Binching RF20-10 Setup guide

This manual suits for next models

6

Table of contents

Popular Control Unit manuals by other brands

Huawei

Huawei EM770U manual

Danfoss

Danfoss VLT HVAC Drive FC 102 operating instructions

Texas Instruments

Texas Instruments TMCS1101EVM user guide

Profort

Profort multiGuard Master IO Start-up

Sun Microsystems

Sun Microsystems Sun Cobalt Control Station Maintaining and Upgrading the Hardware

IBM

IBM 3274 user guide

Lawler

Lawler 802 Installation & maintenance manual

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS CTM-EF 3 3 Series Operating and maintenance instructions

SIGLENT

SIGLENT STB3 user manual

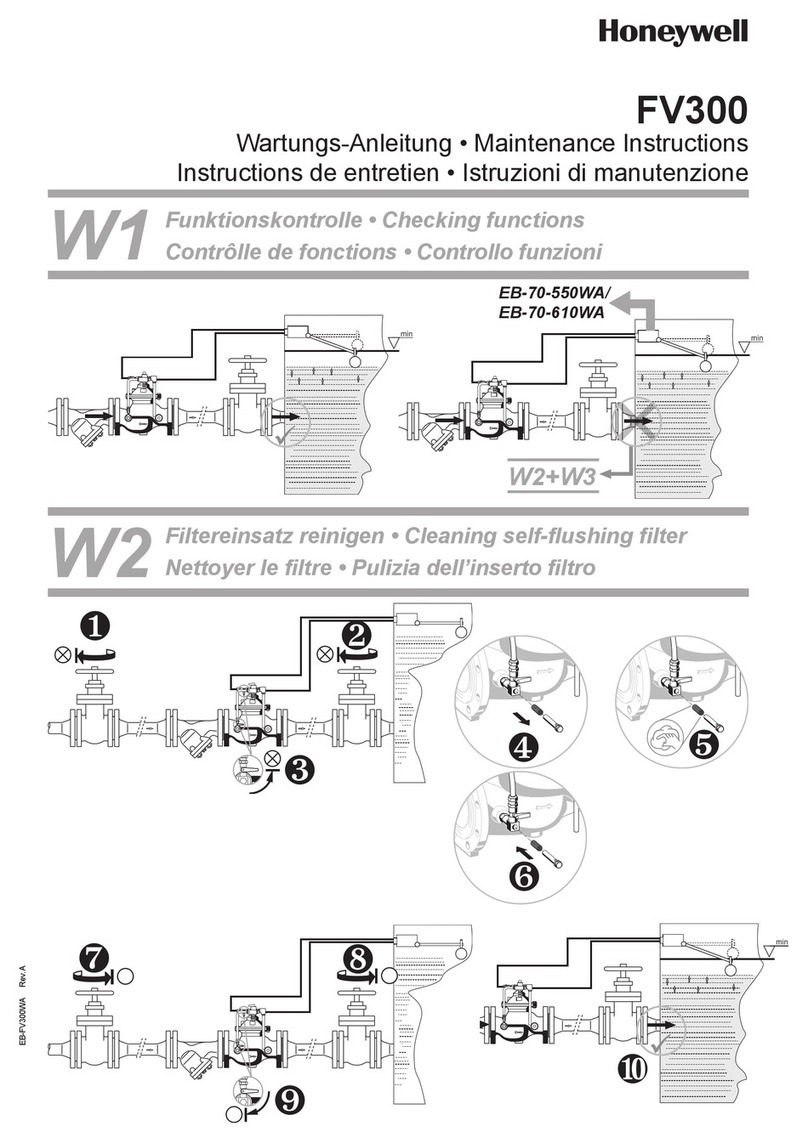

Honeywell

Honeywell FV300 Maintenance instructions

indie

indie iND83405 Quick start user guide

HP

HP Synergy 480 Gen9 Maintenance and service guide

NimbeLink

NimbeLink Skywire NL-SW-LTE-GELS3 manual

Ogden

Ogden ETR-9040 instruction manual

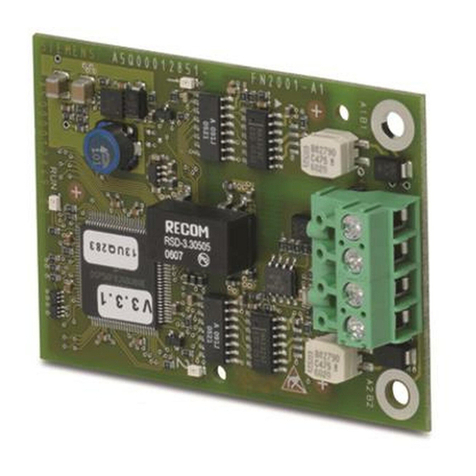

Siemens

Siemens SAFEDLINK Mounting & installation

Videx

Videx 4830 Installation instruction

Espressif Systems

Espressif Systems ESP32-WROVER-E user manual

Spirax Sarco

Spirax Sarco HM Series Installation and maintenance instructions