Bio-Logic PURE WATER PACK BIO 1.5 PWP User manual

1

Document No. 98-1524D2 • May 2017 • ©2017 Atlantic Ultraviolet Corporation®• ASSEMBLED IN THE USA

Models Ballast

120v 50/60 Hz

Ballast

230v 50/60Hz

BIO 1.5 PWP 10-0518A 10-0514A

Extensive Product Information Available at:

ultraviolet.com

buyultraviolet.com

Installation,

Operation

& Maintenance

Read and Follow All Safety

Instructions. Save These

Instructions.

Owner’

s Manual

Owner’

s Manual

2

TABLE OF CONTENTS

SAFETY WARNINGS .......................................................................................................................................................................3

SAFETY INSTRUCTIONS ..............................................................................................................................................................3

SAFETY LABELING........................................................................................................................................................................3

CAUTION...........................................................................................................................................................................................3

PRODUCT APPLICATION .............................................................................................................................................................4

ConstruCtion .................................................................................................................................................................................................... 4

PrinCiPle of oPeration .................................................................................................................................................................................... 4

limitation of use.............................................................................................................................................................................................. 4

Water Quality ................................................................................................................................................................................................. 4

INSTALLATION ...............................................................................................................................................................................5

loCation .........................................................................................................................................................................................5

saddle ValVe installation ............................................................................................................................................................6

fauCet installation ................................................................................................................................................................... 6-7

system installation ................................................................................................................................................................... 7-8

tubing installation .......................................................................................................................................................................9

tubing remoVal .............................................................................................................................................................................9

teChniCal assistanCe .....................................................................................................................................................................9

reCommended oPtions....................................................................................................................................................................9

MAINTENANCE.............................................................................................................................................................................10

insPeCtion .....................................................................................................................................................................................10

filter Cartridge rePlaCement ....................................................................................................................................................10

lamP installation or rePlaCement .............................................................................................................................................11

Quartz sleeVe installation, Cleaning or rePlaCement ............................................................................................................12

rePlaCement of broken Quartz sleeVe................................................................................................................................ 13-14

disPosal of merCury added lamP ..............................................................................................................................................14

TROUBLESHOOTING ..................................................................................................................................................................14

TECHNICAL SPECIFICATIONS.................................................................................................................................................15

DIMENSIONAL DATA...................................................................................................................................................................16

REPLACEMENT PARTS...............................................................................................................................................................17

Bio-Logic®BIO-1.5 Ultraviolet Water Purier .........................................................................................................................17

Pure Water PackTM ...................................................................................................................................................................18

MAINTENANCE NOTES ..............................................................................................................................................................19

USER ASSISTANCE .......................................................................................................................................................................20

PRODUCT REGISTRATION ........................................................................................................................................................20

WARRANTY ....................................................................................................................................................................................20

Patent notiCe...............................................................................................................................................................................20

These instructions generally describe the installation, operation and maintenance of the Bio-Logic®Pure Water PackTM

Questions that are not specically answered by these instructions should be directed to the Factory.

Atlantic Ultraviolet Corporation® takes all possible precautions when packaging equipment to prevent damage.

Carefully inspect and report all damage upon receipt of product. Do not install damaged equipment.

Follow all instructions on all labels and tags. Carefully inspect all packing materials

before discarding to prevent the loss of accessories, mounting hardware,

spare parts or instructions.

The information and recommendations contained in this publication are based upon data

collected by the Atlantic Ultraviolet Corporation®and are believed to be correct. However, no

guarantee or warranty of any kind, expressed or implied, is made with respect to the information

contained herein. Specications and information are subject to change without notice.

3

SAFETY WARNINGS

SAFETY INSTRUCTIONS

• All personnel should be alerted to the potential hazards indicated by the product safety labeling on this unit.

• The following conventions are used to indicate and classify precautions in this manual and on product safety labeling. Failure to

observe precautions could result in injury to people or damage to property.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

This symbol is used to identify the need to wear

protective gloves.

!

Caution indicates a POTENTIALLY

hazardous situation, which, if not avoided,

MAY result in minor or moderate injury.

Caution used without the safety alert symbol

indicates a potentially hazardous situation, which,

if not avoided, may result in property damage.

Warning indicates a POTENTIALLY

hazardous situation, which, if not avoided,

COULD result in death or serious injury.

This symbol is used to identify an

ULTRAVIOLET LIGHT hazard.

This symbol is used to identify an ELECTRICAL

SHOCK or ELECTROCUTION hazard.

This symbol is used to identify the need to wear

approved ultraviolet blocking eyewear.

This symbol is used to identify the need to wear approved

ultraviolet blocking face shield.

This symbol is used to identify components which must

not be disposed of in trash

Danger indicates an IMMINENTLY

hazardous situation, which, if not avoided,

WILL result in death or serious injury.

SAFETY LABELS CAUTION

UV

ULTRAVIOLET

RADIATION

Protect eyes and skin from

direct and reflected radiation.

Turn off and disconnect

power before servicing.

HAZARDOUS

VOLTAGE

DANGER

!

Danger Label: Hazardous Voltage

and Ultraviolet Radiation (00-0196A1)

It is the user’s responsibility to determine and validate the

suitability of this equipment for use in the user’s system or

process.

No warranty or representation is made by the manufacturer

with respect to suitability or performance of this equipment

or to the results that may be expected from its use.

The user should periodically inspect, clean as necessary

and conrm the presence and good legibility of the product

safety labels. Contact the factory for replacement labels in

the event that any of the labels are missing or illegible.

Location of Danger Label

(00-0196A1)

To guard against injury, basic safety precautions should be observed, including the following:

1. Read and follow ALL safety instructions.

2. Do not use this water purier for other than its intended purpose as described in this manual.

3. Do not alter design or construction.

4. Do not remove any labels or devices.

5. To prevent the risk of severe or fatal electrical shock, special precautions must be taken since

water is present near electrical equipment. Always disconnect power before performing any service or maintenance.

6. Avoid exposure to direct or reected germicidal ultraviolet rays. Germicidal ultraviolet rays are

harmful to the eyes and skin.

7. Intended for indoor use only. The water purier should be protected from the elements and from temperatures below freezing.

8. Do not operate water purier if lamp cable, lamp connection, power cord and/or plug are damaged, or if any other damage to

the water purier is visible or suspected

9. Electrical power supplied, to the water purier, MUST match power requirements listed on the water purier.

10. Plug the water purier only into an approved ground fault circuit interrupt (GFCI) receptacle.

11. Do not operate without proper electrical ground.

12. Do not exceed water purier’s maximum rated ow capacity.

13. Do not exceed maximum operating pressure of 100 PSI.

14. Read and follow all notices and warnings on the water purier.

15. SAVE THESE INSTRUCTIONS.

4

PRODUCT APPLICATION

ConstruCtion

• All ltration and disinfection components of the Bio-Logic®Pure Water PackTM are conveniently mounted on a single,

stainless steel, mounting bracket.

• The system is designed to mount on a vertical surface, a secure (stud or concrete) wall or a cabinet wall, by the system-

mounting bracket.

• The faucet, supplied with the system, is a low lead, stainless steel faucet, with a hand operated, spring closed lever. The

faucet can be locked in the “ON” position by pushing the lever up locking it against the spout.

• The water purier’s dual chamber heads are removable and may be rotated independently, which aids in the installation,

maintenance or the retrotting of an existing system.

• The water purier’s chamber, and chamber heads are electropolished and passivated type 316 stainless steel.

• EASY-OFFTM End Caps enable quick and easy lamp change, without disconnecting the system from the water supply or

draining the purier. No tools are required. Always disconnect electrical power when changing lamp.

PrinCiPle of oPeration

The Bio-Logic®Pure Water PackTM lter system removes sediment, rust, scale, and particulates, while reducing tastes, odors,

organic chemicals and turbidity. The Bio-Logic®is the ultraviolet disinfection element of the Pure Water PackTM.

The Bio-Logic® design has been carefully conceived to provide adequate germicidal dosage throughout the disinfection chamber.

The dosage, as it applies to ultraviolet disinfection, is a function of time, and the intensity, of ultraviolet radiation, to which the

water is exposed. The exposure time, in seconds, is the total time it takes the water to ow through the disinfection chamber,

exposing it to the germicidal lamp. Exposure time is related to the ow rate; the higher the ow rate, the lower the exposure time

or the lower the ow rate, the higher the exposure time. The ultraviolet intensity is the amount of energy, per unit time, emitted by

the germicidal lamp. The operation of the Bio-Logic® is as follows:

• Water enters the purier and ows into the annular space between the quartz sleeve and the chamber wall.

• Suspended microorganisms are exposed to the ultraviolet rays emitted by the germicidal lamp.

• The LED indicator light, located on the ballast, provides visual indication of germicidal lamp operation.

• Water leaving the purier is instantly ready for use, no further contact time is required.

limitation of use

The water purier is intended for the use with visually clear water, not colored, cloudy or turbid. See “Water Quality” section

below. The water purier is NOT intended for the treatment of water that has an obvious contamination or intentional source,

such as raw sewage; nor is the unit intended to convert wastewater to microbiologically safe drinking water.

Water Quality

Water quality plays a major role in the transmission of germicidal ultraviolet rays. It is recommended that the water does not

exceed the following maximum concentration levels:

Table 1 - Maximum Concentration Levels

Turbidity < 1 NTU

Manganese 0.05 mg/1

Total Suspended Solids 10 mg /1

pH: 6.5 - 9.5

Color: None

Hardness 6 GPG or 102.6 PPM

Iron 0.3 mg/1

Tannins: < 0.1 ppm (0.1 mg/l)

UV Transmission >85% per cm*

* Contact Factory for recommendations on applications where UV transmission is < 85%

Effectively treating water with higher concentration levels than listed above can be accomplished, but may require added

measures to improve water quality to treatable levels. If, for any reason, it is believed the ultraviolet transmission is not

satisfactory, contact the factory.

5

Pure Water PackTM INSTALLATION

loCation

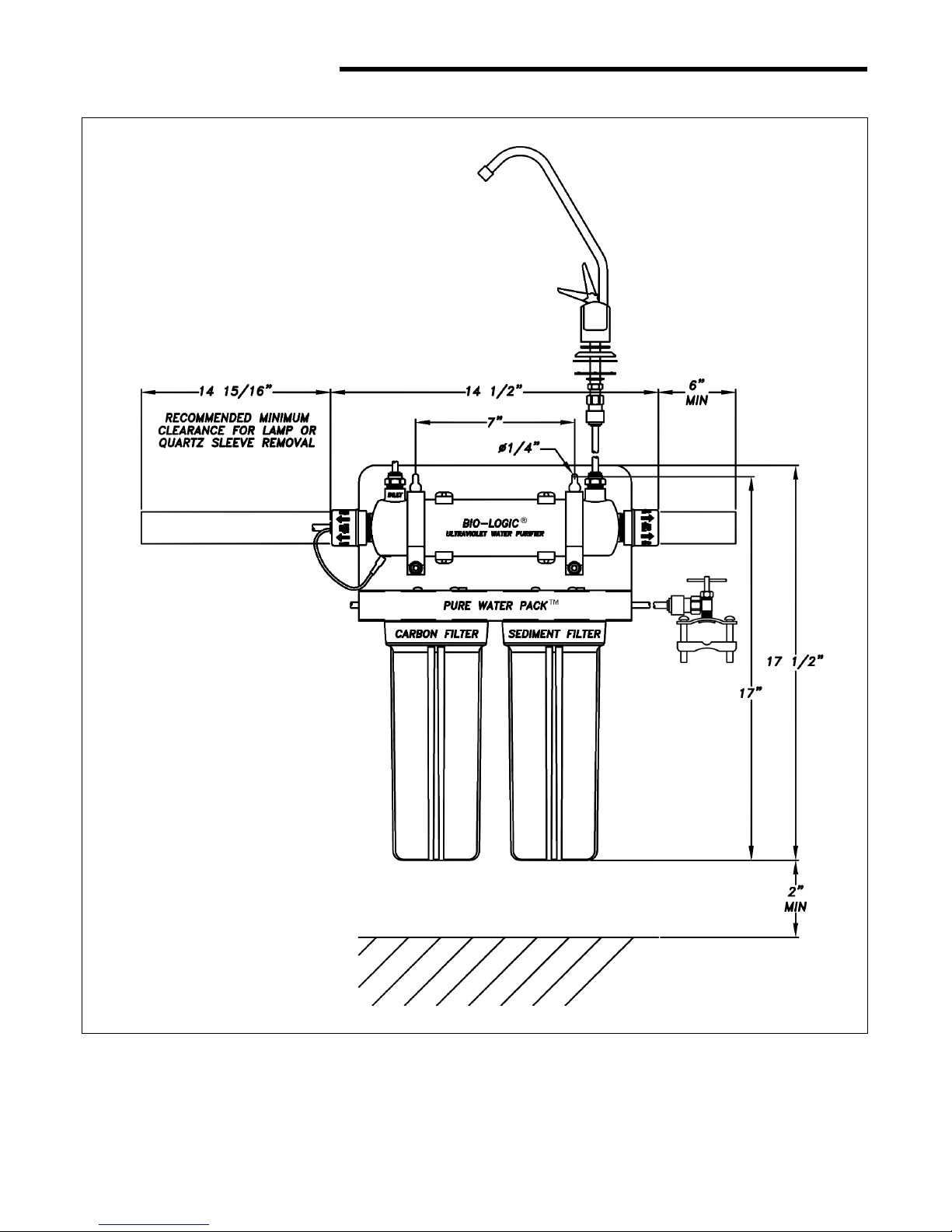

1. The Pure Water PackTM is designed for “under the sink” installation. The system should be mounted vertically, to a secure

wall or cabinet wall, which provides enough room to perform routine maintenance. This includes a minimum of 14-15/16

inches from the chamber end, to allow for removal of the lamp and/or quartz sleeve, a minimum of 6-inches on the backside

of the water purier, and a minimum of 2-inches free space under the lter housings, to allow for housing removal, when

changing lter cartridges.

Figure 1 - Bio-Logic®Pure Water Pack TM - Drinking Water System

2. The water purier is intended for indoor use only. The water purier should be protected from the elements and from

temperatures below freezing. The ambient temperature, in the area surrounding the water purier, should be between

35� F and 100� F.

3. Electrical power supplied to the water purier MUST match power requirements listed on the water purier. Use of a voltage

surge protector is recommended.

4. The water purier MUST be connected to the cold water line only.

5. The system should be located as close to the faucet as possible. This eliminates the possibility of the puried water being

re-contaminated by bacteria in the water distribution system after the water purier.

6. As with any water handling device, the water purier should be located in an area where any possible

condensation or leakage from the water purier, any purier accessory and/or plumbing will not result in damage to the area

surrounding the water purier. For added protection, it is recommended that a suitable drain pan be installed under the

purier. The drain pan must be plumbed to an adequate, free owing, drain to prevent water damage in the event of

a leak. There are numerous leak detection/ood stop devices, available on the market today, designed to stop the ow

of water, reducing the chance of water damage due to leakage. For more details regarding leak prevention and/or

limiting damages due to leaks, please contact the factory.

7. The system should be located within 5-feet of an electrical receptacle. The receptacle must be a properly

installed, grounding type, receptacle that has Ground Fault Circuit Interrupter (GFCI) protection.

6

saddle ValVe installation

IN ORDER TO PERFORM THIS TASK, BE SURE TO WEAR THE FOLLOWING SAFETY

EQUIPMENT: SAFETY GOGGLES OR A FACE SHIELD, AS WELL AS GLOVES

Check with the local public works department for plumbing codes. Follow all local plumbing codes when installing components

of this system.

The system comes supplied with a saddle valve and mounting hardware and is intended to be used on 3/8 inch to 1/2 inch copper

tubing, and should be connected to the cold water line only. NOTE: This valve is not to be used on ex lines.

1. Shut off the cold-water supply valve under the sink or

main valve for the house.

2. Locate saddle valve in an accessible area. Slide the

clamp over the copper tubing and tighten the bottom

screw rmly to hold the clamp in position.

3. Pierce the copper tubing by turning the “T” handle

clockwise, until it is rmly seated. The valve is

CLOSED in this position.

4. Open the cold-water supply valve or main valve, check

for any signs of leaks around valve connection.

5. Install John GuestTM Tubing Connector on to the outlet

of the saddle valve. Insert 1/4 inch OD tubing into the

end of tubing connector see “Tubing Installation”.

DO NOT OPEN saddle valve until system is completely installed, doing so, at this time,

will allow water to ow from the valve.

fauCet installation

IN ORDER TO PERFORM THIS TASK, BE SURE TO WEAR THE FOLLOWING SAFETY EQUIPMENT: SAFETY

GOGGLES OR A FACE SHIELD, AS WELL AS GLOVES

Most sinks have an extra hole to mount additional faucets, sprayers or soap dispensers. If the sink does

not have an additional hole, or it is being used by another attachment, a hole must be drilled in either

the sink or countertop. The faucet stem requires a 1/2 inch diameter clearance hole for mounting; the chrome base plate will cover

up a 1-1/2 inch diameter hole.

Figure 3 - Faucet Mounting

Figure 2 - Saddle Valve with Hardware

7

fauCet installation Cont.

1. Select faucet location.

• Make sure the faucet is far enough away so not to interfere with the regular faucet or any other attachments.

• If mounting faucet on the countertop, make certain the spout of the faucet will reach over the sink.

• Check underneath the sink/countertop for any obstructions and for tool clearances required for mounting the faucet.

• Make certain the faucet will t at against the sink/countertop, so 1-7/8 inch rubber washer will seal against chrome

base plate and sink/countertop.

2. Mark the center of the faucet location.

To avoid possibly damaging sink and/or countertop, consult a qualied plumber or installer,

special tools may be required for drilling porcelain, stainless steel, tile, etc.

3. Using appropriate tools for particular sink or countertop construction, make a 1/2 inch diameter mounting hole.

4. Install the 1-1/4 inch rubber washer onto the faucet, followed by the chrome base plate, and nally the 1-7/8 inch rubber

washer. These parts must be installed onto the faucet before mounting the faucet to the sink or countertop.

5. Install faucet into the mounting hole. From under the sink install the 1-3/4 inch washer, the locking washer and thread the

9/16 inch nut onto the faucet. Align the faucet to desired position, and rmly tighten the nut.

6. Install John GuestTM Tubing Connector on to the inlet of the faucet. Insert 1/4 inch OD tubing into the end of tubing

connector. See “Tubing Installation”.

system installation

IN ORDER TO PERFORM THIS TASK, BE SURE TO WEAR THE FOLLOWING SAFETY

EQUIPMENT: SAFETY GOGGLES OR A FACE SHIELD, AS WELL AS GLOVES

1. Once a suitable location, for the system, has been chosen, mark the location of the mounting screws, using the holes on the

mounting bracket as a template.

2. Using appropriate fasteners, for the type wall chosen, mount the system through the holes of the mounting bracket.

3. Tubing Connections:

a. Run the tubing, connected to the saddle valve, to the inlet tting of the sediment lter.

b. Run the precut 24” tubing from the outlet of the carbon lter, to the inlet of the Bio-Logic® water purier.

c. Run the tubing from the faucet to the outlet of the Bio-Logic® water purier. Measure, cut tubing. The tubing must be

cut square, free of burrs and sharp edges. Leave enough slack in the tubing so the system can be easily

removed, if necessary.

4. Turn on the faucet, supplied by the Pure Water PackTM system. NOTE: Lifting the handle, of the faucet, will lock the

faucet in the “ON” position, while holding the handle down the faucet is “ON”, the faucet will shut off when the handle is

released. Slowly open the saddle valve, by turning the “T” handle counter-clockwise until fully open, and allow the system to

ll with water.

5. Once water begins to ow from the faucet, allow water to run for several minutes until it is clear with no air bubbles. Turn off

the faucet and check the system for leaks. If leaks occur see “Troubleshooting” section. If no leaks occur, proceed to install

the ultraviolet lamp.

6. Unpack the lamp and ballast. While holding lamp end, carefully push lamp socket on. Carefully slide lamp straight into the

quartz sleeve, without angling. Push the End Cap on, over the static gland nut. Attach the ground connector to the grounding

tab of the chamber.

To ensure proper operation and safety of the purier, your unit must be connected

to a known good ground.

Lamp and quartz sleeve are easily damaged. Exercise care when handling.

7. For 120v 50/60Hz operation using ballast no. 10-0518A and 230v 50/60Hz using ballast 10-0514A, plug ballast into

an approved Ground Fault Circuit Interrupt (GFCI) receptacle. Where a 2-prong or unprotected 3-prong receptacle is

encountered, it must be replaced by a properly grounded Ground Fault Circuit Interrupt (GFCI) receptacle. Installation must

be in accordance with the National Electrical Code and any local codes and ordinances by a qualied electrician. For 12v DC

operation, The ballast must be wired to an adequate 12v DC source with appropriate gauge wire for the voltage and current. It

is recommended that the ballast have a dedicated run to the 12v source, and protected by either a fuse or circuit breaker.

Step 7 Continued on Page 8

8

• Always disconnect the battery(s), or other 12v source, before installation or performing any maintenance.

• The ballast is supplied with a 6-foot, 2 wire, power cord and 5-foot lamp cord, the ballast must be located so the lamp is

easily removed and does not put any tension on the lamp, which could cause damage to the lamp and/or quartz sleeve.

All installed wiring should be protected from heat, wear points (abrading) or mechanical stress. Secure ballast using the

mounting tabs located on the ballast body.

• Wire ballast power cord as follows;

• Brown wire - Positive (+) to protected (fuse or circuit breaker) 12v DC source.

• Blue wire - Negative (-) to suitable chassis ground.

• If there are any questions or concerns regarding the installation and/or wiring of the 12v system, consult a qualied

installer.

8. It is recommended, when the carbon lter is new, to ush out the system thoroughly prior to use. Turn on the system’s faucet

and allow water to run for 10 minutes to ush the lter and system.

Figure 4 - Bio-Logic®Pure Water Pack TM - Install

9. Plug ballast into an approved Ground Fault Circuit Interrupt (GFCI) receptacle. Where a 2-prong or unprotected 3-prong

receptacle is encountered, it must be replaced by a properly grounded Ground Fault Circuit Interrupt (GFCI) receptacle.

Installation must be in accordance with the National Electrical Code and any local codes and ordinances by a qualied

electrician.

10. Once the plumbing hook ups are made, it is a good practice to disinfect the “downstream” plumbing. This is done by

introducing chlorine or other disinfectant solution directly into the purier chamber, a 100-ppm of chlorine is suggested. With

the disinfectant solution in the purier chamber, turn the ultraviolet purier on. Open the “downstream” outlet until order is

noticed. Close the outlet and allow the disinfectant to remain in the plumbing for at least three (3) hours. Flush the plumbing

with ultraviolet puried water; allow the water to run for several minutes before use, this will allow the ultraviolet lamp to

reach its full germicidal output.

9

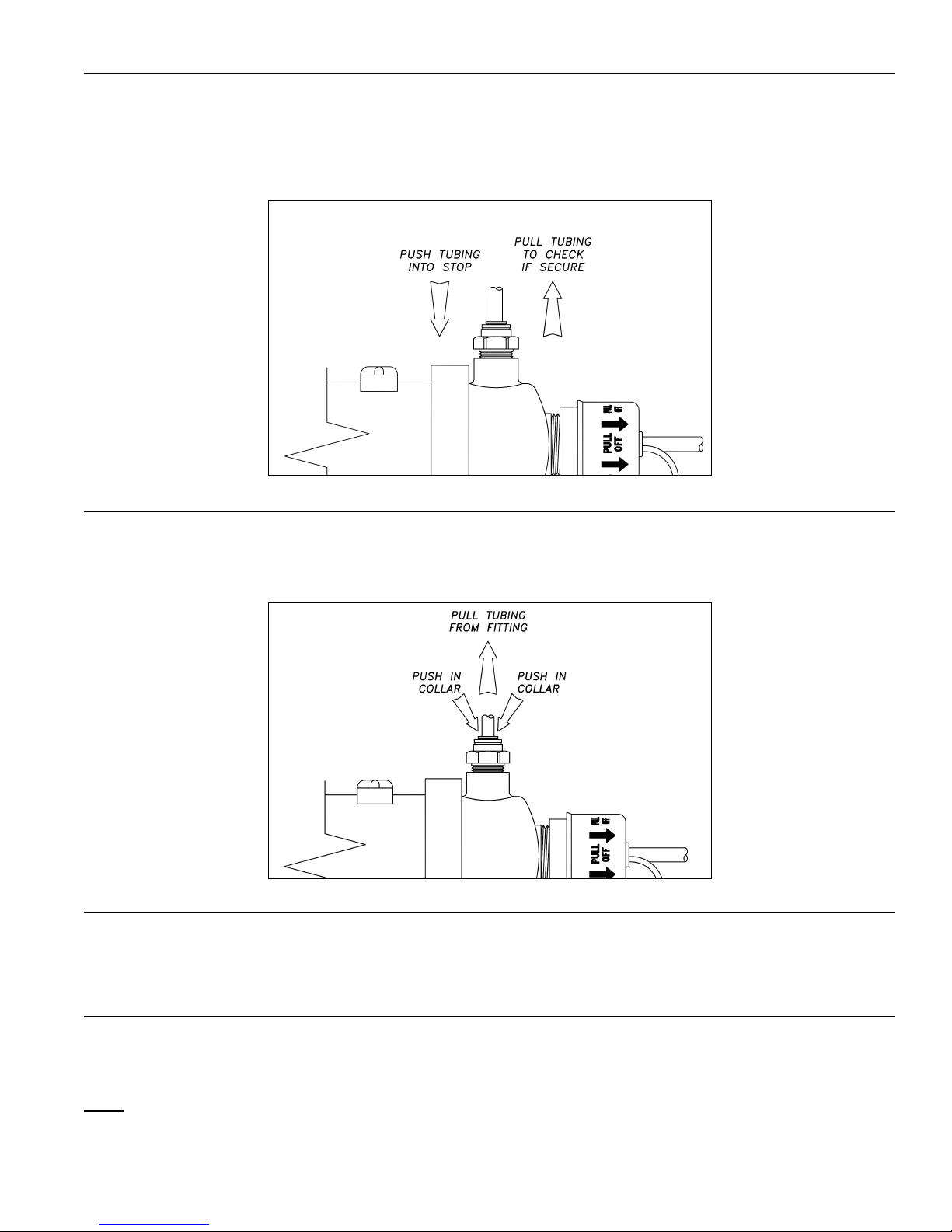

tubing installation

• Measure and cut the tubing to desired length. Leave enough slack in the tubing so the system can be easily removed, if

necessary. Cut the tubing square; remove all burrs and sharp edges.

• Insert tubing into tting; push until it reaches the tube stop. Avoid kinking or stretching tubing. Check that tubing is secure;

gently pull on tubing, tubing should not pull free from tting.

Figure 5 - Tubing Installation

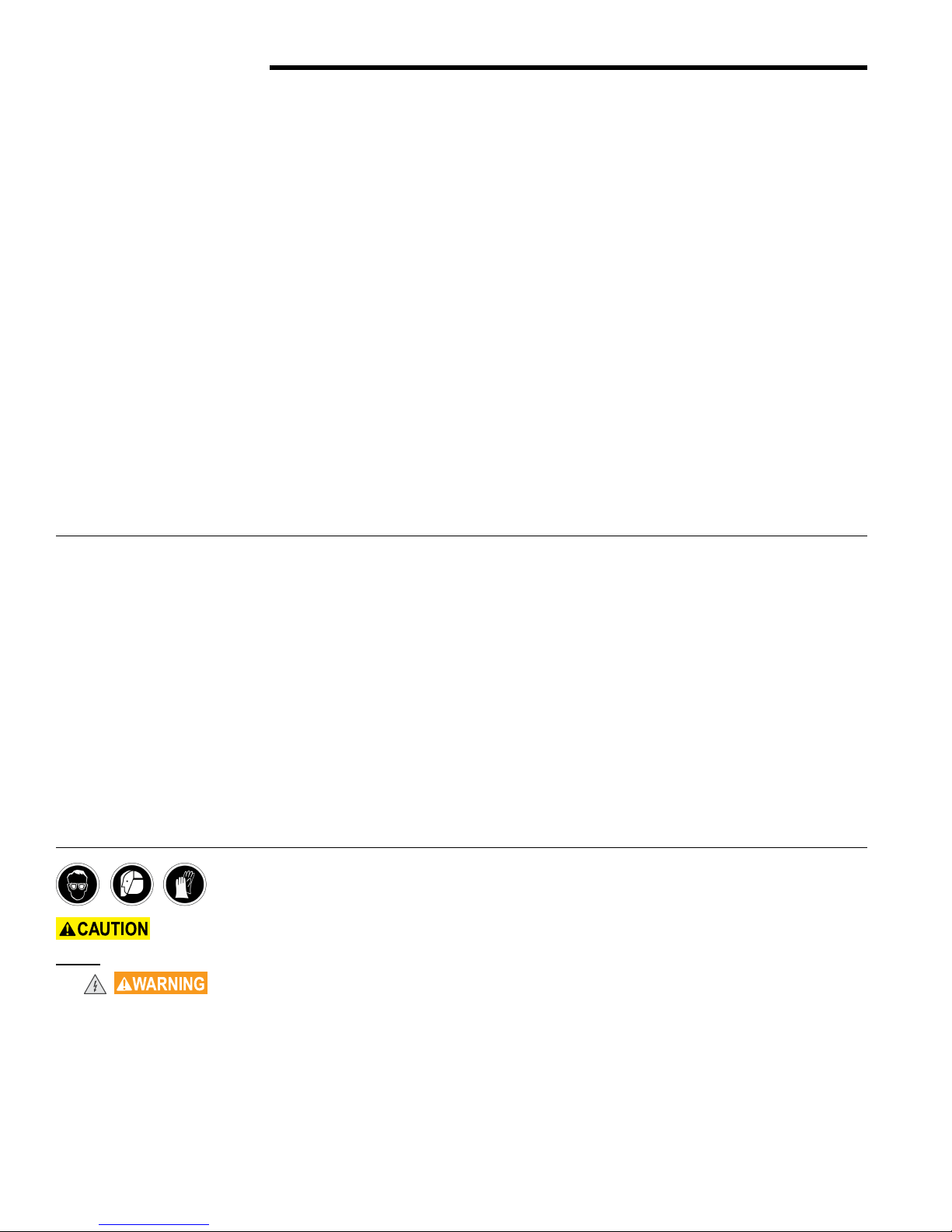

tubing remoVal

• If the system has been in use, shut off supply valve and drain the system before removing any tubing.

• Push in collar, squarely against the face of the tting. Holding collar in position, pull tubing from the tting.

Figure 6 - Tubing Removal

teChniCal assistanCe

Atlantic Ultraviolet Corporation maintains a qualied team of application specialists that can provide any technical assistance,

which maybe required during the use of this system. For any questions, concerns, or technical assistance, regarding this system or

any of our other products, contact our application specialists. Contact options can be found in the “User Assistance” section.

reCommended oPtions

1. PromateTM Safety Goggles: Safety eyewear should be used as general-purpose safety protection and for additional shielding

from ultraviolet rays

2. PromateTM Face Shield: Adjustable headgear and lightweight visor provides eye and face protection from ultraviolet rays.

NOTE: The recommended options above are available from Atlantic Ultraviolet Corporation®or a distributor of their

products. For the other devices that may be required for your application, please contact your local water treatment

dealer, plumber or plumbing supplier.

10

MAINTENANCE

The Bio-Logic®Pure Water PackTM is designed to operate with a minimal amount of maintenance, providing the water

quality does not exceed maximum concentration levels, see “Water Quality” in the “Product Application” section. Ordinary

maintenance consists of:

• Filter cartridge replacement is recommended every 12 months. Over time water pressure to the system faucet will drop,

this is an indication that the lter cartridges are nearing the end of their service life.

• In poor quality water supplies lter cartridges may clog more rapidly, before the 12 months are up, reducing water

pressure to the system faucet. In these cases, change lter cartridges immediately. Changing lter cartridges will restore

normal water pressure.

• Lamp replacement is recommended every 10,000 hours of operation (approximately 12 months of continuous service).

• Cleaning of the quartz sleeve, when conditions warrant. It is recommended that the inspection of quartz sleeve be performed

after one month of use. If quartz sleeve is found to be coated (not clear), then frequency of cleaning must be done more often.

Deposits or discoloration on the surface of quartz sleeve are caused by excessive levels of the subject contaminant within

the water that is in contact with the quartz sleeve. Most deposits on the quartz sleeve are caused by an excess of calcium

(hardness), iron or manganese. Table 1 on Page 4 lists the maximum recommended concentration of these minerals in the

water that passes through the ultraviolet purier. If you encounter difculty due to deposits on the quartz sleeve, your dealer

will be able to recommend suitable pretreatment to reduce or eliminate the offending contaminant. If quartz sleeve is clean

(clear) then frequency of cleaning may be extended.

• Always disconnect the water supply and completely drain the water purier if it will be subjected to temperatures

below freezing.

• Contact factory with questions.

insPeCtion

1. Regularly inspect the water purier to ensure that the germicidal lamp is still in operation.

• An LED indicator light, located on the ballast, provides visual indication of germicidal lamp operation. This provides an

indication of lamp operation and does not indicate the level of ultraviolet intensity or transmission through the water.

2. To ensure proper operation of the Bio-Logic®Pure Water PackTM, regular biological testing of the purier output water

should be performed on a schedule recommended by local public health authorities, or at minimum; at installation, quarterly

for the rst year of service and annually, at lamp replacement, for the life of the water purier.

3. Additional testing should be performed whenever modications, change or additions are made to plumbing system, pumps,

well source water etc. to ensure adequate disinfection under new condition.

4. As with any water purier installation, routine maintenance is necessary to ensure your equipment is operating correctly.

Regular inspection must also include the inspection of the ground to ensure grounding wires are secure to both the water

purier and grounding point as originally installed. Regular inspection must also include conrmation that approved ground

fault circuit interrupt (GFCI) receptacle is still operational and that water purier is plugged into this GFCI. Any components

which are damaged, or broken should be replaced.

filter Cartridge rePlaCement

IN ORDER TO PERFORM THIS TASK, BE SURE TO WEAR THE FOLLOWING SAFETY

EQUIPMENT: SAFETY GOGGLES OR A FACE SHIELD, AS WELL AS GLOVES

Never remove lter housings while the system is pressurized.

NOTE: Place a small bucket under the system, when changing lter cartridges, to catch any water that may leak from system.

1. Disconnect and remove power to water purier.

2. Shut off water supply to the system, by closing the supply valve. Open the system faucet and allow the system to drain.

3. Release the pressure in the lter housing, by pressing the red pressure release button, located on top of each lter housing.

See Figure 4 on page 8 - Bio-Logic®Pure Water PackTM - Drinking Water System for location.

4. Using the lter-housing wrench, loosen the lter housing by turning the housing clockwise. Remove the lter housing. Be

careful, the lter housing will be full with water, adding to the weight of the lter housing. Be sure not to lose the large

O-Ring seal.

5. Drain water from lter housing, remove and discard old lter cartridge. (Continued on Page 11)

11

6. Clean the inside of the lter housing before installing the new lter cartridge. Wash the inside of the lter housing with soap

and hot water, rinse out thoroughly. Make sure the O-Ring is fully seated, in its groove.

7. Remove the wrapper from the new lter cartridge, and place into the lter housing. The lter cartridge will t into the

lter housing in either direction. The system uses 2 different lter cartridges. Be sure to install the correct cartridge into its

corresponding lter housing.

8. Replace lter housing and cartridge onto lter head and rmly tighten, by turning lter housing counter-clockwise. Be careful

not to cross thread the housing and lter head.

9. Repeat to replace the second lter cartridge.

10. Lift the handle, of the system faucet, and lock the faucet in the “ON” position. Slowly open the supply valve, and allow the

system to ll with water.

11. When water begins to ow from the faucet, allow water to run for several minutes until it is clear with no air bubbles. Turn

off the faucet and check between the lter housing and head for leaks.

12. It is recommended, when installing a new carbon lter, to allow the water to run for 10 minutes to ush the lter and system

prior to use.

13. Restore power to the water purier.

lamP installation or rePlaCement bio-1.5 using ballast no.10-0518a 120V50/60hz

and using ballast no.10-0514a 230V50/60hz

IN ORDER TO PERFORM THIS TASK, BE SURE TO WEAR THE FOLLOWING SAFETY

EQUIPMENT: SAFETY GOGGLES OR A FACE SHIELD, AS WELL AS GLOVES

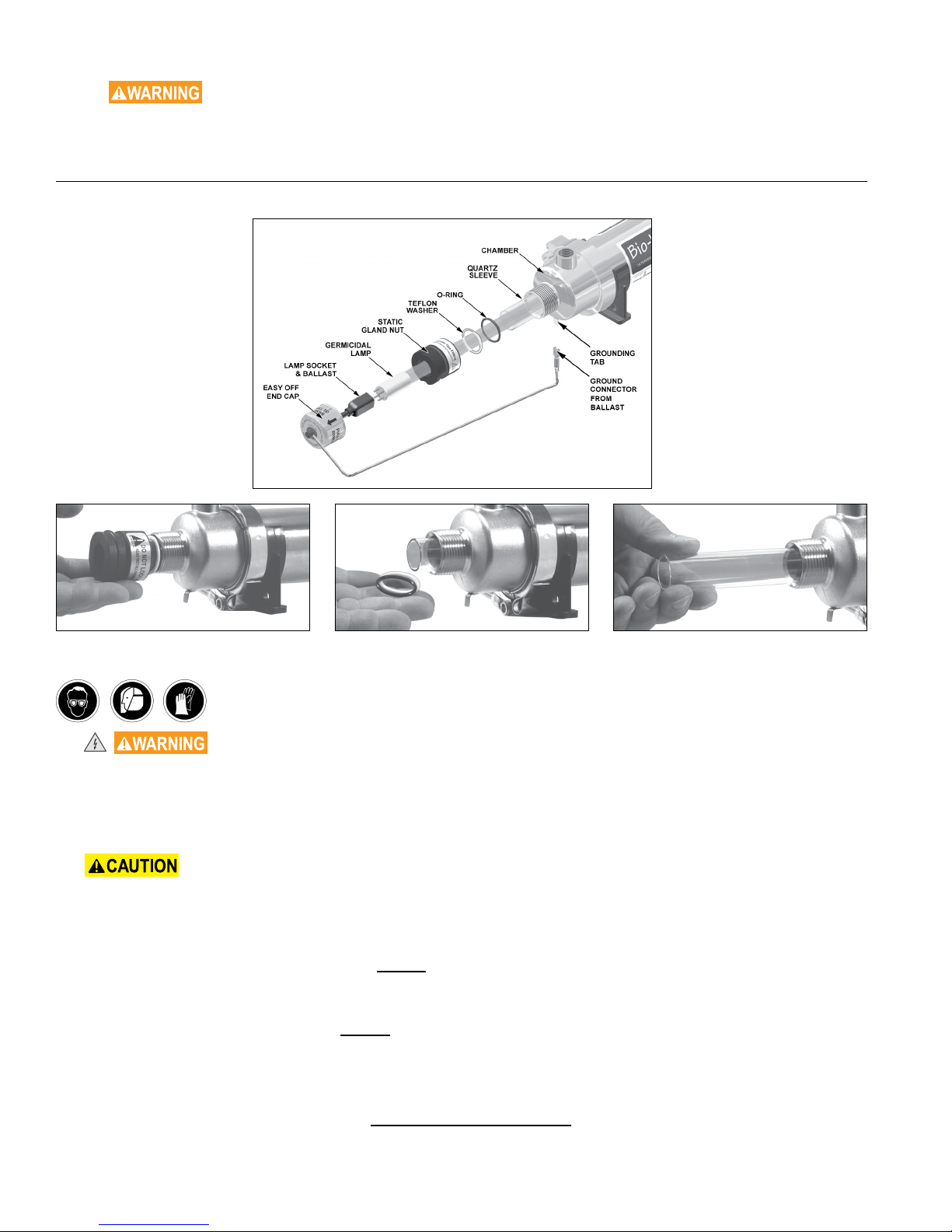

Figure 7 - Lamp Replacement

1. Disconnect power to water purier, and remove ground connector from the chamber.

2. Remove EASY-OFFTM End Cap by pulling cap off static gland nut.

3. Pull lamp cord and carefully withdraw lamp approximately 2 inches from chamber. While holding lamp

end, remove lamp socket from exposed lamp end.

4. Carefully withdraw lamp from chamber. Be sure to withdraw lamp straight out without angling

until completely clear of quartz sleeve.

Lamp and quartz sleeve are easily damaged. Exercise care when handling. (Continued on Page 12)

Step 1 - Disconnect Power to Water

Purier and Remove Ground Connector

Step 4 - Remove Lamp

Step 3 - Remove SocketStep 2 - Remove End-Cap

12

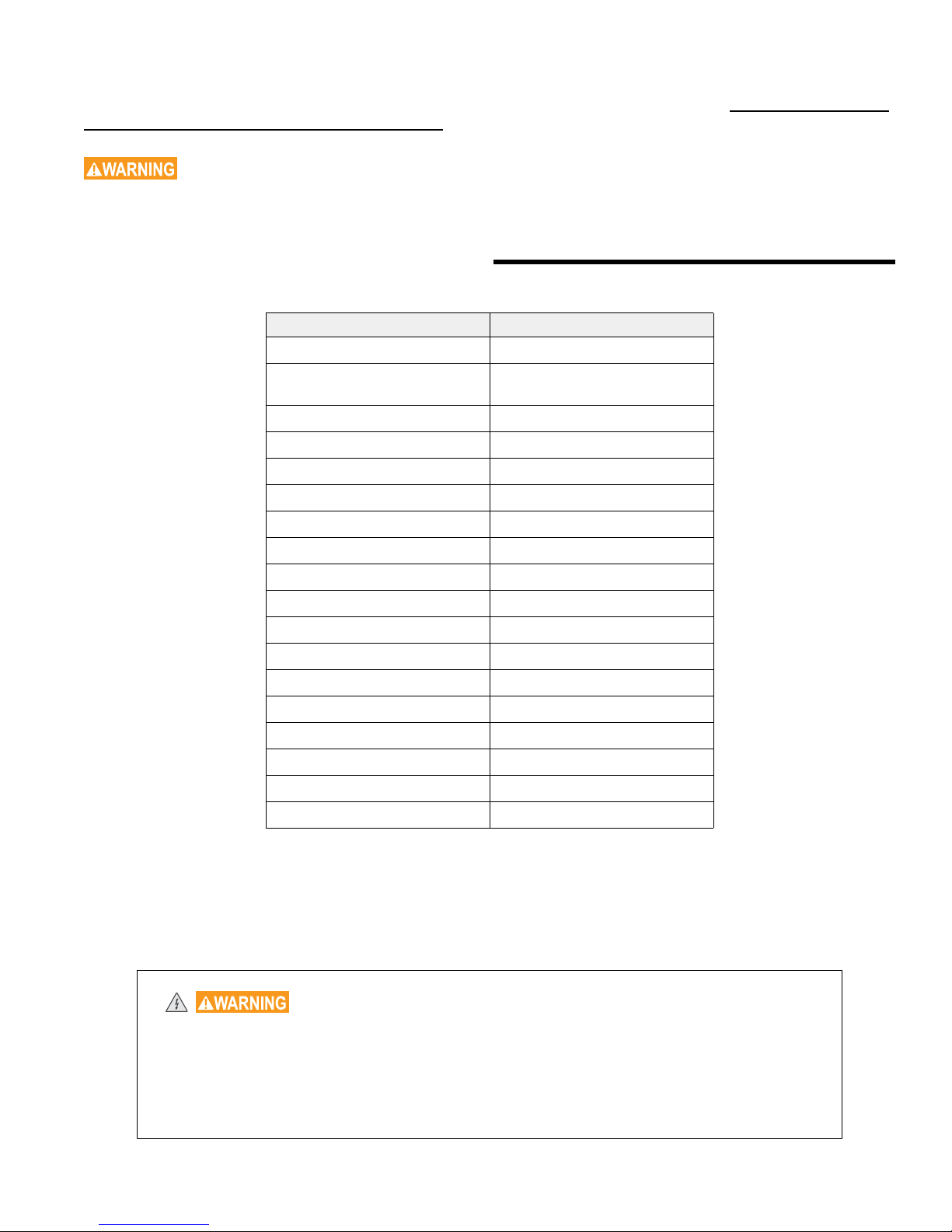

Quartz sleeVe installation, Cleaning or rePlaCement

Figure 8 - Quartz Sleeve Cleaning or Replacement

Step 6 - Remove Quartz Sleeve

Step 5 - Remove Washer & O-Ring

from each end

Step 4 - Remove Gland Nut From Each End

IN ORDER TO PERFORM THIS TASK, BE SURE TO WEAR THE FOLLOWING SAFETY

EQUIPMENT: SAFETY GOGGLES OR A FACE SHIELD, AS WELL AS GLOVES

1. Disconnect power to water purier.

• For 120v 50/60Hz version using ballast no. 10-0518A or 230v 50/60hz version using ballast no. 10-0514A, remove

the ground connector from the chamber, and go to the next step.

2. Shut off water supply to water purier via inlet and outlet shut off valves and drain chamber, if possible.

3. Follow the steps in “Lamp Installation or Replacement” to remove lamp.

Lamp and quartz sleeve are easily damaged. Exercise care when handling.

4. Unscrew static gland nuts from each end of the chamber. Avoid striking quartz sleeve with static gland nut.

5. Remove Teon® washer and O-Ring from both ends of quartz sleeve. Teon® washer will sometimes remain within the static

gland nut. If so, remove Teon® washer from static gland nut before proceeding.

6. Carefully remove quartz sleeve from chamber. NOTE: It is advisable to support the quartz sleeve on the opposite end

with your nger so that it does not drop to the bottom of the chamber as it slides into the chamber.

7. Once the quartz sleeve is removed, clean with alcohol or a mild, non-abrasive detergent. Stubborn stains usually can be

removed with a dilute hydrochloric acid. NOTE: Follow all manufacturer’s instructions and precautions

when handling chemicals.

8. Reassemble in reverse order. Make sure the quartz sleeve protrudes an equal distance past each threaded nipple. Be sure

O-Rings are placed on quartz sleeve before Teon® washer.

9. Tighten static gland nuts rmly by hand only, DO NOT USE HAND TOOLS. Tightening with hand tools is likely to cause

quartz sleeve to break.

10. Slowly restore water supply to water purier and check for leaks. (Continued on Page 13)

5. Reinstall lamp in reverse order.

Germicidal ultraviolet rays are harmful to eyes and skin. Do not restore power to water purier

until lamp and both EASY-OFFTM End Caps have been properly reinstalled.

6. Reattach the ground connector to the grounding tab of the chamber, and restore power to the system.

13

rePlaCement of broken Quartz sleeVe

IN ORDER TO PERFORM THIS TASK, BE SURE TO WEAR THE FOLLOWING SAFETY

EQUIPMENT: SAFETY GOGGLES OR A FACE SHIELD, AS WELL AS GLOVES

Broken Quartz is SHARP. It is recommended that protective goggles and gloves are worn when handling.

1. Follow the steps in “Quartz Sleeve Cleaning or Replacement” to remove lamp and quartz sleeve.

Disconnect power to water purier

Considerable force may be required to pull purier from the mounting clips.

Exercise extreme care when removing purier.

2. Remove the tubing from the inlet and outlet ttings of the Bio-Logic® Ultraviolet Water Purier. See “Tubing Removal” for

the proper method of removing the tubing.

3. Remove the water purier from the mounting clips. Grasp the purier chamber, and rmly pull each end free

of the mounting clips.

4. Carefully remove as much of the broken quartz sleeve as possible, from each end of the chamber.

5. Remove chamber head clamp, by using a 7/16” wrench to loosen and remove the 1/4” nut from the head clamp.

6. Remove chamber head from the chamber.

7. Any broken pieces of the quartz sleeve can now be removed through the open end of the purier chamber. Flush water

through chamber being careful to remove all quartz fragments from the interior of the chamber. Carefully discard all pieces

of the broken quartz sleeve.

8. Inspect the large O-Ring used to seal the chamber and the chamber head. Make sure the O-Ring is seated properly between

the chamber head ring and the are of the chamber head.

9. To reinstall the chamber head, push chamber head ange into the chamber until both ared ends, of the chamber and the

head, mate against the O-Ring.

10. Replace the head clamp around the ared ends of the head and chamber. Install the 1/4” nut and tighten, using a 7/16”

wrench, until approximately 7/8” to 1” of the bolt protrudes past the nut.

11. Carefully insert quartz sleeve into chamber. NOTE: It is advisable to support the quartz sleeve with your nger to guide

it through the opening in the threaded gland tting. Center the quartz sleeve in the chamber, making sure the quartz sleeve

protrudes an equal distance past each threaded gland tting.

12. Reinstall O-Rings, Teon® washers, and static gland nuts. Be sure O-Rings are placed on quartz sleeve before Teon®

washer. Tighten static gland nuts rmly by hand only, DO NOT USE HAND TOOLS. Tightening with hand tools is likely to

cause quartz sleeve to break. (Continued on Page 14)

Figure 9 - Chamber Head Removal

11. If no leaks occur, reinstall lamp, following the steps in “Lamp Installation or Replacement” section.

Germicidal ultraviolet rays are harmful to eyes and skin. Do not restore power to water purier until

lamp and both EASY-OFFTM End Caps have been properly reinstalled.

14

13. Remount the water purier to system-mounting bracket, by rmly pressing the purier into the chamber brackets.

14. Reinstall the tubing; see “Tubing Installation” for the proper method of installing the tubing. Be sure that the tubing from

the outlet of the carbon lter goes to the inlet of the water purier, and the tubing from system faucet goes to the outlet of the

water purier.

15. Lift the handle, of the system faucet, and lock the faucet in the “ON” position. Slowly open the supply valve, and allow the

system to ll with water.

16. When water begins to ow from the faucet, allow water to run for several minutes until it is clear with no air bubbles. Turn

off the faucet and check the water purier for leaks.

Germicidal ultraviolet rays are harmful to eyes and skin. Do not restore power to water purier until

lamp and both EASY-OFFTM End Caps have been properly reinstalled.

17. If no leaks occur, reinstall lamp by following the steps in “Lamp Installation or Replacement” section.

disPosal of merCury added lamPs

Germicidal ultraviolet lamps, like standard uorescent lamps contain small amounts of mercury. Mercury added

lamps should not be placed in the trash. Dispose of properly. For further information regarding the disposal and

recycling of lamps containing mercury, along with Federal and State requirements visit www.lamprecycle.org. For

more information on germicidal ultraviolet lamps, visit Ultraviolet.com or BuyUltraviolet.com.

TROUBLESHOOTING

Always disconnect power to the water purier before performing any service or maintenance.

IMPORTANT: This unit is to be serviced ONLY by qualied, and appropriately licensed, personnel.

Table 2 - Troubleshooting

Problem Possible Cause Corrective Action

Purier not operating No electrical power Verify that the purier is connected to a live power source.

Water leaking from purier

Cracked or broken quartz sleeve

Shut down purier, drain, and replace quartz sleeve. See

“Quartz Sleeve Installation, Cleaning or Replacement”

or “Replacement of Broken Quartz Sleeve” in the

“Maintenance” section.

Quartz sleeve sealing O-Ring (s) worn,

damaged

Shut down purier, drain, and remove static gland nut, replace

sealing O-Ring. See “Quartz Sleeve Installation, Cleaning or

Replacement” in the “Maintenance” section.

Poor, or loose, connections or ttings

Tighten suspect connection or tting; or shut down purier, drain,

and remove tting or connection. Clean threads; reapply thread

sealing tape and reinstall.

Water leaking from tting Tubing may not be installed properly See “Tubing Installation” for the proper method for installing

tubing.

Water cloudy and/or has air bubbles Air in system Open system faucet, allow water to run, until water clears and has

no air bubbles.

Water contains black particles New carbon lter cartridges contain

activated carbon, in a powder from

Open system faucet; allow water to run, purging the carbon

particles from the cartridge, until water is clear.

Water pressure dropped

Filters installed for longer than 12

months Replace both lter cartridges. See “Filter Cartridge

Replacement.”

Water quality poor, lters clogged

Poor purier disinfection performance

Quartz sleeve fouled Clean quartz sleeve, see “Quartz Sleeve Installation, Cleaning

or Replacement” in the “Maintenance” Section.

Germicidal lamp output depreciating Replace lamp, as it nears its end of life (EOL). See “Lamp

Installation or Replacement” in the “Maintenance” section.

Germicidal lamp not functioning Replace lamp. See “Lamp Installation or Replacement” in the

“Maintenance” section.

Low input voltage Verify input voltage to purier.

Change in water quality Have water tested to conrm that it does not exceed maximum

recommended concentration levels for use with this purier.

15

ballast no. 10-0518a and 10-0514a haVe lamP-out ProteCtion

If power is applied to the ballast without a lamp connected to the circuit or if the lamp fails, the ballast’s lamp-out protection

will prevent the ballast from operating, and a red LED light will illuminate and audio alarm will sound. To reset: disconnect the

ballast from power and reconnect or replace the lamp. The ballast must remain disconnected from power for (2) minutes to

reset. After 2 minutes restore input power, ballast should resume proper operation.

The equipment that this ballast is used with requires connection to a known good ground. It is the User’s

responsibility to ensure that their equipment is properly grounded in compliance with the National Electrical Code and any

applicable local codes. Equipment wiring and hook up should be performed by a qualied, licensed electrician. Failure to comply

with this requirement could result in serious injury or death.

TECHNICAL SPECIFICATIONS

Table 3 - Technical Specications

Model: Pure Water PackTM

Flow Rate (GPM): 1.5

Inlet\Outlet Size: 1/4” Tubing to 3/8” MNPT

John GuestTM Connector

Number of Lamps: 1

Lamp Model No.: 05-1366-R

Quartz Sleeve: Yes

Length: 14 1/2”

Width: 5 3 /4”

Height: 18”

Shipping Weight: 18 Lbs

Voltage:120V 50/60Hz

Power Consumption:k14 Watts

Max Operating Pressure: 100 PSI

Ambient Room Temperature: 35° F - 100° F

Lamp Out Indicator Yes

Installation Kit Yes

Sediment Filter Cartridge Yes, 5 Micron

Carbon Filter Cartridge Yes

Chamber Material 316 Stainless Steel

M220v 50/60Hz and 12v DC units are also available. Consult Factory for specic voltage requirements.

kWattage is lamp watts only, and does not include ballast loss.

All specications, dimensional data, etc are approximate and subject to change without notice.

12 Volt and 24 Volt Direct Current (DC) Ballasts and Units

Many individuals regard ballasts and units powered by 12 volt and 24 volt Direct Current (DC) to be

relatively benign from a safety standpoint. However, a DC ballast, in order to operate an ultraviolet

discharge lamp, must produce an output as high as 600 volts. This voltage is high enough to produce a

very serious or even lethal electric shock. IT IS IMPERATIVE that all DC ballasts and DC ultraviolet

units be wired and grounded appropriately.

16

DIMENSIONAL DATA

Figure 10 - Dimensional Data

All specications, dimensional data, etc are approximate and subject to change without notice.

17

REPLACEMENT PARTS

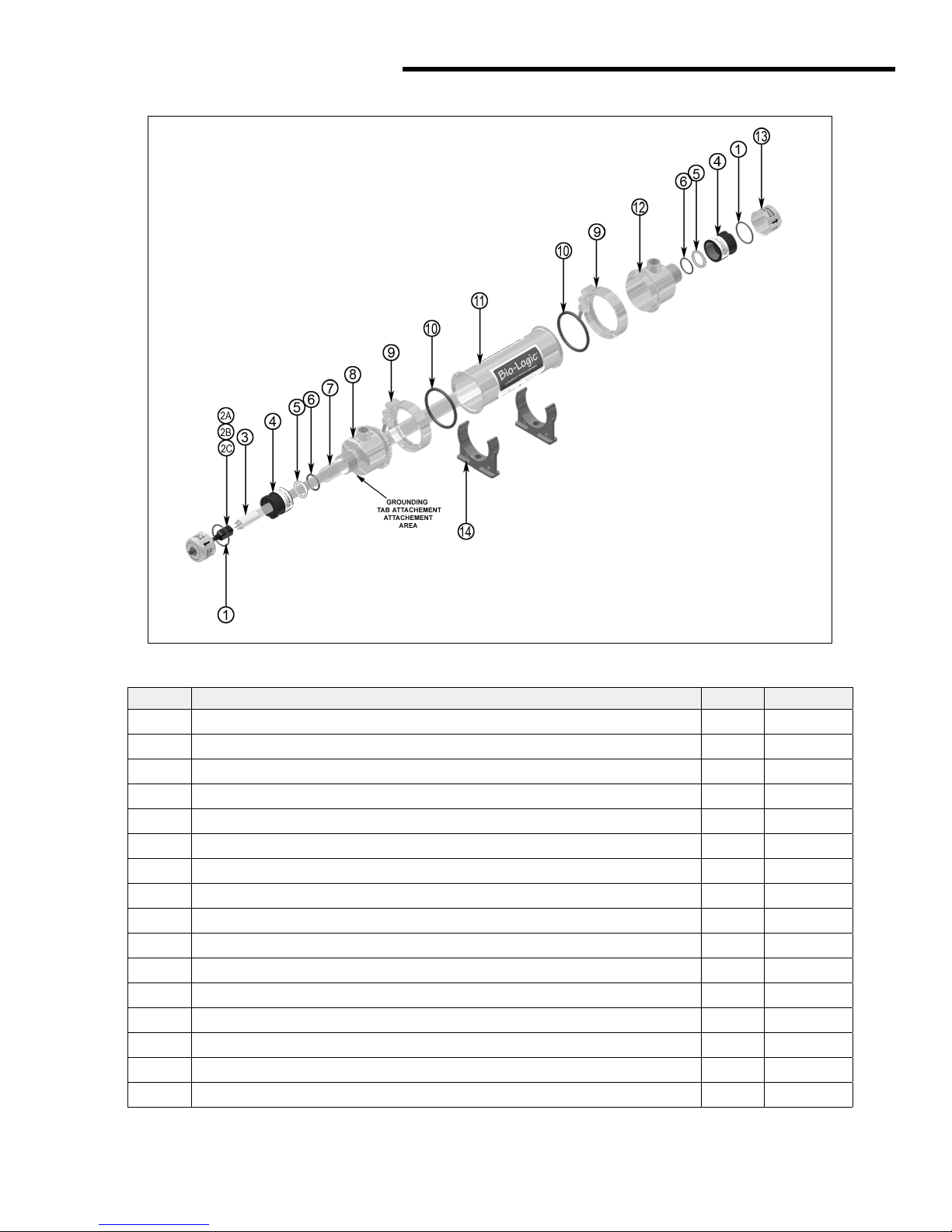

Figure 11 - Exploded View BIO-1.5 Water Purier

Table 4 - Replacement Parts BIO-1.5

Item No. Description Quantity BIO-1.5

1Rubber O-Ring, Static Gland 2 00-1108B

2A SteadfastTM Lamp Socket & SureliteTM Ballast, 120v 50/60Hz 1 10-0518A

2B SteadfastTM Lamp Socket & SureliteTM Ballast, 230v 50/60Hz 1 10-0514A

2C SteadfastTM Lamp Socket & SureliteTM Ballast, 12v DC* 1 10-1201A

3STER-L-RAY ®Lamp 1 05-1366-R

4Static Gland Nut 2 25-1492D

5Teon®Washer 2 25-3023A

6 Rubber O-Ring, Quartz Sleeve 2 00-1023A

7CRYSTAL CLEARTM Quartz Sleeve 1 15-1700A

8Chamber Head, 2 ½” with Ground Terminal 1 25-4506A

9 Chamber Clamp 2 25-6009

10 Chamber O-Ring 2 00-0250A

11 Chamber Tube 1 25-6004A1

12 Chamber Head, 2 ½” 1 25-6042

13 EASY-OFFTM End Cap (no hole) 1 25-1493A

14 Mounting Clip 2 27-0045

All specications, dimensional data, etc are approximate and subject to change without notice.

* Lamp Socket and Ballast not shown

18

REPLACEMENT PARTS

Figure 12 - Exploded View of Bio-Logic® Pure Water PackTM

Table 5 - Replacement Parts for Bio-Logic® Pure Water PackTM

Item No. Description Quantity BIO-1.5

1Filter Bracket 1 25-9132A

2A Bio-Logic® 1.5 120v 50/60Hz 1 25-9125A1

2B Bio-Logic® 1.5 230v 50/60Hz 1 25-9126A1

3Screw, 8-32 x ½” Long 2 50-1394

4 Nut, Hex, 8-32 2 50-1180

5Filter Housing, 10” w/Pressure Relief Valve 2 25-4507

6Screw, 10-16 x ¾” Long 8 50-0096

7Filter Cartridge, 5 Micron, Pleated 1 25-4508

8Filter Cartridge, Carbon 1 25-4509

9Male Connector ¼”x3/8” NPTF John GuestTM 4 25-4513

10 Pipe Nipple, 3/8”x1-½” Long PVC 1 25-4510

11 Tubing ¼” OD x 24” Long 1 25-4515

12 Saddle Valve ts 3/8” - ½” Copper Tubing 1 25-4511

13 Faucet, Long Reach Spout 1 25-4512

14 Tap Adaptor, ¼”x7/16”-24UNS John GuestTM 2 25-4514

15 Tubing, ¼” OD, White Plastic 15’ 25-4516

16 Wrench, Filter Housing 1 25-8000

17 Description O-Ring - Filter Cartridge 2 00-0330

All specications, dimensional data, etc are approximate and subject to change without notice.

19

MAINTENANCE NOTES

20

USER ASSISTANCE

WARRANTY

We warrant that this product will be free from defects in material and workmanship for a period of one year from the date of

shipment thereof or the product’s total rated life, whichever rst occurs. Within the warranty period we shall repair or replace such

products, which are returned to us with shipping charges prepaid, and which are determined by us to be defective. This warranty

will not apply to any product, which has been subjected to misuse, negligence, or accident; or misapplied; or modied; or repaired

by unauthorized persons; or improperly installed.

The Buyer shall inspect the product promptly after receipt and shall notify us at our main ofce in writing of claims, including

claims of breach of warranty, within thirty (30) days after the Buyer discovers or should have discovered the facts upon

which the claim is based. Failure of the Buyer to give written notice of a claim within the time period shall be deemed to be a

waiver of such claim.

The provisions of the above warranty are our sole obligation and exclude all other remedies or warranties, expressed or implied,

including warranties of merchantability and tness for a particular purpose, whether or not purposes or specications are

described herein. We further disclaim any responsibility whatsoever to the customer, or to any person, for injury to person,

damage to, or loss of property or value caused by any product which has been subjected to misuse, negligence, accident; or

modied or repaired by unauthorized persons; or improperly installed.

Under no circumstances shall the Atlantic Ultraviolet Corporation® be liable for any incidental, consequential or special damages,

losses or expenses arising from the contract for this product, or in connection with the use of, or inability to use, our product

for any purpose whatsoever.

Patent notiCe

No attempt has been made to determine the patent status of applications illustrated or described in this publication. Inclusion

in this publication of any design or method of use, which may be patented, is not to be construed as promoting or sanctioning

unauthorized use.

Atlantic Ultraviolet Corporation®

makes every effort to ensure that the

Bio-Logic®Pure Water PackTM

Puriers are products of superior

quality and workmanship. This manual

describes the installation, operation and

maintenance of the Bio-Logic®

Pure Water PackTM

Please read and become familiar with

the contents of this manual before

installing or using this unit. If after

reading the manual you still have

questions, or concerns, regarding the

installation or use of this unit, contact

our ofces, weekdays between 8:30 am

and 5:00 pm Eastern Time, at:

Atlantic Ultraviolet Corporation®

375 Marcus Boulevard

Hauppauge, New York, 11788

Tel: 631.273.0500

Fax: 631.273.0771

E-mail: [email protected]

Website: www.ultraviolet.com

www.buyultraviolet.com

PRODUCT REGISTRATION

Please REGISTER your product immediately - you can do this in a number of ways. Go online to Ultraviolet.com and on the

bottom left of each page either click on “Fill out Warranty Reg. Form on-line!” complete and hit submit or click on “Download a

PDF of the Warranty Reg. card” which you can print, ll out and mail in. If you prefer to register over the telephone

please call 631-273-0500.

Atlantic Ultraviolet Corporation® takes all possible precautions when packaging equipment to prevent damage. Carefully inspect

and report all damage. Do not install damaged equipment. Follow all instructions on any labels or tags. Carefully inspect all

packing materials before discarding to prevent the loss of accessories, mounting hardware, spare parts or instructions.

For your convenience, record the following information below. The model and serial number can be found on a label located on

the Bio-Logic®Pure Water PackTM. Keep this manual, along with proof of purchase, handy when contacting our ofces.

Purchased From: Date:

Model: Serial No.:

Table of contents

Other Bio-Logic Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Waterco

Waterco MultiCyclone Installation and operation manual

Puretec

Puretec Hybrid-R Triple Series user guide

Bluewater

Bluewater Pro 400B-HR Complete user's manual

Alfalaval

Alfalaval FOPX 609TFD-24 manual

KEBCO

KEBCO COMBILINE Z1I05-1001 Series Instructions for use

globalwater

globalwater G500 Installation & operating manual

Eco Pure

Eco Pure EP-RO25 Installation and operation manual

Pure-Pro

Pure-Pro ERS-106M user manual

Alfalaval

Alfalaval MOPX 310TGT-24 manual

Rain Soft

Rain Soft EC4 SERIES owner's manual

Aquapure

Aquapure AP9200+ Installation and operating instructions

ThePondguy

ThePondguy ClearSolution 120800 Installation & maintenance