UF V (E3) 04/2023 Page 2/123

Contents

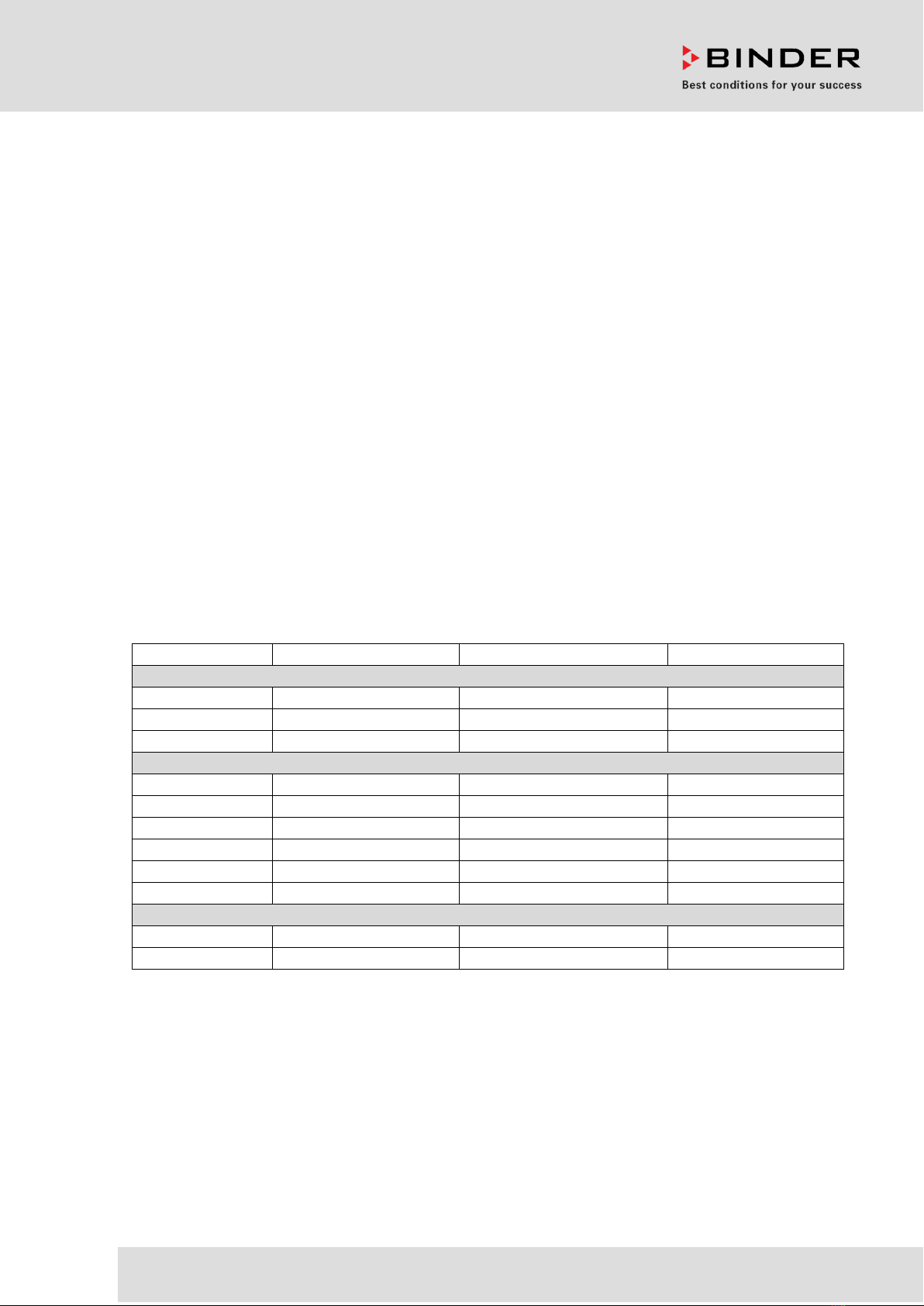

1. SAFETY.................................................................................................................. 6

1.1 Personnel Qualification .......................................................................................................................6

1.2 Operating manual................................................................................................................................6

1.3 Legal considerations ...........................................................................................................................6

1.3.1 Intellectual property ...................................................................................................................7

1.4 Structure of the safety instructions......................................................................................................7

1.4.1 Signal word panel......................................................................................................................7

1.4.2 Safety alert symbol....................................................................................................................8

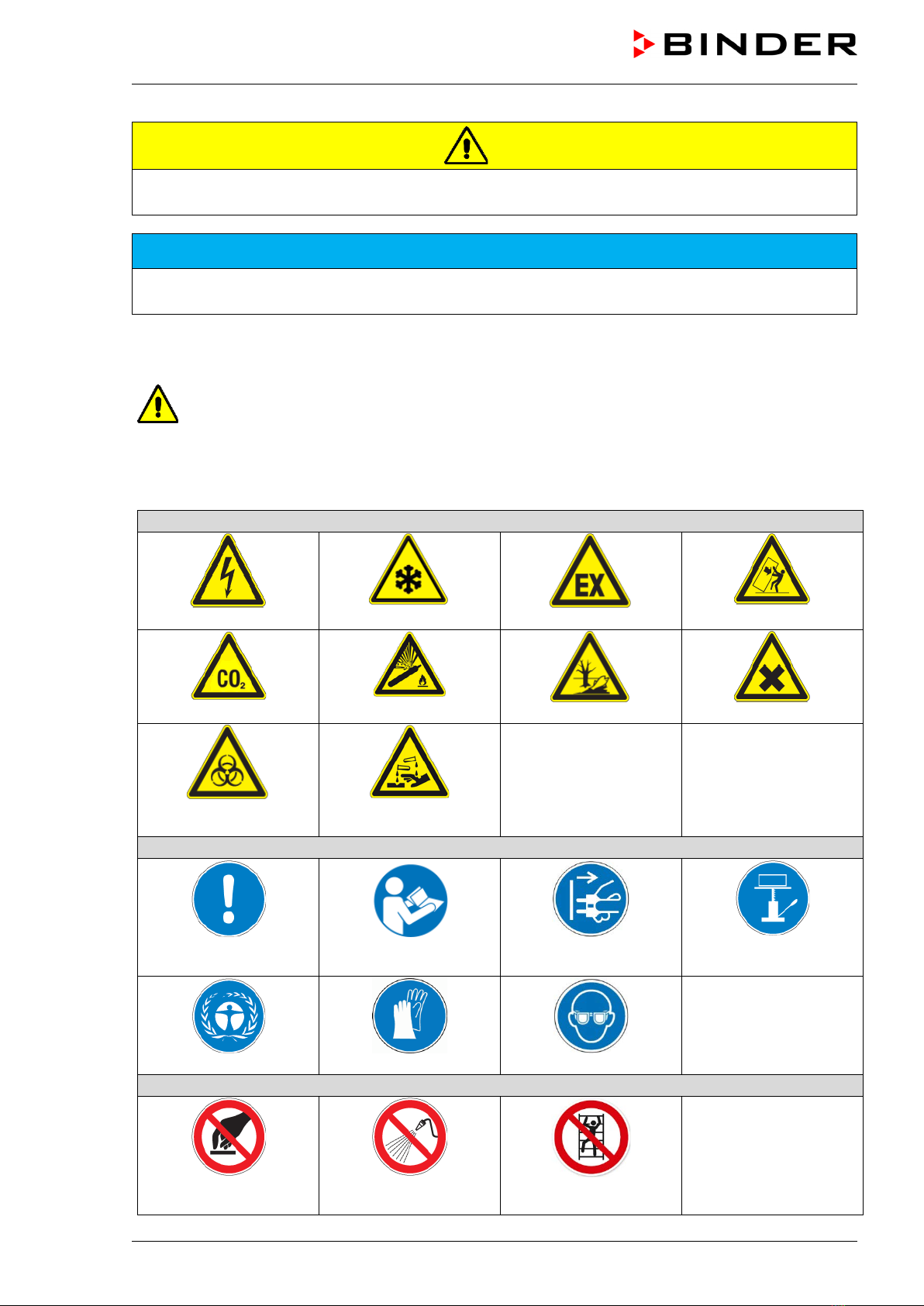

1.4.3 Pictograms.................................................................................................................................8

1.4.4 Word message panel structure .................................................................................................9

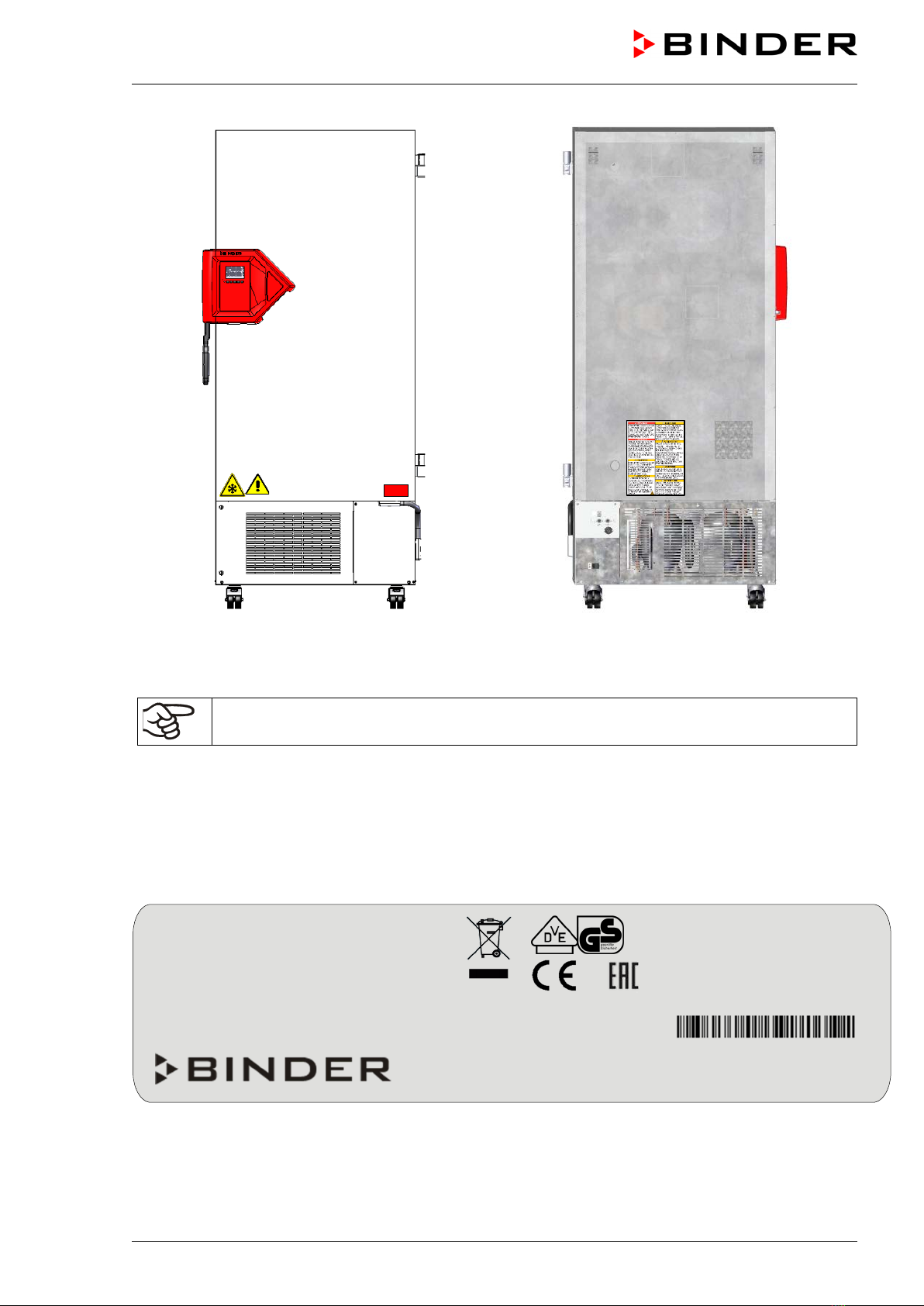

1.5 Localization / position of safety labels at the chamber .......................................................................9

1.6 Type plate..........................................................................................................................................10

1.7 UKCA Label ......................................................................................................................................12

1.8 General safety instructions on installing and operating the chamber ...............................................12

1.9 Intended use .....................................................................................................................................14

1.10 Foreseeable Misuse..........................................................................................................................16

1.11 Residual Risks ..................................................................................................................................16

1.12 Operating instructions .......................................................................................................................18

1.13 Measures to prevent accidents .........................................................................................................18

2. CHAMBER DESCRIPTION .................................................................................. 19

2.1 Chamber overview ............................................................................................................................21

2.2 Door lock and controller housing ......................................................................................................23

2.2.1 Operating the NumPad (option “Door access system” for UF V 500 and UF V 700)..............24

2.2.2 Operating the electromechanical door locking (option “Door access system” for UF V 500 and

UF V 700)................................................................................................................................24

2.3 Main power switch.............................................................................................................................25

2.4 Chamber rear ....................................................................................................................................26

2.5 Doors.................................................................................................................................................27

2.5.1 Outer door ...............................................................................................................................27

2.5.2 Compartment doors.................................................................................................................27

2.5.3 Operating the door lock (option “Lockable door handle”)........................................................28

2.6 Drain well for condensate during defrosting (option) ........................................................................28

3. COMPLETENESS OF DELIVERY, TRANSPORTATION, STORAGE, AND

INSTALLATION.................................................................................................... 29

3.1 Unpacking, and checking equipment and completeness of delivery ................................................29

3.2 Guidelines for safe lifting and transportation.....................................................................................30

3.2.1 Moving the freezer inside a building........................................................................................30

3.2.2 Transport outside a building ....................................................................................................31

3.3 Storage..............................................................................................................................................32

3.4 Location of installation and ambient conditions ................................................................................32

4. INSTALLATION AND CONNECTIONS ............................................................... 34

4.1 Operating instructions .......................................................................................................................34

4.2 Spacers for rear wall distance...........................................................................................................34

4.3 Support feet (UF V 350 only) ............................................................................................................34

4.4 Adjustable shelves ............................................................................................................................35

4.5 Connections of cooling water for chambers with water cooling ........................................................37

4.5.1 Connection of cooling water outlet for water cooling...............................................................37

4.5.2 Connection of cooling water inlet for water cooling.................................................................38

4.5.3 Connection kit for cooling water ..............................................................................................38

4.6 Electrical connection .........................................................................................................................40

4.7 Advanced voltage booster (option) ...................................................................................................40