Billy Smoker OPEN FIRE ARTIST User manual

OPEN FIRE COOKERS

INSTALLATION GUIDE

Designed & Manufactured in Australia by

Plant | Grow | Prosper!

of 126

Revision 2

CONTACT INFORMATION

BILLY SMOKER

Location: Greenhill, SA

Web: billysmoker.com

Mail: hello@billysmoker.com !

Mob: +61 (0)401 553 437

Information in this manual may be updated without notice, please check online for latest version!

of 226

TABLE OF CONTENTS

WARNINGS AND CAUTIONS 4

PLANT | GROW | PROSPER 5

BILLY SMOKER 6

BILLY SAFETY 7

OPEN FIRE COOKERS 8

MODELS & DIMENSIONS

PRODUCT FEATURES

INSTALLATION 11

INITIAL CHECKS

AIR SUPPLY

CLEARANCES TOCOMBUSTIBLES

HEAT SENSITIVE MATERIALS EXCLUSION ZONE

WALL SHIELD REQUIREMENTS

FLOOR PROTECTOR REQUIREMENTS

FLUE REQUIREMENTS

EXAMPLE ENCLOSURE INSTALLATIONS

ASSEMBLING BILLY

OPERATION 19

REMOVABLE DOOR

FUEL

FIRST LIGHT PROCEDURE

REGULAR LIGHT PROCEDURE

HOW TO COOK IN BILLY 21

PIZZA

BAKING

SMOKING

GRILLING

ROTISSERIE

MAINTENANCE 23

ASH REMOVAL

OVEN & STONE CLEANING

FLUE CLEANING

TROUBLESHOOTING 25

BURNING POORLY

DOOR JAMMING

SMOKE SPILL

SPARE PARTS 26

of 326

WARNINGS AND CAUTIONS

•WARNING: THE APPLIANCE AND FLUE SYSTEM SHOULD BE INSTALLED IN ACCORDANCE WITH AS/NZS 2918 AND THE

APPROPRIATE REQUIREMENTS OF THE RELEVANT BUILDING CODE OR CODES

•ANY MODIFICATION OF THE APPLIANCE THAT HAS NOT BEEN APPROVED IN WRITING BY THE TESTING AUTHORITY IS

CONSIDERED TO BE IN BREACH OF THE APPROVAL GRANTED FOR CONFORMANCE WITH AS/NZS 4012 & AS/NZS 4013

•WARNING: ANY MODIFICATION OF THE APPLIANCE THAT HAS NOT BEEN APPROVED IN WRITING BY THE TESTING

AUTHORITY IS CONSIDERED NOT CONFORMING TO AS/NZS 4013

•WARNING: DO NOT USE FLAMMABLE LIQUIDS OR AEROSOLS TO START OR REKINDLE THE FIRE

•WARNING: DO NOT USE FLAMMABLE LIQUIDS OR AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHEN IT IS OPERATING

•WARNING: DO NOT STORE FUEL WITHIN HEATER INSTALLATION CLEARANCES

•WARNING: WHEN OPERATING THIS APPLIANCE AS AN OPEN FIRE USE A FIRE SCREEN

•WARNING: DO NOT BURN WOOD THAT IS PAINTED; OR IS COATED WITH PLASTIC; OR HAS BEEN TREATED WITH ANY

CHEMICAL

•CAUTION: MIXING OF APPLIANCE OR FLUE-SYSTEM COMPONENTS FROM DIFFERENT SOURCES OR MODIFYING THE DIMENSIONAL

SPECIFICATION OF COMPONENTS MAY RESULT IN HAZARDOUS CONDITIONS. WHERE SUCH ACTION IS CONSIDERED, THE

MANUFACTURER SHOULD BE CONSULTED IN THE FIRST INSTANCE

•CAUTION: CRACKED AND BROKEN COMPONENTS, FOR EXAMPLE GLASS PANELS OR CERAMIC TILES, MAY RENDER THE

INSTALLATION UNSAFE

•CAUTION: DO NOT OPERATE THIS APPLIANCE IF GLASS IS CRACKED OR BROKEN

•CAUTION: THIS APPLIANCE SHOULD BE MAINTAINED AND OPERATED AT ALL TIMES IN ACCORDANCE WITH THESE INSTRUCTIONS

Keep these instructions for future reference!

of 426

PLANT | GROW | PROSPER

We develop Australian brands and multicultural cooking products to encourage outdoor living with friends and family in style. Our

smart design principles enable sustainable manufacture within Australia, building and supporting local industry.

The PGP team offers an extensive range of product design & engineering services; from ideation to commercialisation. We utilise

knowledge and manufacturing skills from multiple industries to plant and grow ideas into viable products that help the community

prosper. PGP draws upon over 25 years of combined product development experience to deliver quality Australian made products.

!

of 526

GREG

LIAM

ANDREW

BILLY SMOKER

It is no new philosophy that cooking brings people together. Across time, across cultures, bringing family and friends together

involves – perhaps requires – food. Favourite family dishes become famous family dishes, replicated and re-imagined for

generations to enjoy. While new ways of cooking have and will be engineered, fire offers more. Fire is primal, has supported our very

existence like nothing else and offers a genuine charm, warmth and romance.

The wood crackles in our ears as we find ourselves mesmerised by the flame and are filled with a smoky aroma that foreshadows

the good food yet to come. Our senses are fully engaged with the simple and ancient phenomenon. We have been perfecting the

art of cooking on flame for centuries, however our generation seems to be loosing this knowledge, opting for convenience over

substance. We believe in bringing food back to its roots. It is there you will find flavours and textures unachievable by others

means.

Billy Smoker is owned and made in Australia. Many local families are involved through the products’ lifecycle; research,

development, design, engineering, machining, fabrication, blasting, painting, integration, assembly, marketing, sales, distribution,

logistics, installation and customer support. PGP Enterprise’s goal is to build a sustainable and thriving ecosystem which delivers

long term value to Australian communities.!

of 626

BILLY SAFETY

To get the most enjoyment and longevity out of your Billy Smoker product, there are a few things to keep on top of. Caring for your

Billy also keeps it safe. Remember this manual needs to be kept somewhere accessible near Billy.

Getting to know Billy. If you are a new user or introducing someone to Billy, be sure to understand the information in this manual.

Cooking with fire is fun but should also be done with the upmost respect. Take the time to point out any hot spots and how handles

and mechanisms work before lighting. Children must be supervised when handling a Billy.

Feeding Billy. Billy prefers to burn dry wood, especially hardwood as it burns cleaner and longer. Do not over fire Billy, if parts of

Billy turn red, remove any fuel that is safe to do so and let combustion reduce down.

Billy’s hot and tough. Be conscious of handles that may be hot when operating, we recommend you use oven mitts or welding

gloves when touching Billy's doors. Billy is also tough so do not stress knocking Billy while cooking.

Combusting near Billy. Do not place any combustable items inside the specified clearances area mentioned in the ‘Installation’

section of this document.

A clean Billy is a safe Billy and a safe Billy is a happy Billy. Please remember to crank Billy and burn offany organic matter left

on the cooking surfaces after use. Periodically scrape offany remaining fat or creosote on surfaces. Pro tip: before emptying ash,

use it as an abrasive and to soak up liquids when cleaning.

Billy needs to breathe. Due to the nature of open coal cooking is it important to make sure the flue system is installed correctly

according to the Australian and New Zealand Standard for the installation of domestic solid fuel burning appliances (AS NZS 2918).

Failure to do so will cause an uncomfortable amount of smoke and hazardous combustion fumes to spill from the firebox opening.

If installed indoors, be sure to monitor anything (especially exhaust fans) that may cause a negative pressure in the room. See

‘Troubleshooting’ section of this document for further information.

A damaged Billy. If any parts of Billy become damaged do not use the appliance. See the ‘Repairs Section’ of this document to find

out how to fix it.

of 726

OPEN FIRE COOKERS

The Open Fire Cookers stay true to our philosophy of bringing people together around fire and food. Designed to suit both indoor

and outdoor living spaces, certain to create an impressive and memorable atmosphere. Clean and minimal form with elegantly

designed componentry, they come in three variants for different settings and install environments.

The Sideways Collection has been designed and engineered to meet the safe installation requirements stipulated in AS NZS 2918

(Australian and New Zealand for installation of solid fuel burning appliances).

Defined as cooking appliances, the Sideways Collection complies with the AS NZS 4012 and AS NZS 4013 (Australian and New

Zealand Standards for emissions and efficiency).

Meeting the Australian Environmental Protection Authority (EPA) requirements for air quality, these products can be installed

throughout all of Australia (including New South Wales).

MODELS & DIMENSIONS!

of 826

PRODUCT FEATURES

!

of 926

FIREBOX (CM)

MATERIAL

FINISH

OVEN VOLUME

OVEN (CM)

OPEN COAL VOLUME

MAX LOG (CM)

BAFFLES & DOORS

HEAT BANKS

SPIGOT

100W x 30D x 38H

3-6mm steel

metallic black paint

29 ltr

36W x 43D x 18H

136 ltr

220Ø x 85L

steel

ceramic plate

fully welded

!

of 10 26

PIZZA OVEN

Fits a 13 inch Pizza and comes

with a high temperature pizza

stone for hot and fast wood oven

pizza

BAKING OVEN

The ventilated upper wood oven

creates an easy-to-use low and

slow smoking environment with

adjustable smoke flow

SMOKING

The ventilated upper wood oven

creates an easy-to-use low and

slow smoking environment with

adjustable smoke flow.

ROTISSERIE

(SOLD SEPARATELY)

The Slimspit is a clip on rotisserie

attachment available for grilling

with your Open Fire Cooker

GRILLING

Flame grill in style with ample

room to control and push

coals around

REMOVABLE DOOR

Keep on to retain maximum heat,

smoke and sparks inside the unit or

remove after cooking for full view of

the fire

INSTALLATION

INITIAL CHECKS

Please consider the following points before installing Billy:

•Regulations & Council Requirements. Consult your council, either directly or via the avenue of sale to find out if any install

approval, local guidelines or permits are needed when installing a cooking product.

•Qualified Installer. The appliance must be installed by a qualified installer that adheres to local regulations and standards.

•Clearances to combustibles. The appliance must be installed at a distance from any combustibles no less than stated in

these instructions.

AIR SUPPLY

If installing indoors, make sure the room can provide plenty of free air to feed the appliance. Be sure to identify and monitor

anything that may cause a negative pressure in the room (exhaust fans) as this can cause smoke spillage. A solution could be to

turn offfans, open a window or add an external air supply in the room. If installing outdoors, for best results choose a location that

is protected from any cross winds.

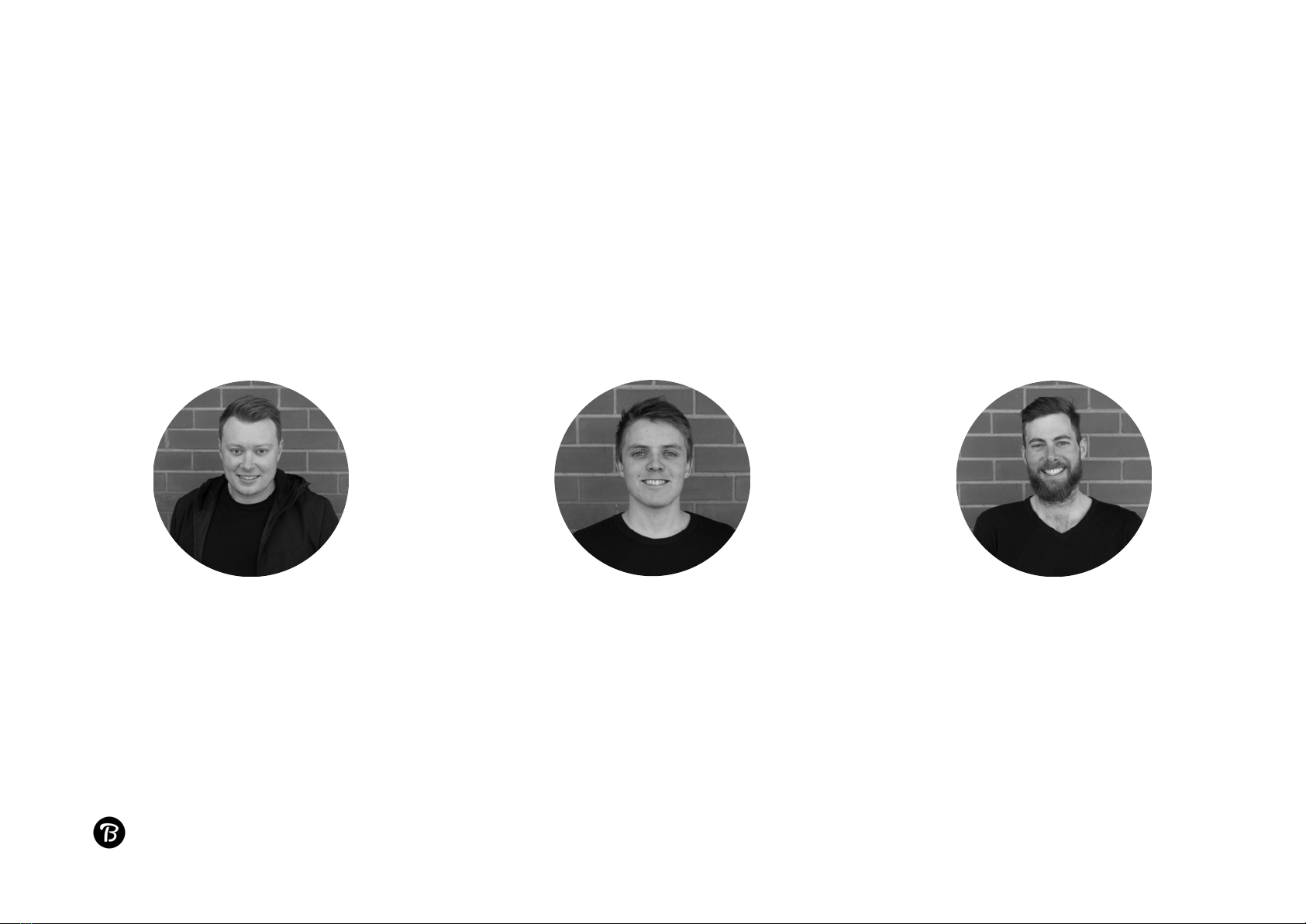

CLEARANCES TOCOMBUSTIBLES

The Open Fire Cookers have been designed and engineered to meet the safe installation requirements stipulated in AS NZS 2918.

Some installation configurations and requirements may not be included in this manual, use as a guide only. Installation must

comply with the latest release of AS NZS 2918.

of 11 26

HEAT SENSITIVE MATERIALS EXCLUSION ZONE

CLEARANCE

IDENTIFIER

0 SHIELDS

1 SHIELD

(12MM GAP)

1 SHIELD

(25MM GAP)

2 SHIELDS

(12MM GAPS)

SIDE

A

1200

480

360

240

REAR

B

1200

480

360

240

FRONT

C

1200

480

360

240

TOP

D

1500

N/A

N/A

N/A

BOTTOM

E

1200

960

720

N/A

Safety clearances apply to both variants; Artist & Chef

of 12 26

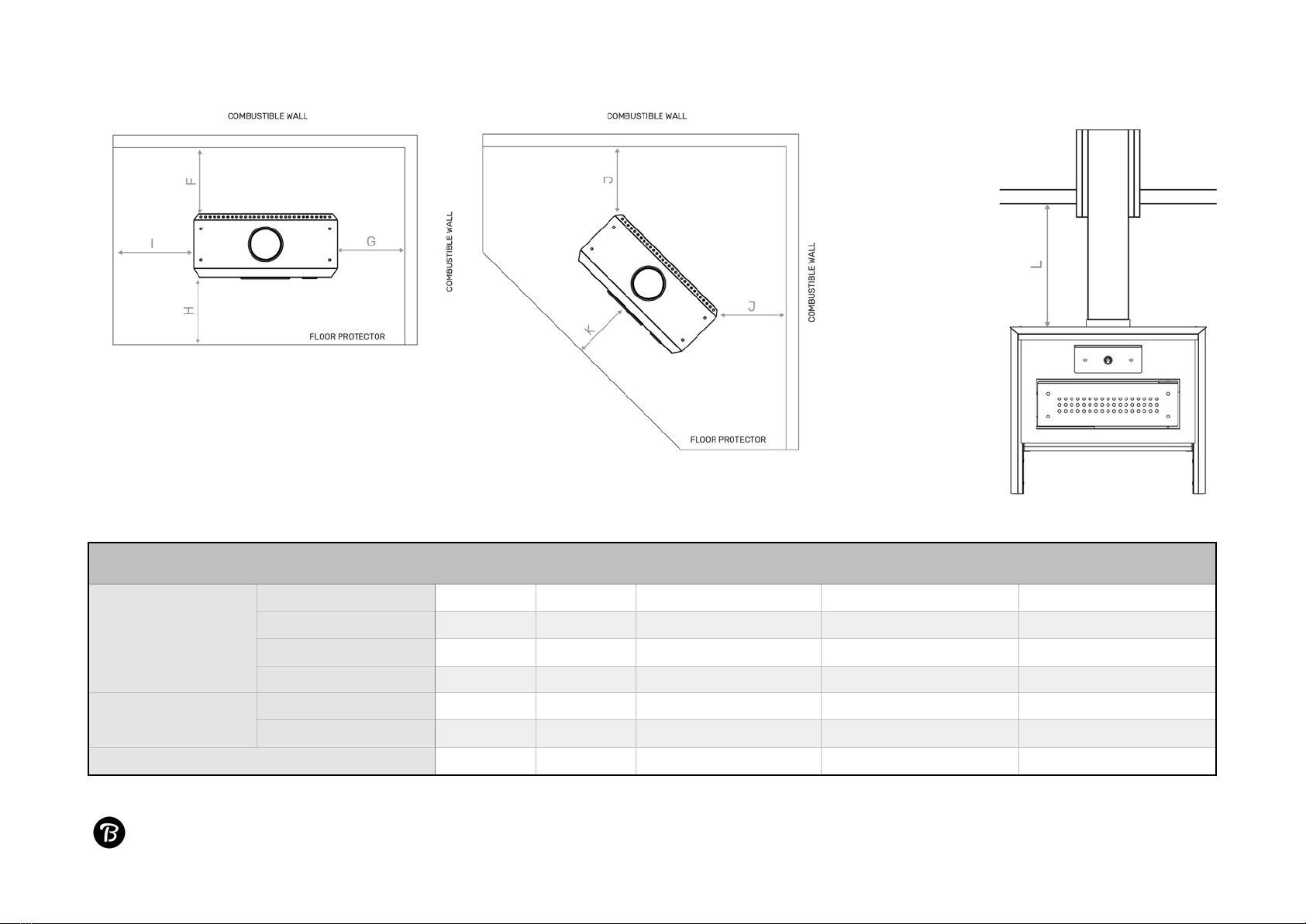

ARTIST

CHEF

CLEARANCE

IDENTIFIER

0 SHIELDS

1 SHIELD

12MM GAP)

1 SHIELD

(25MM GAP)

2 SHIELDS

(12MM GAPS)

STANDARD INSTALL

COMBUSTIBLE WALL REAR

F

1200

480

360

240

COMBUSTIBLE WALL SIDE

G

1200

480

360

240

FLOOR PROTECTOR FRONT

H

1000

1000

1000

1000

FLOOR PROTECTOR SIDE

I

1000

1000

1000

1000

CORNER INSTALL

COMBUSTIBLE WALL REAR

J

1200

480

360

240

FLOOR PROTECTOR FRONT

K

1000

1000

1000

1000

CEILING

L

1500

N/A

N/A

N/A

of 13 26

ENTERTAINER

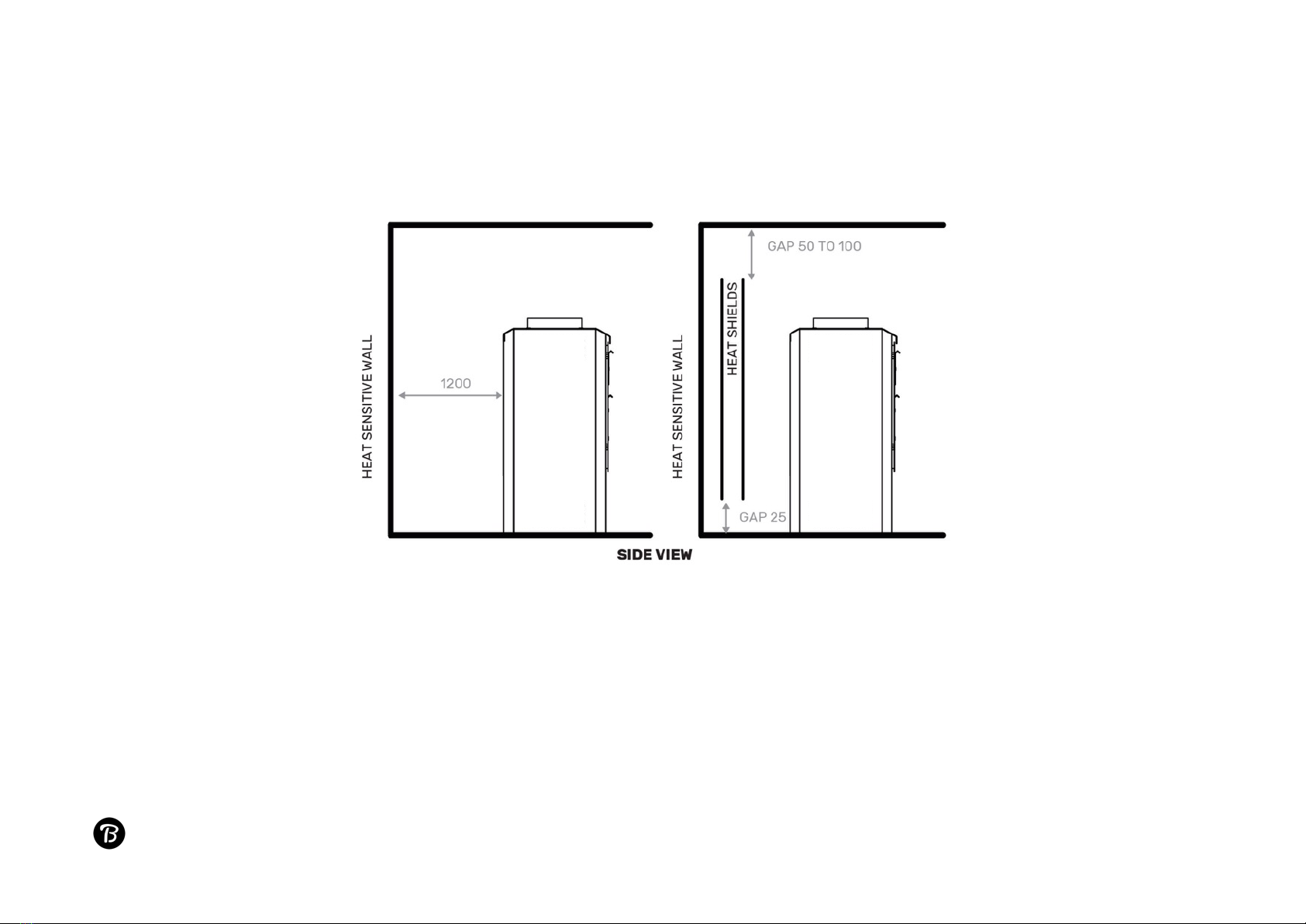

WALL SHIELD REQUIREMENTS

Wall shields must be made from heat-tolerant material (allowable service temperature greater than 150°C but less than 600°C).

Vertical shields must be vented by a 25mm gap at the bottom and a 50mm to 100mm gap at the top. They must extend no less

than 450mm either side of the appliance.!

of 14 26

FLOOR PROTECTOR REQUIREMENTS

To achieve a clean aesthetic it is recommended to install Open Fire Cooker units on or above heat-resistant material (allowable

service temperature of 600°C or greater). Appropriate materials include but are not limited to; cement, concrete, slate, brick and

steel.

A floor protector is required when any part of the floor area within 1000mm of the appliance is heat-sensitive material (allowable

service temperatures less than 150°C).

Floor protectors shall be constructed from any material, or combination of heat-resistance materials, which ensures the protector

is in accordance with or exceeds the requirements of AS NZS 2918.

The floor protector shall extend either to a distance of not less than 1000 mm beyond any part of the appliance or a lesser distance

at which it forms an abutment with a heat-resistant wall and shall be constructed in accordance to AS NZS 2918.

of 15 26

FLUE REQUIREMENTS

The flue system, including any access port covers, shall be constructed from Grades 301, 302, 304, 310, 316 or Grade 321 austenitic

stainless steel having a minimum thickness of 0.52mm in accordance to AS NZS 2918.

Flue casings (inner and outer) shall be constructed from stainless steel not less than 0.52mm or corrosion protected steel not less

than 0.55mm in accordance to AS NZS 2918.

Flue casings must be vented top and bottom as per AS NZS 2918 and with 25mm air gap all round between each. There must be at

least 25mm air gap from outer casing to heat sensitive materials.

In addition to complying with AS NZS 2918, the flue system must be installed as per the flue manufacturer’s installation

instructions.

FLUE SIZING TABLE

Active Flue

Inner Casing

Outer Casing

Cowl

Flue Pipe Diameter (Ø)

250mm / 10”

300mm / 12”

350mm / 14”

Suits 250mm/10” (Active)

Flue Pipe Material:

Stainless Steel

Galvanised Steel

Galvanised Steel

Stainless Steel

Crimp Direction:

Down

Up

Up

Sizing are the same for all Open Fire Cooker units.

of 16 26

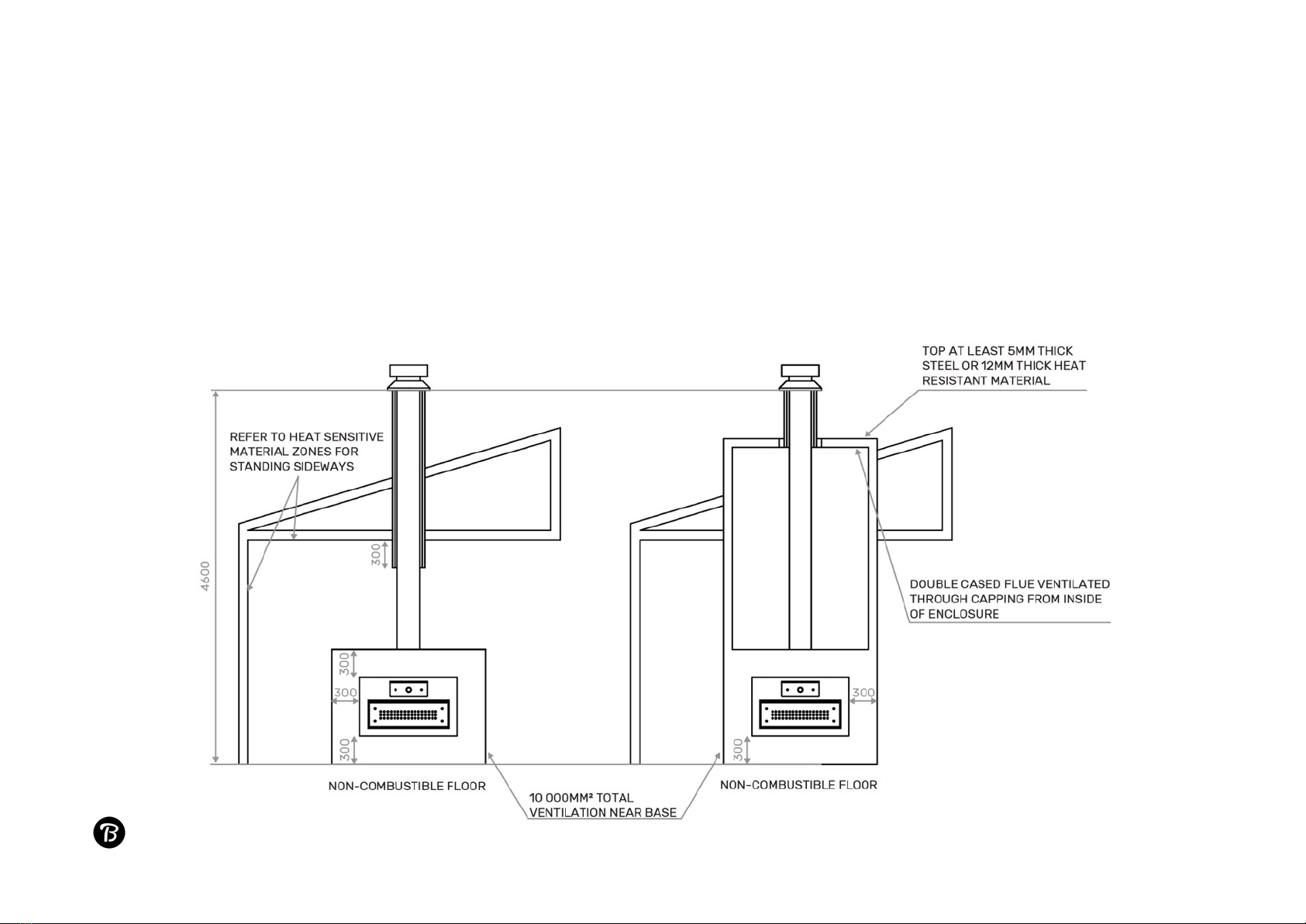

EXAMPLE ENCLOSURE INSTALLATIONS

We recommend building your enclosure from any of the following materials:

•19mm cement sheet

•75mm standard brick

•50mm Skamol board

•100mm Hebel panel!

of 17 26

FREESTANDING ENCLOSURE INSTALLATION

MASONRY ENCLOSURE INSTALLATION

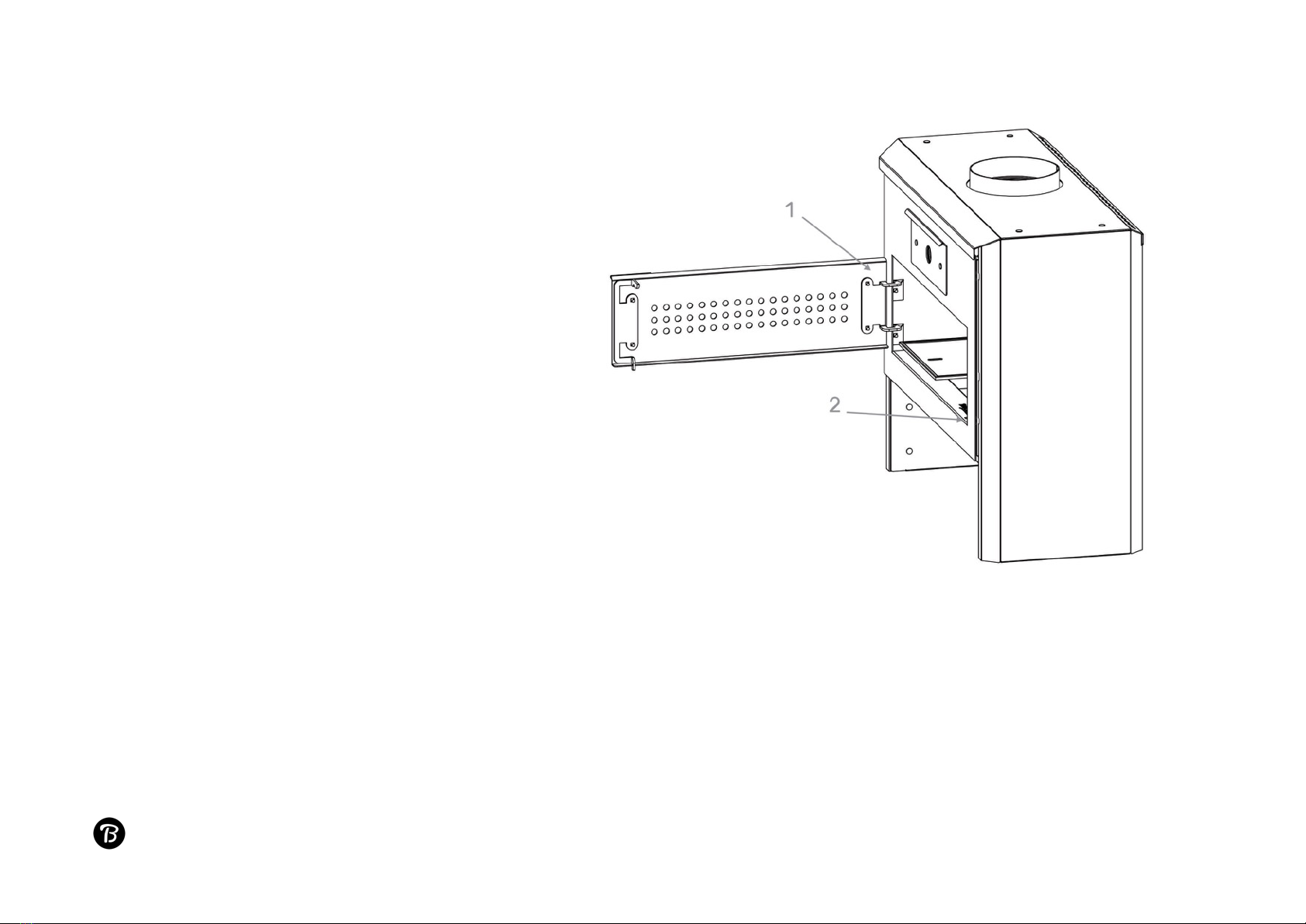

ASSEMBLING BILLY

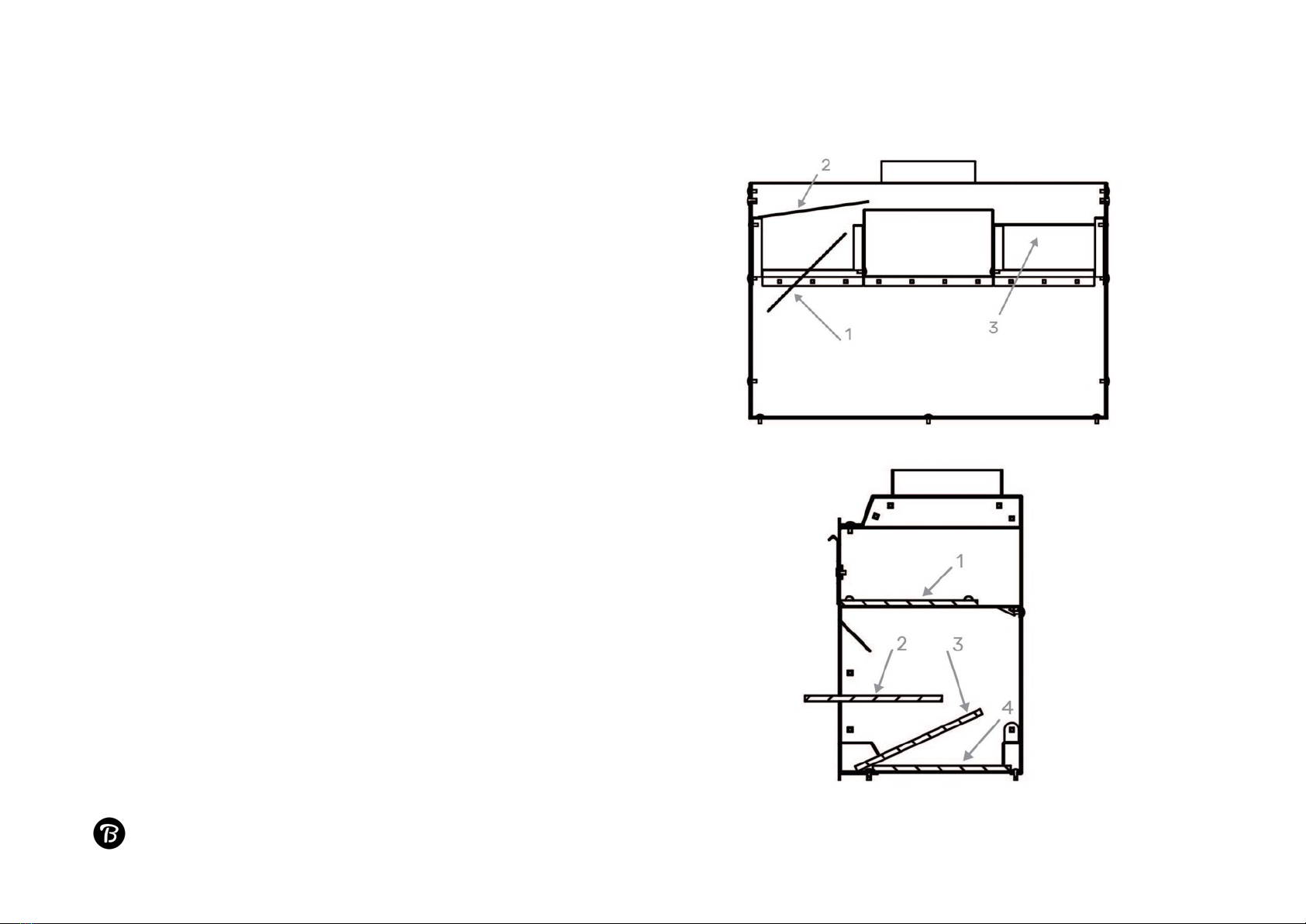

BAFFLES

1. Lift the inner side of the baffle past the inner baffle shelf

2. Lift baffle above the oven until it clears the outer baffle shelf

3. Drop into place on top of baffle shelves

4. Repeat for both left and right baffles

STONES

1. Open oven door and slide a stone into place leaving no gap at

the front

2. Feed 3 stones through the main opening

3. Tuck front under the ash lip and pivot to floor

4. Stones sit flat between raised locators in base!

of 18 26

OPERATION

REMOVABLE DOOR

This door is removable and can be used or put aside

based on your needs, for example:

ON

•Cook at higher temperatures

•Retain heat for the pizza oven

•Prevent smoke spillage

•Retain falling logs or sparks

OFF

•Grill with plenty of space

•Appreciate the aesthetics of the fire

1. To attach the door, drop the hinge pins (vertical bolts)

through the tabs hidden behind the front left opening

2. To close the door, lift the handle until the latch

catches the slot on the ash lip

FUEL

Billy is designed to burn dry wood for cleaner and longer operation. Prohibited items include but are not limited to, plastics, paper

(large amounts), cardboard, treated wood, composite woods or flammable liquids. Burning prohibited items increases the likelihood

of a flue fire and creates a toxic environment.!

of 19 26

Do not over fill the appliance. If the appliance glows red, wait until it stops glowing before adding more fuel.

Wood should be stored in a dry place. It is recommended to be split and seasoned for a year to reduce moisture content before

burning. For more information about seasoning and storing timber we recommend Norwegian Wood: Chopping, Stacking, and

Drying Wood the Scandinavian Way - Lars Mytting.

FIRST LIGHT PROCEDURE

The first time you light your Billy it will emit smoke and a strong odour into the air, this is the paint curing. During this process, it is

important not to touch any surfaces as the paint temporarily becomes soft and is easily marked. Ensure all packaging has been

removed.

When lighting Billy for the first time…

•Keep all doors open so they are not in contact with other curing surfaces

•Leave the removable door slightly ajar to cure without damaging paint on ash lip

•Provide as much ventilation to the area as possible to remove odour

•Maintain only a small fire for the first 15 minutes

•Build the fire slowly to a medium size and maintain for 60 minutes

•Carefully increase to a very hot fire (approximately 1/3 of firebox) and maintain for another 60 minutes

•To complete the curing process, let the fire cool to room temperature

REGULAR LIGHT PROCEDURE

Once the initial curing procedure has taken place follow these points for lighting a cold Billy…

•Place firelighters and kindling stack in the middle of the firebox

•Light Billy

•Gradually build up the fire to desired size by regularly adding fuel

•Keep the removable door closed to speed up the fire building process and avoid smoke spill!

of 20 26

This manual suits for next models

6

Table of contents

Popular Cooker manuals by other brands

Parkinson Cowan

Parkinson Cowan Lyric 55G Owner's handbook

Zanussi Electrolux

Zanussi Electrolux Cookers user manual

GIGA

GIGA I2P Installation, operating and maintenance instructions

InstantPot

InstantPot RIO PLUS user manual

Bayou Classic

Bayou Classic KDS-1 SAFETY ALERTS, ASSEMBLY & OPERATING INSTRUCTIONS GENERAL MAINTENANCE & STORAGE

Smeg

Smeg SA9066XS Brochure & specs

Siemens

Siemens HS 33024 instruction manual

SKLADOVA TEHNIKA

SKLADOVA TEHNIKA Plamak instruction manual

IH

IH GTB2 Quick start instructions

CDA

CDA RV911SS/1 Installation, use and maintenance

montpellier

montpellier MTCC60FW Installation and operating instructions

Belling

Belling Cookcenter Series Installation & user's instructions