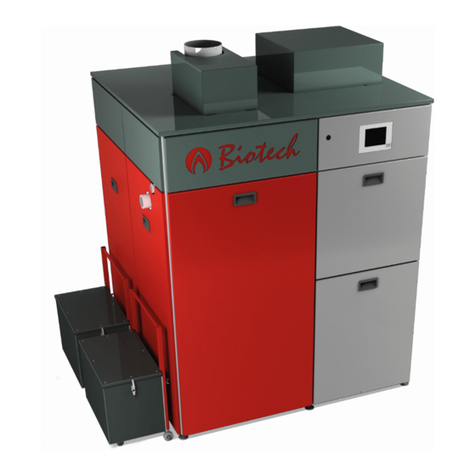

Biotech Top Light Series User manual

Planing folder

Pellet boiler | Top Light Series | PZ Series

www.biotech-heizung.com

HEATING WITH BIOMASS

Innovative

co²-neutral

Quality

Know-how

Sustainable

Ecient

2

Optimise PDF view

In order to ensure an optimal display, the following settings can be activated when

using Adobe Acrobat Reader:

ADOBE ACROBAT READER

2 3

1GENERAL NOTES .................................................................................................................................................................... 5

2TECHNICAL DATA.................................................................................................................................................................... 7

3DIMENSIONS ...............................................................................................................................................................................9

3.1 TOP LIGHT M .............................................................................................................................................................................9

3.2 TOP LIGHT M MBW ............................................................................................................................................................. 10

3.6 PZ25RL ..............................................................................................................................................................................14

3.7 PZ25RL MBW............................................................................................................................................................................15

3.8 PZ32/35RL ..............................................................................................................................................................................16

3.9 PZ32/35RL MBW .....................................................................................................................................................................17

3.10 PZ45/50/55RL.........................................................................................................................................................................18

3.11 PZ65/69RL ..............................................................................................................................................................................19

3.12 PZ80RL ............................................................................................................................................................................. 20

3.13 PZ90/100/101RL.....................................................................................................................................................................21

4CHIMNEY SPECIFICATION................................................................................................................................................22

4.1 EFFECTIVE HEIGHT.................................................................................................................................................................22

5RETURN BOOST FLOW.......................................................................................................................................................22

6 PELLET STORAGE ROOM ..................................................................................................................................................23

6.1 LOCATION OF THE BOILER ROOM....................................................................................................................................23

6.2 SIZE OF THE PELLET STORAGE ROOM............................................................................................................................ 24

6.3 STATIC REQUIREMENTS FOR THE PELLET STORE .........................................................................................................25

6.4 MAINTENANCE........................................................................................................................................................................25

6.5 FLOOR PLAN / SECTION PELLET STORAGE ROOM...................................................................................................... 26

6.6 NOTES ON THE DESIGN OF THE FILLING SYSTEM........................................................................................................27

6.7 SLOPING FLOOR.................................................................................................................................................................... 28

6.8 INSTALLATIONS IN THE PELLET STORE........................................................................................................................... 28

7DELIVERY SYSTEMS.............................................................................................................................................................. 29

7.1 IMPACT MAT ............................................................................................................................................................................ 29

7.1.1 FILLING SYSTEM........................................................................................................................................................ 29

7.1.2 ADJUSTATION VARIATIONS.................................................................................................................................... 29

7.1.3 EXTRACTION SYSTEMS PZ100|101RL................................................................................................................... 29

CONTENT

4

7.2 SUCTION POINT .................................................................................................................................................................... 30

7.3 SCREW DISCHARGE ...............................................................................................................................................................31

7.3.1 OPERATING PRINCIPLE ...........................................................................................................................................31

7.3.2 ASSEMBLY ...................................................................................................................................................................32

7.4 MOLE SYSTEM 33

7.4.1 OPERATING PRINCIPLE............................................................................................................................................33

7.4.2 ASSEMBLY ...................................................................................................................................................................33

7.5 DISCHARGE FROM THE BAG SILO..................................................................................................................................... 34

7.5.1 OPERATING PRINCIPLE .......................................................................................................................................... 34

7.5.2 ASSEMBLY .................................................................................................................................................................. 34

7.5.3 GROUNDING THE BAG SILO................................................................................................................................. 34

7.6 DISCHARGE FROM THE UNDERGROUND TANK.............................................................................................................35

7.6.1 OPERATING PRINCIPLE ...........................................................................................................................................35

7.6.2 GROUNDING OF THE UNDERGROUND TANK..................................................................................................35

8HYDRAULIC SCHEMES....................................................................................................................................................... 36

9DECLARATION OF CONFORMITY............................................................................................................................... 39

10 NOTES ............................................................................................................................................................................. 40

INHALTSVERZEICHNIS

4 5

01 GENERAL NOTES

• This planning document contains product-

specific information on the installation and use of

Biotech pellet heating systems. It does not replace

compliance with country-specific regulations, laws,

standards, etc. These must be observed in addition.

These must be complied with in addition.

• The pellet boiler described in these instructions has

been tested in accordance with EN303-5.

• Only use the fuels specified by us - wood pellets

in accordance with EN ISO17225-2:2014 class

A1 (Ø 6 mm). This is the only way to ensure low-

emission, economical and trouble-free operation

of your pellet boiler. Non-observance will result in

the loss of the warranty. Biotech accepts no liability

whatsoever for damage caused by the use of fuel

that does not have this certification.

• Bei einer Pelletheizung mit einer Nennleistung

von mehr als 50 kW muss der Puerspeicher so

dimensioniert sein, dass bei der Tagesbefüllung

des Puerspeichers genügend Betriebswasser für

ca. 1,5 Stunden im Puerspeicher vorhanden ist.

Mindestens zweimal täglich schaltet sich die Anlage

zur Reinigung (Wärmetauscher- und Rostreinigung)

automatisch ab. Abhängig von der Restmenge an

Pellets im Vorratsbehälter sowie dessen Größe und

der Anlagenleistung kann der Vorgang (Ausbrennen

/ Befüllen / Zünden) bis zum Erreichen der

Nennlast (100% Leistung) bis zu 1,5 Stunden dauern

- in dieser Zeit wird der Puer nicht beladen.

• For long burner running times, to reduce start-stop

emissions and to reduce wear, the boilers should

be equipped with buer storage, thermosiphon

buer storage or combi storage. In practice,

buer sizes between 40 and 75 litres/kW have

proved successful. Observe the country-specific

requirements for buer storage tanks. Operation

of the system is only permissible if it can be

guaranteed that 50% of the nominal boiler heat

output is drawn o for a period of at least 2 hours

per system start. The firing capacity modulates in

a capacity range of 30% to 100% of the nominal

capacity. If possible, the units should be operated

in the medium and upper output range (adapted

to the respective heat demand) in order to avoid

unnecessary emissions in low-load operation.

• After a maximum of 12 hours of continuous

operation, the units shut down to carry out a

cleaning cycle or to fill the intermediate container

with pellets. Depending on the type of unit, it then

takes up to 45 minutes until the nominal output of

the system is available again. This must be taken

into account in the power requirement calculation.

Please also note that poor fuel quality can reduce

the heating time to less than 12 hours.

• When planning biomass systems, it must

be ensured that noise is generated by the

corresponding mechanics or by drives such as

ignition fans and vacuum turbines. Appropriate

insulation measures must be taken on site. It

is strongly advised not to locate heating or

installation rooms directly under living and/or

sleeping areas.

• The assembly, installation and commissioning

(adjustment) of our pellet heating systems may only

be carried out by our customer service or by an

authorised specialist company certified by us.

• Carry out the cleaning work recommended by

us in the instructions at regular intervals on your

pellet boiler, the discharge system and the storage

room. This will not only ensure the functional

reliability of the system, but also the ecient and

low-emission operation of the system. You can

achieve the best care for your pellets heating

system by concluding a maintenance contract. The

specified cleaning and maintenance intervals must

be observed. Please note that there is no warranty

claim for damage caused by non-compliance with

the maintenance instructions. Biotech accepts no

liability whatsoever for damage caused by non-

compliance with the cleaning and maintenance

intervals.

• For legionella protection, the generally applicable

rules of heating technology must be observed.

• The regulations according to Ö-Norm M 7136

(transport and storage logistics) and M 7137, or VDI

guideline 3464, or country-specific requirements

for pellet storage must be observed.

ATTENTION!

The mandatory maintenance of the unit must

be carried out at least once a year, at the latest,

however, after reaching 1500 operating hours in

the performance range of 80 - 100 % by authorised

specialist personnel.

6

01 ALLGEMEINE HINWEISE

• Objects with a high level of safety with regard

to heat supply (hotels, process heat...) are to

be designed as double boiler systems. In case

of non-compliance, we reject all claims due to

consequential damage caused by insucient heat

supply. In the case of a biomass heating system,

the system requires appropriate supervision (by the

caretaker, porter...) so that the prescribed cleaning

work is carried out regularly! If, in the event of a

malfunction, a reaction time or an alarm chain

has to be observed, this has to be done before the

system is sold. The rest of the time, for example,

only one flat or oce building is heated with a very

low output, e.g. 10 kW. Unfortunately, in addition

to this, buer volumes are often either not realised

or too small, resulting in the most unfavourable

operation imaginable (start-stop) of a biomass

system. This mode of operation leads to increased

wear of the ignition devices, unfavourable emission

behaviour, etc. We would like to point out that any

resulting complaints cannot be accepted and do

not constitute a guarantee or warranty claim. In

such cases, we recommend that the systems be

designed as double (cascade) systems or that the

buer storage volume be selected accordingly.

• To ensure the operation of the heating system, it

must be supplied with sucient combustion air in

the boiler room. The regulations of the respective

countries must be observed. It should also be

noted that insucient oxygen supply (supply air)

can lead to malfunctions that are not covered by

the warranty or guarantee. Ventilation openings

(supply air) must never be blocked and/or covered.

• Notice sign „Smoking and handling of naked flames

and fires prohibited“ must be attached. A tested

fire extinguisher must be installed in the boiler

room. Secure the boiler room against unauthorised

access, especially by children.

• Safety and monitoring devices must not be

removed, bypassed or otherwise rendered

inoperative. Use a dust mask during cleaning and

ash disposal to avoid health hazards and damage.

• Electrical connection: 230 V, 50 Hz; fuse protection

16 A, tripping behaviour slow. Protective measure

Zeroing with Fi circuit breaker ( voltage limits

according to EN-50160) ATTENTION: ISO standard

60364 must be observed! Operating limits: Max.

Ambient temperature 0-45°C; max. humidity 0-95 %.

• There must be an emergency heating switch (all

poles and all sides can be switched o) in front of

the boiler room! Switch it o before carrying out

maintenance and / or service work!

• The heating system may only be installed and

operated in properly designed heating or installation

rooms and is not designed for outdoor use, nor may

it be operated if it is exposed to external influences

of water (dripping, splashing and jetting water).

• The combustion air in the heating or installation

room must be free of halogenated hydrocarbons (e.g.

contained in spray cans, solvents and cleaning agents,

paints, adhesives). The installation of a washing

machine and/or tumble dryer is also not permitted,

otherwise the guarantee / warranty will expire.

• A suitable vent valve must be fitted at the top of the

boiler.

• The boiler must be filled with heating water

according to VDI 2035 or Ö-Norm H 5195-1.

• When connecting the pellets boiler to the water

supply or to the heating circuit, the pellets boiler

must be secured against excessive water pressure

by means of an appropriate safety device on the

system side (e.g. overpressure valve). According to

the country-specific regulations, a water shortage

protection must be provided.

• When connecting the pellet boiler to the water

supply, an appropriate safety device on the system

side must ensure that non-potable water is

prevented from being sucked back into the water

supply system.

• The fire protection regulations must be

implemented on site in accordance with the

applicable ocial regulations!

6 7

Boiler type Top Light M Top Light M MBW PZ25RL PZ25RL MBW PZ32/35RL

Boiler class 5 5 5 5 5

Nominal heat output (kW) 14,9 14,9 25,0 25,0 32,2 / 35,0

Eciency full load (%) 93,0 93,0 94,19 94,19 92,39

Eciency part load (%) 93,5 93,5 93,8 93,8 95,76

Max. adjustable boiler temperature (C°) 90 90 90 90 85

Permissible operating pressure (bar) 3 3 3 3 3

CE marking according to Low Voltage Directive

CE CE CE CE CE

Dimensons

Boiler width (mm) 1155 1155 1305 1305 1305

Boiler depth (mm) 667 667 667 667 667

Total depth (mm) 1052 11052 11052 11052 11052 1

Boiler height (mm) 1542 21341 21644 21444 21894 2

Height flue pipe connection (mm) 1420 21420 21075 21075 21325 2

Height forerun (mm) 1435 21435 2452 2452 2452 2

Height return (mm) 1435 21435 21180 21180 21425 2

Vent height (mm) 1435 21435 21190 21190 21440 2

Flue pipe connection diameter (mm) 130 130 130 130 130

Total weight loose (kg) 332 325 356 349 411

Water content (l) 60 60 80 80 120

Reservoir - filling quantity (kg) 40 150 70 187 134

Ash pan usable (l) 6 6 23 23 23

Ash box usable (l) 42 142 142 ¹ 42 142 1

Connections

Forerun (Inch) 1 1 1 1 1⁄

Return (Inch) 1 1 1 1 1⁄

Ventilation for boiler (Inch) ⁄ ⁄ ⁄ ⁄ ⁄

Boiler draining (Inch) ⁄ ⁄ ⁄ ⁄ ⁄

Flow resistance on the heating water sideFlow resistance on the heating water side

ΔT= 20 K (mbar) 5 5 32,9 32,9 103

ΔT= 10 K (mbar) 20 20 131,7 131,7 412

Exhaust gas values

Exhaust gas temperature at full load (C°) 120 120 120 120 120

Exhaust gas temperature at part load (C°) 100 100 100 100 100

Exhaust gas mass flow at full load (g/s) 9,0 9,0 15,0 15,0 22,0

Exhaust gas mass flow at part load (g/s) 3,0 3,0 5,5 5,5 5,8

Co2at full load (Vol%) 13,5 13,5 13,5 13,5 13,5

Co2at part load (Vol%) 10,0 10,0 10,0 10,0 10,0

Necessary flue draught full load (Pa) 38 8 8 8 8

Necessary flue draught part load (Pa) 4 4 4 4 4

Electrical power consumption

Standby (W) 20 20 20 20 20

Filling turbine (W) 1340 0 1340 0 1340

Grate cleaning (W) 65 65 65 65 65

Prefill (W) 75 75 75 75 75

Ignite (W) 1034 1034 1034 1034 1034

Continuous operation Partial load / Full load (W) 50 / 80 50 / 80 50 / 80 50 / 80 50 / 80

Minimum distance masonry

To the front (mm) 900 4900 4900 4900 4900 4

To the back (mm) 50-200 550-200 5500-900 500-900 500-900

Left to masonry (mm) 100-300 6100-300 6100-300 6100-300 6100-300 6

Right to masonry (mm) 400-900 400-900 400-900 400-900 400-900

Minimum room height (mm) 2000 2000 2200 2200 2200

Insert dimension

At least (mm) 750 750 750 750 750

1) Ashbox optionally available

2) excl. adjustable feet, adjustment range up to 55 kW 15–30 mm

3) From 10 Pa, a draught limiter must be used below the firing connection

4) with mounted ash discharge 1200 mm

5) with automatic ash discharge min. 500 mm

6) Recommendation at least 250 mm, otherwise increased maintenance eort (costs)

02 TECHNICAL DATA

Individual values are based on the standard type test. These may deviate in practice.

8

1) Ashbox optionally available

2) excl. adjustable feet, adjustment range up to 55 kW 15–30 mm and from

65-101 kW 50-80 mm

3) From 10 Pa, a draught limiter must be used below the firing connection

4) with mounted ash discharge 1200 mm

5) with 1 suction turbine

6) Recommendation at least 250 mm, otherwise increased maintenance eort (costs)

7) incl. cover for cleaning

8) incl. ashbox

Boiler typeBoiler type PZ32/35RL MBWPZ32/35RL MBW PZ45/50/55RLPZ45/50/55RL PZ65/69/80RLPZ65/69/80RL

PZ90/100/101RLPZ90/100/101RL 55

PZ100/101RLPZ100/101RL

Boiler class 5 5 5 5 5

Nominal heat output (kW) 32,2 / 35,0 44,9/ 49,0 / 52,8 64,9 / 69,0 / 80,0

90,0 / 99,9 / 101,0

99,9 / 101,0

Eciency full load (%) 92,39 93,7 93,4 94,8 94,8

Eciency part load (%) 95,76 93,0 94,6 95,3 95,3

Max. adjustable boiler temperature (C°) 85 85 85 85 85

Permissible operating pressure (bar) 3 3 3 3 3

CE marking according to Low Voltage Directive

CE CE CE CE CE

Dimensons

Boiler width (mm) 1305 1505 1744 81745 81745 8

Boiler depth (mm) 667 817 1221 / (1339 7) 1221 / (1339 7) 1221 / (1339 7)

Total depth (mm) 1052 11202 - - -

Boiler height (mm) 1694 21944 21820 22068 22068 2

Height flue pipe connection (mm) 1325 21235 21769 22020 22020 2

Height forerun (mm) 452 2190 2176 2176 2176 2

Height return (mm) 1425 21450 21246 21491 21491 2

Vent height (mm) 1440 21453 21333 21578 21578 2

Flue pipe connection diameter (mm) 130 130 180 200 200

Total weight loose (kg) 404 503 920 / 930 1153 1160

Water content (l) 120 180 248 273 273

Reservoir - filling quantity (kg) 246 210 152 323 323

Ash pan usable (l) 23 - - - -

Ash box usable (l) 42 142 2x42 2x42 2x42

Connections

Forerun (Inch) 1 ⁄ 1 ⁄ 2 2 2

Return (Inch) 1 ⁄ 1 ⁄ 2 2 2

Ventilation for boiler (Inch) ⁄ ⁄ 1 1 1

Boiler draining (Inch) ⁄ ⁄ ⁄ ⁄ 1/2

Flow resistance on the heating water sideFlow resistance on the heating water side

ΔT= 20 K (mbar) 103 4 5 5 5

ΔT= 10 K (mbar) 412 16,3 20 20 20

Exhaust gas values

Exhaust gas temperature at full load (C°) 120

120

120 120 120

Exhaust gas temperature at part load (C°) 100

100

100 100 100

Exhaust gas mass flow at full load (g/s) 22,0

32

41 52 52

Exhaust gas mass flow at part load (g/s) 5,8

12,3

10,5 13 13

Co2at full load (Vol%) 13,5 13,5 13,5 13,5 13,5

Co2at part load (Vol%) 10,0 10,0 10,0 10,0 10,0

Necessary flue draught full load (Pa) 8 8 8 8 8

Necessary flue draught part load (Pa) 4 4 4 4 4

Electrical power consumption

Standby (W) 20 20 14 14 14

Filling turbine (W) 0 1340 1340 2720 2720

Grate cleaning (W) 65 65 65 65 65

Prefill (W) 75 75 75 75 75

Ignite (W) 1034 1034 1034 1034 1034

Continuous operation Partial load / Full load (W) 50 / 80 52,6 / 101,4 97 / 153 111 / 200 111 / 200

Minimum distance masonry

To the front (mm) 900 1200 200 200 200

To the back (mm) 500-900 700-900 700 700 700

Left to masonry (mm) 100-300 6700-900 1200 1200 1200

Right to masonry (mm) 400-900 600-900 750 750 750

Minimum room heigh (mm) 2200 2300 2300 2500 2500

Insert dimension

At least (mm) 750 875 1000 1000 1000

03 TECHNICAL DATA

Individual values are based on the standard type test. These may deviate in practice.

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

A2

Status Änderungen Datum Name

Gezeichn.

Kontroll.

Norm

Datum Name

20.07.2021 PoSe

Biotech Biotech Energietechnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

TLM m. Turbine

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: 325,66 kg Fläche: 37994558,56 mm^2

M: 1 : 10

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1

OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

1542

1341

1435

320

75

488

667

65 420 125

55

1155

1402

1542

1435

1341

1420

667

55

488

75

320

65 420

1155

125

4

3

2

1

min. 2000 mm

8 9

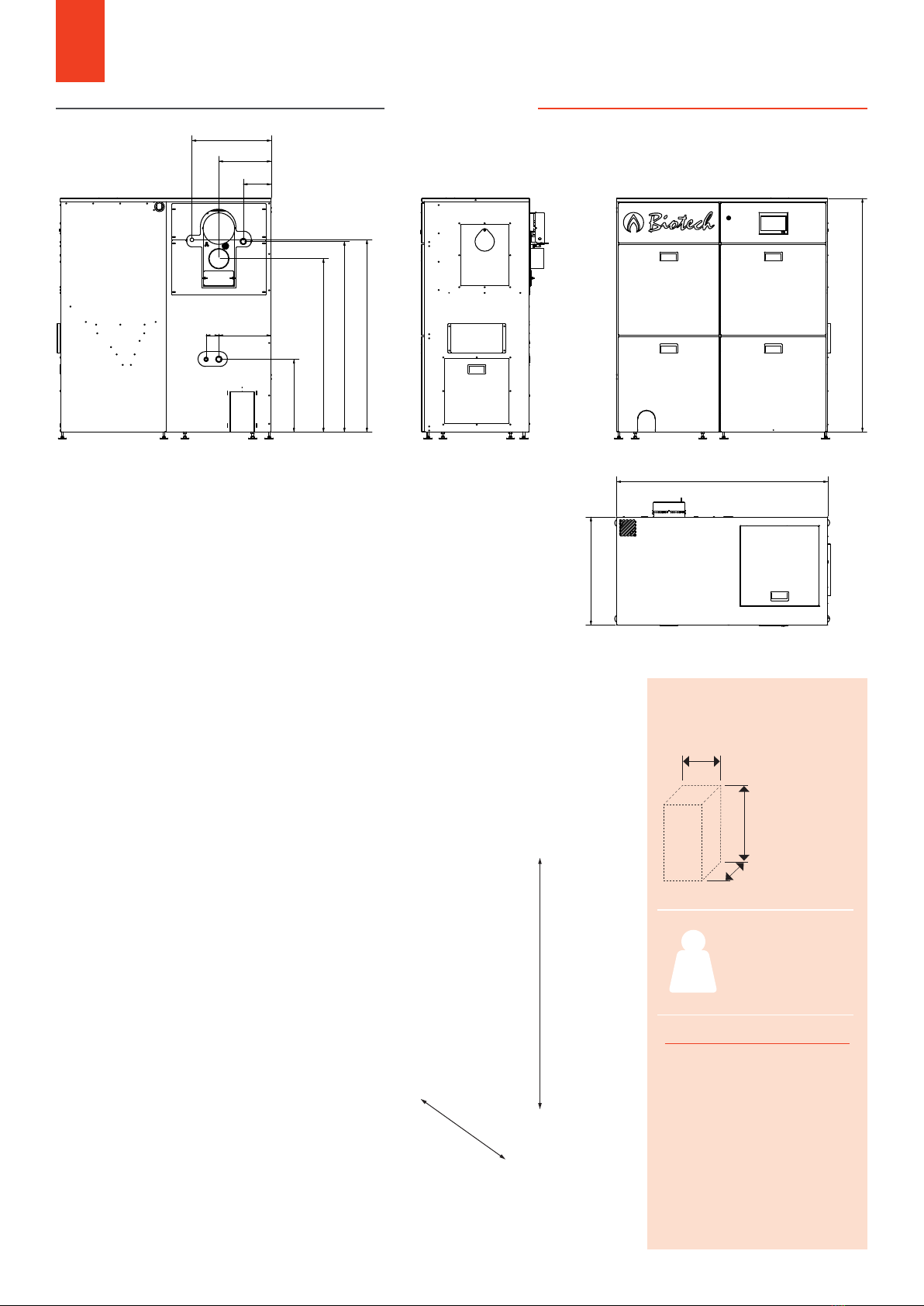

03 DIMENSONS

3.1 TOP LIGHT M

TOP LIGHT M

Pellet boiler

Insert dimensions

boiler (min.)

A : 610 mm

B : 1460 mm

C : 650 mm

Insert dimensions

container (min.)

A : 620 mm

B : 1550 mm

C : 670 mm

Boiler 204 kg

Container 66 kg

Cladding 62 kg

Ash box 15 kg*

All 332 kg

A

B

C

KG

1) with mounted ash discharge 1200 mm

2) Recommendation min. 250 mm, other-

wise increased maintenance eort (costs)

3) with automatic ash discharge min. 500

mm

Minimum distance masonry

1 : 900 mm 13 : 100-300 mm 2

2 : 400-900 mm 4 : 50-200 mm 3

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

A2

Status Änderungen Datum Name

Gezeichn.

Kontroll.

Norm

Datum Name

20.07.2021 PoSe

Biotech

Biotech Energietechnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

TLM-MBW

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: 314,06 kg Fläche: 35769556,38 mm^2

M: 1 : 10

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1

OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

1341

1435

320

488

65 420 125

75

667

1155

55

1402

1435

1341

1420

667

488

75

55

65 420

1155

320

125

4

3

2

1

min. 2000 mm

TOP LIGHT M MBW

Pellet boiler

Insert dimensions

boiler (min.)

A : 610 mm

B : 1460 mm

C : 650 mm

Insert dimensions

container (min.)

A : 620 mm

B : 1390 mm

C : 670 mm

Boiler 204 kg

Container 59 kg

Cladding 62 kg

Ash box 15 kg*

All 325 kg

A

B

C

KG

1) with mounted ash discharge 1200 mm

2) Recommendation min. 250 mm, other-

wise increased maintenance eort (costs)

3) with automatic ash discharge min. 500

mm

Minimum distance masonry

1 : 900 mm 13 : 100-300 mm 2

2 : 400-900 mm 4 : 50-200 mm 3

10

03 DIMENSIONS

3.2 TOP LIGHT M MBW

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

A2

Status Änderungen Datum Name

Gezeichn.

Kontroll.

Norm

Datum Name

20.07.2021 PoSe

Biotech

Biotech Energietechnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

PZ-25 m. Turbine

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: 355,84 kg Fläche: 42439629,88 mm^2

M: 1 : 10

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1

OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

1444

1644

323

78,5

452

1075

1180

1190

173

323

489

1305

667

1190

1180

1075

173

323

1305

667

489

1644

1444

452

32378,5

4

3

2

1

PZ25RL

Pellet boiler

Insert dimensions

boiler (min.)

A : 610 mm

B : 1400 mm

C : 720 mm

Insert dimensions

container (min.)

A : 740 mm

B : 1650 mm

C : 670 mm

Boiler 218 kg

Container 69 kg

Cladding 69 kg

Ash box 15 kg*

All 356 kg

A

B

C

KG

1) with mounted ash discharge 1200 mm

2) Recommendation min. 250 mm, other-

wise increased maintenance eort (costs)

Minimum distance masonry

1 : 900 mm 13 : 100-300 mm 2

2 : 400-900 mm 4 : 500-900 mm

10 11

03 DIMENSIONS

3.6 PZ25RL

min. 2200 mm

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

A2

Status Änderungen Datum Name

Gezeichn.

Kontroll.

Norm

Datum Name

20.07.2021 PoSe

Biotech

Biotech Energietechnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

PZ-25 MBW

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: 342,75 kg Fläche: 39944106,50 mm^2

M: 1 : 10

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1 OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

1444

323

78,5

452

1075

1180

1190

173

323

489

1305

667

1190

667

1444

489

1305

323

173

1180

1075

32378,5

452

4

3

2

1

PZ25RL MBW

Pellet boiler

Insert dimensions

boiler (min.)

A : 610 mm

B : 1400 mm

C : 720 mm

Insert dimensions

container (min.)

A : 740 mm

B : 1500 mm

C : 670 mm

Boiler 218 kg

Container 62 kg

Cladding 69 kg

Ash box 15 kg*

All 349 kg

A

B

C

KG

1) with mounted ash discharge 1200 mm

2) Recommendation min. 250 mm, other-

wise increased maintenance eort (costs)

Minimum distance masonry

1 : 900 mm 13 : 100-300 mm 2

2 : 400-900 mm 4 : 500-900 mm

12

03 DIMENSIONS

3.7 PZ25RL MBW

min. 2200 mm

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

A2

Status Änderungen Datum Name

Gezeichn.

Kontroll.

Norm

Datum Name

20.07.2021 PoSe

Biotech Biotech Energietechnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

PZ-35 m. Turbine

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: 411,03 kg Fläche: 48189773,59 mm^2

M: 1 : 10

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1

OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

452

323

78,5

1325,00

1425

1440

173,00

323

489

1894,00

1694,00

1305

667

452

489

1325

323

323

1425

173

1440

78,5

1694

1894

667

1305

4

3

2

1

PZ32/35RL

Pellet boiler

Insert dimensions

boiler (min.)

A : 610 mm

B : 1650 mm

C : 720 mm

Insert dimensions

container (min.)

A : 740 mm

B : 1880 mm

C : 670 mm

Boiler 258 kg

Container 78 kg

Cladding 75 kg

Ash box 15 kg*

All 411 kg

A

B

C

KG

1) with mounted ash discharge 1200 mm

2) Recommendation min. 250 mm, other-

wise increased maintenance eort (costs)

Minimum distance masonry

1 : 900 mm 13 : 100-300 mm 2

2 : 400-900 mm 4 : 500-900 mm

12 13

03 DIMENSIONS

3.8 PZ32/35RL

min. 2200 mm

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

A2

Status Änderungen Datum Name

Gezeichn.

Kontroll.

Norm

Datum Name

20.07.2021 PoSe

Biotech

Biotech Energietechnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

PZ-35 MBW

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: 397,94 kg Fläche: 45694250,21 mm^2

M: 1 : 10

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1

OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

323

78,5

452

1325

1425

1440

173

323

489

667

1305

1694

452

489

1325

323

323

1425

173

1440

78,5

1694

667

1305

4

3

2

1

PZ32/35RL MBW

Pellet boiler

Insert dimensions

boiler (min.)

A : 610 mm

B : 1650 mm

C : 720 mm

Insert dimensions

container (min.)

A : 740 mm

B : 1730 mm

C : 670 mm

Boiler 258 kg

Container 71 kg

Cladding 75 kg

Ash box 15 kg*

All 404 kg

A

B

C

KG

1) with mounted ash discharge 1200 mm

2) Recommendation min. 250 mm, other-

wise increased maintenance eort (costs)

Minimum distance masonry

1 : 900 mm 13 : 100-300 mm 2

2 : 400-900 mm 4 : 500-900 mm

14

03 DIMENSIONS

3.9 PZ32/35RL MBW

min. 2200 mm

A ( 1 : 10 )

A

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

A2

Status Änderungen Datum Name

Gezeichn.

Kontroll.

Norm

Datum Name

20.07.2021 PoSe

Biotech

Biotech Energietechnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

PZ 45 m. Turbine

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: - Fläche: -

M: 1 : 10

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1

OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

40

70

70 485

190

1235

1450

140 485

150

1944,00

1744,00

80

817

385

1505

A ( 1 : 10 )

A

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

A2

Status Änderungen Datum Name

Gezeichn.

Kontroll.

Norm

Datum Name

20.07.2021 PoSe

Biotech

Biotech Energietechnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

PZ 45 m. Turbine

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: - Fläche: -

M: 1 : 10

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1

OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

40

70

70 485

190

1235

1450

140 485

150

1944,00

1744,00

80

817

385

1505

1505

485

150

48570

70

140

817

1944

1744

1450

1235

190

40

385 80

4

3

2

1

PZ45/50/55RL

Pellet boiler

Insert dimensions

boiler (min.)

A : 800 mm

B : 1800 mm

C : 800 mm

Insert dimensions

container (min.)

A : 840 mm

B : 1950 mm

C : 820 mm

Boiler 324 kg

Container 84 kg

Cladding 95 kg

Ash box 15 kg*

All 503 kg

A

B

C

KG

Minimum distance masonry

1 : 1200 mm 3 : 700-900 mm

2 : 600-900 mm 4 : 700-900 mm

14 15

03 DIMENSIONS

3.10 PZ45/50/55RL

min. 2300 mm

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

A A

B B

C C

D D

E E

F F

G G

H H

A1

Status Änderungen Datum Name

Gezeichn.

Kontroll.

Norm

Datum Name

20.07.2021 PoSe

Biotech

Biotech Energiete chnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

MBG PZ 65 m. Verkleidung

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: 808,89 kg Fläche: 101388280,38 mm^2

PZ 65

M: 1 : 8

PT-06-03-M01-03

L1010E090

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1

OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

1246

1333

1794

1221

1210

1297

1733

140

1339

1744

1769

1820

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

A A

B B

C C

D D

E E

F F

G G

H H

A1

Status Änderungen Datum Name

Gezeichn.

Kontroll.

Norm

Datum Name

20.07.2021 PoSe

Biotech

Biotech Energiete chnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

MBG PZ 65 m. Verkleidung

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: 808,89 kg Fläche: 101388280,38 mm^2

PZ 65

M: 1 : 8

PT-06-03-M01-03

L1010E090

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1

OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

1246

1333

1794

1221

1210

1297

1733

140

1339

1744

1769

1820

1794

1733

1297

1210

140

1246

1221

1744

1333

1769

1820

1339

4

3

2

1

16

03 DIMENSIONS

3.11 PZ65/69RL

PZ65/69RL

Pellet boiler

Insert dimensions

boiler (min.)

A : 850 mm ¹

B : 1805 mm ²

C : 1280 mm

Insert dimensions

container (min.)

A : 740 mm

B : 1800 mm ²

C : 1260 mm

All 920 kg

A

B

C

Minimum distance masonry

1 : 200 mm 3 : 1200 mm

2 : 750 mm 4 : 700 mm

KG

min. 2300 mm

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

A A

B B

C C

D D

E E

F F

G G

H H

A1

Status Änderungen Datum Name

Gezeichn.

Kontroll.

Norm

Datum Name

20.07.2021 PoSe

Biotech

Biotech Energietechnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

MBG PZ 65 m. Verkleidung

2.Var

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: 816,79 kg Fläche: 102925815,39 mm^2

PZ 80

M: 1 : 8

PT-06-03-M14-03

L1010E091

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1

OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

1246

1333

1794

140

1210

1297

1733

1221

1769

1744

1339

1820

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

A A

B B

C C

D D

E E

F F

G G

H H

A1

Status Änderungen Dat um Name

Gezeichn.

Kontroll.

Norm

Datum Name

20.07.2021 PoSe

Biotech

Biotech Energietechnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

MBG PZ 65 m. Verkleidung

2.Var

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: 816,79 kg Fläche: 102925815,39 mm ^2

PZ 80 M: 1 : 8

PT-06-03-M14-03

L1010E091

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1 OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

1246

1333

1794

140

1210

1297

1733

1221

1769

1744

1339

1820

1794

1733

1297

140

1210

1246

1339

1333

1769

1820

1221

1744

4

3

2

1

16 17

03 DIMENSIONS

3.12 PZ80RL

PZ80RL

Pellet boiler

Insert dimensions

boiler (min.)

A : 850 mm ¹

B : 1805 mm ²

C : 1280 mm

Insert dimensions

container (min.)

A : 740 mm

B : 1800 mm ²

C : 1260 mm

All 920 kg

A

B

C

Minimum distance masonry

1 : 200 mm 3 : 1200 mm

2 : 750 mm 4 : 700 mm

KG

min. 2300 mm

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

A A

B B

C C

D D

E E

F F

G G

H H

A1

Status Änderungen Datum Name

Gezeichn.

Kontroll.

Norm

Datum Name

20.07.2021 PoSe

Biotech

Biotech Energiete chnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

MBG PZ 100 mit Verkleidung

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: 355,25 kg Fläche: 82661081,11 mm^2

PZ 100 M: 1 : 8

PT-07-03-M01-02

L1010E735

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1

OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

140

1458

1545

1220

1988

1491

1578

2045

1745

1339

2068

2020

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

A A

B B

C C

D D

E E

F F

G G

H H

A1

Status Änderungen Datum Name

Gezeichn.

Kontroll.

Norm

Datum Name

20.07.2021 PoSe

Biotech

Biotech Energietechnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

MBG PZ 100 mit Verkleidung

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: 355,25 kg Fläche: 82661081,11 mm^2

PZ 100

M: 1 : 8

PT-07-03-M01-02

L1010E735

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1

OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

140

1458

1545

1220

1988

1491

1578

2045

1745

1339

2068

2020

2045

1988

1545

1458

1491

1578

2020

2068

1339

140

1220

1745

4

3

2

1

18

03 ABMESSUNGEN

3.13 PZ90/100/101RL

PZ90/100/101RL

Pellet boiler

Insert dimensions

boiler (min.)

A : 850 mm ¹

B : 1992 mm ²

C : 1280 mm

Insert dimensions

container (min.)

A : 740 mm

B : 2030 mm ²

C : 1260 mm

All 1160 kg

A

B

C

Minimum distance masonry

1 : 200 mm 3 : 1200 mm

2 : 750 mm 4 : 700 mm

KG

mind. 2300 mm

A4

Status Änderungen Datum Name

Gezeichn.

Kontroll.

Norm

Datum Name

22.07.2021 PoSe

Biotech

Biotech Energietechnik GmbH

Plainfelder Straße 3

A-5303 Thalgau

AAllllggeemmeeiinnttoolleerraannzzeennnnaacchh::

Material:

Gewicht: 2105,59 kg Fläche: 64931164,42 mm^2

M: 1 : 17

Oberfläche:

DIN ISO 2768-1/2 m/K EN ISO 9013-331 >10mm

EN ISO 9013-332 <10mm EN ISO 5817- D EN ISO 13920- BF

RReevv..

Blatt 1

UUnnbbeemmaaßßtteeWWeerrkkssttüücckkkkaanntteenn

nnaacchhÖÖNNoorrmmIISSOO1133771155

-0,5

-1

OObbeerrffllääcchhee

ISO 1302

DIN ISO 16016

130-140 mm

600

All dimensions in mm!

18 19

REQUIREMENTS FOR THE FLUE PIPE

• Connect the flue pipe to the chimney at an angle

of at least 10°, ideally 30 to 45°.

• The exhaust pipe must not be reduced, the

diameter of the exhaust pipe must correspond to

that of the exhaust connection.

• The flue pipe must be pressure-tight and fitted with

thermal insulation at least 25 mm thick over its

entire length.

• The draught regulator must be installed at least

600 mm below the flue pipe inlet in the flue

system.

ATTENTION: If the chimney draught regulator is

installed directly in the flue pipe, contrary to the location

suggested below, due to the situation on site, an

increased dust load in the boiler room must be expected

- PLEASE take this into account when planning!

A moisture-resistant (FU) chimney (material 1.4401 or 1.4404 recommended) with a maximum flue draught of 10 Pa (0.10

mbar) is required. The connecting pipe (flue gas pipe) must be laid with a minimum gradient of 10° (30-45° is optimal)

with a maximum length of 3.0 metres. The flue pipe must be insulated with at least 25 mm. If possible, make the flue

connection with 45° bends. A connection with 90° bends can cause flue gas problems. The flue pipe must be connected

to the chimney in such a way that no condensation water can flow into the boiler. The boiler and the chimney must be

matched to each other (see chimney recommendation). EN 13384-1 must be used as a calculation aid.

The eective height is the flue length between the flue gas inlet into the flue and the flue mouth.The flue must be

adapted to the local, legal regulations! Low-emission operation according to the quality seal is only guaranteed if the

system can be operated with the low flue gas temperatures of the smallest heat output (30% of the nominal load).

This usually requires an acid-proof chimney.

It must be ensured that the return temperature does not fall below 55°C under any circumstances.

Since this cannot be guaranteed without an automatic return flow increase, it is mandatory to install

one! Failure to comply will invalidate the warranty.

04 CHIMNEY SPECIFICATION

05 RETURN FLOW BOOST

4.1 EFFECTIVE HEIGHT

ATTENTON!

The chimney must be insensitive to moisture (FU)!

The installation of a draught regulator is required.

A chimney calculation according to standard EN

13384-1 is required! See page 7 & 8 for data.

600

130-140

Filling nozzle

House junction box

max. 30 m

Pellet storage room Heating room

20

The pellets are delivered by a silo truck and blown into the storage room. The silo truck usually has a pump

hose with a maximum length of 30 running metres. length. The pellet storage room or the filling couplings may

therefore be a maximum of 30 running metres from the unloading point of the truck. If longer pump hoses are

necessary, clarify this with your pellet supplier. The longer the pipe is chosen, the more the quality of the pellets

is aected. This can lead to a situation where the fuel in the storage room no longer meets the requirements. If

possible, the pellet storage room should be adjacent

to an outside wall, as the filling spouts should be

accessible from the outside. The masonry must not

have any moisture under any circumstances! If the

storage room is inside, the blow-in and exhaust air

connections can be extended to the outside wall, or

the pellet supplier‘s pump hose can be laid through the

house during filling.

If possible, the boiler room should also be adjacent to an outside wall to ensure a direct combustion air supply to

the pellet heating system. If the boiler room is inside, a supply air duct must be led from the boiler room to the

outside wall (FeuVO). Country-specific regulations must be observed.

06 PELLET STORAGE ROOM

6.1 POSITION OF THE BOILER ROOM

ATTENTION!

Switch o the heating before filling the pellet store!

Please note that longer pipes lead to increased

abrasion (loss of quality).

This manual suits for next models

18

Table of contents

Other Biotech Boiler manuals

Popular Boiler manuals by other brands

Vaillant

Vaillant ecoTEC exclusive 843 Installation and maintenance instructions

Potterton

Potterton 40eL user guide

DeDietrich

DeDietrich MCA 45 user guide

Gruppo Imar

Gruppo Imar Gimax 25 Installation, commissioning, use and maintenance manual

Indol

Indol Supreme 200SA++ quick start guide

Viessmann

Viessmann VITORONDENS 200-T Service instructions

New Yorker

New Yorker AP-U SERIES Installation, operation and service instructions

First Choice

First Choice Zip Hydroboil Plus manual

Hamworthy

Hamworthy PUREWELL VariHeat c Instructions for use

Biasi

Biasi RIVA COMBI Service manual

Ferroli

Ferroli ECOUNIT 1C 200 manual

Traid

Traid TRIUMPH SS SERIES Operating and maintenance manual