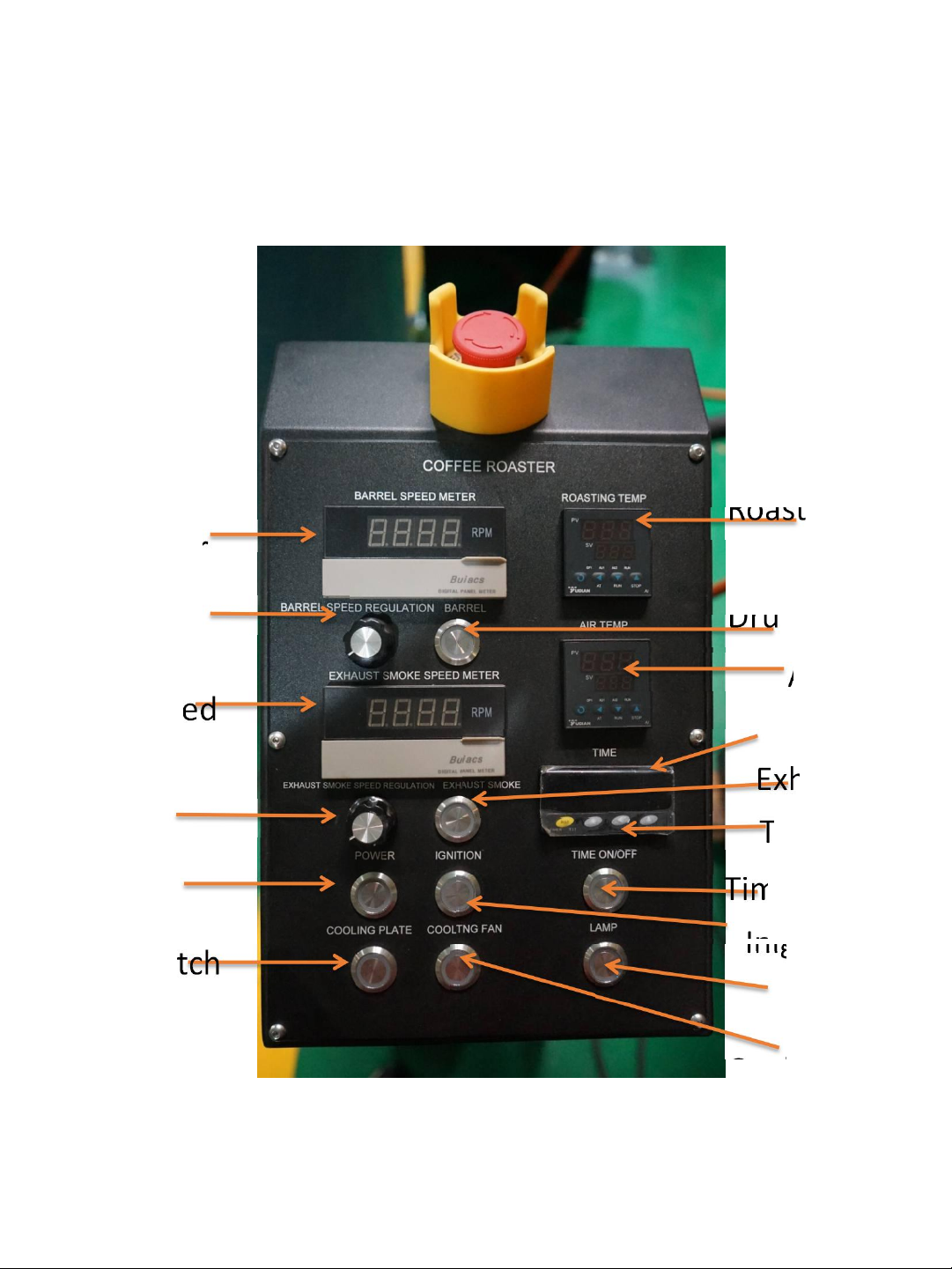

P14

Exhaust speed

meter

Exhaust speed

controller

Drum speed

control meter

Power

Roasting time

Drum Switch

Air Tempe

Timer

Cooling fan

switch

Drum Speed

controller

Cooling Switch

Exhast switch

Timer setting

Timer switch

Inigtion

Lamp

A: Power

Turn on it,the machine will be under the working,the drum will move ,and the

exhaust motor too.

B: Cooling

Turn on the stirring arms will start to stir.

C: Timer

Turn on it,it will start computing time until reach the setting time,the buzzer will

ding ding ding ~~

D: Roasting time

Press the setting key,using shift key and ascending key to preset roasting

time ,press the setting key again, the setting is done.The roasting time will be zero

after pressing the RST .

E: Roasting temperature

Showing the temperature in the drum,it will automatically stop supplying gas

when the temperature reaches setting one,when the temperature reduce 10c,the

machine will supply the gas and fire automatically.

Pressing shift key, down key and up key can set the temperature.

(NOTE:In genera,please do not use the Mode Key,due to the machine has set the

proper parameter .)

F: Hot blast temperature

Showing the hot air temperature before the hot air into the drum.Setting it will

not influence the machine to work.

G: Ignition

Press to turn on “igniter”,and after 5’ ,

electromagnetic valve will connect the gas supply to fire ,and the indicator light

will be lighted.

Press to turn off “stop”,the electromagnetic valve will stop connecting the gas

supply and extinguish, the indicator light will turn off .If firing is unusual , the

igniter buzzer will ding ding ~~.

H:Drum Motor Switch

Turn on it ,then the Drum moves

I:Exhaust Motor Switch

Turn on it ,then the Exhaust Motor works

P15

P16

② Gas Power adjustment guidance

uGas Pressure Adjustment Knob

To left : turn down pressure,

heating power low

To right: turn up pressure,heating

power strong

(4)Roasting operation

1.Making sure the machine is clean and under the normal situation.Turn on

the main power (back of the electric cabinet)

2.Setting the highest roasting temperature on the roasting

thermometer,and the roasting time

(Note:If all of the setting is done when you received machine,and that

setting meets your request on roasting,then no need to do these

steps before every starting on.)

3.Turn on the “operation” switch

Turn on the “start “switch to preheating

(NOTE:”Start”switch Can Not be turn on if the operation switch don’t

be turned on firstly.Or the Drum will be deformed,and the residual

gas will cause the potential danger.)

4.Adjust the exhaust flow at 5 or 6 scale,turn up the power,during the

temperature up to 180℃-190℃,preheating within15-20 minutes,turn

down the power,when the temperature down to 150℃,then start to

roast.

P17

5.Many different ways of roasting,low temperature roasting,high temperature

roasting,the second roasting(Same batch,same beans) ,all of them are up to

the operators.

Such as:Roasting from low to high temperature environment ,this kind way of

roasting.

When the preheated temperature down to150℃,dump the

green beans into drum,adjust the power into half,starting

the low temperature roasting,almost 7-10 minutes to

evaporate the moisture in the green beans slowly and

fully. When you observe the color of beans changed,turn up

the power to rise temperature soon.

(This machine quite works,only can hear the sound of the

beans touch the drum)

when you hear the first crack,observe the beans’ color

through the glass,and take out the beans by samplers to

observe (If you also find there are same chaff and smoke

out from the sample hole,you need to turn up the exhaust

air flow to control that issue),after finishing the first crack,

turn down the power to reduce the speed of rise temperature,

making the beans finish the second crack completely. Then

open the cooling air flow,make sure it is fully open,adjust the

exhaust air flow at 1 scale,turn on the cooling tray arms,

let the roasted beans out,within 3-5minutes cooling,one batch

is done.

6.During the cooling process,you can dump another batch green

beans into the next roasting,just like before what you did to roasting

consecutively.After first roasting,the temperature is high in the drum,the next

roasting process will be finished in the shorter time than first batch.

7.If you keep roasting into 24KG green beans,please turn off the

chaff collector cyclone switch,clean the drawer and put it back

where is should be,then keep enjoy roasting process.

8.If you wanna finish roasting,please DO NOT turn off the main power

of the roasting machine firstly .For the electric type one,firstly turn off

the heating switch,for Gas type one,firstly turn off the gas open

switch,after the temperature down to 80℃,then turn off the power

which is back of the back of the electric cabinet.Then do the clean

job to prepare for next roasting when you want.

P18

5.Cleaning and maintain

a、The roasting total capacity up to 24kg,turn off the chaff collector cyclone

switch,pull out the drawer,clean up the chaff,then put it back to the original

place.Turn on the switch,keep roasting.

b、Clean the chaff collector cyclone when you finish and stop the roasting .

c、Clean the area under the cooling tray,there will collect some coffee beans’

residue,or it will influence the cooling system.Besides that the conveyer belt

and cooling motor also should be clean and adjusted.

d、If the machine working hour up to one month,please loose the screws

which are used to fix exhaust pipe by Allen key ,dismantle the exhaust pipe to

clean,making sure the pipe is clear in side (For exhaust smoke and chaff,keep

the roasted beans flavors)

1)Clean the parts

P19

Broken Beans

and Chaff

Drawer

Cooling Tray

Chaff Collector

Exhaust pipe

a、when the machine working hour up to 150 hours, the bearing (Back or

Front of the roaster )should be added the food grade grease resistant to high

temperatures .Making sure to lubricate the bearing completely,to be durable.

NOTE:When you add the grease,please make sure you have turned off the

power ,and the machine is under the room temperature,do this operation

to avoid harm .

b 、 Loose three screws of the front pedestal cap by Allen key before adding

the grease.Taking out the cap,adding the grease on bearing balls ,making

sure grease is smeared evenly.

2)Daily maintain

P20

hree screws on the

front pedestal cap

Adding the food grade

grease resistant to high

temp.

Table of contents