BILT HARD TL-LB-H26 User manual

Model: TL-LB-H26

26cc GAS LEAF BLOWER

User Manual

Thank you for ordering our product. If you have any

issue, please email it and your order ID to

inquiry@bilthardusa.com or call (888) 680-2849.

1

our website: bilthardusa.com

Using tips: Video on YouTube

Model: TL-LB-H26

2

TABLE OF CONTENTS

SYMBOLS

SAFETY INSTRUCTIONS

STRUCTURAL COMPONENTS

PARAMETERS

ASSEMBLING THE TUBE

MIXING FUEL

FILLING THE FUEL TANK

STARTING THE BLOWER

ADJUSTING ENGINE IDLE SPEED

STOPPING THE ENGINE

USING THE BLOWER

ROUTINE MA INTENANCE

SPARK ARRESTOR MAINTENANCE

TROUBEL SHOOTING GUIDE

3

4

6

7

8

9

10

11

13

13

13

14

17

19

WARNING!

This manual contains impoatant instructions for

operating this product. For you safety, and the

safety of others, be sure to read this manual

thoroughly before operating the product.

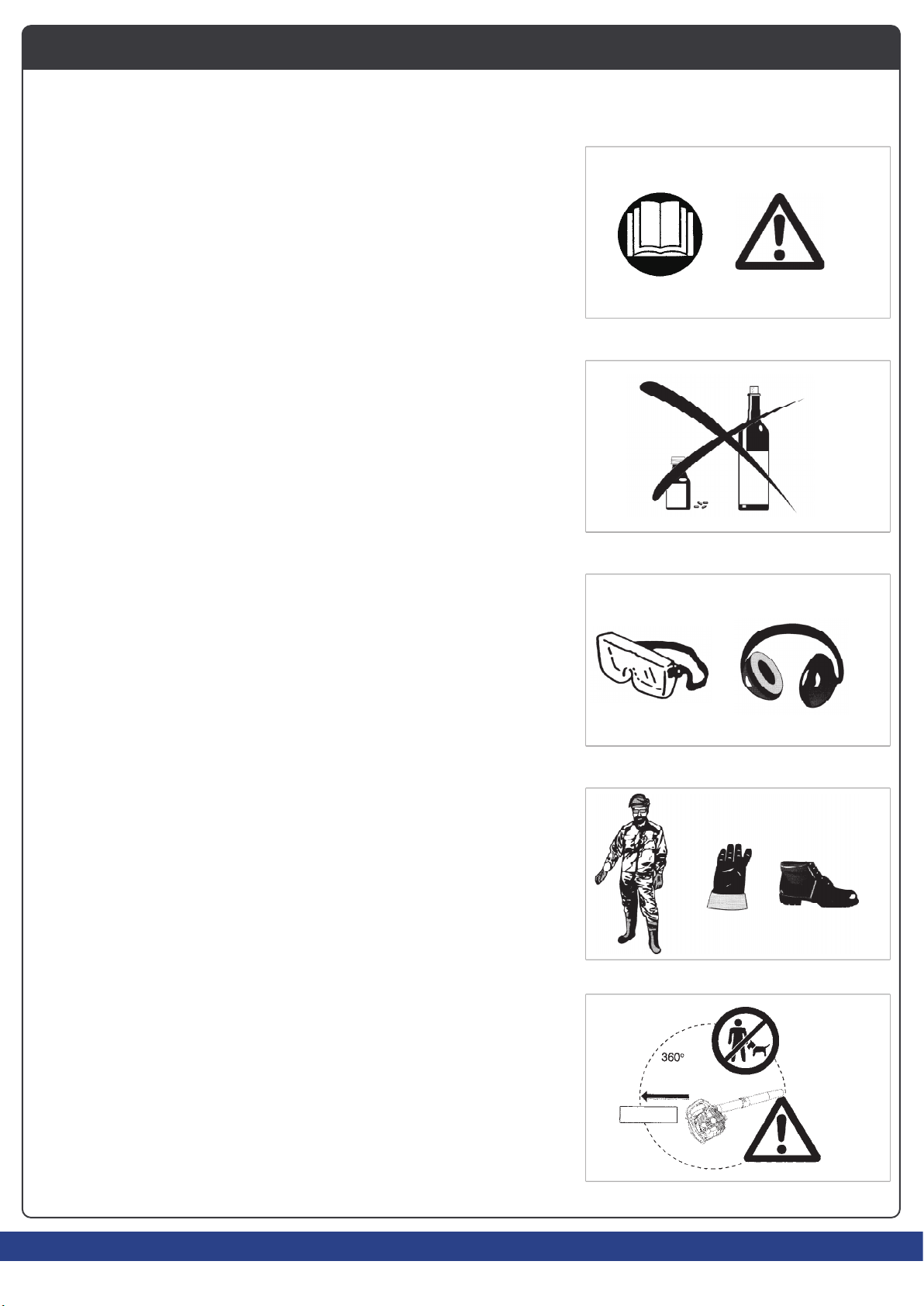

It is very important to understand the following symbols wher reading this instructions manual.

WARNING/DANGER

Read, Understand and Follow

Instruction Manual

Forbidden

No Smoking

No Open Flame

Protective Gloves Must be Worn

Keep the Area of Operation

Clear of All Persons and Pets

Wear Eye and Ear Protection

OFF/STOP

ON/START

Recyling

First Aid

Emergency Stop

Engine-manual Start

Fuel (Gasoline)

Model: TL-LB-H26

3

Thank you very much for selecting the BILT HARD blower. We are pleased to be able to offer you the BILT HARD

blower which is the resut ofa long development programme and many years of knowledge and experience.

The blower models TL-LB-H26 combines the advantages of state-of-the-art technology with ergonomic

design. They are of light welght, handy, compact and represent professional equipment fora great varlety of

applcations.

Please read, understand and follow this booklet which refers in detal to the varous points that will

demonstrate its outstanding performance. This wil assist you to safety obtain the best possible results from

your BILT HARD Blower.

SYMBOLS

SAFETY INSTRUCTIONS

4

(2)

(3)

(4)

(1)

SAFETY INSTRUCTIONS

(5)

15meters

General Instructions

• To ensure correct and safe operation, the user must read,

understand and follow this instruction manual to assure familiarity

with the handling of the blower (1). Users insufficiently informed

will risk danger to themselves as well as others due to improper

handling.

• It is recommended only to loan the blower to people who have

proven to be experienced with blowers.

• Always hand over the instruction manual.

• First-time users should ask the dealer for basic instructions to

familiarize oneself with the handling of a blower.

• Children and young persons aged under 18 years must not be

allowed to operate the blower. Persons over the age of 16 years

may however use the tool for the purpose of being trained only

while under the direct supervision of a qualified trainer.

• Use blowers with the utmost care and attention.

• Operate the blower only if you are in good physical condition.

• Perform all work conscientiously and carefully. The user has to

accept responsibility for others.

• Never use the blower while under the influence of alcohol or drugs

(2).

• Do not use the unit when you are tired.

• Save these instructions for future referral.

SAFETY INSTRUCTIONS

Personal Protective Equipment

• The clothing worn should be functional and appropriate, I. e. It

should be tight-fitting but not cause a hinderance. Do not wear

jewelry, clothing or long hair which could be drawn into the air

intake.

• In order to avoid head-, eye-, hand- or foot injuries as well as to

protect your hearing the following protective equipment and

protective clothing must be used during operation of the blower.

Pay particular attention to the following regulations

• Clothing must be sturdy and snug-fitting, but allow complete

freedom of movement. Avoid loose-fitting jackets, flared or cuffed

pants, scarfs, unconfined long hair or anything that could be drawn

into the air intake. Wear overalls or long pants to protect your legs.

Do not wear shorts. (4)

• Blower noise may damage your hearing. Wear sound barriers (ear

plugs or ear mufflers) to protect your hearing. Continual and

regular users should have their hearing checked regularly. (3)

• Use of gloves when working with the blower is recommended.

Good footing is most important. Wear sturdy shoes with nonslip

soles. (4)

• Proper eye protection is a must. Even though the discharge is

directed away from the operator, ricochets and bouncebacks can

occur during blower operation. (3)

• Never operate a blower unless wearing goggles or properly fitted

safety glasses with adequate top and side protection which comply

with ANSI Z 87. 1 (or your applicable national standard).

Starting up the blower

• Please make sure that there are no children or other people within a

working range of 15 meters (5), also pay attention to any animals in

the working vicinity. Never use the blower in urban areas.

• Before operating, always check that the blower is safe for

operation:

Check the security of the throttle lever. The throttle lever should be

checked for smooth and easy action. Check for proper functioning

of the throttle lever lock. Check for clean and dry handles and test

the function of the l-O switch. Keep handles free of oil and fuel.

SAFETY INSTRUCTIONS

Method of operation

5

• Use the blower only in good light and visibility. During cold seasons

beware of slippery or wet areas, ice and snow (risk of slipping).

Always ensure a safe footing.

• Never work on unstable surfaces or sleep terrain.

• To reduce the risk of personal injury, do not direct air blast towards

bystanders, since the high pressure of the air flow could injure

eyes and could blow small objects at great speed.

• Never insert any foreign object into the air intake of the machine or into

the nozzle of the blower. It will damage the fan wheel and may cause

serious injury to the operator or bystanders as a result of the object or

broken parts being thrown out at high speed.

• Pay attention to the direction of the wind, i.e., do not work against

the wind.

• To reduce the risk of stumbling and loss of control, do not walk

backward while operating the machine.

• Always shut off the engine before cleaning or servicing the unit or

replacing parts.

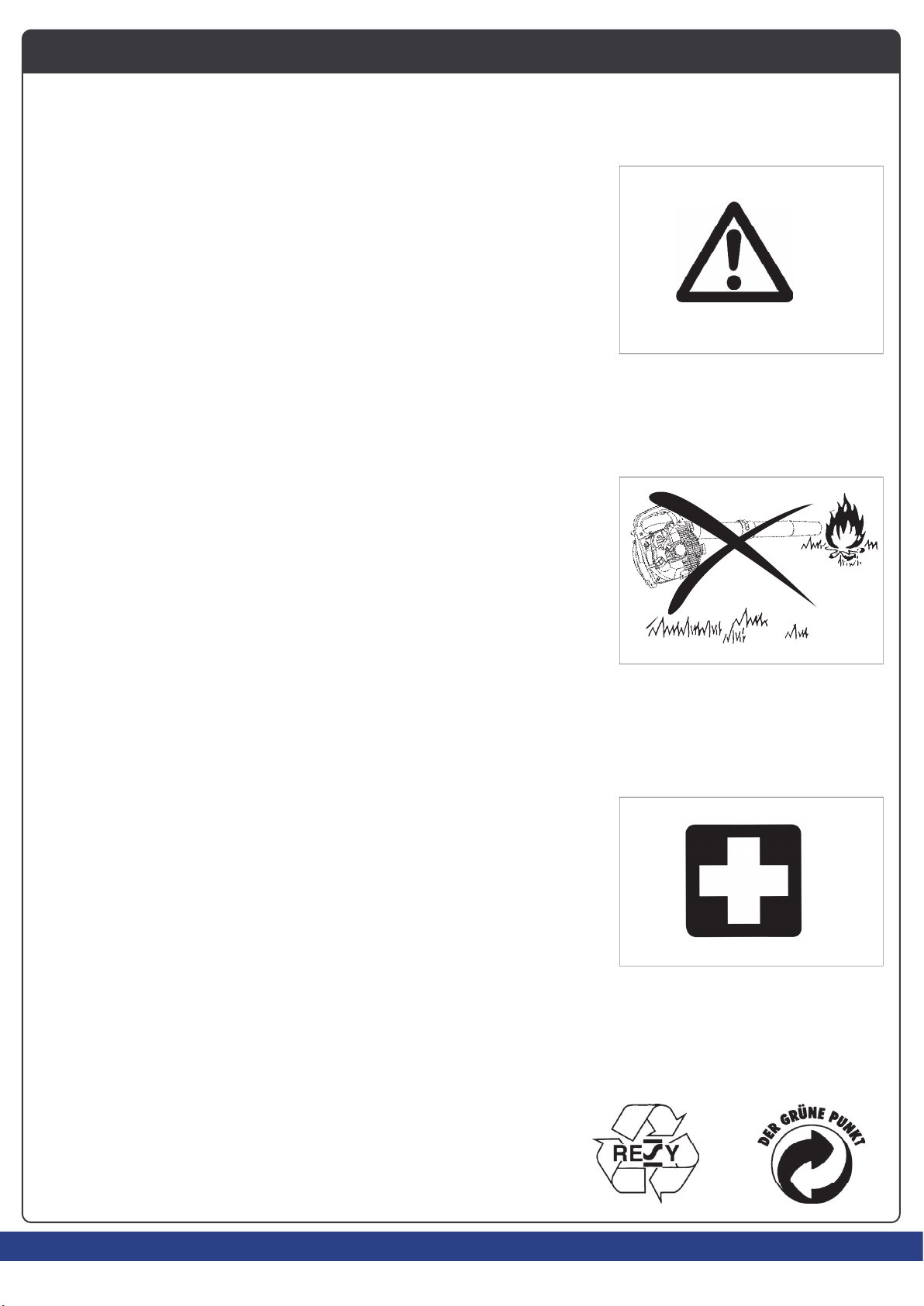

Maintenance instructions

Packaging

First Aid

When asking for help, please give the following information:

• Be kind to the environment. Operate the blower with as little noise

and pollution as possible. In particular check the correct adjustment

of the carburetor.

• Clean the blower at regular intervals and check that all screws and

nuts are securely tightened.

• Never service or store the blower in the vicinity of open flames,

sparks, etc. (11).

• Always store the blower in a well-ventilated locked room and with

an emptied fuel tank.

Observe and follow all relevant accident prevention

instructions issued by the trade associations and by

insurance companies. Do not perform any modifications to

the blower as this will risk your safety.

The performance of maintenance or repair work by the user is limited

to those activities as described in this instruction manual. All other

work is to be done by Authorized Service Agents.

Use only genuine spare parts and accessories supplied by BILT HARD.

Use of non-approved accessories and tools means increased risk of

accidents and injuries. BILT HARD will not accept any liability for

accidents or damage caused by the use of any non-approved

attachment or accessories.

(10)

(12)

(11)

In case of accident make sure that a well-stocked first-aid kit is

available in the vicinity of the operations. Immediately replace any item

taken from the first aid kit.

• Place of accident

• What happened

• Number of injured persons

• Extent of injuries

• Your name

The BILT HARD blower is delivered in a protective cardboard box to

prevent shipping damage. Cardboard is a basic raw material and is

therefore consequently reusable or suitable for recycling (waste

paper recycling).

Table of contents

Other BILT HARD Blower manuals

Popular Blower manuals by other brands

Lithium Earthwise

Lithium Earthwise LB20024 Operator's manual

EINHELL

EINHELL GE-CL 36 Li E Original operating instructions

EINHELL

EINHELL VENTURRO 18/210 operating instructions

Troy-Bilt

Troy-Bilt 657 Operator's manual

Weed Eater

Weed Eater VS2000BV instruction manual

KRAUSMANN

KRAUSMANN U37020-00 Operation manual