Biomet 3i Navigator Reference guide

The Parallel Walled

Navigator®System For Guided Surgery

Procedure Manual

Navigator®CT Guidance: Steps to Success ................................................................................................................................... 1

Getting Started............................................................................................................................................................................... 3

Introduction And Treatment Planning ............................................................................................................................................. 4

Instrumentation Overview ............................................................................................................................................................. 5

Surgical Plan Overview................................................................................................................................................................... 9

Tips And Techniques ................................................................................................................................................................... 10

Immediate Provisionalization Option ............................................................................................................................................ 12

Fabrication Of A New Denture Or Partial Denture And CT Scanning Appliance ........................................................................... 13

Fabrication Of CT Scanning Appliance Using An Existing Denture ................................................................................................. 15

Pre-Surgical Fabrication Of An Edentulous Fixed Provisional Restoration........................................................................................ 16

Pre-Surgical Fabrication Of A Partially Edentulous Fixed Provisional Restoration ............................................................................. 17

Cement-Retained PreFormance®Post .......................................................................................................................................... 18

Cement-Retained Provide®Abutment And Temporary Cylinder ................................................................................................... 20

Screw-Retained Low Profile Abutment And Temporary Cylinder ................................................................................................. 22

Screw-Retained PreFormance Temporary Cylinder....................................................................................................................... 24

Combination Cement / Screw-Retained QuickBridge®Restoration And Low Profile Temporary Cylinder Multiple-Unit Only..........26

Table Of Contents

1

IMMEDIATE

PROVISIONAL

DESIRED?

1. The scanning appliance may be created from an existing

denture or new wax-up to visualize the soft-tissue and

tooth position in the third party planning software chosen.

2. A CT scan of the patient is taken by an imaging center or

in the clinician’s office. Data from the scan is converted into

the planning software.

3. The clinician plans the case within the planning software

and the case plan is sent to the surgical guide manufacturer.

Fixation of the guide can also be planned at this time.

a. The software company may act as the surgical guide

manufacturer or

b. A laboratory may create the surgical guide.

4. The surgical guide manufacturer develops a case-specific

surgical plan and surgical guide.

5. The surgical plan and surgical guide are sent to the dental

laboratory or restorative doctor and used in conjunction

with the Parallel Walled Navigator

Laboratory Kit (if no immediate provisional is desired,

go to step 8).

6. The master cast is poured into the guide or the implant

analogs are placed in the preoperative cast on a partially

edentulous case using the guide.

7. The abutments are selected and the provisional prosthesis

is fabricated and sent to the clinician.

8. The surgical guide and surgical plan are sent to the

surgeon and used in conjunction with the Parallel Walled

Navigator Surgical Kit.

9. The surgical guide is placed and may be fixated with 2mm

fixation screws.

10. The clinician will prepare the site(s) with the case-specific

surgical plan and surgical guide for implant placement with

the BIOMET 3i Parallel Walled Navigator Surgical Kit.

11. The implants are placed through the surgical guide.

12. The Implant Mounts and surgical guide are removed.

13. If a traditional procedure is desired, a one or two-stage

procedure is completed and a traditional provisional

prosthesis – denture/Maryland Bridge/flipper partial – may

be delivered.

14. The abutments and the provisional prosthesis are delivered.

15. The patient is able to go home that day with a brand

new smile!

1

2

3

4

5

8

Navigator®CT Guidance: Steps to Success

2

Photos courtesy of Dr. Harold Baumgarten†, Philadelphia, PA and Dr. Alan Meltzer†, Voorhees, NJ

NO

YES

TRADITIONAL

PROCEDURE

IMMEDIATE

PROVISIONAL

10

67

911 12

14

15

IMMEDIATE

PROVISIONAL

DESIRED?

13

†Dr. Baumgarten and Dr. Meltzer have financial relationships with BIOMET 3i LLC resulting from speaking engagements, consulting

engagements and other retained services.

3

Getting Started

In order to utilize the Parallel Walled Navigator®System,

clinicians will need to purchase CT planning software from

one of the planning software companies and have access

to a CT scanning facility. Training on how to use the CT

planning software chosen is essential for all clinicians and

technicians involved in case treatment-planning. In addition,

laboratory technicians will need to obtain the Parallel

Walled Navigator System Laboratory Kit to fabricate

the preoperative master cast and clinicians will need to

obtain the Parallel Walled Navigator System Surgical Kit to

place the implants. The complete system overview that

describes each instrument and component included in the

kits and their associated use begins on page 5.

Prior to sending the patient to the CT scanning facility,

a radiopaque scanning appliance may be fabricated to

show the desired tooth position of the restoration when

seated in the mouth during the CT scan. Pages 13-17 in

this manual are designed to guide surgeons, restorative

clinicians and laboratory technicians through the process of

fabricating a scanning appliance from an existing denture, a

newly fabricated denture or a diagnostic wax up.

A page with tips from clinicians who evaluated the

system prior to market release is also included in this

manual on pages 10-11. These tips will help to ensure

a smooth process from CT scan to the day of surgery

and provisional delivery when using the system and may

reduce the learning curve associated with use of the

Parallel Walled Navigator System For

Guided Surgery.

Open Architecture System

The Parallel Walled Navigator System is designed to allow

clinicians to place and provisionalize BIOMET 3i Dental

Implants using a variety of compatible CT planning software

and surgical guides. The system is open architecture to be

compatible with the current software and surgical guide

providers listed below.

Materialise Dental, Inc.

810-X Cromwell Park Drive

Glen Burnie, MD 21061

United States

(443) 557-0121

www.materialisedental.com

Materialise Dental, NV

Technologielaan 15

3001 Leuven

Belgium

+32 16 39 66 20

iDent – US

2652 NW 31st Ave

Ft. Lauderdale, FL 33311

United States

(954) 495-8684

www.ident-surgical.com

iDent – Israel

4 Yohanan Street

Box 6402

Hod Hasharon 45241

Israel

+972-52-546-2366

www.ident-surgical.com

SICAT Gmbh + Co. KG

Brunnenallee 6

D-53177 Bonn

Germany

+49-228-854-6970

4

Introduction And Treatment Planning

This manual is designed to serve as a reference

guide for dental practitioners to utilize

Restorative Components and

instruments. BIOMET 3i Implant Systems have

been developed to meet the diverse needs of

patients and to offer practitioners a choice of

customized restorative techniques.

BIOMET 3i Implant and restorative component designs

provide practitioners with a wide range of restorative

options, including support for single tooth crowns, fixed

and removable prostheses and attachments for securing

overdentures. BIOMET 3i Implant and Abutment Systems

utilize proven restorative designs and provide clinicians and

patients with predictable treatment options.

General Information

This manual provides guidelines for surgical and restorative

practitioners and laboratory technicians in the use of the

BIOMET 3i Navigator®System For Guided Surgery. The

success of any dental implant system depends upon proper

use of the components and instrumentation. This manual is

not intended for use as a substitute for professional training

and experience.

Treatment Planning

Patient Evaluation And Selection

Several important factors must be considered when

evaluating a patient prior to implant surgery. The

presurgical evaluation must include a careful and detailed

assessment of the patient’s general health, medical history,

oral hygiene, motivation and expectations. If the patient’s

medical history reveals an existing condition or signals a

potential problem that may compromise treatment and/

or the patient’s well being, consultation with a physician is

recommended. In addition, the clinician should determine

if the patient presents with an acceptable anatomical

foundation that is conducive to implant placement. An

extensive intraoral examination should be performed to

evaluate the oral cavity for any potential bone or soft-

tissue pathology. The clinician should also determine the

periodontal status of the remaining teeth, the health of

the soft-tissue, the presence of occlusal abnormalities or

parafunctional habits, such as bruxism or crossbite and

any other conditions that could adversely affect the

restorative outcome.

Pre-Operative Planning

Proper treatment planning includes selection of

appropriate implant lengths, diameters and locations.

The number of implants is a fundamental consideration

for the long-term success of an implant supported

restoration. Before an implant is placed, the anatomical

foundation of the treatment area must be carefully

assessed.

During the presurgical restorative planning phase of cases

with immediate provisionalization, it is important for the

surgeon, restorative dentist and laboratory technician

to participate in determining the type of prosthesis and

restorative components that will be used. Such decision

making is critical for determining the location of implants

and should be finalized prior to implant surgery. A top-

down treatment planning approach is recommended,

whereby the final prosthesis is designed, implant locations

determined and restorative components selected prior to

initiating implant surgery.

Clinical information necessary for determining

appropriate treatment options includes but is not

limited to: determining vertical dimension, evaluating

the space available between the alveolar crest and the

opposing dentition to confirm that available space exists

to accommodate the proposed abutment and final

restoration, locating the position of important anatomic

structures and determining bone dimensions where

implants are to be placed. The height required by the

restorative components varies with the type of abutment.

Therefore, the surgeon and restorative dentist should

carefully evaluate abutment dimensions. Diagnostic casts

should be used pre-operatively to evaluate the residual

ridge and to determine the position and angulation of all

implants. These casts allow the clinician to evaluate the

opposing dentition and its effect on implant position. A

surgical guide is helpful in determining the precise intraoral

position and angulation of the implants and should be

included in the pre-operative treatment plan.

By visualizing the final design of the prosthesis prior to

implant surgery, both restorative and surgical clinicians have

the opportunity to identify potential restorative problems.

They can then make the necessary modifications to implant

selection, location and the overall treatment plan prior

to actually placing the implants, thus improving treatment

predictability and success.

5

The Navigator®System For Guided

Surgery was developed in response to clinicians’ growing

interest in dental implant placement utilizing the benefits of

Computed Tomography (CT) and the desire to accelerate

patient provisionalization.

The Navigator System is open architecture. The system is

used in conjunction with the leading planning software and

case-specific surgical guides to enhance treatment planning

and improve the accuracy of placing BIOMET 3i Implants.

CT guidance technology allows clinicians to determine

more precisely the locations of anatomical structures and

the dimensions of underlying bone as well as to ascertain

bone densities in order to plan and perform cases. Use

of CT scans allows procedures to be less invasive than

traditional surgery. The necessary planning and added

instrument precision can shorten chair time for full-arch,

single-tooth and short-span implant cases, allowing for

more efficient procedures.

The Navigator System can be used to fabricate a

provisional prosthesis prior to implant placement by

creating a master cast using the surgical guide.

The system allows clinicians to place dental implants in

predetermined locations with proper hex orientation. This

feature is especially beneficial for single tooth and cement

retained provisionals. It offers clinicians the option to

deliver a provisional prosthesis the day of surgery and the

opportunity to perform bone, teeth and tissue supported

(flapless) surgery.

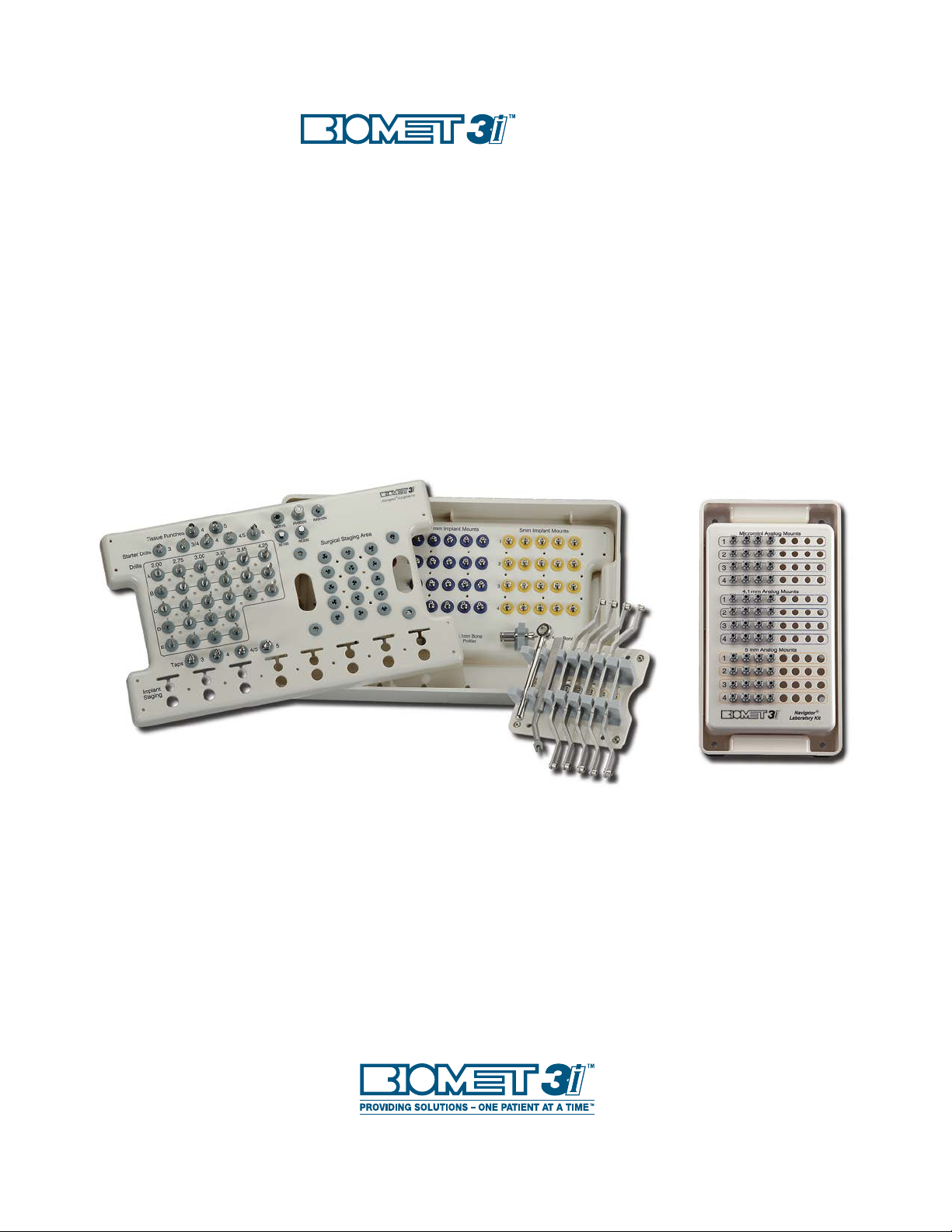

The BIOMET 3i Parallel Walled Navigator System For

Guided Surgery includes the Parallel Walled Navigator

Surgical Kit and the Parallel Walled Navigator Laboratory

Kit. These kits make it possible for clinicians to restore and

place Certain®Parallel Walled 3.25, 4 & 5mm Implants,

OSSEOTITE XP®4/5mm Implants, PREVAIL®3/4/3,

4/5/4 and straight PREVAIL 4/3 and 5/4mm Implants. With

this design, BIOMET 3i is able to support the majority of

clinical situations and compliment the use of a wide range

of prosthetic options.

A 2mm Fixation System (31-3100) is available through

BIOMET Microfixation. To order this Fixation System,

please contact BIOMET Microfixation at 1-800-874-7711.

Instrumentation Overview

6

Instrumentation Overview (continued)

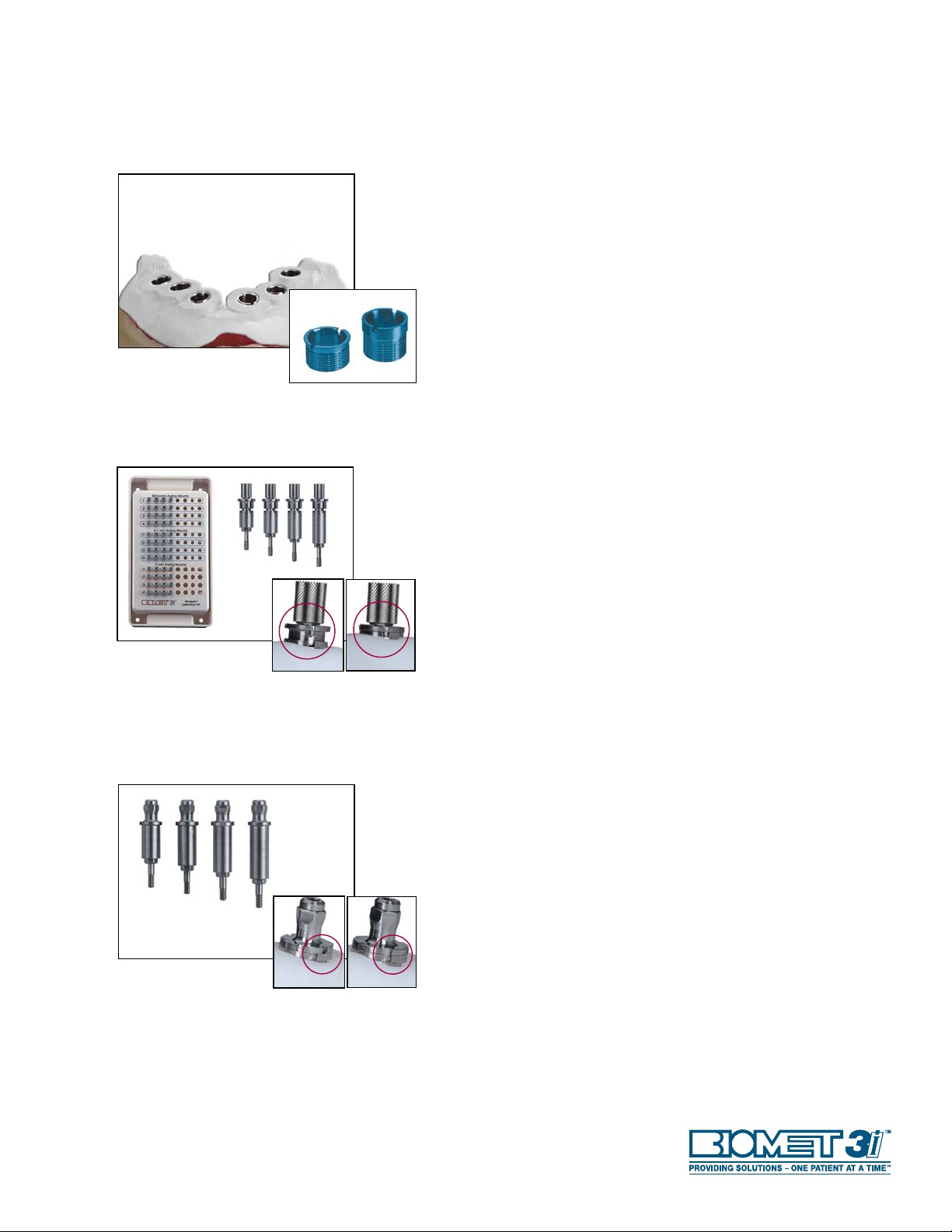

MASTER TUBES

Master Tubes guide instruments through the surgical guide.

These provide a predetermined depth stop for the Twist Drills

and Implant Mounts and ensure identical hex orientation and

positioning between the lab analog and final implant placement.

The Master Tubes are positioned in the surgical guide by the

surgical guide manufacturer.

The “slot” feature on the Master Tubes is used for alignment

with the Analog Mounts for analog placement when fabricating

the master cast and for alignment with the Implant Mounts and

implants during surgery.

LABORATORY KIT COMPONENTS

IMPLANT ANALOG MOUNTS

The Parallel Walled Navigator®Laboratory Kit is comprised

of Implant Analog Mounts used through the Master Tubes in

the surgical guide to position implant analogs into a cast. The

laboratory kit, like the surgical kit, contains twelve unique mounts

with the Certain®Connection and these mounts are available in

three diameters (3.4, 4.1 and 5mm) and four lengths identified

as (1), (2), (3), and (4). Because a specific Analog Mount may be

required multiple times, four complete sets of Analog Mounts are

available in the kit for a total of 48 Analog Mounts. The Analog

Mounts feature a mechanical-locking system to hold the implant

analog in place (vertically, laterally and rotationally) within the

Master Tube. A peg on the side of the Analog Mounts is aligned

with one of the slots on the Master Tube to ensure accurate

transfer of the hex orientation from the pre-operative master cast

to the mouth.

SURGICAL KIT COMPONENTS

IMPLANT MOUNTS

Implant Mounts are used through the Master Tubes in the surgical

guide to place implants. The Implant Mounts have the Certain

Connection and are available in three diameters (3.4, 4.1 and

5mm) and four lengths identified as (1), (2), (3), and (4) for a

total of twelve unique Implant Mounts. Because a specific Implant

Mount may be required multiple times, five complete sets of

Implant Mounts are available in the kit for a total of 60 Implant

Mounts. Implant Mounts are depth specific with a flange for a

depth stop. A “spline” feature on the flange can be used as a visual

reference during implant placement to orient the hex connection

of the implant. The cutouts on the flange are aligned with the

slots on the Master Tube to ensure accurate transfer of the hex

orientation from the pre-operative master cast to the mouth.

7

Instrumentation Overview (continued)

TISSUE PUNCHES

The Tissue Punches are used through the Master Tubes in the

surgical guide to remove soft tissue for flapless surgery. The

Tissue Punches are available in two diameters (4 and 5mm) and

one length and contain depth markings of (1), (2), (3) and the

top of the Tissue Punch (4) to correspond with the surgical plan

(protocols) for use during surgery.

The recommended drill speed is 300rpm.

STARTER DRILLS

The Starter Drills are used through the Master Tubes in the

surgical guide to perforate the cortical plate, create a 2mm pilot

and countersink the osteotomy. The Starter Drills are available in

five diameters (3.4, 3/4, 4, 4/5 and 5mm) to countersink different

implant collar shapes. These contain depth markings of (1), (2),

(3) and the top of the Starter Drill body (4) to correspond with

the surgical plan (protocols) for use during surgery.

The recommended drill speed is 1200 - 1500rpm.

DRILL POSITIONING HANDLES

The handles contain drill guide tubes that are placed within the

Master Tubes of the surgical guide to guide and stop the Twist

Drills at a specific predetermined depth for preparation of the

osteotomy. There are five handles [handles (1) and (2) for use

with 4mm Master Tubes and handles (3), (4) and (5) for use

with 5mm Master Tubes]. These contain drill guide tubes to

accommodate the various drill diameters (2, 2.75, 3, 3.25, 3.85

and 4.25mm).

8

Instrumentation Overview (continued)

TWIST DRILLS

The Twist Drills are used to prepare the osteotomy for implant

placement. Once the surgical guide is in place, the Drill Positioning

Handles with drill guide tubes are inserted into the Master Tubes of the

surgical guide. The Twist Drills are inserted through these guide tubes.

The drills are depth-specific with no depth lines and contain flanges

to stop the drills when these make contact with the drill guide tube

component of the Drill Positioning Handles. Twist Drills are available in

six diameters (2, 2.75, 3, 3.25, 3.85 and 4.25mm) to allow surgeons

to appropriately size osteotomies based on observed bone densities,

clinical preference and multiple lengths (A, B, C, D, E).

The recommended drill speed is 1200 - 1500rpm.

The drills included in the surgical kit will accommodate 90% of all

possible scenarios. Special drills required for the remaining 10% have

been left out to simplify the surgical kit. In these special cases, Y or

Z drills may be prescribed by the surgical plan. These drills may be

purchased separately as needed.

NOTE: Drill lengths do not necessarily correspond to implant lengths;

rather these are dictated by the surgical plan (protocols) based on the

prolongation (distance between the position of the Master Tubes and

implant seating surface).

BONE TAPS

Bone Taps are used through the Master Tubes in the surgical guide to

thread a 5.5mm section of the osteotomy prior to implant placement.

The Bone Taps are available in four diameters (3.25, 4, 4/5 and 5mm)

and one length. These contain depth markings (1), (2), (3) and at (4) the

Bone Tap body has a depth stop. These markings correspond with the

surgical plan (protocols) for use during surgery.

The recommended drill speed is 15 - 20rpm.

IMPLANT STAGING

The Parallel Walled Navigator®Surgical Kit contains eight implant holder

slots to receive the inner packaging of Implants, similar

to existing surgical kits. Implants will be manually

pre-mounted here in preparation for placement.

BONE PROFILERS

Handheld Bone Profilers are available to manually remove crestal bone

for proper abutment seating after the surgical guide is removed for 3.4,

4 and 5mm implants.

MISCELLANEOUS TOOLS

Miscellaneous standard drivers and ratchets are included in the system

to place BIOMET 3i Implants. These tools include the following:

PHD02N, RASH3N, MDR10, CW100, WR150 and RE100.

9

Surgical Plan Overview

Tooth number/

Implant position

Indicates 4mm diameter

Tissue Punch

Indicates drill diameter 2, length

(B) to be used with

Handle 3 Indicates 4mm diameter

Bone Tap

Indicates 3mm hand

held Bone Profiler

Indicates 4mm Analog Mount with a

(1) depth

Indicates 4mm Implant Mount

with a (3) depth

Indicates 4mm diameter

Starter Drill

Specifies preparation depth for Tissue

Punch, Starter Drill and Bone Taps with a

depth of (2)*

(4)

(3)

(2)*

(1)

The surgical plan specifies the depth line for instruments

that pass directly through the surgical guide Master Tubes

including the Tissue Punch, Starter Drill and Bone Taps.

These instruments have landmarks referenced as (1), (2),

(3) and (4) that indicate the proper depth to which these

instruments should be used through the Master Tubes

(Figure 1). There are three lines on each instrument; the

first line represents depth line (1), while the top of the

instrument represents depth line (4). The instruments

pass through the Master Tube until the center of the

specified line on the instrument reaches the top of the

Master Tube (Figure 2).

The depth lines also determine what Implant Mount and

Implant Analog Mount must be used. These are labeled

by diameter and length. Therefore a 4mm implant that

has a 3mm depth line will be specified as a 4(3).

Figure 1

Figure 2

The Parallel Walled Navigator®System For Guided

Surgery works in conjunction with the surgical plan,

which is provided by the CT planning software

company. Each surgical plan is case-specific to provide

direction regarding the instrumentation that will be used

for each implant site.

10

Planning:

• Be sure the CT scanning appliance fits and is seated

completely in the mouth before the scan is performed.

Failure to confirm a stable fit of the scanning appliance

may result in a poorly fitting surgical guide affecting the

outcome of the procedure.

• Refer to the surgical guide manufacturer for specific

instructions on how to mask anatomical structures and

plan for fixation of the surgical guide.

• Download the most recent version of planning software

including implant libraries.

• Implants currently compatible with the Navigator®

System Include:

• Certain®Parallel Walled 3.25, 4 & 5mm Implants

• OSSEOTITE XP®4/5mm Implants

• PREVAIL®3/4/3, 4/5/4 and straight PREVAIL

4/3 and 5/4mm Implants.

• Height of the master cylinder above the implant platform

is variable (7.5, 9, 10.5, 12mm) and determined by the

surgical guide manufacturer.

• If planning a cement-retained full arch case, consider

implant sites with the greatest potential for stability in

order to screw-retain these locations in combination

with cement retaining others based on:

• Bone density readings (in Hounsfield Units) from

CT Scan

• Potential implant length and position relative to

the restoration

Preparation:

• Inspect the surgical guide for imperfections and reinforce

potential weak areas of the surgical guide with acrylic.

• Try-in the Drill Positioning Handles in case the guide may

need adjustments to allow the Drill Positioning Handles

to fully seat.

• Clear the Master Tubes of any material remaining from

the surgical guide manufacturer.

• Score the Master Tube notch position on the surgical

guide to record the hex-orientation landmarks (Figure 1).

• Preparation of a master cast may be advised to confirm

the planned position and restorative considerations of

implants prior to surgery.

• Review the CT scan data for bone density to anticipate

areas of poor bone quality and areas where implant

stability may be compromised. During use, surgical

guides provide little tactile confirmation of bone density.

Clinical Use:

• For flapless cases, use a Tissue Punch prior to fixation of

the Surgical Guide. Remove the Surgical Guide and the

tissue plugs. Then, replace and fixate the Surgical Guide.

• All instrumentation should be advanced as far as possible

through the Master Tube(s) or the Drill Positioning

Handles and into the osteotomy prior to activation.

This will limit the possibility of damaging either the

instruments or the tube(s) (Figure 2).

Tips And Techniques

Figure 1

Figure 2

11

Tips And Techniques (Cont’d)

Figure 3

• Use copious irrigation on instruments prior to and during use to

provide lubrication and cooling when passing through the Master

Tube(s) and/or Drill Positioning Handle(s). Irrigate and suction the

osteotomy and tubes to remove debris between each step of the

Surgical Plan and prior to implant placement.

• Undersize the osteotomy to increase likelihood of initial implant

stability (ie. when planning for a 4mm implant use 3mm as

final Twist Drill; 5mm implant use 3.85mm as final Twist Drill.

If necessary, increase the diameter of the final Twist Drill

appropriately).

• Avoid applying lateral force on the instrumentation during use, as

this may cause damage or premature wear.

• When using the Implant Mounts and Bone Taps, progress the

instruments until the instrument flange contacts the Master Tube.

It is recommended to use the WR150 Ratchet Wrench

with extension for final rotations of these instruments.

Once seated, do not continue to rotate these instruments as this

can cause damage to the instrumentation or osteotomy (Figure 3).

• The Implant Mounts must be fully engaged within the implant

prior to tightening the Implant Mount Screw.

• Sequence the placement of implants in an alternating cross

arch pattern, moving from one side to the other so as to not

compress soft-tissue. For cases requiring more than

two (2) implants, removal of the subsequent Implant

Mounts immediately following implant placement will

reduce divergent forces on the Surgical Guide.

• When removing Implant Mounts, remove along the path of

insertion and avoid applying lateral force. A slight counter-

clockwise torque applied to the Implant Mount with the CW100

may assist with Implant Mount removal.

• Use Bone Profilers prior to placing abutments of any type. Use

an oversized profiler when placing angulated abutments.

12

A key benefit of using the Navigator®

System For Guided Surgery is the option to use a CT

surgical guide to create a preoperative master cast and

a fixed provisional restoration in the laboratory prior to

the day of surgery. This may allow the clinician to insert

a provisional restoration immediately following implant

placement using the surgical guide and provides the patient

with aesthetic and functional teeth the same day.

Pages 13-28 in this manual are designed to guide surgeons,

restorative clinicians and laboratory technicians through

the process of fabricating a preoperative master cast

and a provisional restoration for insertion following the

placement of BIOMET 3i Implants using the Parallel Walled

Navigator System For Guided Surgery. The CT software

company may also offer the option of fabricating a stereo

lithographic model for use in creating a master cast.

The provisional may be fabricated using a variety of

BIOMET 3i Provisional Components. These components

and manual guidelines were developed to provide an

easy to use way to deliver an accurately fitting provisional

restoration on the day of surgery regardless of potential

error from CT scan data, cast fabrication or implant

placement. When selecting the provisional component

to use, it is important to identify the type of definitive

prosthesis and the abutment system that will be used to

create it. The chart below includes recommendations that

a clinician may want to consider for provisional component

selection dependent upon the type of definitive restoration

planned.

Immediate Provisionalization Option

Provisional Component Seating Platform Provisional Restoration Final Restoration

PreFormance®Posts Direct To Implant Cement-Retained Cement-Retained Or

Screw-Retained

PreFormance Temporary

Cylinders Direct To Implant Screw-Retained Cement-Retained Or

Screw-Retained

Provide®Temporary

Cylinders

Abutment Level

(For Provide Abutments Only) Cement-Retained Cement-Retained

QuickBridge®Provisional

Restoration Components

Abutment Level

(for Conical Abutments Only) Cement-Retained Screw-Retained

13

Fabrication Of A New Denture Or Partial

Denture And CT Scanning Appliance

1. CLINICIAN

Make impressions of the maxillary and mandibular arches.

2. LABORATORY

Pour the maxillary and mandibular impressions in die stone.

Fabricate baseplate(s) and wax occlusal rim(s) on the cast(s).

3. CLINICIAN

Place the wax occlusal rim(s) in the mouth, contour appropriately

and make an interocclusal registration.

4. LABORATORY

Articulate the maxillary and mandibular casts using the interocclusal

registration. Set denture teeth on the baseplate(s) and wax for try in.

14

Fabrication Of A New Denture Or Partial

Denture And CT Scanning Appliance (continued)

5. CLINICIAN

Place the wax try-in(s) in the mouth. Verify the occlusion, aesthetics

and phonetics. Make any adjustments necessary. If major adjust-

ments are necessary, make a new interocclusal registration and

return to the laboratory for a new set-up and wax try-in.

6. LABORATORY

Wax the denture for the arch in which implants will be placed for

processing, and flask it. Separate the flask, and boil away the wax.

Process, finish and polish the denture. Using a denture duplication

flask, mix the duplication material and place it into one side of the

flask. Place the patient’s existing denture into the material with the

soft-tissue side down. Allow the duplication material to set per the

manufacturer’s instructions. Apply a separator to the surface. Mix the

duplication material and place it into the other side of the flask and

close the flask over the denture. Allow the duplication material to

set. Separate the flask and remove the denture.

7. Create a mixture of 30% barium sulfate and cold-cure acrylic resin.

Pour the mixture into the tooth areas only. Allow the acrylic resin

to set per the manufacturer’s instructions. Create a mixture of 10%

barium sulfate and cold-cure acrylic resin. Pour the mixture into the

flask. Close the flask tightly. Allow the acrylic resin to set.

8. Remove the CT scanning appliance from the flask, finish and polish.

Place the appliance on the cast. Place the cast on the articulator and

make an interocclusal registration. The scanning appliance is returned

to the clinician for the CT scan and the occlusal registration is set

aside for later use.

15

Fabrication Of CT Scanning Appliance Using An

Existing Denture (continued)

1. CLINICIAN OR LABORATORY

Using a denture duplication flask, mix the duplication material

and place it into one side of the flask. Place the patient’s existing

denture into the material with the soft-tissue side down. Allow

the duplication material to set per the manufacturer’s instructions.

Apply a separator to the surface. Verify the occlusion duplication

material and place it into the other side of the flask and close

the flask over the denture. Allow the duplication material to set.

Separate the flask and remove the denture.

2. Create a mixture of 30% barium sulfate and cold-cure acrylic resin.

Pour the mixture into the tooth areas only. Allow the acrylic resin

to set per the manufacturer’s instructions. Create a mixture of

10% barium sulfate and cold-cure acrylic resin. Pour the mixture

into the flask. Close the flask tightly. Allow the acrylic resin to set.

3. Remove the CT scanning appliance from the duplication flask, finish

and polish.

4. CLINICIAN

Place the CT scanning appliance in the mouth and equilibrate.

Make an interocclusal registration. Send the scanning appliance

with the patient for the CT scan and set aside the interocclusal

registration for later use.

16

1. LABORATORY

Select the proper diameter and length Analog Mounts for each

implant position following the instructions provided by the Surgical

Guide manufacturer. Place the Implant Analogs onto the Analog

Mounts, line up the hexes and thread the thumb screws into

these approximately two turns. Place the Analog Mount/Analog

assemblies through the Master Tubes, engage the rotational

positioning pin into the notch and tighten the thumb screws using

the Square Driver.

TIP: Over-tightening the Analog Mounts outside of the Master

Tubes may damage the Analog Mounts.

2. Bead and box the Surgical Guide using rope wax. Apply a stone

separator around the inside of the guide. Syringe soft-tissue

material around the analogs approximately 2mm apical from the

interface of the Analog Mount. Pour stone into the Surgical Guide

to create the master cast and allow it to set. Unscrew the thumb

screws and remove the Analog Mounts. Carefully separate the

Surgical Guide from the master cast.

3. Place the scanning appliance on the master cast and verify the fit

and tooth position. Articulate the master cast with the opposing

cast using the scanning appliance and the interocclusal registration.

4. Make a vacuum formed template over the scanning appliance on

the cast. Remove the template and the scanning appliance and

separate those.

Continue on to step 5 (pages 22, 24 or 26) for abutment

selection and provisional restoration fabrication.

Pre-Surgical Fabrication Of An Edentulous

Fixed Provisional Restoration

Fabrication Of Master Cast, Articulation And Vacuum Formed Template

17

1. LABORATORY

Select the proper diameter and length Analog Mounts for each

implant position following the instructions provided by the Surgical

Guide manufacturer. Place the Implant Analogs onto the Analog

Mounts, line up the hexes and thread the thumb screws into these

approximately two turns. Place the Analog Mount/Analog assemblies

through the Master Tubes, engage the rotational positioning

notches and tighten the thumb screws using the Square Driver.

TIP: Over-tightening the Analog Mounts outside of the Master

Tubes may damage the Analog Mounts.

2. Mark the planned implant locations on the preoperative cast and

drill holes for each implant that is slightly larger in diameter than the

Implant Analogs. Do not drill through the guide. Insert the Implant

Analogs attached to the Surgical Guide into the holes, and seat the

guide onto the remaining teeth on the cast. Fixate the analogs in the

cast using stone or pattern resin. Unscrew the thumb screws and

remove these. Remove the Surgical Guide from the master cast.

3. If a scanning appliance was fabricated on the cast, place it on the

master cast and verify the fit and tooth position. Articulate the

master cast with the opposing cast using the occlusal registration.

4. Make a vacuum formed template over the scanning appliance

or diagnostic setup on the cast. Remove the template and the

scanning appliance or setup and separate those.

Continue on to step 5 (pages 18 or 20) for abutment

selection and provisional restoration fabrication.

Pre-Surgical Fabrication Of A Partially Edentulous Fixed

Provisional Restoration

Fabrication Of Master Cast, Articulation And Vacuum Formed Template

Table of contents