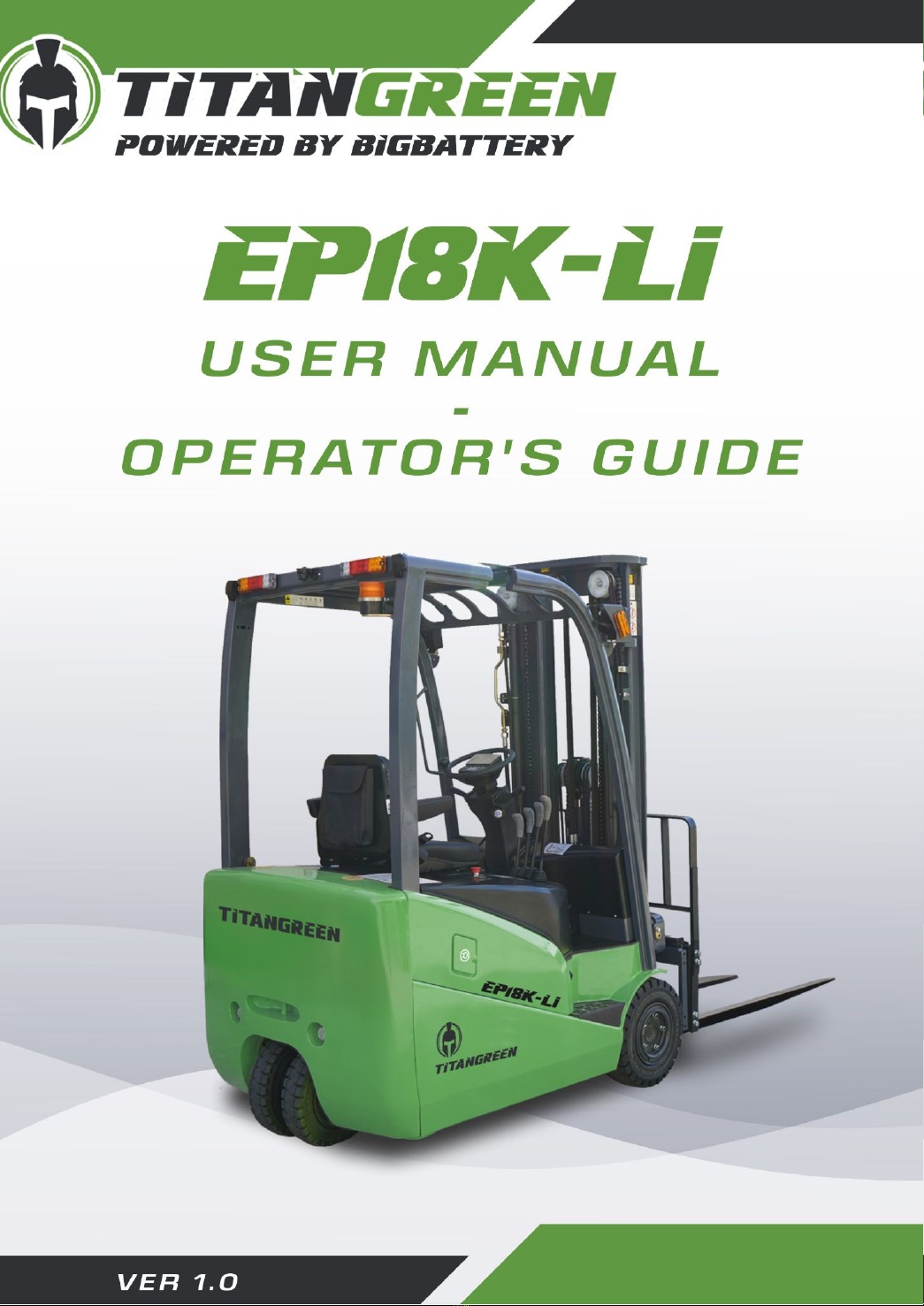

BigBattery TITANGREEN EP18K-Li User manual

Table of Contents

1. External view and technical parameter ..................................................................................... 4

2. Safe driving, operation and maintenance of forklift ................................................................. 6

2.1 Transportation,loading,unloading and lifting of forklifts ................................................... 7

2.1.1 Forklift transportation ...................................................................................................... 7

2.1.2 Forklift loading and unloading ......................................................................................... 7

2.1.3 Lifting of forklifts ............................................................................................................ 7

2.2 Parking of forklifts .............................................................................................................. 8

2.3 Preparation before use ......................................................................................................... 8

2.4 Precautions for safe operation ............................................................................................. 9

2.5 Maintenance of lithium battery forklift ............................................................................. 13

2.5.1 New forklift maintenance .............................................................................................. 13

2.5.2 Starting essentials ........................................................................................................... 13

2.5.3 Maintenance Summary .................................................................................................. 13

2.5.4 Forklift oil and grease .................................................................................................... 15

2.6 Brief operating instructions .............................................................................................. 16

2.6.1 Control mechanism and instrument ............................................................................... 16

2.6.2 Brief description of operation ........................................................................................ 17

2.6.3 Maintenance of control system ...................................................................................... 18

2.6.4 Special reminder ............................................................................................................ 19

2.7 Warning sign ..................................................................................................................... 19

3. Structure, principle, adjustment and maintenance of lithium battery forklift ......................... 25

3.1 drive system ...................................................................................................................... 25

3.1.1 Summary ........................................................................................................................ 25

3.1.2 Removal of drive system ............................................................................................... 27

3.1.3 Installation of transmission system ................................................................................ 28

3.1.4 Addition of gear oil ........................................................................................................ 30

3.2 braking system .................................................................................................................. 31

3.2.1 Summary ........................................................................................................................ 31

3.2.2 Maintenance and adjustment essentials of brake system ............................................... 34

3.3 steering system .................................................................................................................. 35

3.3.1 Summary ........................................................................................................................ 35

3.3.2 Adjustment and maintenance essentials. ........................................................................ 39

4. Electrical system ..................................................................................................................... 41

4.1 Summary ........................................................................................................................... 41

4.2 Instrument ......................................................................................................................... 44

4.2.1 Summary ........................................................................................................................ 44

4.2.2 Instrument interface ....................................................................................................... 44

4.2.3 Instrument instructions ................................................................................................... 45

4.2.4 Instrument working process and instructions ................................................................ 47

4.2.5 Instrument main menu and instructions ......................................................................... 49

4.2.6 matters needing attention ............................................................................................... 54

4.3 Inmotion AC electric control assembly ........................................................................... 55

4.3.1 summary ......................................................................................................................... 55

4.3.2 Controller structure ........................................................................................................ 55

4.3.3 Controller fault code ...................................................................................................... 56

4.4 AC electron accelerator ..................................................................................................... 60

4.4.1 Appearance and port function ........................................................................................ 60

4.4.2 Wiring and port diagram ................................................................................................ 61

5. Inmotion three-phase AC motor .............................................................................................. 61

2

5.1 Summary ........................................................................................................................... 61

5.2 Operating environmental conditions ................................................................................. 62

5.3 Routine inspection and maintenance of AC motor ........................................................... 62

6. Lithium battery and charger .................................................................................................... 62

6.1 Use and maintenance of lithium battery ............................................................................ 62

6.1.1 Instructions for use of lithium battery ............................................................................ 62

6.1.2 Charging steps and precautions of lithium battery ......................................................... 63

6.1.3 Lithium battery storage ................................................................................................... 65

6.1.4 Treatment of lithium battery ........................................................................................... 65

6.1.5 Lithium battery safety precautions ................................................................................. 65

6.1.6 Lithium battery maintenance .......................................................................................... 66

6.2 Charger .............................................................................................................................. 67

6.2.1 Use of charger and charging method .............................................................................. 67

7. Hydraulic system ..................................................................................................................... 68

7.1 Summary ........................................................................................................................... 68

7.1.1 Oil pump ........................................................................................................................ 69

7.1.2 Multiway valve .............................................................................................................. 69

7.1.3 Lifting cylinder .............................................................................................................. 76

7.1.4 Speed limiting valve ...................................................................................................... 79

7.1.5 Tilt cylinder (Fig. 7-17) ................................................................................................. 80

7.1.6 Hydraulic oil tank .......................................................................................................... 81

7.1.7 Hydraulic system schematic diagram ............................................................................ 82

7.2 Maintenance and adjustment of hydraulic system ............................................................ 82

7.2.1 Maintenance of hydraulic oil pump ............................................................................... 82

7.2.2 fault diagnosis ................................................................................................................ 86

8.Mast system .............................................................................................................................. 87

8.1 Summary ........................................................................................................................... 87

8.1.1 Internal and external mast(Fig. 8-1) ............................................................................... 88

8.1.2 Fork carriage .................................................................................................................. 89

8.1.3 Fork locating pin ............................................................................................................ 90

8.1.4 Roller position ................................................................................................................ 90

8.2 Maintenance and adjustment of gantry system ................................................................. 90

8.2.1 Lifting cylinder adjustment ............................................................................................ 90

8.2.2 Height adjustment of fork rack ...................................................................................... 91

8.2.3 Replace the fork carrier roller ........................................................................................ 91

8.2.4 Replace the gantry roller (Fig. 8-8) ................................................................................ 92

3

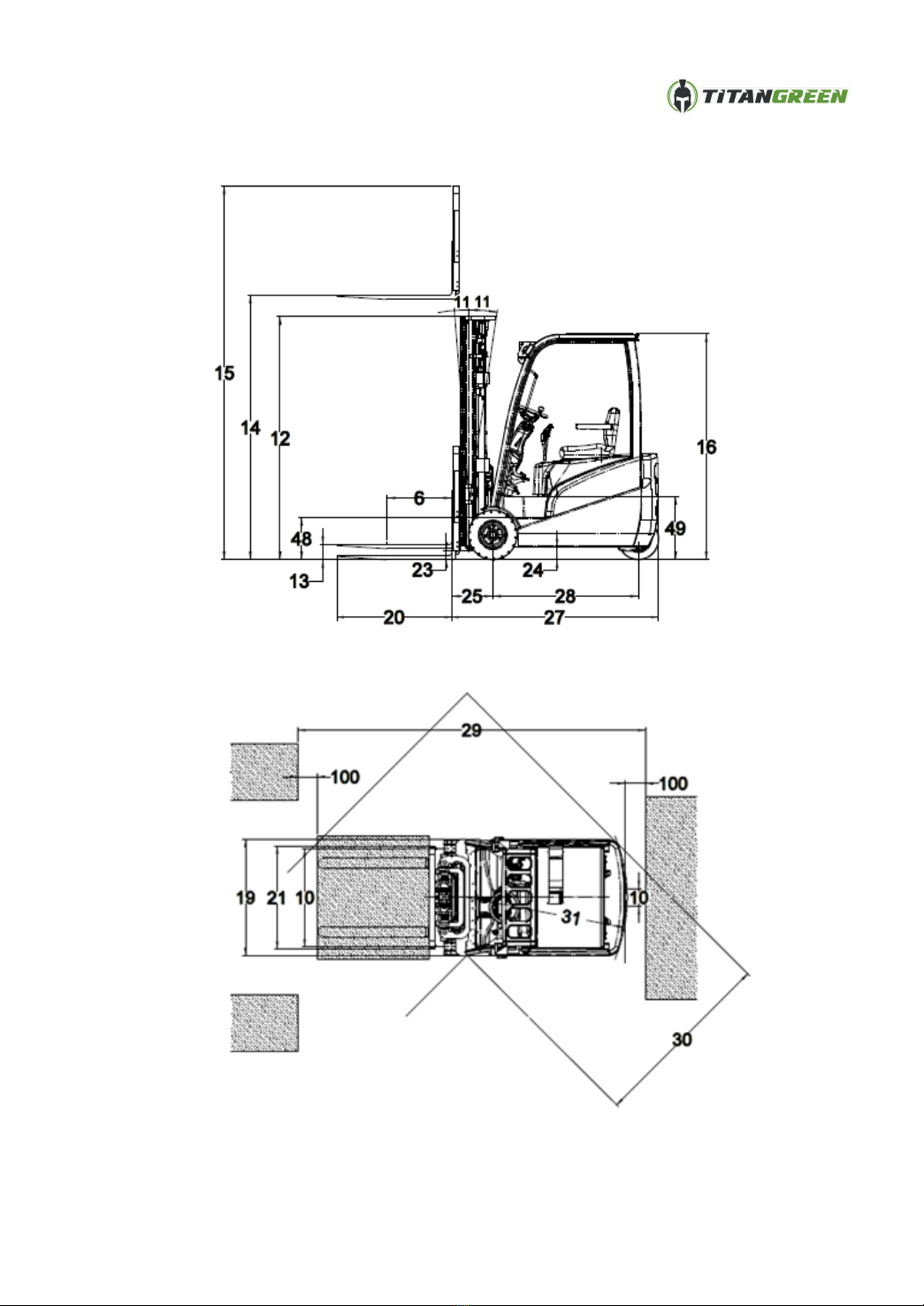

1. External view and technical parameter

Outline drawing of three-wheel lithium battery forklift

4

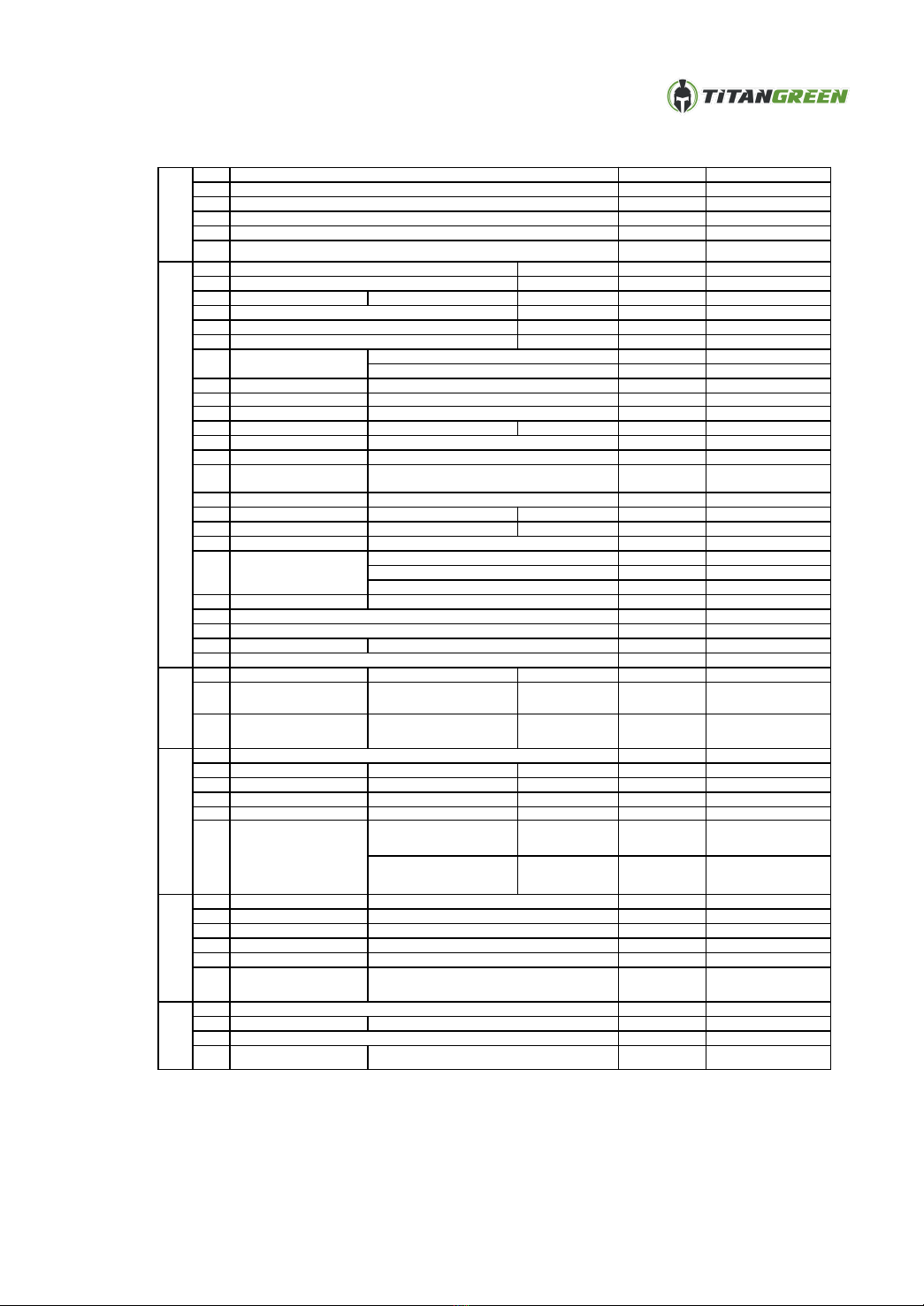

Performance parameters of three-wheel lithium battery forklift

G

E

N

E

R

A

L

1

Manufacturer

TITANGREEN

2

Model designation

1.8T

3

Power

Electric

4

Operation

Sit

5

Rated capacity

lb(kg)

3968(1800)

6

Load center

in(mm)

24(610)

D

I

M

E

N

S

I

O

N

S

7

Tire type-cushion, solid, pneumatic, etc.

Drive/steer

solid/solid

8

Tire size

Drive/steer

in

18X7-8/15×4.5-8

9

Wheels - number

X=driven

Drive/steer

2X/2

10

Tread

Tires Std dr/steer

in(mm)

37.8/7(960/178)

11

Mast tilt

Std

degrees

3.5F/5B

12

Mast - lowered height

Std mast

in(mm)

87(2220)

13

Free lift - top of fork

Std 2 stg limited free lift mast

in(mm)

5(140)

Opt 2 stg full free lift mast with/without LBR

in(mm)

39/58(990/1475)

14

Lift height - top of fork

Std 2 stg limited free lift mast

in(mm)

118(3000)

15

Mast - extended height

Std mast with / without LBR

in(mm)

157/137(3995/3490)

16

Overhead guard height

Std/drive in rack/opt/opt flat plate

in(mm)

81.4(2070)

17

Sip to bottom std ohg

Susp at mid-point

Std/susp/swivel

in(mm)

39.4(1000)

18

Tow pin height

Vertical center of pin

in(mm)

19.9(505)

19

Overall width

Standard tread

in(mm)

44.4(1130)

20

Forks

Thickness x width x length

in(mm)

1.6x3.9x42(40×100×1

070)

21

Standard carriage width

Class II

in(mm)

39.7(1008)

23

Ground clearance

Lowest point

NL/RL

in(mm)

3.3/3.1(85/80)

24

Ground clearance

Center of truck

NL/RL

in(mm)

4.3/3.9(110/100)

25

Load distance

Center of wheel to face of forks

in(mm)

15.1(384)

26

Battery compartment

Height

in(mm)

22(560)

Width

in(mm)

31.5(800)

Length

in(mm)

16.5(420)

27

Length to face of forks

Chassis length

in(mm)

75.9(1927)

28

Wheelbase

in(mm)

53.5(1360)

29

Right angle stack

in(mm)

125.9(3197)

30

Equal aisle

90˚ Intersecting aisle

in(mm)

73.6(1870)

31

Outside turning radius

in(mm)

61.4(1560)

W

E

I

G

H

T

32

Truck weight

Without battery (NL)

NL

lb(kg)

6797(3083)

33

Axle loading-drive

Static with max. wt. battery

NL/RL

lb(kg)

3284/10141

(1490/4600)

34

Axle loading-steer

Static with max. wt. battery

NL/RL

lb(kg)

3836/948 (1740/430)

P

E

R

F

O

R

M

A

N

C

E

35

Voltage

51.2

36

Travel speed

Extended shift off

NL/RL

mph(km/h)

9.32/8.39(15/13.5)

37

Lift speed

Std 3 stg FFL mast

NL/RL

ft/min(m/sec)

83/69(0.42/0.35)

38

Lower speed

Std 3 stg FFL mast

NL/RL

ft/min(m/sec)

69/79(0.35/0.40)

39

Gradeability

5 Minute rating

NL/RL

ft/min(m/sec)

24/18

41

Brake

Method of control

Service/parking

ft/min(m/sec)

Hydraulic/mechanical

Method of operation

Service/parking

ft/min(m/sec)

Foot/foot

E

L

E

C

T

R

I

C

42

Battery

Type

lithium-ion

43

Traction motor

60 Minute rating

hp(kW)

8.8(6.5)

44

Pump motor

15% Rating

hp(kW)

20(15)

45

Traction motor

Type/control method

AC/transistor

46

Pump motor

Type/control method

AC/transistor

47

Number of speeds

Traction/pump

Infinitely variable

/ infinitely variable

O

T

H

E

R

48

Step height

in(mm)

15.2(386)

49

Floor height

Lowest point

in(mm)

22.8(580)

50

Attachment relief pressure(mech levers/mini-levers)

psi(bar)

2540/2320(175/160)

51

Sound level

Measured per ANSI B56.11.5

dB(A)

70

5

2. Safe driving, operation and maintenance of forklift

Forklift drivers and managers must remember "safety first". Before the first operation, please

carefully read the Operation and Maintenance Manual, which will enable you to fully

understand our forklift and operate it correctly and safely.

2.1 Transportation,loading,unloading and lifting of forklifts

2.1.1 Forklift transportation

(1)When the forklift is transported by container or truck, the parking brake pedal shall

be pressed after the forklift is parked in place

( 2 ) Fix the mast and the balance weight with steel wire and use jacks to prevent the

forklift trucks from moving in the container.

(3)Pay attention to the overall length, width, height when loading, unloading and shipping

and conforming the regulations is necessary.

(4)If necessary, the working device can be disassembled and transported separately.

2.1.2 Forklift loading and unloading

(1)Use the plate with enough length, width and strength.

(2)Pull the parking brake and use jacks to stop the wheel.

(3)Fasten the plate on the center of the cabin, there must be no grease on the plate.

( 4 ) The left and right height of the plate must be equal to make the loading and

unloading smooth.

(5)Don’t change the direction on the plate to prevent the danger.

(6)Reverse the forklift slowly when loading it on the freight car.

2.1.3 Lifting of forklifts

(1)Only the specially trained personnel can sling the truck.

(2)Sling points should always be at the positions specified in sling nameplate.

(3)The slinging cable must be enough to hang the forklift truck.

(4)Disassembled parts of the forklift truck must be slung in the appointed position.

Model

Mast

Dimensions(mm)

Weight(kg)

1.8T

2100×1088×393

700

6

Notice:

Dismantling and slinging the component shall not be performed without the

approval of our company. Under special circumstances, the appointed sling

position should be used. The balance weight, fork and mast of the forklift

truck all have their appointed sling position.The above weights are for

reference only and may be adjusted due to different counterweights or

technical optimization.

2.2 Parking of forklifts

(1)The mast is lowered to the lowest position.

( 2 ) Turn left the key switch and press the emergency stop switch, place all control

levers in the empty position, and unplug the power plug.

(3)Tighten the handbrake lever.

(4)Chock the front and rear tires.

( 5 ) When the forklift is out of service for a long time, the wheels should be overhead.

Before long-term storage, confirm that the power of the battery system is not less than 50% and

not more than 80%, and charge and maintain it every two months. After storage for more than

two months, please confirm whether the power battery system has a fault alarm before reuse).

( 6 ) Forklifts shall be stored in a dry and ventilated environment away from heat sources as

far as possible after long-term shutdown.

2.3 Preparation before use

(

1)Check whether all instruments are normal.

(2)Check tire wear.

(3)Check all handles and pedals.

( 4 ) (Before using the vehicle for the first time, it needs to be charged to 100% before

use. After the vehicle is powered on, confirm that there is no battery system alarm message on

the instrument panel. Please check the remaining power before use. It is recommended that the

SOC be used between 50% and 100%. If the SOC is less than 15%, it is not recommended to

continue to use. Please charge as soon as possible.).

(5)Check whether the battery and vehicle power line connectors and signal line connectors

are reliable.

7

(6)Check the hydraulic oil and brake fluid for leakage.

(7)Check the tightness of the main fasteners.

(8)Check whether the lighting and signal are normal.

(9)Release the parking brake.

( 10 ) Carry out the trial operation of mast lifting, forward and backward tilting, forklift

steering and braking.

(11)The contamination degree of hydraulic oil is not greater than Grade 12.

2.4 Precautions for safe operation

( 1 ) Forklift belongs to special equipment. Only drivers who have passed the training

and examination and hold the driving license can drive; The maintenance of the forklift should

also be carried out by trained and qualified personnel to ensure the normal use of the forklift.

(2)Wear the safety guards, such as clothing, shoes, helmet and gloves while

operating the truck.

( 3 ) When the center of gravity of the goods is 600mm from the front wall of the vertical

section of the fork, the maximum load is the rated lifting weight, and the load should not

exceed the specified value during handling. If the center of gravity of the goods is more than

600mm from the front wall of the vertical section of the fork, the lifting capacity shall be

reduced according to the value specified in the load curve, and overloading is strictly

prohibited.

(

4)Operate your forklift truck on hard ground. Operate on other ground, the lift

capacity and travel speed must be decreased. Wipe off the oil and grease from the floor.

( 5 ) Daily maintenance should be done before or after using the truck. Anytime you find

that the truck is not functioning normally, operation of the truck should be halted and checked

or repaired at once.

(6)When operating one lever, pay attention not to shift another lever. Don’t operate

the lever at any position out of the driver’s seat.

(7)Don’t handle unfixed or loose goods. Be careful to handle bulky goods. To

prevent the collapse of stacked goods, tighten them. Forbid loading loose or little

volume goods without pallets.

( 8 ) Forklifts with accessories specially ordered by users can make their use more

extensive. However, the forklift with attachments will reduce the payload and stability of the

forklift. Do not use the accessories and special devices for other purposes. Please read the

8

additional instructions we provide for you and use them strictly according to the requirements.

Users are not allowed to modify without permission.

( 9 ) Do not use a fork to pull the embedded object (if necessary, the pulling force shall

be calculated first).

(

10

)

When loading goods, the distance between forks shall be adjusted according to the

size of the goods, and the weight of the goods shall be equally shared by the two forks, so as to

prevent the goods from slipping to one side during eccentric loading or driving; It is prohibited

to pick up goods with a single fork.

( 11 ) When carrying large volume goods, the goods block the driver's sight, and the

forklift should be driven in reverse.

( 12 ) When loading goods, put the fork to the bottom. After the fork is inserted into the

cargo pile, the front wall of the vertical section of the fork should be in contact with the goods,

and then the gantry should be tilted back to the limit position, and the fork should be lifted 200

mm - 300 mm from the ground before driving

( 13 ) When lifting or lowering goods, no one is allowed under the lifting frame; It is

forbidden to lift people with a fork.

(14)When loading and unloading goods, keep the mast vertical and the truck is in

braking state.

(15)Because the forklift truck turns by the rear wheels, the end counterweight may

swing widely when turning. Use care in narrow aisles and other workplaces.

( 16 ) During operation, pay attention to the performance and condition of the system of

machinery, hydraulic, electric and speed-adjuster etc.

(

17 ) Turn on the power, step on the brake, press the one-button start switch, select the

position of the direction switch, turn the steering wheel to see if the vehicle turns normally, and

slowly step on the accelerator pedal to maintain the proper starting acceleration.

(

18 ) Pay attention to observe the SOC. When the forklift is working, if the SOC power

is lower than 15%, it is recommended to stop the operation as soon as possible, charge the

lithium battery or replace the lithium battery with sufficient power. If the SOC power is lower

than 10%, the forklift will be forced to operate with reduced power for the protection of the

battery. At this time, it is necessary to go to the charger immediately for charging.

(

19) The speed of cargo lifting or lowering can be controlled by the number of

movements of the operating handle of the multi way directional valve. The initial speed of

9

cargo lifting or lowering should not be too fast.

( 20 ) Before tilting the mast forward and backward, the forklift shall be braked, and

shall tilt slowly when tilting forward to prevent the goods from slipping out suddenly.

(

21 ) Tilt the mast of the high lift forklift truck as backward as possible when operating

the truck. Use minimum forward and backward tilt when loading and unloading. It is dangerous

to travel or turn when lifting the goods at high levels.

(22) It is noted that the goods will fall down when the forks of the truck with lifting

height more than 3m lift, take the protection measures if necessary.

( 23 ) The overhead guard is the main part which is strong enough to meet safety

standards, and protect the operator from falling materials. It’s very dangerous to dismantle or

rebuild the overhead guard, because these conditions could lead to an accident.

(24) The shelf is a safety part. When the goods are stacked high on the fork and the

gantry is tilted backward, the goods shall be prevented from sliding backward to avoid personal

injury to the driver.

(25) The height of loading and unloading shall be limited to the height of the shelf. If

the height of the goods exceeds the shelf, it is easy to cause the goods to slide to the operator,

which will lead to serious accidents.

( 26 ) During outdoor operation, the wind has a great impact on the stability of the

forklift, so please pay special attention.

(27)When driving on the wharf or temporary planking, be careful and drive slowly.

( 28 ) When carrying goods, do not tilt the mast forward, do not load or unload, and do

not brake to prevent the goods from slipping out.

( 29 ) Forklifts should drive into the cargo pile at a low speed, and pay attention to

whether there are protruding hard objects near the cargo to avoid puncturing the tires.

( 30 ) When driving, pay attention to pedestrians, obstacles and potholes, and pay

attention to the clearance above the forklift.

( 31 ) When the forklift is running, the handle, foot and other parts of the body are not

allowed to extend out of the cab, and the vehicle is not allowed to carry people.

( 32 ) Drive carefully on the ramp, and do not turn, drive laterally or diagonally,

otherwise the forklift may roll over; When carrying goods on a large ramp, drive forward when

going uphill and backward when going downhill; Please use foot brake when going downhill

and drive carefully; When driving on the ramp, it is prohibited to slide in neutral gear and use

the emergency stop button carefully.

10

( 33 ) Start, turn, drive, brake and stop carefully, especially when turning on wet or

smooth roads.

( 34 ) It is forbidden to suddenly start, accelerate, stop and turn the forklift. Improper

operation may cause the forklift to roll over. If this happens, the driver should keep calm and

avoid jumping. He should hold the steering wheel with both hands and lean to the opposite

direction of the forklift.

(35)Forklifts with attachments shall be operated as loaded forklifts when empty.

(

36 ) During the use of the chain, it should be checked regularly to ensure that there are

good lubrication conditions between the chain links, and the tightness of the left and right

chains is consistent; If the chain is worn during use, and the change value of the chain pitch

exceeds 2% of the standard value, the chain must be replaced to ensure safe loading.

( 37 ) Before the forklift is safely decelerated and stopped, the reverse gear cannot be

engaged to ensure the driver's safety.

(38)When the forklift is running with load, emergency braking shall be avoided.

( 39 ) When leaving the vehicle, lower the fork to the ground, place the shift handle in

neutral, and disconnect the power supply. When parking on the ramp, pull the parking brake or

step down the parking brake. If the parking time is long, chock the wheels.

( 40 ) When the mast is tilted forward or backward to the limit position or the fork is

lifted to the maximum height, the handle must quickly return to the middle position.

( 41 ) The pressure of the multi way valve and safety valve of the forklift has been

adjusted before leaving the factory. Users should not adjust them randomly during use to avoid

damage to the entire hydraulic system and hydraulic components due to excessive pressure

adjustment.

(

42 ) During the operation of the forklift, additional noise values may be added due to

different operations and the impact of the external environment, which may lead to higher or

lower noise values.

( 43 ) The driver will feel the vibration of the forklift when operating and driving. The

total vibration value of the double arms transmitted by the forklift to the operator shall not

exceed 1.3m/s2, but the vibration frequency characteristics of the human body depend on the

working conditions (such as road conditions, operation methods, etc.), so the actual vibration

frequency characteristics are determined by the site conditions when necessary.

( 44 ) In order to handle super wide goods, users can choose "lengthened fork", but it is

worth noting that the bearing capacity of the lengthened fork should work strictly according to

11

the requirements of the load curve. Within the specified load center, its bearing capacity is the

same as that of the standard fork. When the load center moves forward, the load must be

lowered; It is strictly forbidden to lift or hit the goods with the fork tip. Pay special attention to

safety when driving or turning.

(

45 ) Be familiar with and pay attention to the functions of various signs on the forklift,

and timely subsidize if lost.

( 46 ) Forklifts are generally used in an environment below 1000m above sea level, with

a temperature of 5℉-104℉ ( - 15 ℃ - 40 ℃) and a relative humidity of 95%; Use with

caution in other harsh environments.

(

47 ) In order to prevent fire, accident or other unpredictable events, fire extinguishers

shall be set in advance and operated according to the use requirements of fire extinguishers.

( 48 ) Without the written approval of our company, it is not allowed to modify the

forklift or add any working device, otherwise the rated load or safe operation may be affected.

(49)Pay special attention to safety during high maintenance.

2.5 Maintenance of lithium battery forklift

In the process of using the forklift, careful operation, reasonable use, regular inspection

and maintenance must be carried out to keep the forklift in good working condition for a long

time.

2.5.1 New forklift maintenance

The performance and service life of the forklift are closely related to the maintenance of

the new car in the running period. During the running in period, special attention shall be paid

to:

The gear oil in the differential or reducer shall be replaced after the first 1000 hours of

operation of the new forklift, and all fasteners shall be re-tightened after replacement.

2.5.2 Starting essentials

( 1 ) Oil volume of hydraulic oil: the oil level shall be in the middle of the oil level gauge

scale.

(

2 )Check the pipes, joints, pumps and valves for leaks and damage.

( 3 ) Check the service brake: the idle stroke of the brake pedal shall be 5mm. When the

brake is effective, the gap between the front floor and the pedal shall be greater than 20mm.

( 4 ) Check the parking brake function: when the parking brake is fully depressed, it should be

stopped on the specified ramp (no load).

12

( 5 ) Instruments and lighting fixtures: check whether the instruments, lighting,

connectors, switches and electrical circuits work normally.

2.5.3 Maintenance Summary

(1)Forklifts need to replace some key safety parts regularly. Please use our pure parts.

(2)The same type of oil must be used when replacing or refueling.

(

3 ) When the forklift is found to be damaged or faulty, stop operating the forklift and

inform the qualified maintenance personnel of the forklift's condition in time. Do not operate

the forklift until it has been thoroughly overhauled.

( 4 ) The motor, electric control and lithium battery shall be maintained according to the

provisions of their instructions.

(5)All connectors shall be checked once a month.

( 6 ) Pay attention to the waterproofing of the forklift and avoid washing with the

high-pressure water gun.

( 7 ) The surface of the lithium battery shall be kept clean and dry, and dirt shall be

removed frequently.

( 8 ) After normal use, the forklift shall be regularly maintained according to the table

below.

No

Item

Maintenance content

Maintenance intervals

Note

1

Steering wheel bearing

Replace grease

1200 hours

2

Foot brake pin

Add grease

200 hours

3

Reduction gearbox

Replace gear oil

1000 hours

4

brake fluid

Add/replace

Anytime/1200 hours

5

Tilt cylinder pin

Add lubricating

grease

400 hours

6

Hydraulic tank and screen

clean

1000 hours

7

Hydraulic oil tank and

filter

Clean or replace the

oil filter

1200 hours

8

Lifting Chain

replace

3000 hours

Replace at any

time in case of

damage

9

High pressure rubber hose

replace

3000 hours

10

Lifting motor switch

Decontamination

200 hours

13

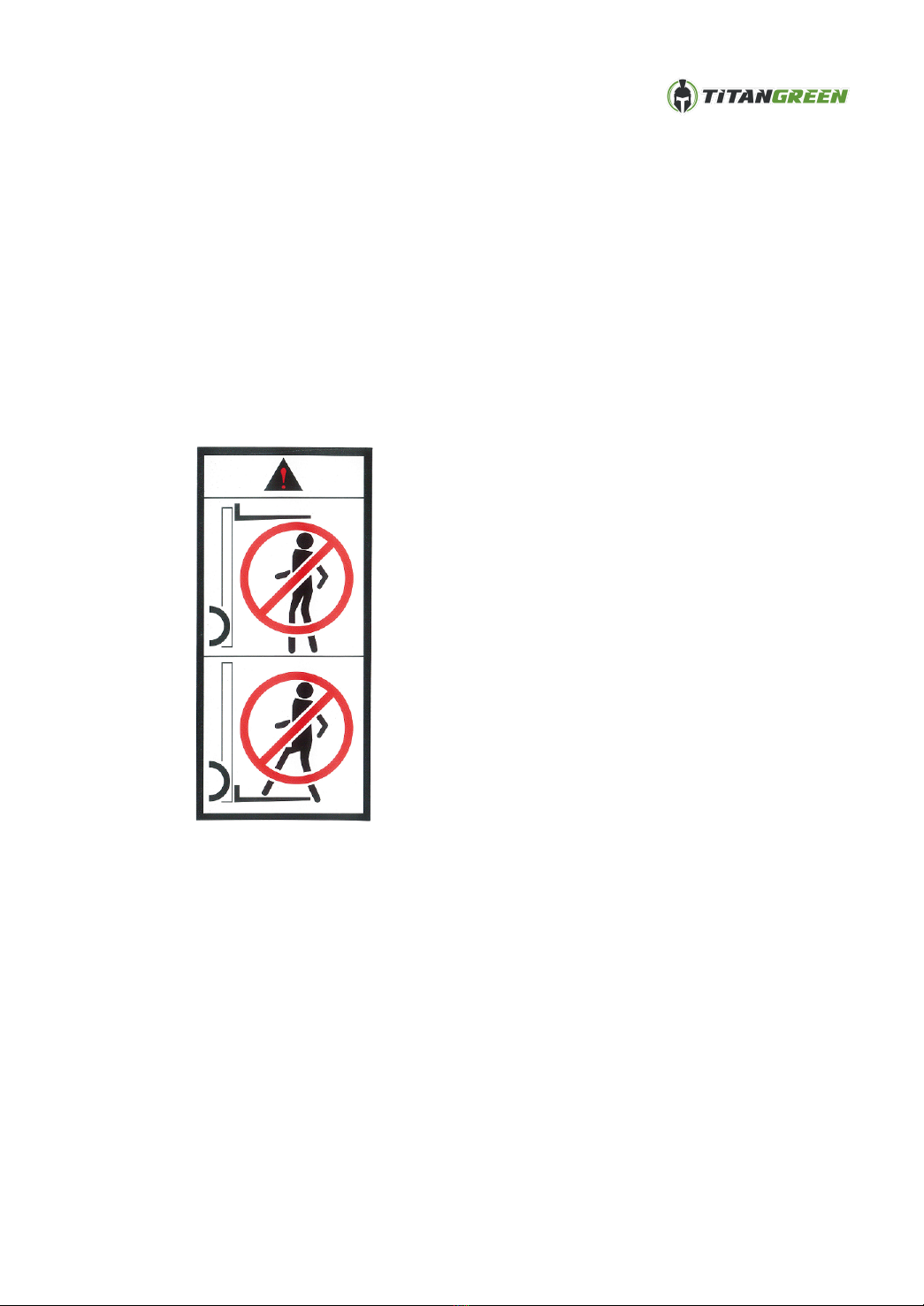

Note: During maintenance and inspection, it is not allowed to use the forklift

body as a step or the mast and shelf as a ladder. This is very dangerous.

Unsafe actions may lead to serious accidents.

2.5.4 Forklift oil and grease

Name

Brand and code

Qty

Note

Hydraulic

oil

ISOVG0

24L

Between the

oil dipstick

line

gear oil

DONAXTM

0.55~0.65L(PMP)

To oil level

overflow P23

0.35~0.4L(ZF)

Brake fluid

DOT3 Synthetic brake fluid

0.6 L

grease

JISK2220/2#

appropriate amount

The filling of oil, grease and brake fluid shall be carried out according to relevant automobile

standards. When handling and replacing the above hazardous substances, please handle them

according to relevant laws and regulations. Improper treatment will pollute water, soil and

atmosphere. This is prohibited by law. When filling various types of oil products, wear safety

protection articles, such as safety glasses and thick gloves, to avoid direct contact with the body.

14

2.6 Brief operating instructions

2.6.1 Control mechanism and instrument

Function and use status of control mechanism

Name

Function

Usage status

1

Parking brake control

Realize forklift parking brake

Step to the bottom to realize braking

function

2

shift knob

Change the driving direction of

the forklift

Push forward, reverse backward,median

neutral

3

Steering wheel

adjusting handle

Adjust the front and rear angle

of the steering wheel

4

Horn button

Switch for controlling horn

The horn sounds when pressed

5

Instrument panel

See the specific introduction of

instruments in the electrical

system section of this manual

Display vehicle status

15

6

pedal brake

Brake forklift

Press the brake

7

Centralized light and

turn signal switch

Used to operate the two

position light control and turn

signal switch

Move the combination switch forward to

turn left and backward to turn right.

8

Accelerator pedal

Drive vehicle travel

Step down and accelerate

The controller outputs the corresponding

speed according to the amplitude of the

step

9

Lifting cylinder joystick

Operating lifting cylinder

Pull the door frame backward to lift, and

vice versa

10

Tilt cylinder joystick

Operating the tilt cylinder

Pull the mast backward to tilt backward

and reverse to tilt forward

11

Side Shifter joystick

Operating sideshift cylinder

12

Accessory joystick

Manipulating accessories

13

Emergency stop switch

Control electrical system

Press to disconnect the power supply

2.6.2 Brief description of operation

( 1 ) Start: the driver should correctly sit on the driver's seat and fasten the safety belt.

Before starting the forklift, the parking brake switch should be placed in the braking position,

the shift direction switch should be in the middle position, that is, the N position. Turn the

emergency stop switch key to release the emergency stop).

Turn the key switch to the right, and after 1.5 seconds, the instrument panel will light up,

the lithium battery will discharge, the forklift self check will be completed and powered on, and

the instrument panel indicator and electrical circuit power will be connected.

Push the shift direction switch forward, and the instrument will display the D gear, that

is, in the forward gear, release the foot brake pedal, press the accelerator pedal, and the forklift

will move forward. Pull the direction switch backward, and the instrument will display the R

gear, that is, in the reverse gear. At this time, the reversing light will be on, and the reversing

buzzer will sound. If the forklift is equipped with a reversing image, then the instrument will

display the reversing image picture).. Note that the instrument will display different fault codes

in case of operation sequence error or others.

16

Light control switch:

The switch has two positions. The switch rotates at different positions, and the lamp

lights up as shown below.

Lamp name Phase 1 Phase 2

headlamps ----- on

Side marker lamp on on

(2) Turn signal: pull the turn signal switch backward, the front small light and rear upper

and lower combination light turn signal lights on the right side of the forklift are on, and push

the turn signal switch forward, the front small light and rear upper and lower combination light

turn signal lights on the left side of the forklift are on, and the corresponding instrument turn

indicator lights will also flash at the same time.

(3)Brake signal: When the forklift is braking, step on the brake pedal, and the brake

light (red) under the rear combination light will be on.

(4)Reversing signal: When the forklift is reversing, pull the direction switch backward,

and the travel motor will reverse, the reversing light (white) on the rear combination light will

be on, and the reversing buzzer will beep. If the forklift is equipped with a reversing image, the

reversing image on the instrument panel will be on.

(5)The ESH key under the instrument is the switch key of the whole vehicle working

mode, and the whole vehicle has three working modes: E, S and H. E is the energy-saving

mode, in which the battery life is the longest; S is the standard mode, with moderate power

consumption and endurance; H High performance mode, in which the power is strong.

2.6.3 Maintenance of control system

During the use of lithium battery forklift, the control system shall be regularly maintained

as follows:;

( 1 ) Check the contact wear of the contactor and whether the contactor moves freely.

The contacts shall be checked every three months.

( 2 ) Check the foot pedal or handle the microswitch. Use a multimeter to measure the

voltage drop between contacts and ensure that there is no resistance between contacts. The

sound of microswitch opening and closing should be clear and crisp. The microswitch shall be

inspected every three months.

( 3 ) Check the connecting wires of the main circuit to ensure that the cables of the

lithium battery, controller and motor are well insulated and firmly connected.

17

Cables shall be checked every three months.

( 4 ) Check the spring of the pedal or handle. Ensure that the spring can deform normally

and return to its original position. Check every three months.

( 5 ) Check the movement of the contactor. The contact of the contactor should move

freely to ensure that the contact is not bonded. Check every three months.

Note:

Please do not open the controller by yourself, otherwise the controller will be damaged

and the warranty will be invalid. Keep the controller clean and dry, and regularly check and

eliminate the diagnostic history files. It is strictly forbidden to start the electric control for

vehicles with incorrect installation.

Regular maintenance should be carried out by trained professionals. If damaged parts need to

be replaced, please use the original accessories provided by our company to ensure quality.

If any condition that may cause damage or endanger the safety is found during the inspection,

the dealer shall be informed immediately, and the dealer shall decide the operation safety of the

vehicle.

2.6.4 Special reminder

(1)As a special vehicle, the lithium battery forklift needs to be operated and maintained

by qualified professionals, and attention should be paid to its use characteristics and working

environment in order to avoid unnecessary failures of the electrical system (including

instruments).

( 2 ) As the vehicle power source, lithium batteries are different from traditional energy

sources. Its actual capacity is directly related to the working condition and its own aging

condition, and is somewhat different from the rated capacity. According to the general use of

lithium batteries, when the power drops to 20% (1 grid), the lithium battery must be charged,

which will help to extend the life of the lithium battery.

( 3 ) Using a PC or handheld device to connect with the controller, users can access the

powerful software setting interface within certain permission, so as to more intuitively detect

and understand the working conditions of the whole vehicle, such as the working current and

speed of (AC) drive motors, and improve a series of system parameters such as the working

current, speed, service time, fault list, etc. of the motor.

18

2.7 Warning sign

The warning board affixed to the vehicle is used to explain the use methods and precautions

of the vehicle. Please read carefully before driving. This is for your sake as well as for the

vehicle. If the warning sign falls off, please re attach it immediately. After repair and

maintenance, please check whether the nameplate is complete and the handwriting is clear. If it

is lost, please complete it.

(1)Safety signs

No one is allowed to stand up or down the fork

19

(2)General information when operating

(3)Lubrication system

20

Table of contents

Popular Forklift manuals by other brands

Hyster

Hyster R30XMF3 Service & repair manual

CMCO

CMCO TIGRIP TKG 1,0 vh operating instructions

Cascade

Cascade Turnafork E Series installation instructions

Presto Lifts

Presto Lifts Power Stak PPS3000-125FS Installation, operation and service manual

Total Source

Total Source TRP0029 operating manual

Big Joe

Big Joe PDI Series Operation maintenance manual & parts list