5

TABLE OF CONTENTS

Table of Contents

Preface ....................................................................................................................................................3

Signal words and symbols .............................................................................................................3

More symbols.................................................................................................................................3

Laws and guidelines.......................................................................................................................4

Warranty and liability......................................................................................................................4

Support ........................................................................................................................................4

Copyright........................................................................................................................................4

Table of Contents ...................................................................................................................................5

List of Figures.........................................................................................................................................7

List of Tables ..........................................................................................................................................8

Standards for EMC components...........................................................................................................9

Product standards:.........................................................................................................................9

Basic standards:.............................................................................................................................9

General standards:.........................................................................................................................9

1 Basic Safety Instructions............................................ 10

1.1 Target group...................................................................................................................................10

1.2 Transport, storage and proper use .............................................................................................. 10

1.3 Installation...................................................................................................................................... 11

1.4 Electrical connection ....................................................................................................................12

1.5 Start-up and operation ..................................................................................................................12

1.6 Repair .............................................................................................................................................13

1.7 Disposal..........................................................................................................................................13

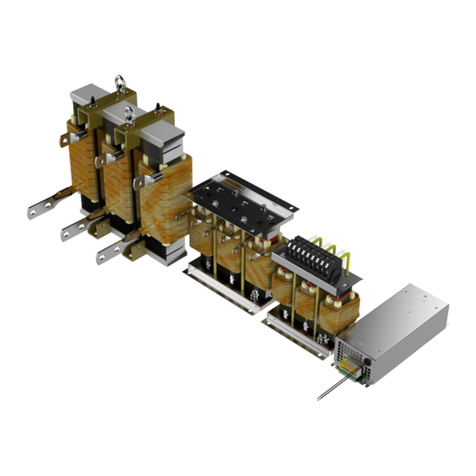

2 Product Description .................................................... 14

2.1 Intended use ..................................................................................................................................14

2.2 Improper use..................................................................................................................................14

2.3 Product features ............................................................................................................................14

3 Technical Data.............................................................. 15

3.1 Operating conditions ....................................................................................................................15

3.1.1 IP protection classes ..........................................................................................................15

3.1.2 Climatic conditions .............................................................................................................15

3.1.3 Mechanical ambient conditions ..........................................................................................16

3.1.4 Chemical/mechanical active substances............................................................................16

3.1.5 Electrical operating conditions............................................................................................16

3.1.5.1 Equipmentclassication..................................................................................................16

3.2 Electrical data ................................................................................................................................17

3.2.1 Electrical equivalent circuit diagram...................................................................................17

4 Installation and Connection........................................ 18

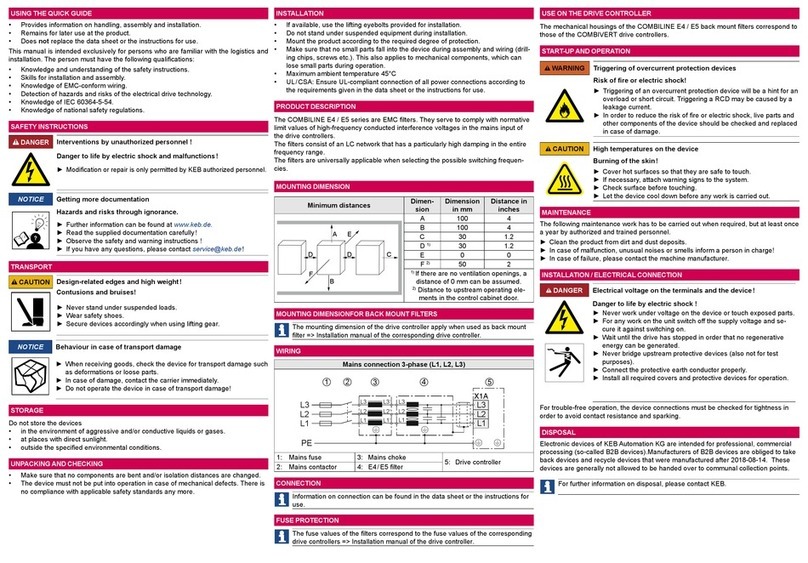

4.1 Schematic diagram........................................................................................................................18