Termaline® Load Resistor

viii

About This Manual

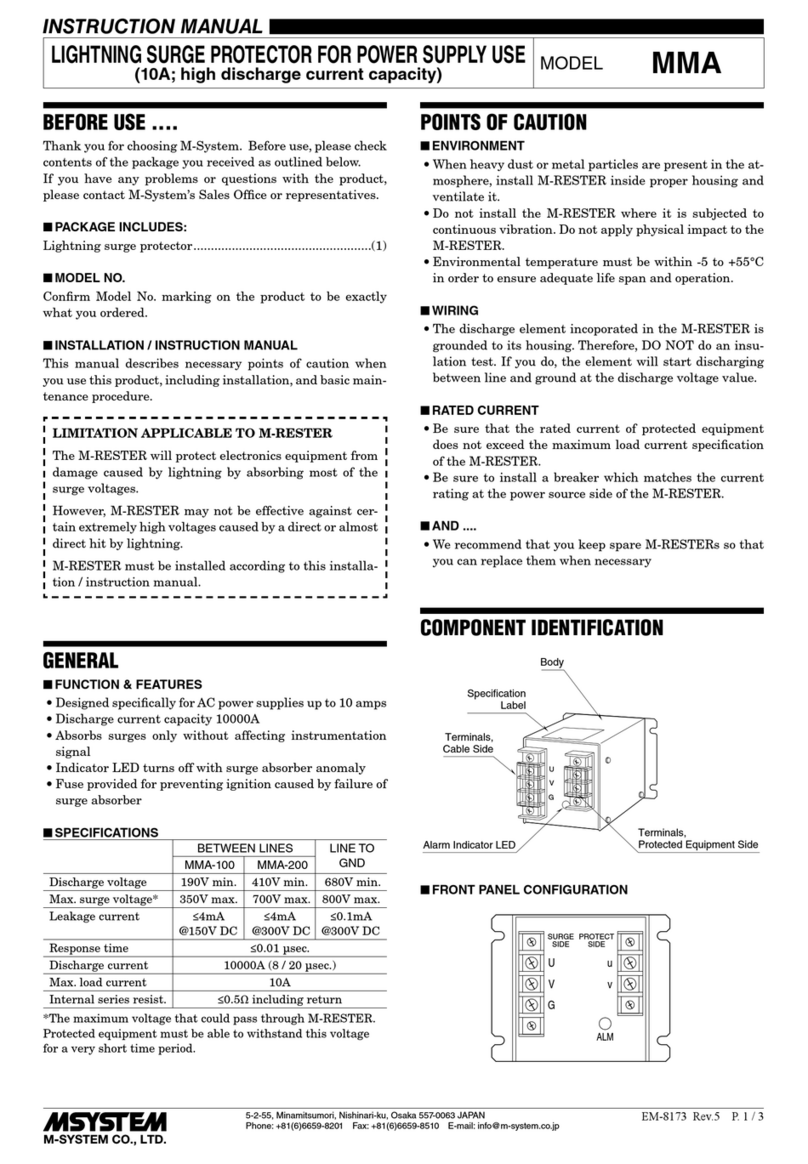

This manual covers the operating and maintenance instructions for the following models

When used in the rest of the manual, 8890 series refers to all models. 889x–300 refers only to

loads without a blower. –315 and –320 refer to loads with attached blowers.

Changes to this Manual

We have made every effort to ensure this manual is accurate. If you discover any errors, or if you have suggestions

for improving this manual, please send your comments to our Solon, Ohio factory. This manual may be periodically

updated. When inquiring about updates to this manual refer to the part number and revision on the title page.

Chapter Layout

Introduction — Describes the features of the Bird Termaline, Semiconductor, RF Load Resistor lists equipment

supplied and optional equipment, and provides power-up instructions.

Theory of Operation — Describes how the Termaline, Semiconductor, RF Load Resistor works and its functions.

Installation — Describes the how to install the Termaline, Semiconductor, RF Load Resistor.

Operation with Blower — Describes procedures require for operating the load resistor equipped with a blower

unit.

Maintenance — Lists routine maintenance tasks as well as troubleshooting for common problems. Specifications

and parts information are also included.

Connector

Model Number

Without

Blower

Blower,

115 VAC

Blower,

230 VAC

Female LC 8890-300 8890-315 8890-320

3-1/8" EIA Flanged 8891-300 8891-315 8891-320

1-5/8" EIA Flanged 8892-300 8892-315 8892-320

1-5/8" EIA Unflanged 8895-300 8895-315 8895-320

3-1/8" Unflanged, Flush Center, 51.58896-300

3-1/8" Unflanged, Flush Center 8897-300 8897-315 8897-320

3-1/8" Unflanged, Recessed Center 8898-300 8898-315 8898-320

Digital, 3-1/8" EIA Flanged 8891D300

Digital, 1-5/8" EIA Flanged 8892D300 8892D320

Digital, Female 13-30 8892D13-30