SKLADOVA TEHNIKA Plamak User manual

INSTRUCTION MANUAL

for solid fuel cookers

SKLADOVA TEHNIKA

25 Sveti Knyaz Boris I St.

5100 Gorna Oryahovitsa

Republic of Bulgaria

phone: +359 618 60576

www.st-bg.com

2

CONTENTS

1. Introduction ............................................................................................................................3

2. Technical data .........................................................................................................................3

3. Cooker assembling..................................................................................................................3

4. Cooker operating ....................................................................................................................4

5. Cleaning...................................................................................................................................6

6. Important directions for fire-precaution and safety regulations ...........................................7

7. Possible defects and their causes ...........................................................................................8

Instruction for assembling and operation of solid fuel cookers with integral boiler .................9

Installation diagram for solid fuel cookers with an integral boiler...........................................10

3

Dear customers,

Your cooker is produced and tested in conformity with the requirements of standard EN

12815:2001 and responds to the approved technical documentation.

Don’t leave the instruction manual unread. The assembly and the exploitation of a cooker are

connected with different legal obligations, which are explained in this instruction. According to

the laws and regulations for safety, when using a cooker of such class, the buyer and the user of

the fireplace are obligated, with the help of this instruction, to inform themselves for the

assembling and the right operation of the appliance.

1. Introduction.

Solid fuel cookers are designed for cooking and heating, and the used fuel can be wooden logs,

briquettes and other types of coals and fuel as well. The cooker can be used in kitchens and houses,

but it is not suitable for integrating into kitchen furniture.

2. Technical data.

The technical specifications of solid fuel cookers are mentioned in Table 1.

Table 1.

Cooker type

Nominal heat output (kW)

Space heating output (kW)

Water heating output (kW)

Overall dimensions

(mm)

Flue gas mass (g/s)

Flue gas temperature (°C)

Weight (kg)

Minimum flue draught at nominal heat

output (Pa)

Boiler capacity(l)

width

depth

height

Plamak

wood

9

-

-

840

600

890

12.57

290

130

12

coal

9

-

-

13.42

273

Metalurgia

wood

9

-

-

840

590

775

12.57

290

72

12

coal

9

-

-

13.52

273

Plamak В

wood

9

5

4

840

600

890

19.71

230

130

12

12

Overall dimensions of the oven

(mm)

width

410

depth

440

height

220

3. Cooker assembling.

For ensuring safe and correct operation of the cooker it is necessary to keep the following

conditions:

The cooker has to be mounted in rooms which have enough fresh air supply, which is necessary

for burning. After placing the cooker, it has to be connected to the chimney with the proper

fluepipes, but before connecting them, their functionality has to be checked and inspected.

Not every cooker can be mounted to every chimney. Before installation, the static pressure and

the size of the chimney have to be checked if they fit to the required parameters of the cooker. If

4

the cooker is not compatible with the chimney, this will lead to weaker burning and contamination

of the glass with soot.

The chimney has to be high enough (not less than 5m.) It’s allowed only one more appliance to

be connected to the same chimney. The flue draught of the chimney has to be over 10Pa, and over

15 Pa for cookers with water boiler. If the chimney is very high (flue draught over 35Pa) it is

necessary to install additional valve for reducing the flue draught. The internal shape of the

chimney has to be even and round to its full length, not square or with changing shape.

To ensure safe operation, the cooker has to be connected to the chimney by means of a spigot

on the wall, and the connection has to be sealed very well. The connecting fluepipe between the

cooker and the spigot has to be as short as possible, this means not to use horizontal and angular

connected fluepipes. It is recommended to use not more than two crooked fluepipes, in order to

avoid tar accumulation on the horizontal fluepipes and the chimney, which therefore leads to lower

flue draught in the chimney.

The fluepipe does not have to enter in the chimney because this will reduce its draught.

The cooker should not be connected to a chimney, when there is already connected appliance

with water boiler.

The chimney has to be designed in a way that it will allow easy mechanical cleaning.

The floor, where the cooker will be placed, should be smooth and leveled, made of non-

combustible materials (such as mosaic, marble, terracotta, etc.), and possessing the required load

capacity.

If the floor in front of the cooker is not heat resistant (carpets, linoleums or others of the same

kind) a stable, non-combustible platform should be used, (made of steel, glass or ceramic, etc),

which should come out: 50 cm in front and 30 cm from both sides, measured from the firedoor of

the cooker.

Distances at which the cooker should be installed for fire precaution:

Distance to near combustible materials:

Plamak, Metalurgia

in front -80сm, side -40сm, back -40сm

Plamak В

in front -80сm, side -30сm, back -30сm

If there are any easy inflammable materials and constructions, the cooker should be 80 cm

away from them or it has to be supplied with non-combustible shield. The upper surface (frames

and plates) should stay at least 1m away.

If the cookers are supplied with: decorative rail –1pce. and decorative sphere –2 pcs., then the

installation is made in the following way: on the decorative rail mount decorative sphere –2 pcs,

after that they are installed on the cooker frame by means of the given connecting elements: screw

М5х12 DIN 933 – 2pcs, washer М5, DIN 125 – 2pcs and washer 2 5 L DIN 127. The mounting is done

when the firedoor and the oven door are opened.

On cooker Plamak and Plamak В are mounted:

- handle for oven door 2 pcs. by means of screw M5x45 -4 pcs

- small handle –1pce., by means of screw М5х14- 2pcs and a washer М5 –2pcs.

4. Cooker operating.

4.1. Fuel materials.

The most appropriate fuels are dry cleaved wood (wood logs) and briquettes. The wood logs,

stored in the open under sheds, reach a humidity level of 10-15% after 2 years, when they are most

suitable for combustion. We recommend to burn wood dried as much as possible. The maximum

heat output of the cooker is reached after burning wood logs dried for at least 2 years period of

time.

5

The fresh cut wood has little calorific effect, high humidity and burns poorly –they extract a lot

of flue gases and additionally contaminate the environment. This leads to minimizing the longevity

of the cooker and chimney as well. When using them, the heat output of the cooker falls to 50%,

and the fuel consumption grows twice.

Type and recommended quantity of fuel

Type

Wood (кg/h)

Coal (кg/h)

Plamak , Metalurgia

3.53

2.06

Plamak В

З.46

-

It is not recommended to use the following fuels in the fireplace: wet or tarred wood, shavings,

fine coal, paper and cardboard (except for the ignition).

Do not use liquid fuels.

Do not use the cooker like a furnace for burning waste matters.

If the cooker is used for burning unalloyed fuels then the warranty is not valid

At each ignition of the cooker you should observe the following: Clean the bottom grate, and

the ashtray if needed, but you should do this only if the cooker is in cold condition.

4.2. Ignition at operation.

Your cooker is designed for intermittent burning and operates only with doors closed. At each

ignition you should observe the following:

4.2.1. Ignition at lower combustion.

Lower combustion is obligatory used for cooking and baking in the oven, and when cooking the

regulator for the flue gas, positioned to the flue pipe outlet needs to be fully opened. With this

regulator you can adjust the temperature for baking - up and down. The internal temperature of

the oven depends on the intensity of burning, the flue draught and the amount of fuel. The

intensity of burning is regulated by the primary air. By adjusting the primary air you can achieve

proper regulation of the temperature inside the oven. If you want to reach high temperature in the

oven and the cooker is still cold it is recommended to ensure high heat and temperature in the

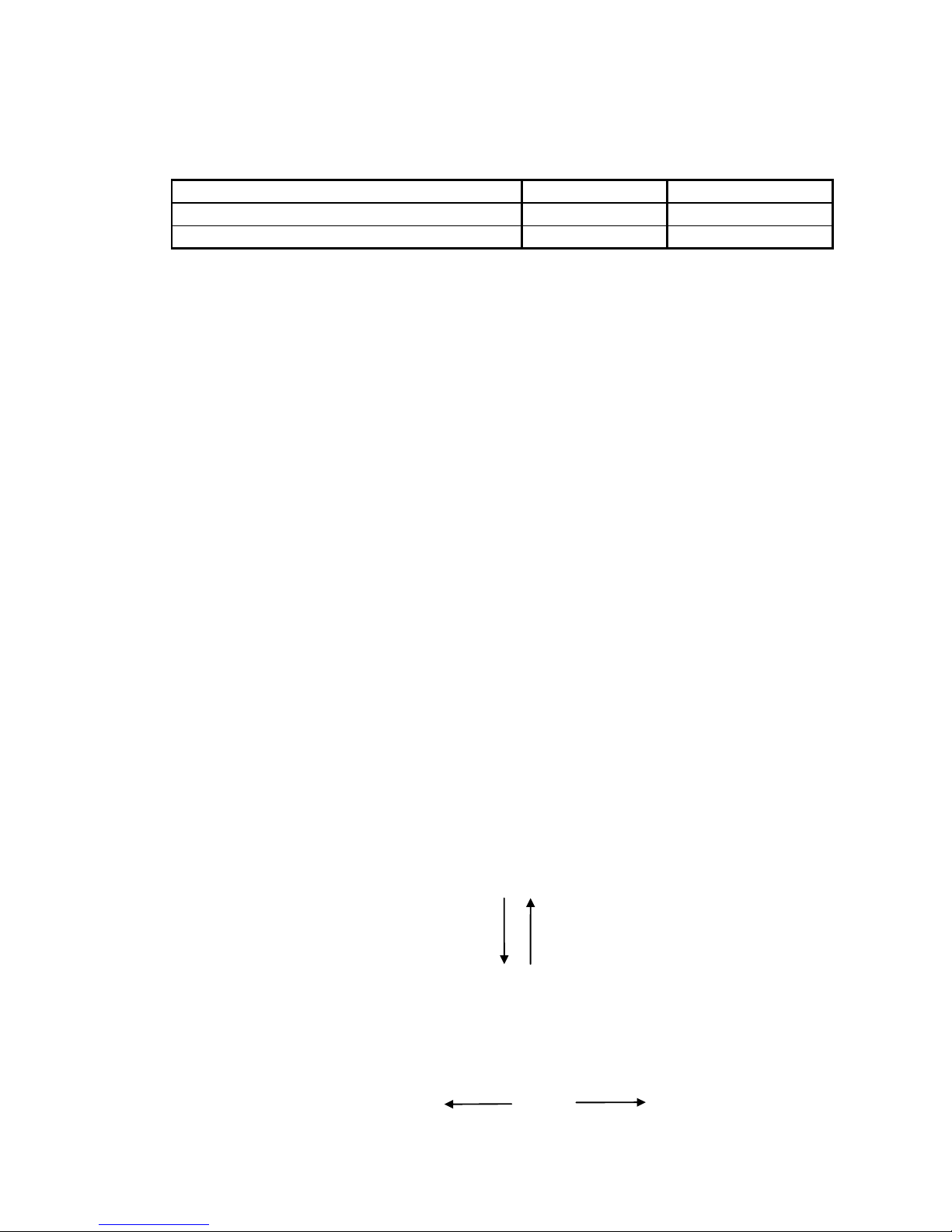

cooker and to open the regulator for the oven (see fig.1) and the regulator for the primary air. (see

fig.2) by moving the adjuster in the given directions. When the required temperature is reached in

the oven the intensity of burning has to be decreased by closing the primary air regulator and the

oven air inlet control. This will keep the temperature in the oven constant.

For Plamak, Plamak B, and Metalurgia:

When the air inlet control of the oven is positioned at:

rearmost position it is open;

foremost position it is close -the heat will go under the oven;

middle position -opened ½ the heat will go under and above the oven.

close open

Fig.1. -The air inlet control of the oven is positioned on the top plate of the cooker by the flue gas outlet.

For Plamak, Plamak B and Metalurgia:

When the air inlet control for primary and secondary air supply are positioned in:

End left position -close

End right position -open

close open

Fig.2. -The air inlet control is positioned on the firedoor.

This manual suits for next models

2

Table of contents

Other SKLADOVA TEHNIKA Cooker manuals